Communicative 24 V supply system

Data transparency for superior system availability

Data is the new gold. In industries where high system availability is key, knowledge about system states and operating states is essential. Operating data can be used to identify, localize, and correct critical operating states and anomalies promptly before they result in expensive production downtime. The new, communicative 24 V supply system increases the data transparency of the entire system and provides information on all relevant operating and diagnostic data. Preventive function monitoring helps you reduce downtimes to a minimum. The modular solution consists of the communicative QUINT POWER power supply, the CAPAROC circuit breaker system, and the intelligent QUINT DC UPS.

Your advantages

- Transmission of all relevant operating data through the circuit breaker system or the UPS to the controller via fieldbus

- Easy integration of IO-Link into the controller

- Complete transparency of operating data from the input to every single circuit breaker

- Downtimes are reduced to a minimum

Communicative QUINT POWER power supplies

Communicative power supply

The communicative QUINT POWER power supply provides complete transparency regarding the operating data from the AC side to the 24 V DC side. It can be quickly and easily integrated or parameterized in your control environment via fieldbus or IO-Link.

Integration via fieldbus:

- Via connection to the CAPAROC circuit breaker system and the integrated PROFINET interface

- Via connection to the DC UPS and the integrated interface for EtherNet/IP™, EtherCAT, Modbus, or PROFINET

Integration via IO-Link:

- Direct connection to the IO-Link master

In addition, the communicative power supply enables preventive function monitoring and maintenance, thus ensuring superior system availability.

Increased data transparency with QUINT POWER

Maximum system transparency Comprehensive condition monitoring for high system availability

The communicative QUINT POWER power supply provides complete data consistency from the 400 V AC side to the 24 V DC side. This enables errors to be detected, localized, and corrected promptly.

- Digital nameplate: Clear identification of the device in the system

- Input data: Initial indication of the network quality and detection of phase failures

- Output data: Current and voltage monitoring and anomaly detection

- Operating data: Comprehensive condition monitoring including information on the remaining service life for predictive maintenance

- Events: Fast detection and localization of critical system states

- Data logging: Analysis and permanent optimization of the entire system

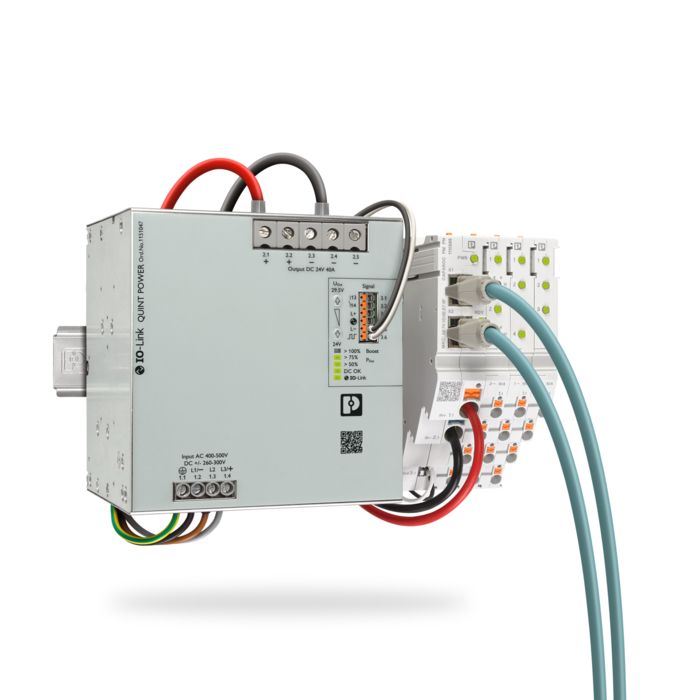

QUINT POWER power supply and CAPAROC circuit breaker system

Power supply and circuit breaker system The intelligent solution for a protected 24 V supply system

Combine the QUINT POWER power supply with the CAPAROC circuit breaker system and benefit from the advantages of system integration. One central interface for QUINT POWER and CAPAROC enables simple and cost-effective integration of the power supply into the network protocol of the circuit breaker system:

- The PROFINET interface enables complete transparency and access to the entire system.

- A web server allows for on-site access to operating states, error messages, and setting details of the system solution.

The supply solution provides complete data consistency from the primary side right through to the protected load circuits.

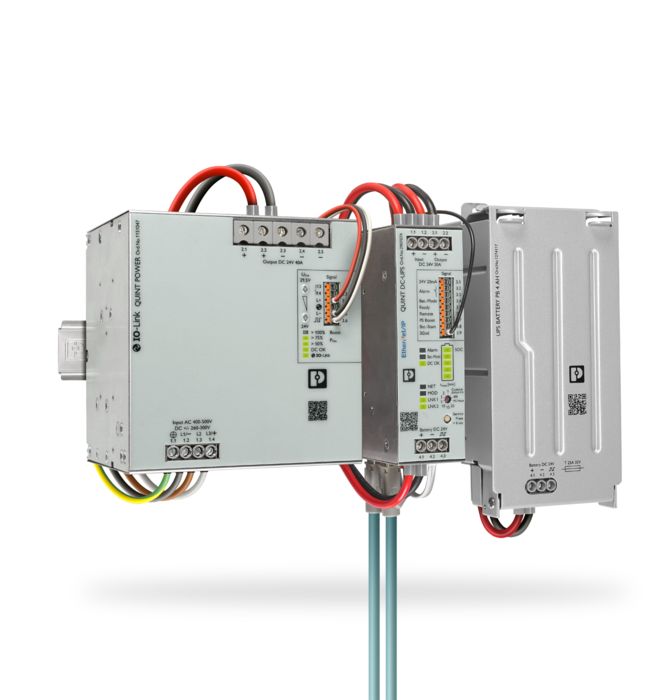

Uninterruptible power supply solution

Power supply and UPS The intelligent solution for an uninterruptible 24 V supply system

Combine the QUINT POWER power supply with the intelligent QUINT DC UPS to create an uninterruptible 24 V supply system that provides all data from the power supply right through to the battery.

- The QUINT DC UPS provides interfaces and protocols for different industrial networks.

- The corresponding software packages for the PLCnext, TIA Portal, Studio 5000, and TwinCAT engineering environments are included.

- The POWER MANAGEMENT SUITE software can be used for function monitoring and configuration of the entire system.

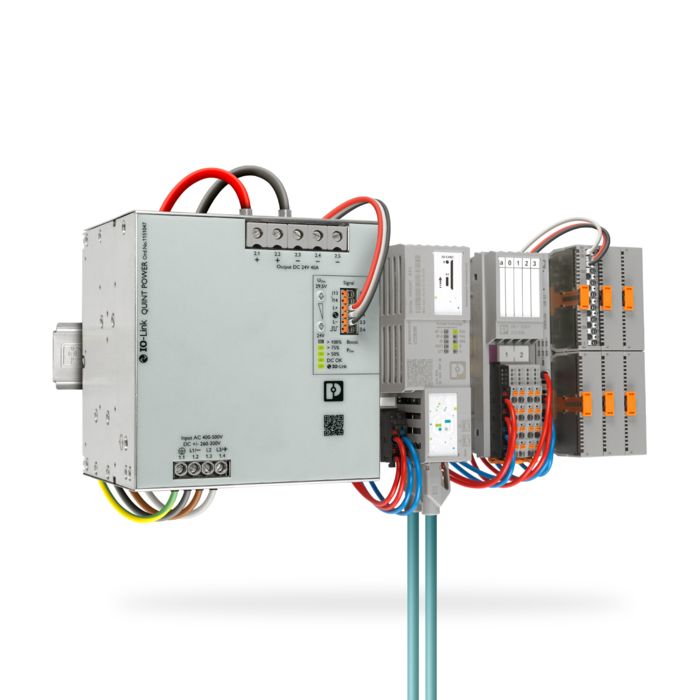

Communicative QUINT POWER power supply and PLCnext Control

Integration of the power supply via IO-Link Direct connection to the controller

If your system already contains an IO-Link master, the QUINT POWER power supply can be easily integrated into the control environment by means of the integrated IO-Link interface.

- Complete data consistency from the primary side right through to the protected load circuits: energy monitoring, device identification, condition monitoring

- Easy replacement of specially configured devices, as the PLC handles configuration

- Cost-effective data access, as only one device in the system needs to have a fieldbus interface