EAC

Approval ID: RU C-DE.BL08.B.00644cULus Recognized

Approval ID: E60425| Nominal voltage UN | Nominal current IN | Cross section AWG | Cross section mm2 | |

|---|---|---|---|---|

| B | ||||

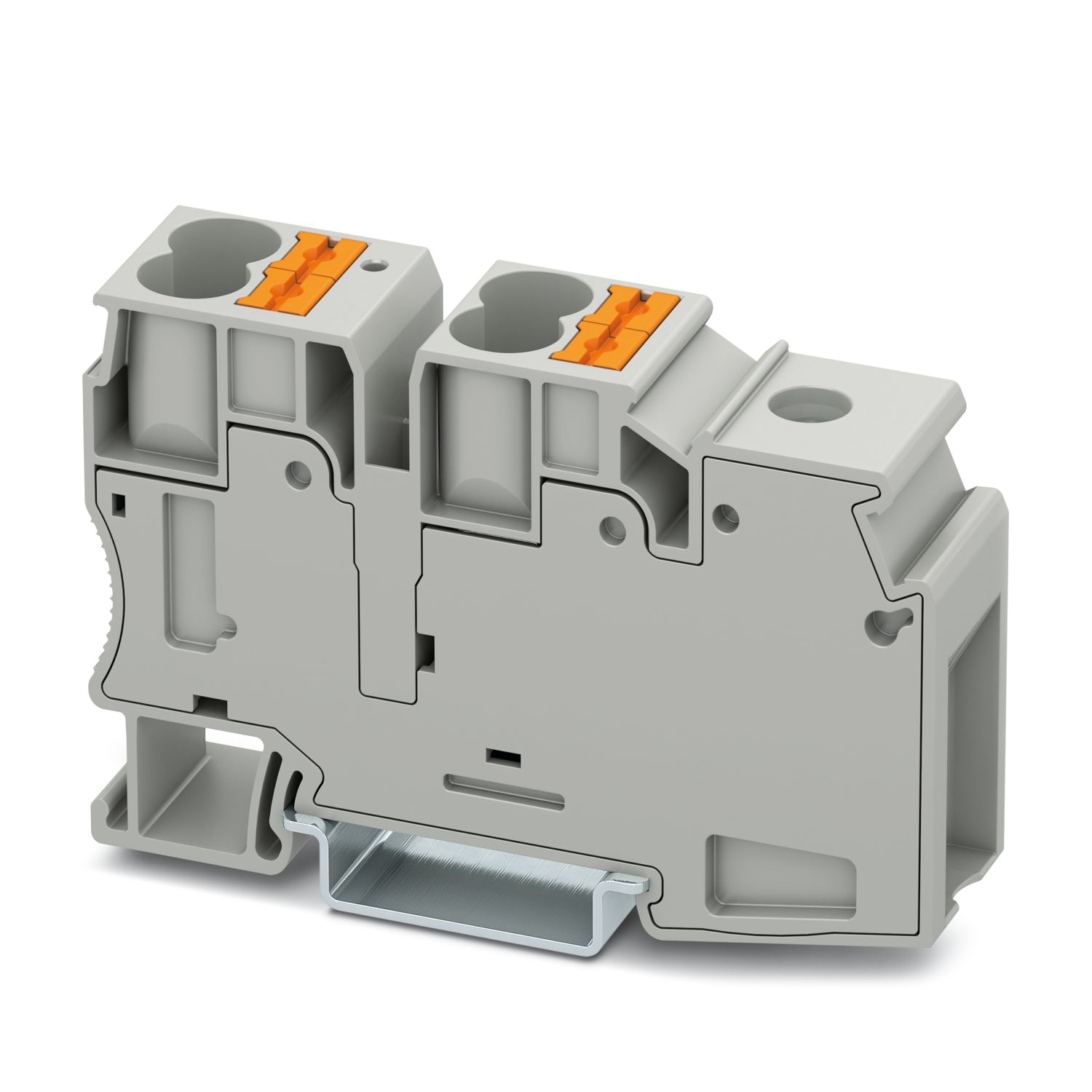

| Spring-cage connection | 600 V | 36 A | 20 - 8 | |

| Screw connection | 600 V | 86 A | 14 - 3 | |

| C | ||||

| Spring-cage connection | 600 V | 36 A | 20 - 8 | |

| Screw connection | 600 V | 86 A | 14 - 3 | |