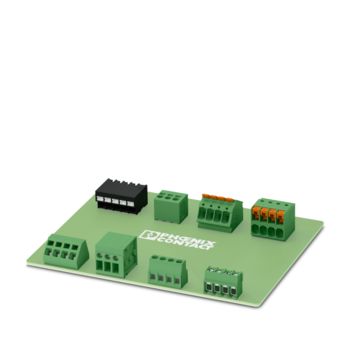

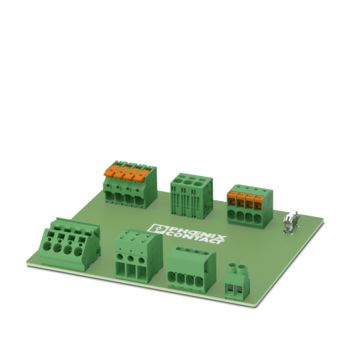

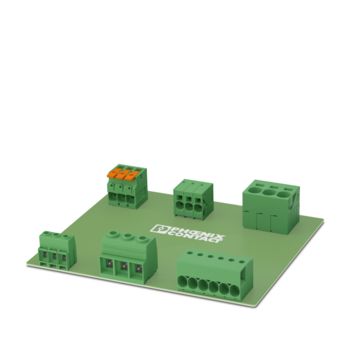

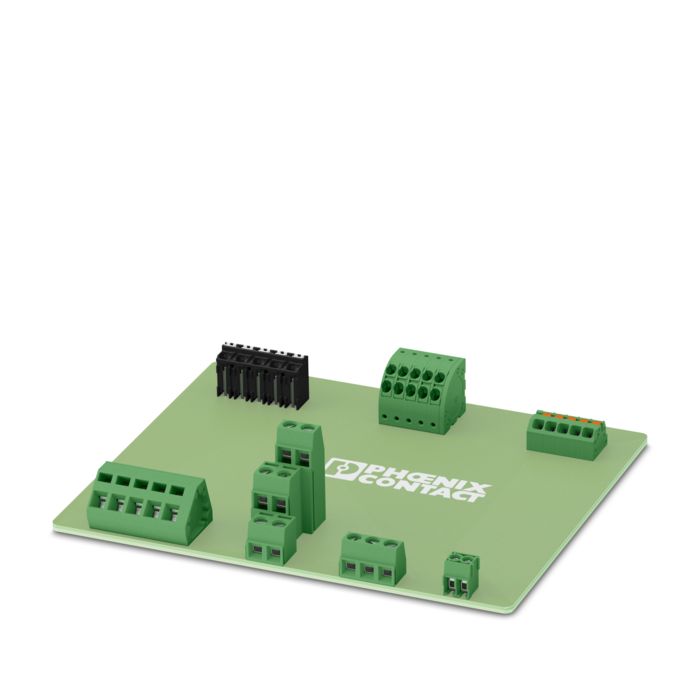

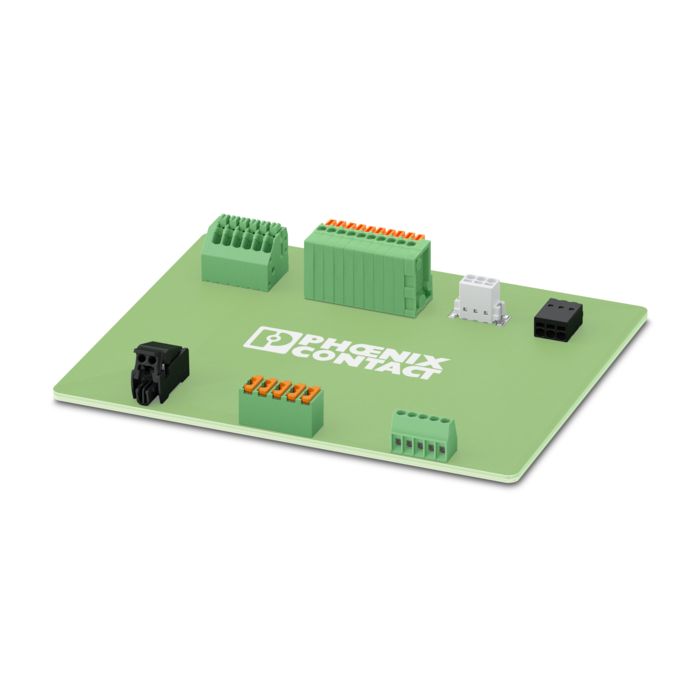

Main features

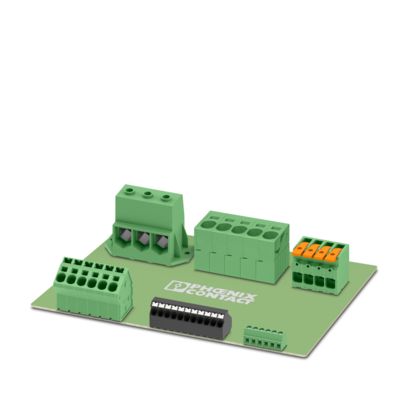

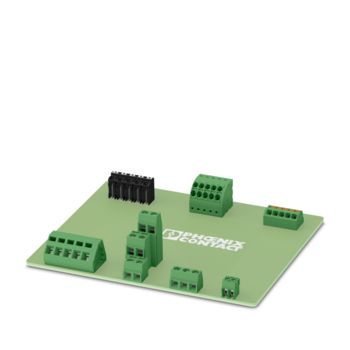

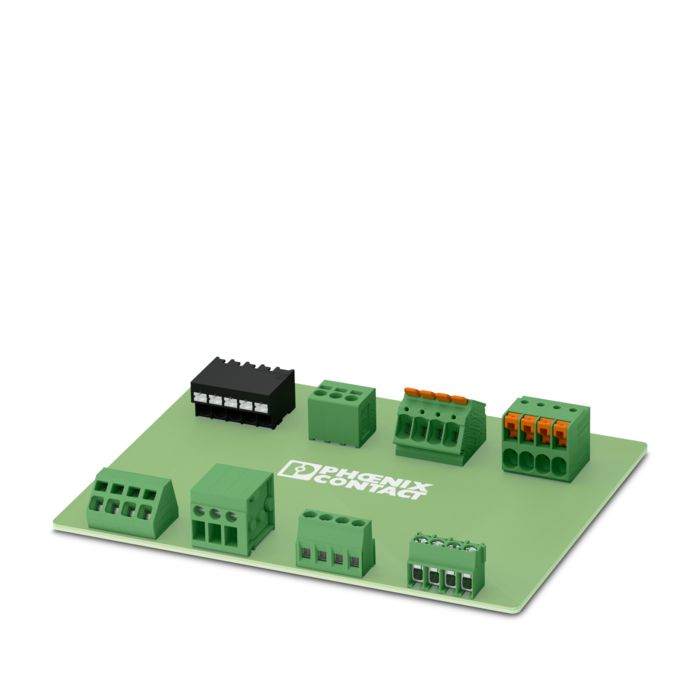

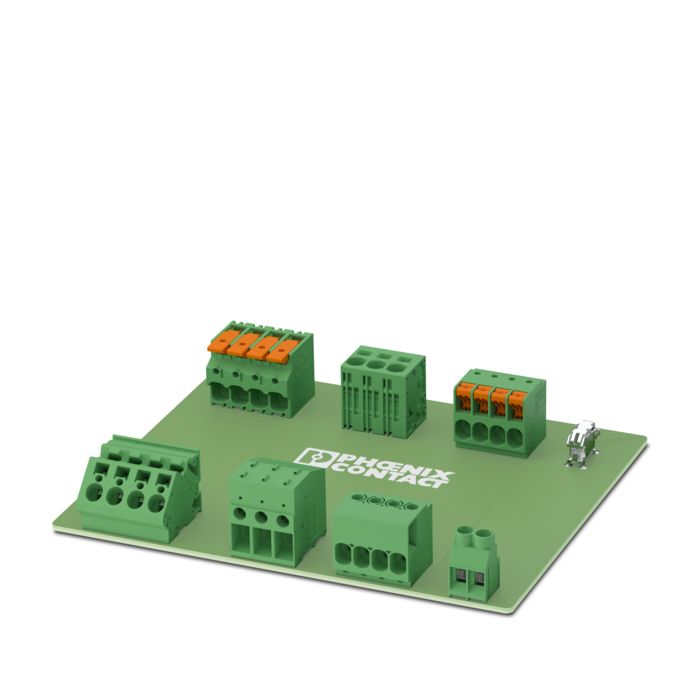

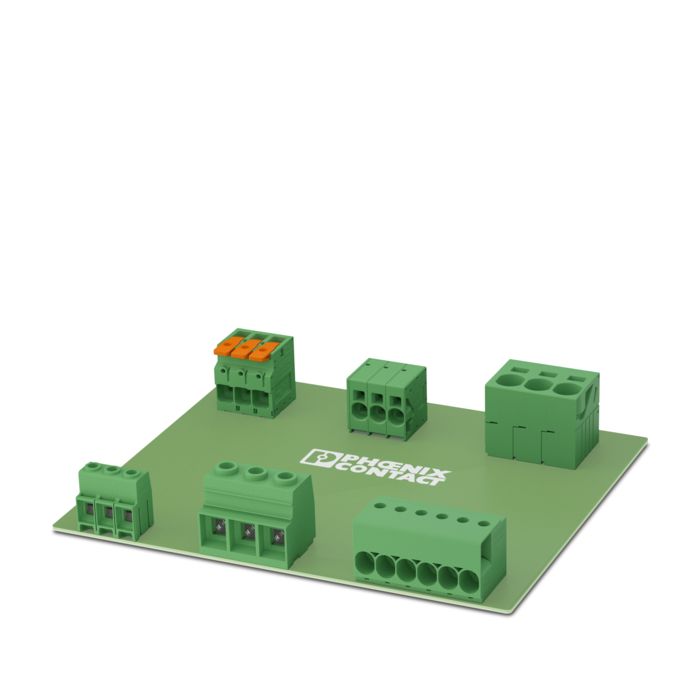

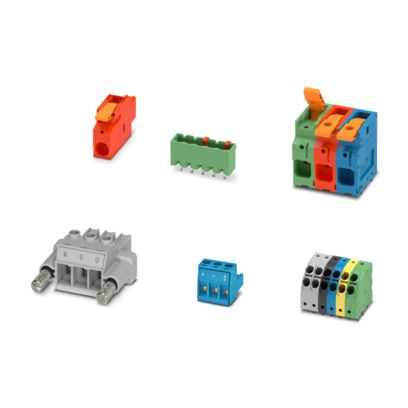

- For 2.5 to 3.81 mm pitch

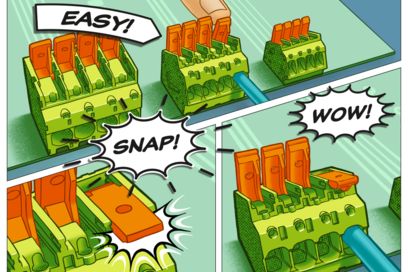

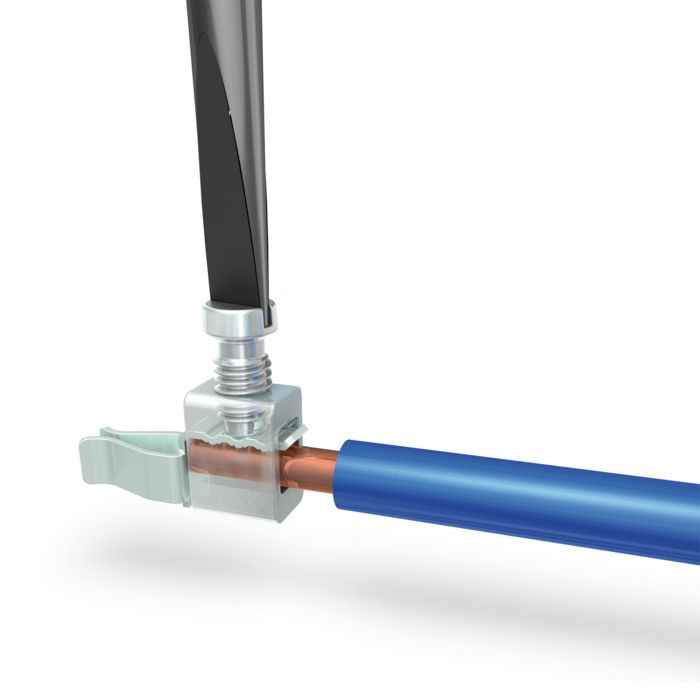

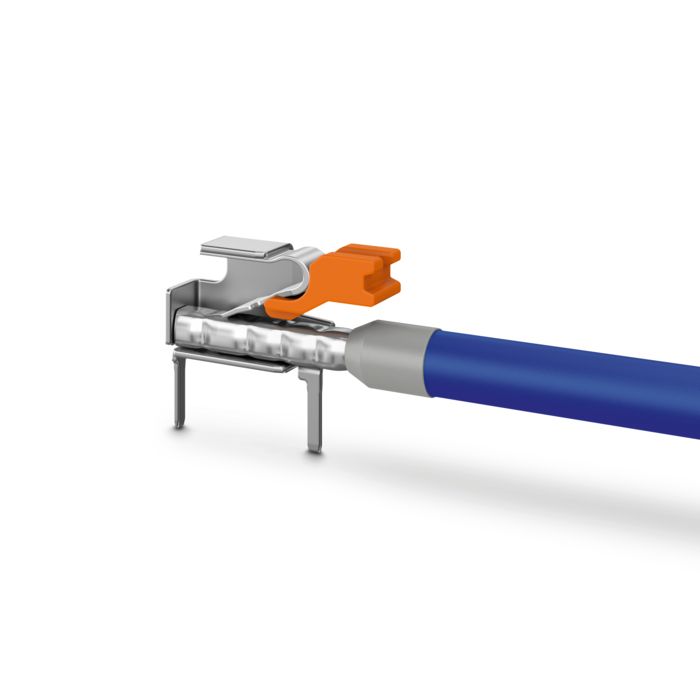

- Connection technologies with screw, spring, and insulation displacement connection

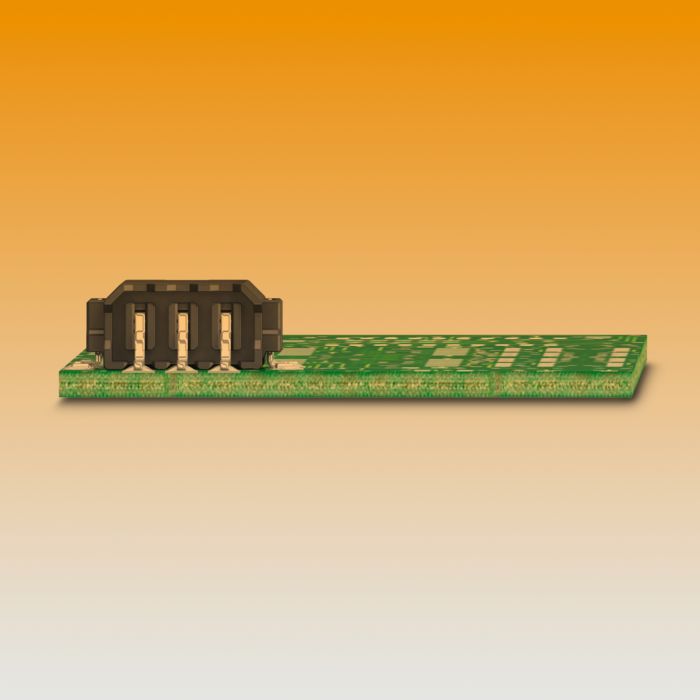

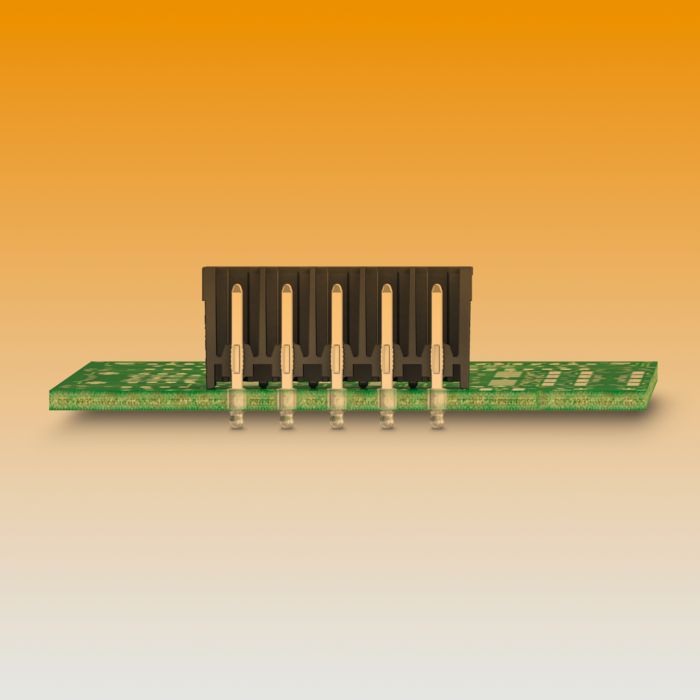

- Assembly via wave, THR, and SMT soldering

- Various connection and actuation directions

- Versions with TWIN connection and integrated testing option