Protection against lightning - Part 1: General principles

Protection against lightning - Part 1: General principles

• IEC 62305-1

• EN 62305-1

• DIN EN 62305-1 (VDE 0185-305-1)

Protection against lightning - Part 2: Risk management

Protection against lightning - Part 2: Risk management

• IEC 62305-2

• EN 62305-2

• DIN EN 62305-2 (VDE 0185-305-2)

Protection against lightning - Part 2: Risk management - Supplement 1: Lightning threat in Germany

Protection against lightning - Part 2: Risk management - Supplement 1: Lightning threat in Germany

• DIN EN 62305-2 Supplement 1 (VDE 0185-305-2 Supplement 1)

Protection against lightning - Part 2: Risk management - Supplement 2: Calculation assistance for assessment of risk for structures, with CD-ROM

Protection against lightning - Part 2: Risk management - Supplement 2: Calculation assistance for assessment of risk for structures, with CD-ROM

• DIN EN 62305-2 Supplement 2 (VDE 0185-305-2 Supplement 2)

Protection against lightning - Part 2: Risk management; Supplement 3: Additional information for the application of DIN EN 62305-2 (VDE 0185-305-2)

Protection against lightning - Part 2: Risk management; Supplement 3: Additional information for the application of DIN EN 62305-2 (VDE 0185-305-2)

• DIN EN 62305-2 Supplement 3 (VDE 0185-305-2 Supplement 3)

Protection against lightning - Part 3: Physical damage to structures and life hazard

Protection against lightning - Part 3: Physical damage to structures and life hazard

• IEC 62305-3

• EN 62305-3

• DIN EN 62305-3 (VDE 0185-305-3)

Protection against lightning - Part 3: Physical damage to structures and life hazard - Supplement 1: Additional information for the application of DIN EN 62305-3

Protection against lightning - Part 3: Physical damage to structures and life hazard - Supplement 1: Additional information for the application of DIN EN 62305-3 (VDE 0185-305-3)

• DIN EN 62305-3 Supplement 1 (VDE 0185-305-3 Supplement 1)

Protection against lightning - Part 3: Physical damage to structures and life hazard - Supplement 2: Additional information for special structures

Protection against lightning - Part 3: Physical damage to structures and life hazard - Supplement 2: Additional information for special structures

• DIN EN 62305-3 Supplement 2 (VDE 0185-305-3 Supplement 2)

Protection against lightning - Part 3: Physical damage to structures and life hazard - Supplement 3: Additional information for the testing and maintenance of lightning protection systems

Protection against lightning - Part 3: Physical damage to structures and life hazard - Supplement 3: Additional information for the testing and maintenance of lightning protection systems

• DIN EN 62305-3 Supplement 3 (VDE 0185-305-3 Supplement 3)

Protection against lightning - Part 3: Physical damage to structures and life hazard - Supplement 4: Use of metallic roofs in lightning protection systems

Protection against lightning - Part 3: Physical damage to structures and life hazard - Supplement 4: Use of metallic roofs in lightning protection systems

• DIN EN 62305-3 Supplement 4 (VDE 0185-305-3 Supplement 4)

Protection against lightning - Part 3: Physical damage to structures and life hazard; Supplement 5: Lightning and overvoltage protection for photovoltaic power supply systems

Protection against lightning - Part 3: Physical damage to structures and life hazard; Supplement 5: Lightning and overvoltage protection for photovoltaic power supply systems

• DIN EN 62305-3 Supplement 5 (VDE 0185-305-3 Supplement 5)

Protection against lightning - Part 3: Physical damage to structures and life hazard; Supplement 6: Additional information on the requirement for lightning protection according to DIN EN 62305-3 (VDE 0185-305-3)

Protection against lightning - Part 3: Physical damage to structures and life hazard; Supplement 6: Additional information on the requirement for lightning protection according to DIN EN 62305-3 (VDE 0185-305-3)

• DIN EN 62305-3 Supplement 6 (VDE 0185-305-3 Supplement 6)

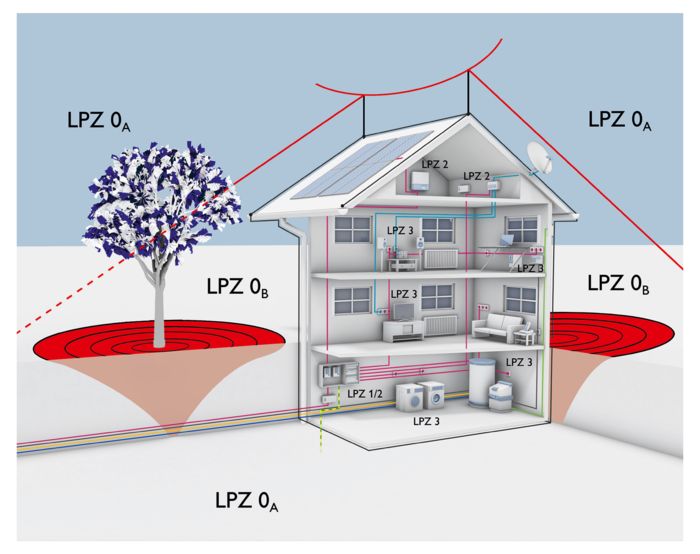

Protection against lightning - Part 4: Electrical and electronic systems within structures

Protection against lightning - Part 4: Electrical and electronic systems within structures

• IEC 62305-4

• EN 62305-4

• DIN EN 62305-4 (VDE 0185-305-4)

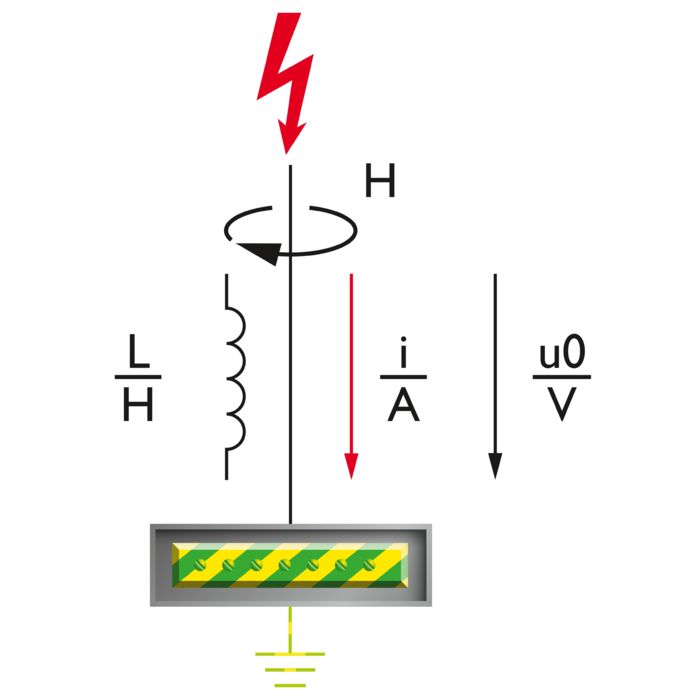

Protection against lightning - Part 4: Electrical and electronic systems within structures - Supplement 1: Sharing of the lightning current

Protection against lightning - Part 4: Electrical and electronic systems within structures - Supplement 1: Sharing of the lightning current

• DIN EN 62305-4 Supplement 1, VDE 0185-305-4 Supplement 1