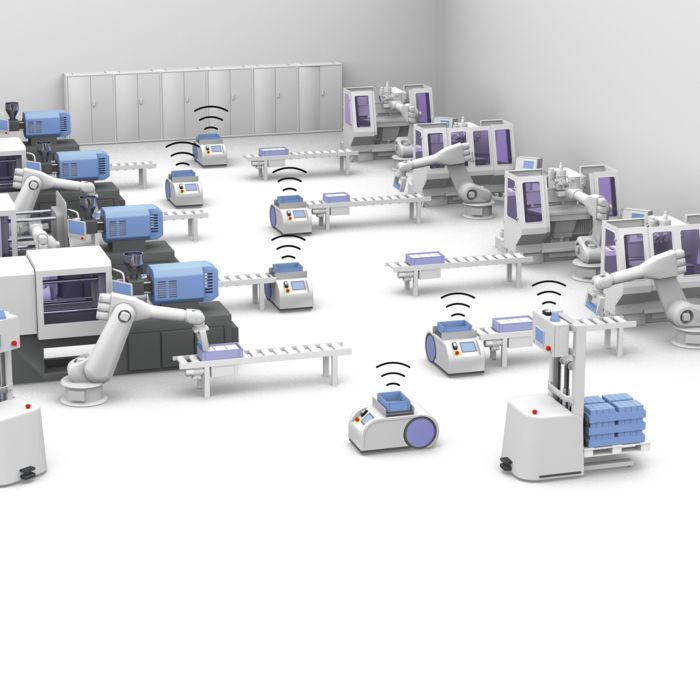

The open interfaces of our PLCnext Control platform allow you to continue using your existing IT systems and customized fleet management system as usual. This makes connecting and replacing your existing components easy and flexible.

Additional advantages:

- Time savings and error prevention in programming – Due to our modular system and easy-to-integrate apps.

- Safety integrated – Our safety solution is integrated into the AGV control system in accordance with current standards simply by connecting the safe PLC.

- Compliant with directives – ISO 6244 certification directly meets the requirements of the new Machinery Regulation for cyber resilience.

- App store – Our modular software for controlling your AGV is available in our app store.