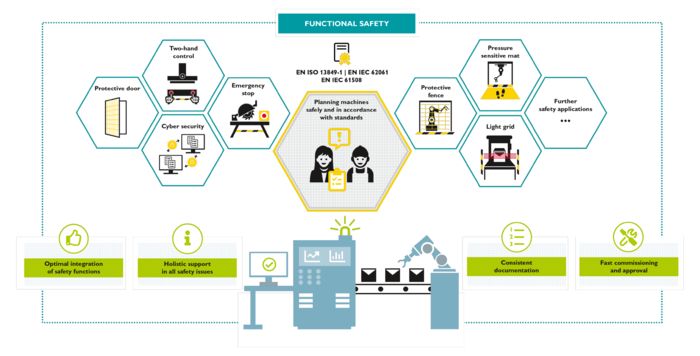

In Europe, the Machinery Directive sets the standard. It defines basic safety requirements that are specified in harmonized standards. Using it is voluntary, but does offer legal advantages. No official approval is required – the CE marking and a declaration of conformity from the manufacturer are sufficient. A notified body must only be involved for high-risk products. The new requirements of the EU Machinery Regulation 2023/1230 must be implemented by January 27, 2027.