Quality tests The quality of our products is our top priority. Quality is not only tested retrospectively on finished products, but is ensured responsibly at every stage of our production and logistics operations. To ensure that our products can be used in all relevant industries, our products undergo a wide range of test procedures. Along with standard test procedures in accordance with IEC 60947-7-1/-2/-3, our products are also subject to specific quality tests where they are qualified in accordance with numerous approvals.

Laboratory testing

Principles Basic principles of quality testing

Basic principles of quality testing

To fundamentally ensure the quality of our products, it is very important to us that our high quality standards are met in all areas of manufacturing at Phoenix Contact. Our laboratories play a very important role in the quality assurance of our products throughout the entire manufacturing process. This is why our laboratories are always the focus of continuous optimization and have a large number of accreditations, such as CE and UL accreditation.

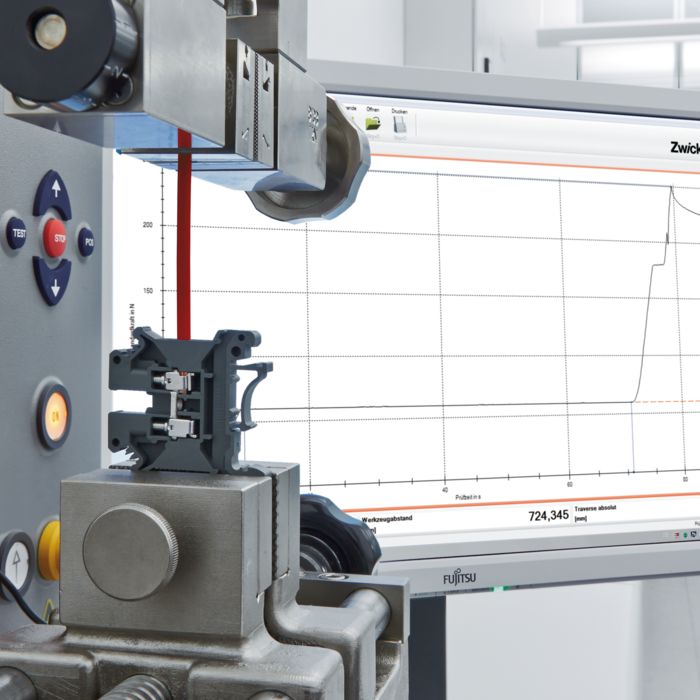

Conductor pull-out test (IEC 60947-7-1/-2) on a terminal block

Mechanical tests Tests relating to the mechanical properties of a terminal block

Tests relating to the mechanical properties of a product

The mechanical quality tests are primarily used to test the clamping parts and insulating housings. These tests focus on the product’s ability to withstand various influences such as vibration, conductor movement, and conductor pull-out, or its mechanical strength. By performing these quality tests, we are able to guarantee you very high quality standards with respect to the mechanical properties.

Examples of mechanical tests:

- Connection capacity

- Flexion test

- Conductor pull-out test

- Mechanical strength

- Temperature shock test

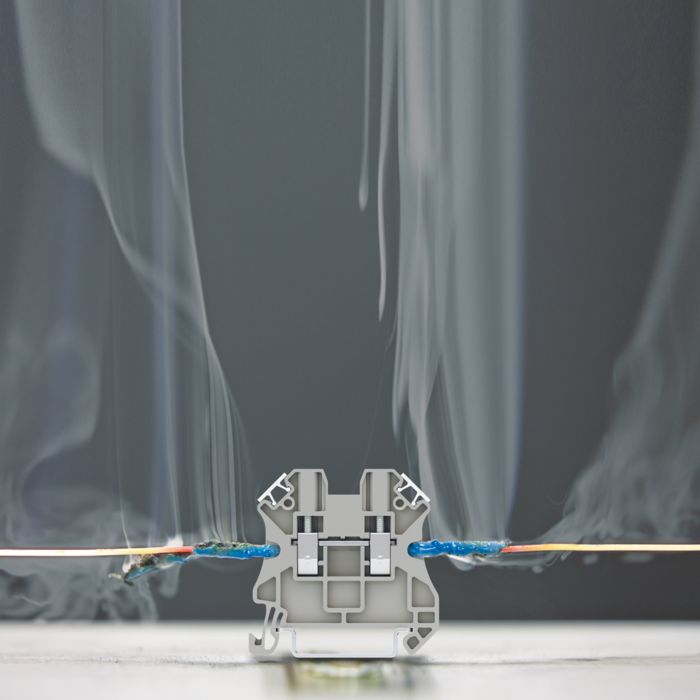

Short-time withstand current test on a terminal block (IEC 60947-7-1/-2)

Electrical tests

Electrical tests

Quality tests relating to the current flow of products

The electrical quality tests concern the current flow in the products. They involve imitating various scenarios in which the terminal blocks are tested for short circuits or heat generation, for example.

The creepage distances and insulation properties of the terminal blocks are also tested to ensure adequate electrical isolation. To ensure the efficiency of the individual products, they are also tested with respect to voltage drop. Examples of electrical tests:

- Temperature-rise test

- Dielectric test

- Air clearances and creepage distances

- Voltage-drop test

- Surge voltage test

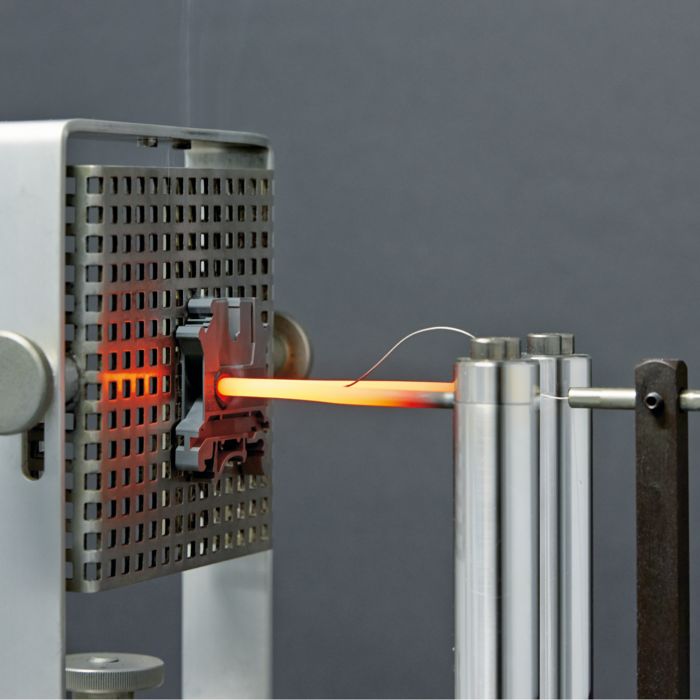

Glow-wire test (IEC 60695-2-11) on a terminal block

Material tests Test relating to the material properties of products

Test relating to the material properties of products

Material tests are used to check the products for material changes. The focus of the material tests is on longer load tests in the form of constantly higher temperatures, the development of creepage due to moisture and dirt, and the simulated aging of materials.

Examples of material tests:

- Aging test

- Inflammability classification

- Insulating material properties

- Corrosion test

- Needle flame test