SFB Technology Our powerful QUINT POWER power supplies with SFB Technology are ideally suited for ensuring the availability of your system. With the SFB Technology, standard miniature circuit breakers are tripped selectively and loads that are connected in parallel continue working without interruption.

Selective protection for systems

For superior system availability, standard miniature circuit breakers must be tripped magnetically so that faulty current paths can be switched off selectively. To ensure this, power supplies and DC/DC converters with SFB (Selective Fuse Breaking) Technology supply several times the nominal current for a short period, thus providing the necessary power reserve.

QUINT POWER with SFB Technology

Cost-effective protection with miniature circuit breakers

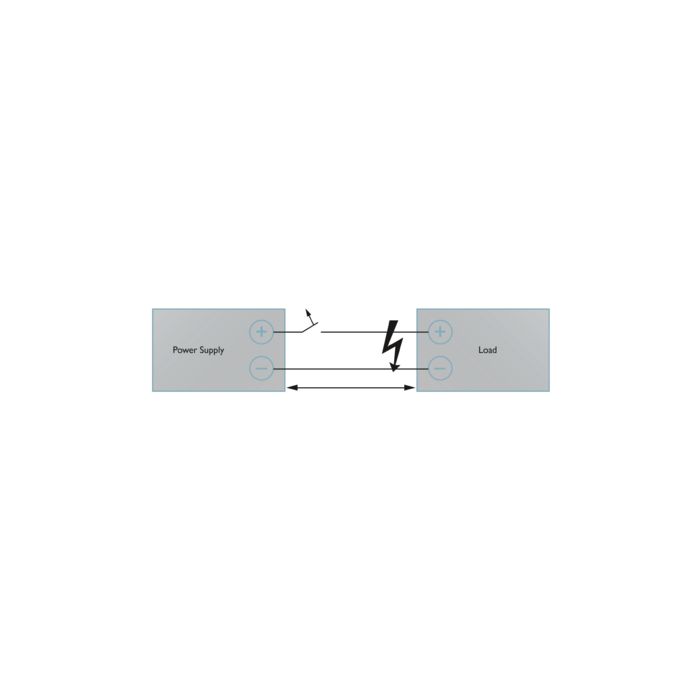

Additional loads, such as sensors or actuators, are usually connected to a power supply unit parallel to the controller. To minimize downtimes, each of these current paths should be protected individually. Should a short circuit then occur, only the faulty power supply path will be disconnected and the other loads will continue working without interruption. Standard miniature circuit breakers currently represent the most cost-effective solution for protecting a circuit. They can be tripped electromagnetically or thermally via a bimetal. To ensure that they trip within a few milliseconds, the current for the integrated solenoid must always be significantly higher than the nominal current of the circuit breaker.

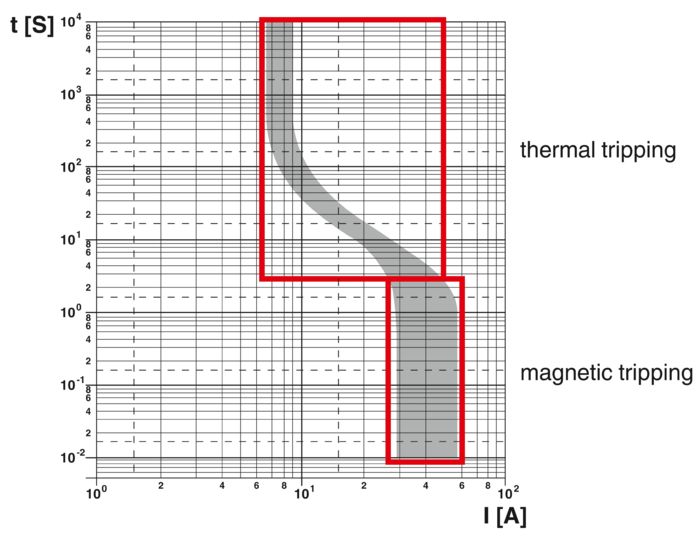

Miniature circuit breaker characteristics

Miniature circuit breaker characteristics

The short-circuit currents required for electromagnetic tripping are usually specified for alternating current (AC) by manufacturers. Users must therefore make sure that the DC values are up to 1.5 times higher.

Miniature circuit breakers are offered in various tripping characteristics. In the industrial environment, circuit breakers with B or C characteristics are used in most cases. For characteristic B, the following currents are necessary to trip the circuit breaker:

- AC applications: three to five times the nominal current

- DC applications: three to seven-and-a-half times the nominal current

Therefore, under the most unfavorable conditions, 187.5 A is required to trip a 25 A characteristic B circuit breaker within a few milliseconds. C characteristic circuit breakers require the following currents:

- AC applications: five to 10 times the nominal current

- DC applications: five to 15 times the nominal current

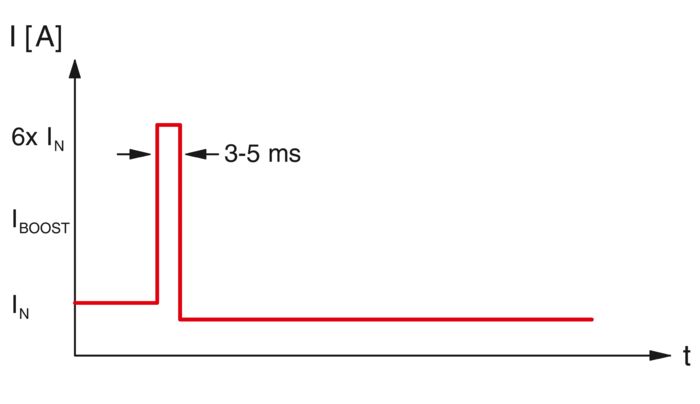

SFB pulse

SFB Technology prevents voltage dips

In the event of a fault, long cable paths limit the required tripping current. This can delay or even prevent the miniature circuit breaker from tripping. If power supplies can only offer a lower power reserve, thermal tripping may take several seconds or minutes. Finding the fault in this case is quite simple, as you can see which circuit breaker has tripped. However, during this time the 24 V DC voltage of the power supply has already been interrupted and the controller has failed.

In the worst-case scenario, the power supply unit delivers such a low current, or merely a brief power reserve of just a few seconds, that the fuse is not even tripped. Troubleshooting then becomes very time-consuming and expensive. With SFB Technology, devices in the QUINT series supply up to six times the nominal current. The circuit breakers are tripped magnetically with this pulse within a few milliseconds.

SFB configuration matrix

Cable length and conductor cross-section

Whether a circuit breaker is tripped quickly enough also depends on the length and cross-section of the cable connecting the load. It is not just the amount of current that the power supply unit can supply which is crucial here. It is only when the impedance of the faulty current path is low enough that high current can also flow in the short circuit and trip the circuit breaker magnetically.

To determine the right power supply for your application, based on the cable length and cross-section, please refer to our configuration matrix.

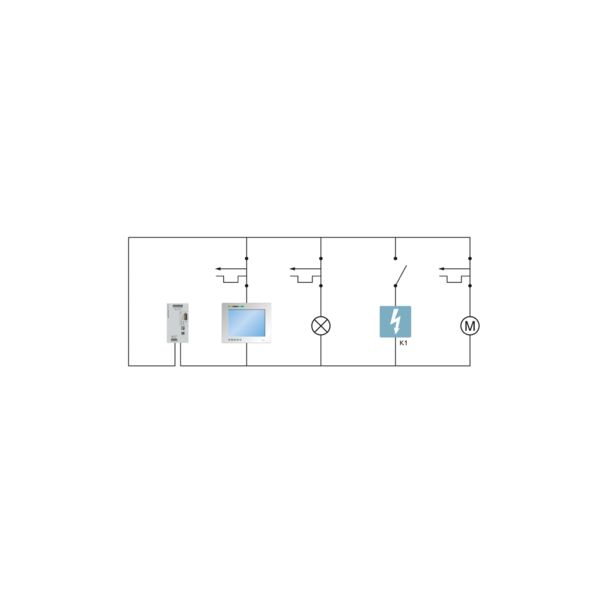

Example scenario for SFB Technology

- A power supply (24 V / 20 A)supplies a controller and three other loads.

- Each current path is protected by a miniature circuit breaker (6 A with B characteristic).

- Current paths consist of 25 m long copper conductors (cross-section 2.5 mm2)

In the event of a short circuit in this example, the 20 A power supply unit supplies six times the nominal current for a short period using SFB Technology, i.e., a maximum of 120 A. The circuit breaker is always tripped within 3 to 5 ms with 10 times the rated current in the magnetic range of its characteristic curve.

The other loads continue operating, the controller is consistently supplied with 24 V DC and continues running without interruption despite the short circuit.

Example scenario for SFB Technology

Device circuit breakers

The Phoenix Contact family of thermomagnetic circuit breakers is the first to use the SFB characteristic curve.

This tripping characteristic was specifically developed for use with power supplies that operate on the basis of SFB Technology. Combining these two devices ensures particularly reliable tripping in the event of a fault, even in the case of long cable runs between the power supply and end device. The SFB characteristic curve is based on characteristic C, but its tolerance is significantly narrower. The circuit breaker therefore reaches its tripping current faster and so is tripped sooner. This limits the short-circuit current and reduces the load on cables and connected devices.