The extruded profiles are cut to customer-specific lengths. They are available in lengths from 30 to 1,000 mm. Precise housing lengths down to the millimeter save you valuable space.

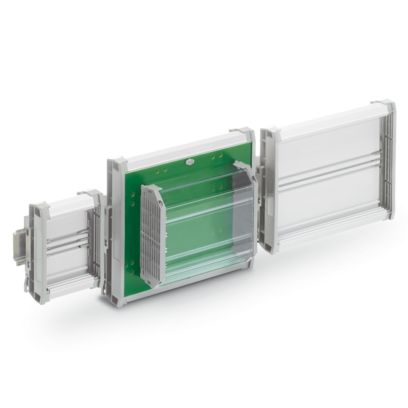

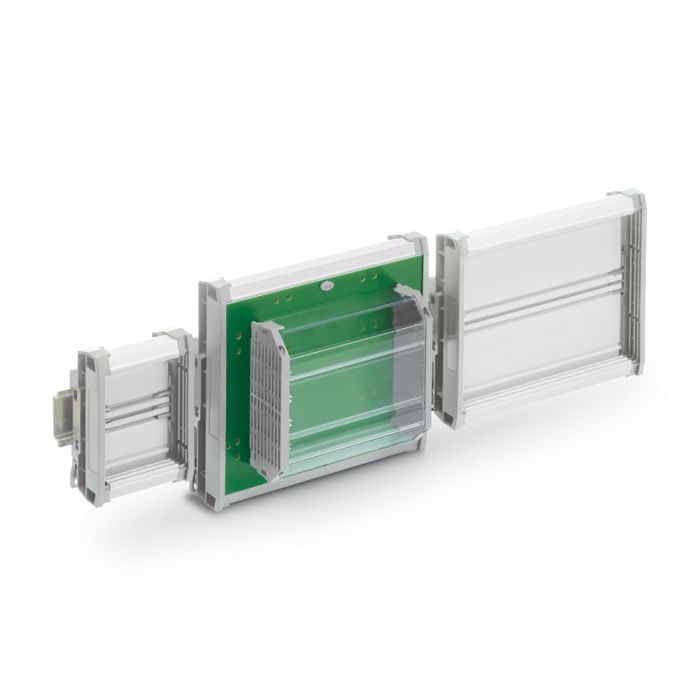

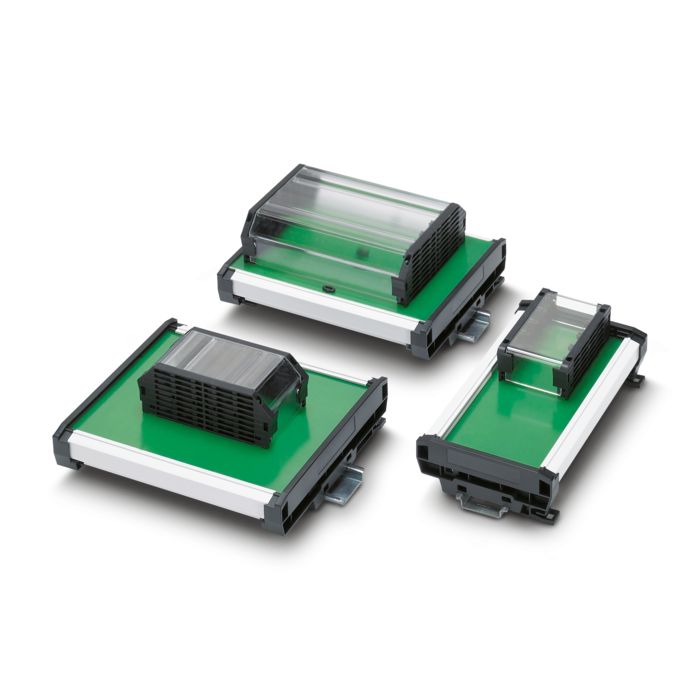

Extruded profile housings from the UM-BASIC series combine short installation times with a high degree of freedom when choosing the connection technology. They allow individual PCB positioning and custom PCB sizes. The low-profile design supports the assembly of flat electronics modules and their mounting on standard DIN rails or directly on the wall. This allows for a high degree of freedom when designing devices – such as in industrial electronics.

Profile housing (PVC), mounting type: DIN rail mounting, dimensions on the DIN rail: width: 153.8 mm, height: 127.8 mm, depth: 39.45 mm, incl. 2 lateral elements (PA), color: light gray (7035), for PCBs with width: 108 mm, length: 150 mm, PCB surface: 13780 mm2

Press-drawn section housings, Latching with side elements, latching with foot element, Basic profile, profile length (configurable): 3 cm ... 200 cm, depth: 19.8 mm, Note: required profile length = PCB length - 16.2 mm

PE contact for UM-PRO panel mounting base for connecting the PCB to the DIN rail at level 3

Lateral element (left) with mounting foot for DIN rails for UM-BASIC profiles with a PCB width of 108 mm

Lateral element (right) with mounting foot for DIN rails for UM-BASIC profiles with a PCB width of 122 mm

Locking element for locking the upper PCB onto UM-BASIC/PRO housings close to the edge

PE contact for UM-PRO panel mounting base for connecting the PCB to the DIN rail at level 1

Lateral element (left) with mounting foot for DIN rails for UM-BASIC profiles with a PCB width of 72 mm

Press-drawn section housings, DIN rail mounting, for the DIN rail, for mounting below UM-BASIC PROFILE (width: 122 mm), Foot element

Locking element for locking the PCB onto UM-BASIC/PRO housing at level 1

The evaluation (EVA) board holder for UM-BASIC and UM-PRO is a flexibly adjustable holder system for accommodating PCBs of various sizes by means of latching or screw connection. The system can be mounted on a UM-BASIC/-PRO 122 profile from Phoenix Contact.

Do you need plenty of freedom when developing the PCBs for your devices? - The UM-BASIC extruded profile housing offers you an open construction principle, custom mounting positions for PCBs, and flexible lengths from 3 to 200 cm. This means that even large-scale device concepts can be implemented.

As a leading manufacturer of connectors and electronics housings, Phoenix Contact is always working to find new solutions for the growing requirements placed on your industrial and infrastructure applications.

Discover our new device connection technology for the transmission of signals, data, and power as well as our versatile electronics housings.

Extruded profile housings are characterized by the fast, tool-free assembly using the snap-mount principle and the precisely configurable housing length for the position and size of the PCB. Develop devices in accordance with your requirements with a free choice of PCB connection technology. The open design principle is ideal for PCBs with large components. Optional covering hoods that can be freely positioned protect your electronics.

The extruded profiles are cut to customer-specific lengths. They are available in lengths from 30 to 1,000 mm. Precise housing lengths down to the millimeter save you valuable space.

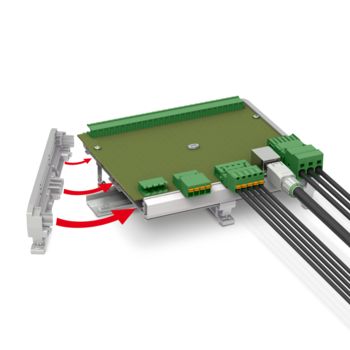

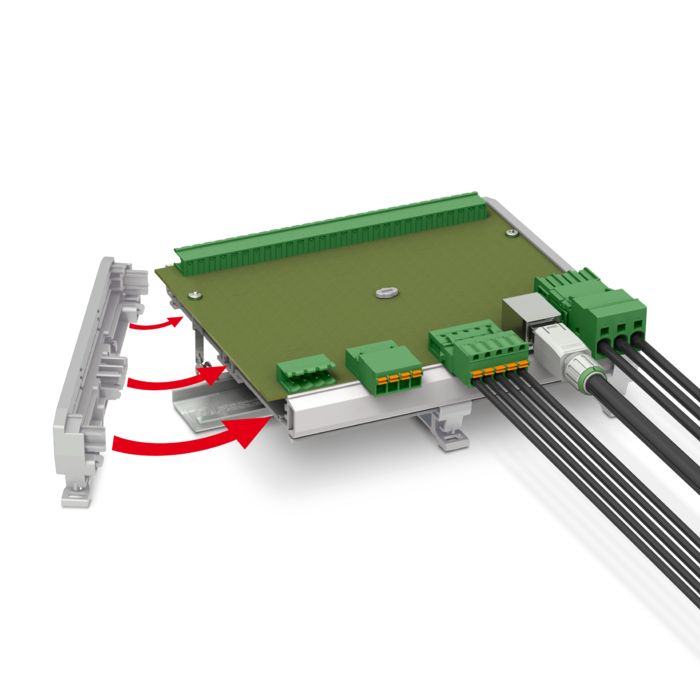

Simply snap the sides into place with the snap-mount principle, thereby saving installation time. Screws are not necessary.

Assemble your PCB right to the edge. This means you will make the best use of your space.

Tailor the design of your housing to the device with freely positionable covering hoods. The hoods are available in different geometries. Moreover, they also feature an optional integration option with guides for integrating printed circuit boards.

Simplify device communication with optional bus cross-connectors. Connect several modules together quickly and securely. The load capacity is a current strength of up to 8 A and 160 V.

Connect the PCB in all three different PCB levels to the DIN rail via PE contact.

Learn how easy it is to assemble the UM-BASIC housing. The assembly takes just a few minutes.

Electronics housings are an elementary part of a device. They determine its appearance and protect the electronics from external influences. In addition, they enable assembly in superordinate units. Device manufacturers must therefore pay attention to many details, and not only in the design, but also in the choice of housing when it comes to materials and quality testing. This brochure provides you with all the details.