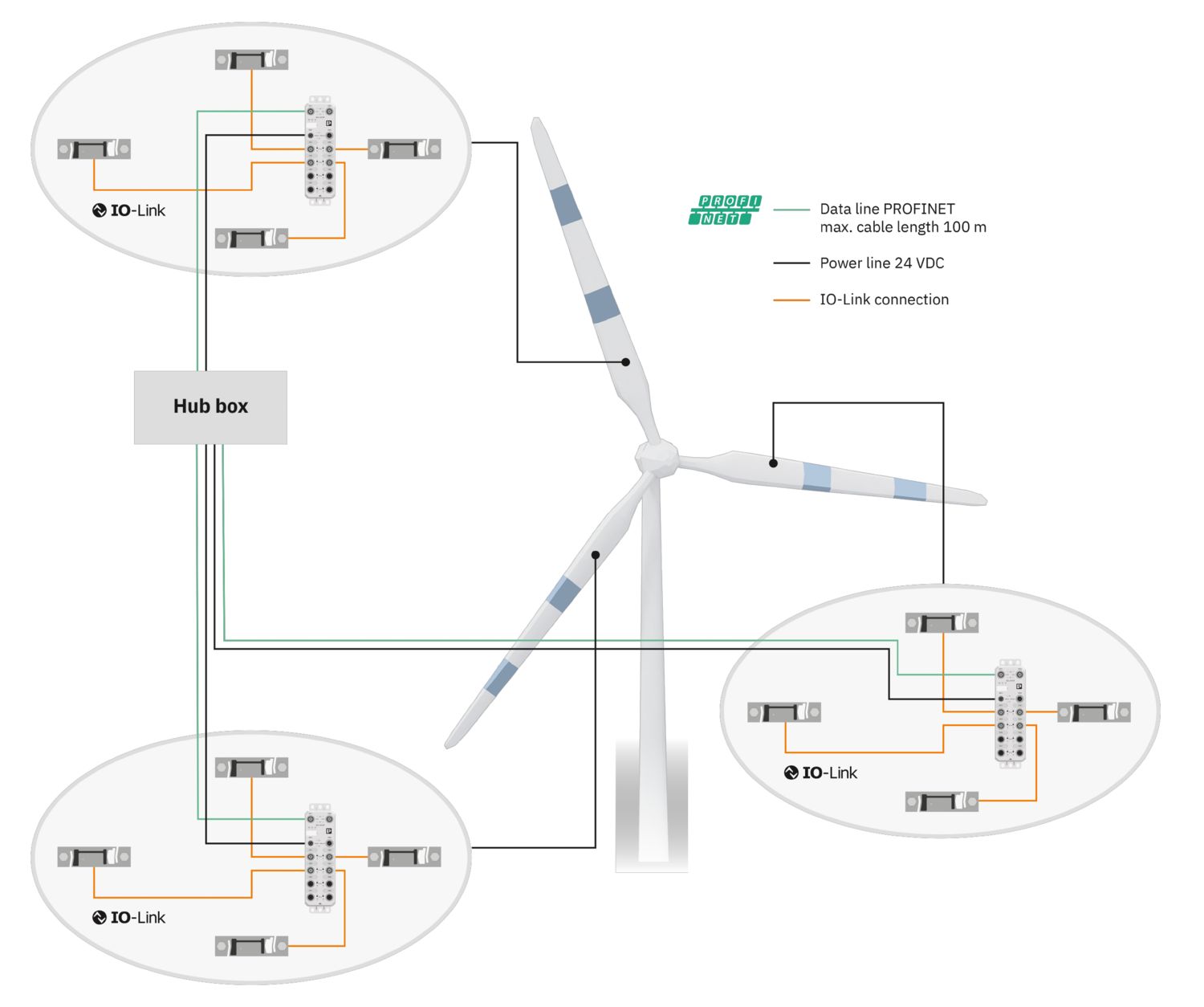

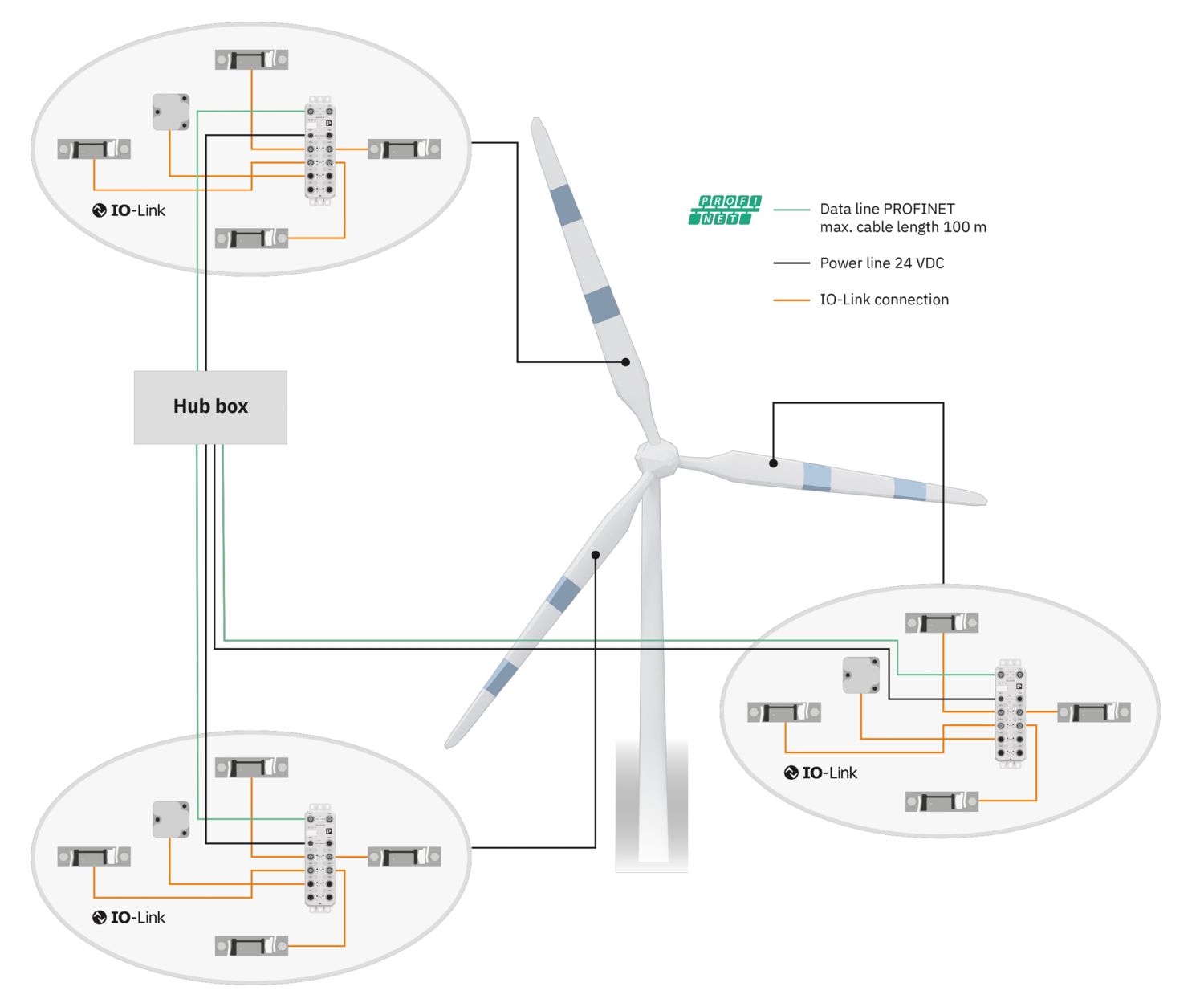

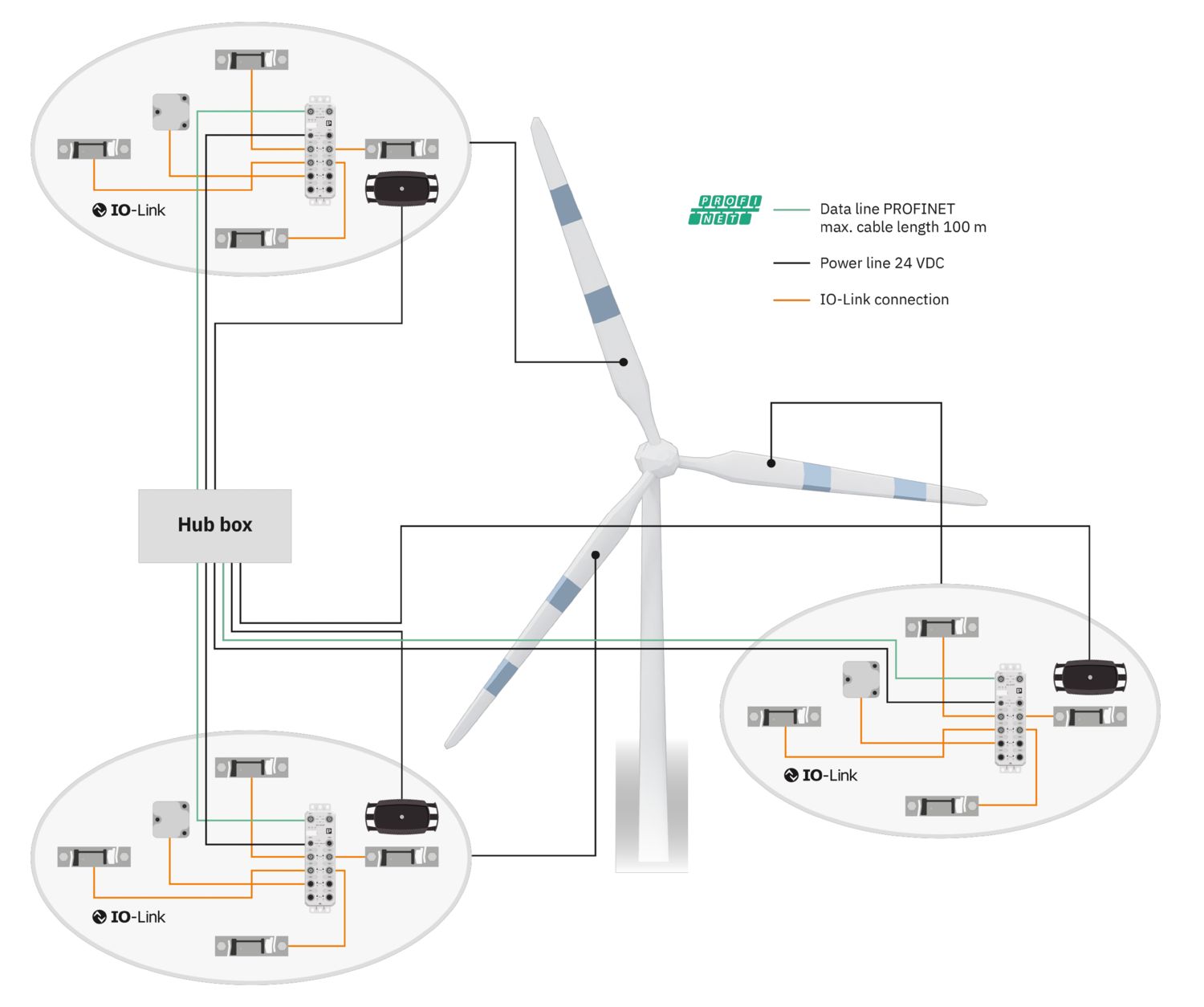

The sensor with integrated strain gauge is an essential component for load monitoring (rotor monitoring system (RM-S)) on rotor blades of wind turbine generators.Using the RM-S, actual loads and bending moments in the rotor blade can be measured and continuously monitored. This allows for load-optimized control of the system and increases the service life of the rotor blade. Changes in the material structure of the rotor blade can be detected at an early stage and investigated more closely to avoid major repairs as well as consequential damage. The sensor is mounted on the inside of the rotor blade. IO-Link is used for communication to the higher-level controller. The WIL-RM-S-MP mounting kit is required for mounting (see accessories). Four sensors and four mounting kits are required for each rotor blade. The sensor is part of the Blade Intelligence rotor blade monitoring system product portfolio for wind turbine generators. The system essentially consists of sensors for ice detection, load monitoring, lightning current measurement, and structural health monitoring, which were specially developed for use on the rotor blade. The sensors can be combined individually. The sensor data is transmitted to a common evaluation unit via the IO-Link communication module. The evaluation unit is available as a ready-to-use switchgear and controlgear assembly (see accessories). For alternatives to the ready-to-use switchgear and controlgear assembly solution, please contact your Phoenix Contact subsidiary. The Blade Intelligence rotor blade monitoring system can also be reliably integrated into existing systems.