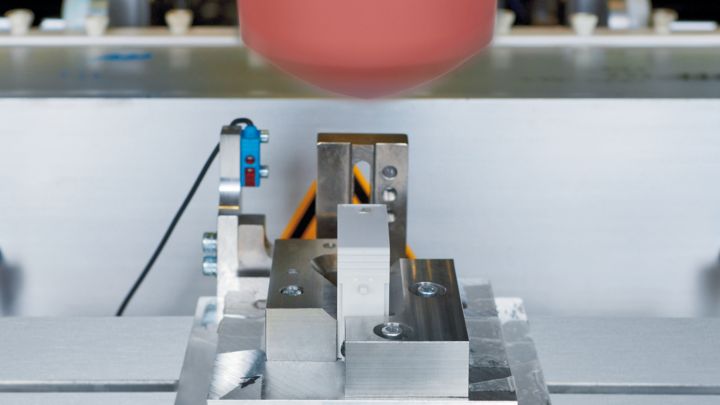

Customized cutouts can be made on each side of the housing with our state-of-the-art milling machines. Rely on the highest quality and cost-effective implementation even for small and medium quantities.

Our range of housing and connection technology solutions includes many options for designing state-of-the-art devices. Configure solutions for your individual application using the configurator for electronics housings. From color versions, through printing and processing, right through to customer-specific variations, almost anything is possible – even completely new product developments.

Ask a question for additional information about these products

Benefit from our extensive service portfolio. We provide a wide range of processes for the cost-effective implementation of your housing version. They range from mechanical machining with milling machines, through tool inserts in the existing original mold, all the way to the individual design of individual housing components.

Customized cutouts can be made on each side of the housing with our state-of-the-art milling machines. Rely on the highest quality and cost-effective implementation even for small and medium quantities.

For large quantities, it is often more cost-effective to replace mechanical processing with an injection-molded version. Benefit from the rapid implementation of your adapted version directly from the original tool.

To achieve your tailored solution, it is sometimes necessary to replace individual standard housing parts with customer-specific designs. We develop housing components in accordance with your specifications and combine them with proven standard components.

In particular for the ICS series, you can even design individual housing covers using the configurator. To do so, take advantage of the PROTIQ 3D printing services for the production of prototypes and subsequent series production.

From color versions, through printing and marking, to the tailored design of a membrane keypad, we provide you with a wide range of options for customizing your application.

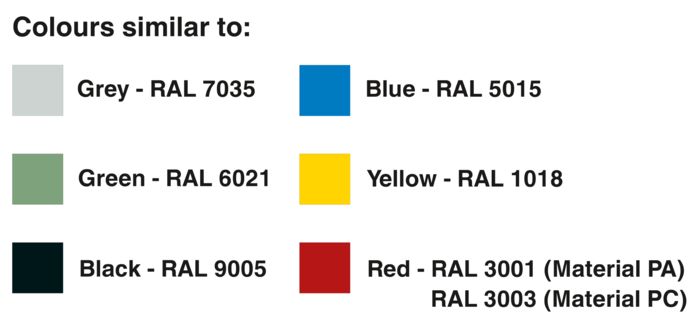

With your own company color, you increase the recognition value of your application. Thanks to our extensive portfolio of standard colors, you can match your housing color perfectly to your application.

The fine-tuning of the application-specific appearance is achieved via the company logo and the marking of the existing control elements. Take advantage of our numerous options and print and mark your electronics housings tailored to your needs.

Quickly and easily integrate preconfigured membrane keypads and displays for some housing families. You can freely adapt the shape, color and printing of the membrane keypads to your wishes, and it is also possible to apply additional marking with a company logo.

Tailor your application with the matching color version for your housing. Qualification of each new color version is made in the original tool.

Find out about the printing versions for your application.

|

|

|

|

|---|---|---|---|

| Pad printing | Screen printing | Laser marking | |

| Properties | |||

| Advantages | Cost-effective functional printing | Brilliant colors | Abrasion resistant, continuous coding |

| Number of possible colors | One to two color | Multi-colored | One color (color change) |

| Areas of application | Texts and logos | Large area or multicolor prints | Texts and logos, barcodes, QR codes, and data matrix codes, as well as serial numbers |

Use our configurator to quickly and easily assemble your own electronics housing online. Select the desired housing series, the corresponding lower part, and the cover. Add the appropriate connection technology and the process is complete. In addition, you can integrate operating elements such as membrane keypads and displays for the ICS, ME-IO, and UCS series and test your application with regard to thermal properties.

Do you have specific requirements and need a new product tailored to your preferences? With our expertise in development, production, and quality assurance, we will support you throughout the implementation process. We will provide you with all the required services for your new product. This includes, for example:

Miniaturization brings with it ever-higher packing densities in electronics. This, in turn, requires efficient cooling. Heat dissipation in electronics housings is ensured by individual heatsinks. This means the housings can also be used in thermally demanding applications. As a device manufacturer, do you need thermal simulations to support you in designing the PCB layout? Please contact us.

Electronics housings are an elementary part of a device. They determine its appearance and protect the electronics from external influences. In addition, they enable assembly in superordinate units. Device manufacturers must therefore pay attention to many details, and not only in the design, but also in the choice of housing when it comes to materials and quality testing. This brochure provides you with all the details.