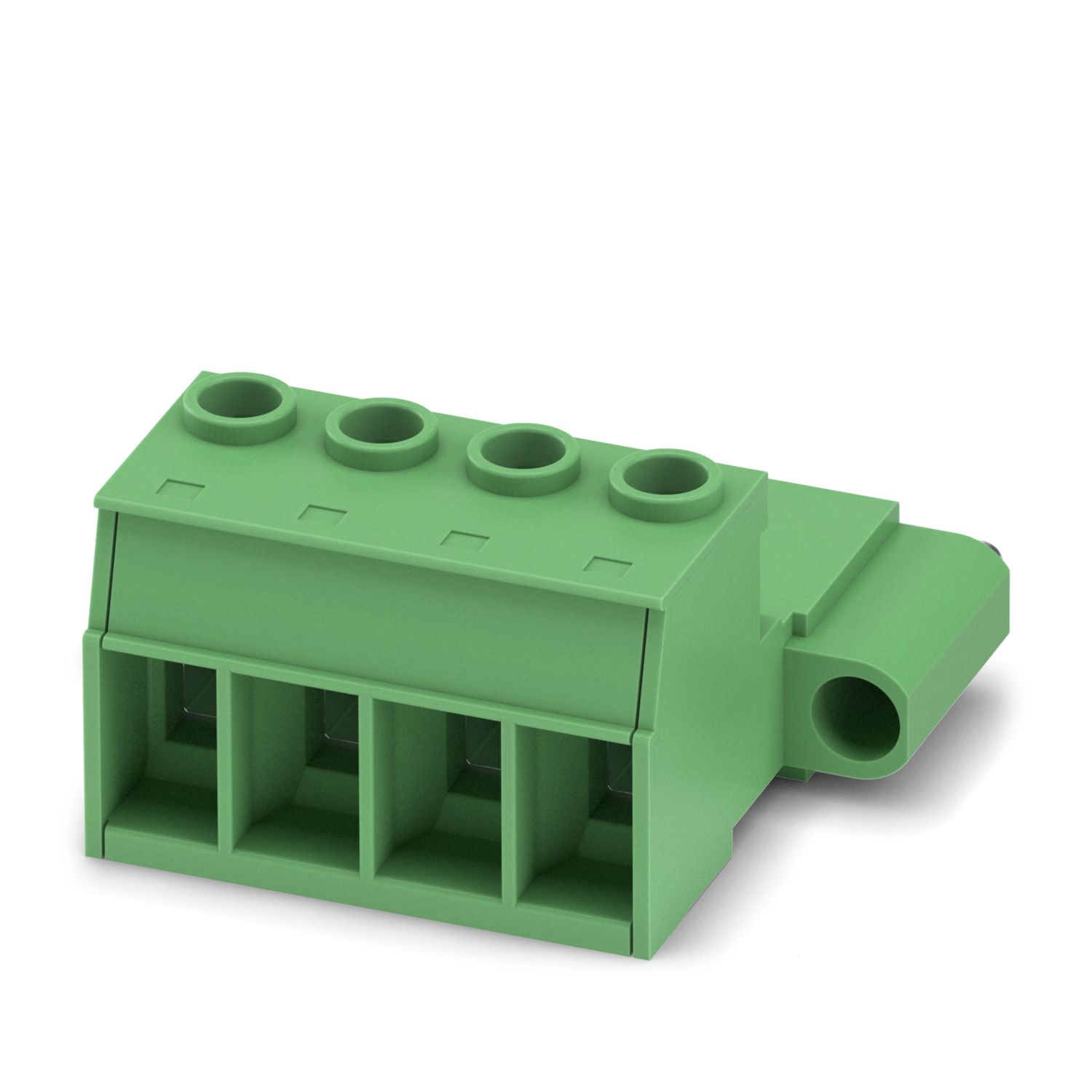

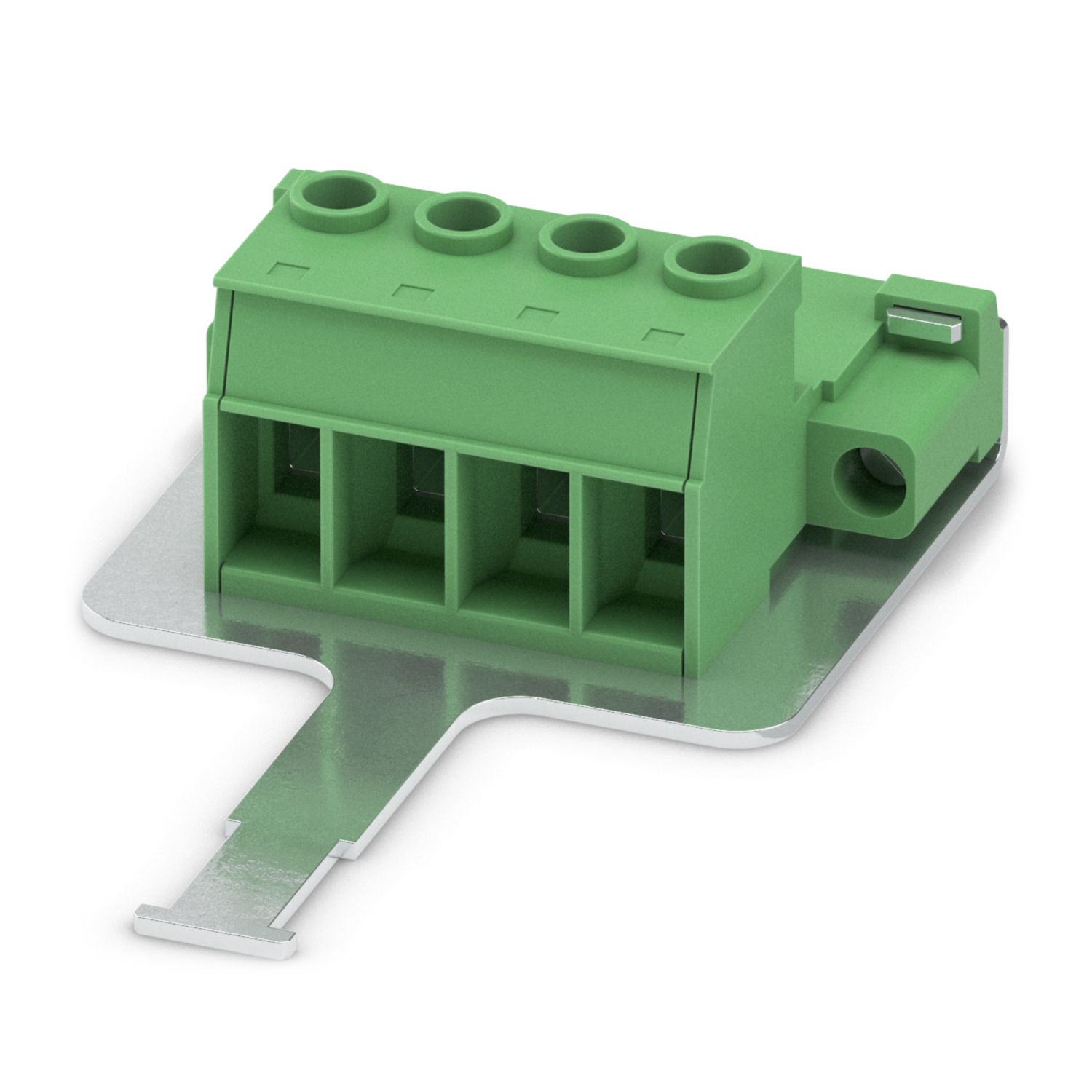

product line COMBICON Connectors XL

cross section 16 mm2

mounting type Wave soldering

type of packaging packed in cardboard

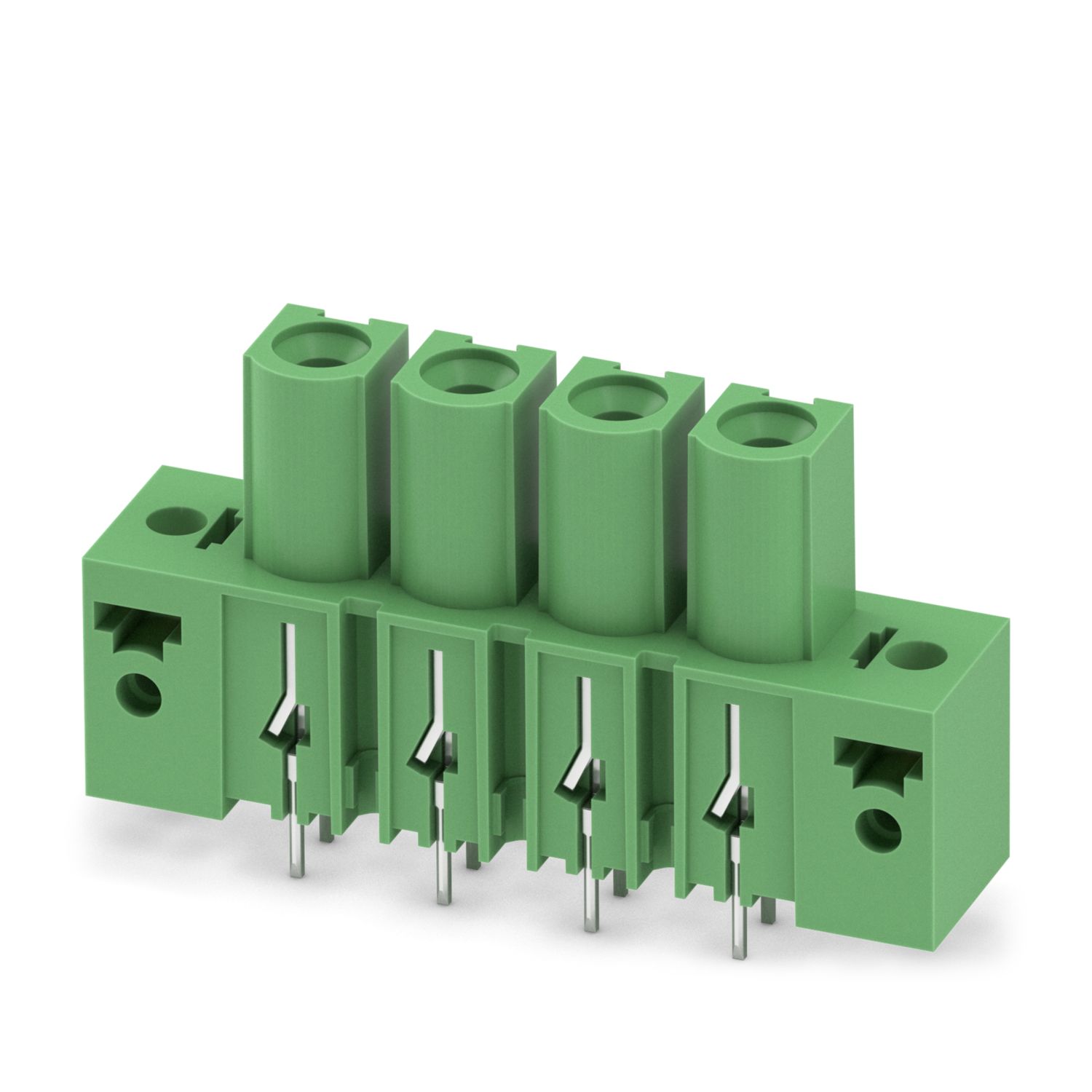

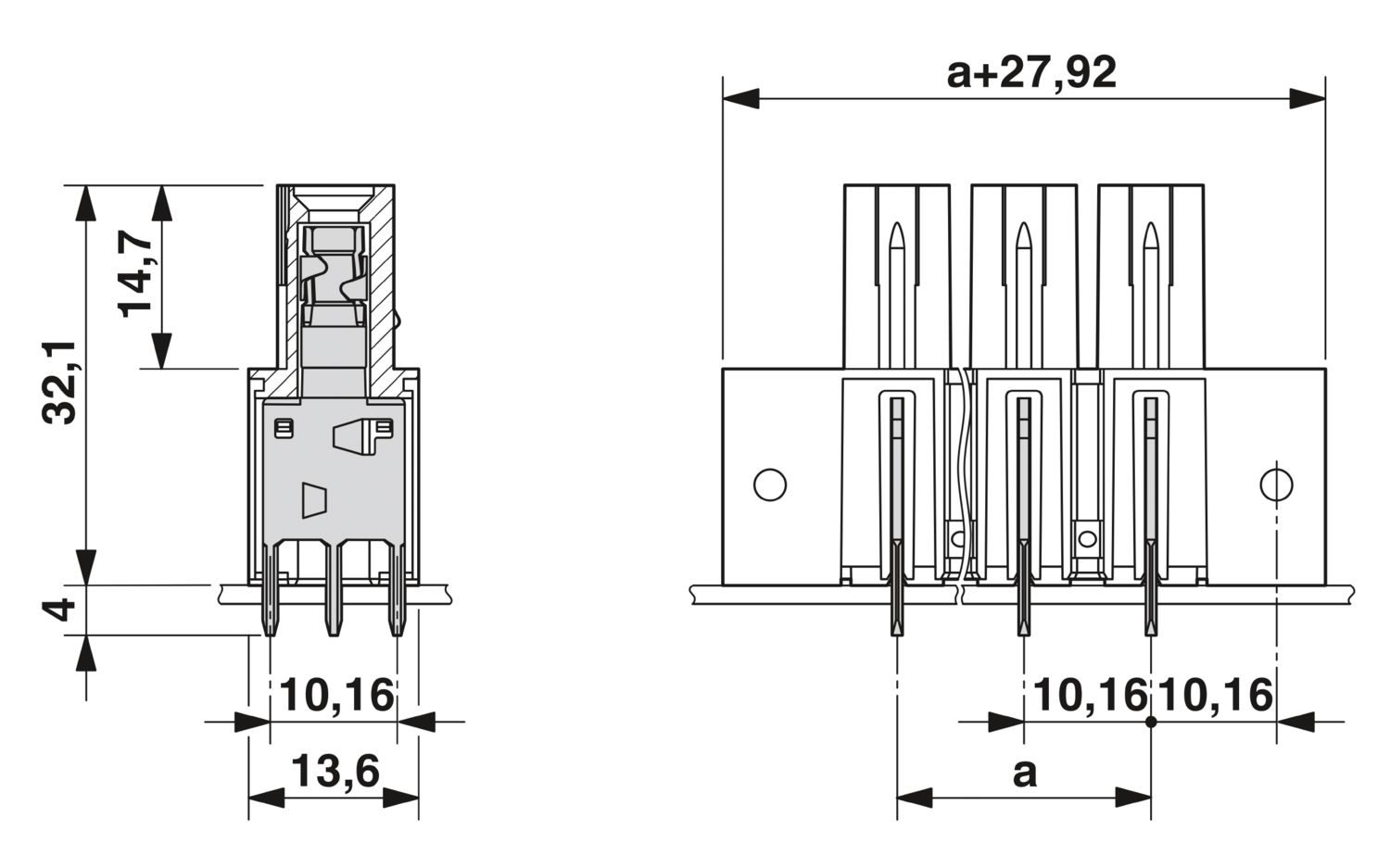

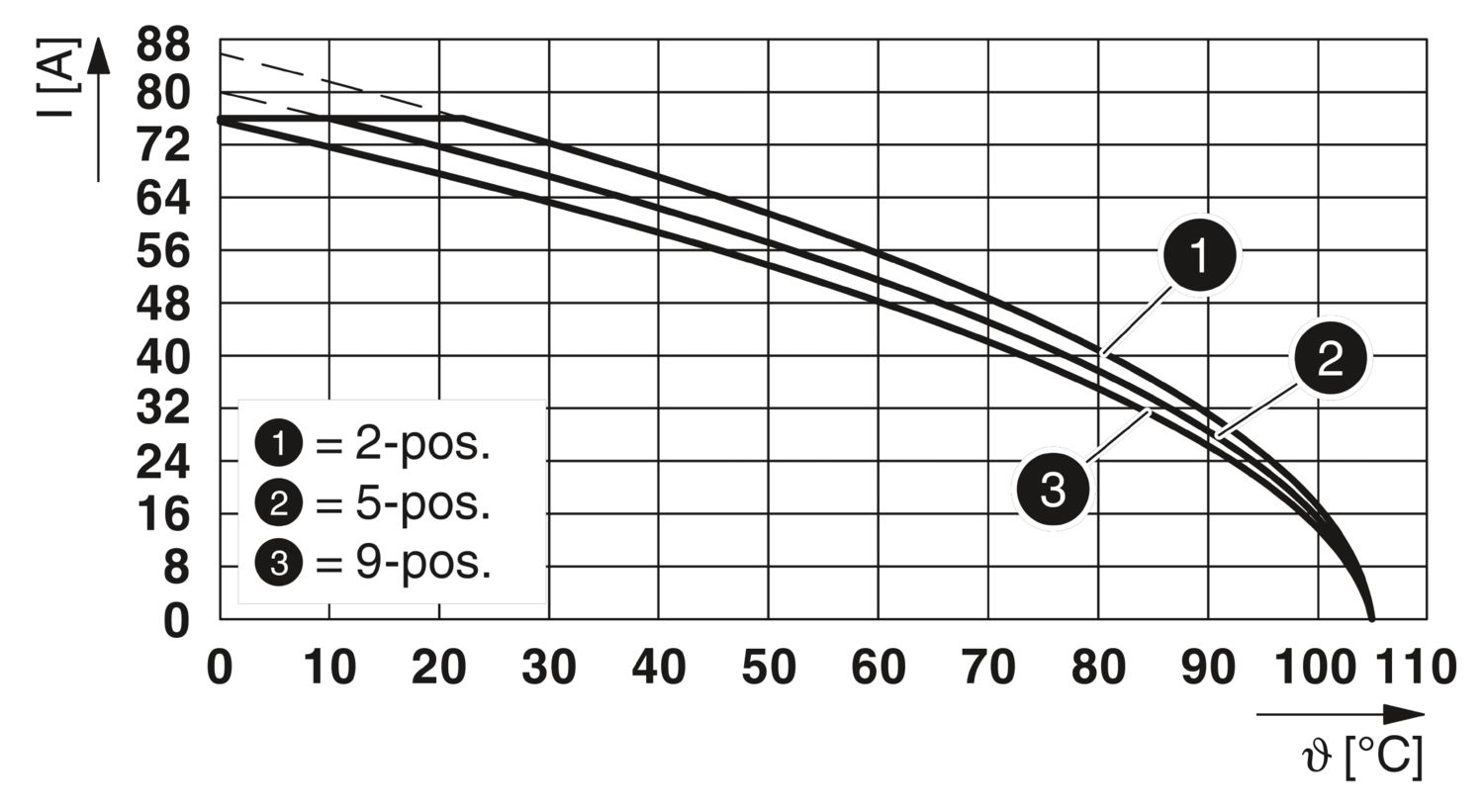

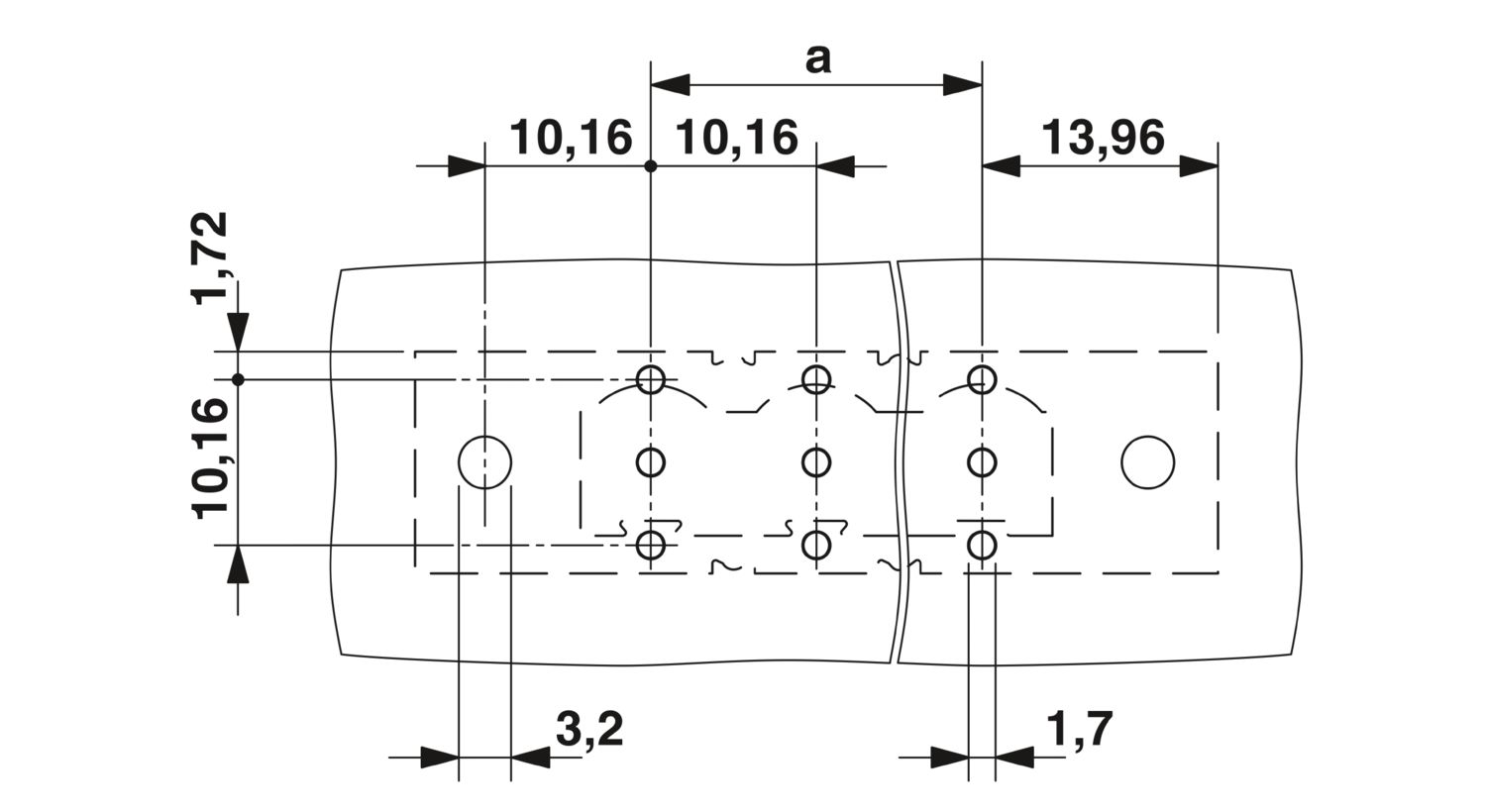

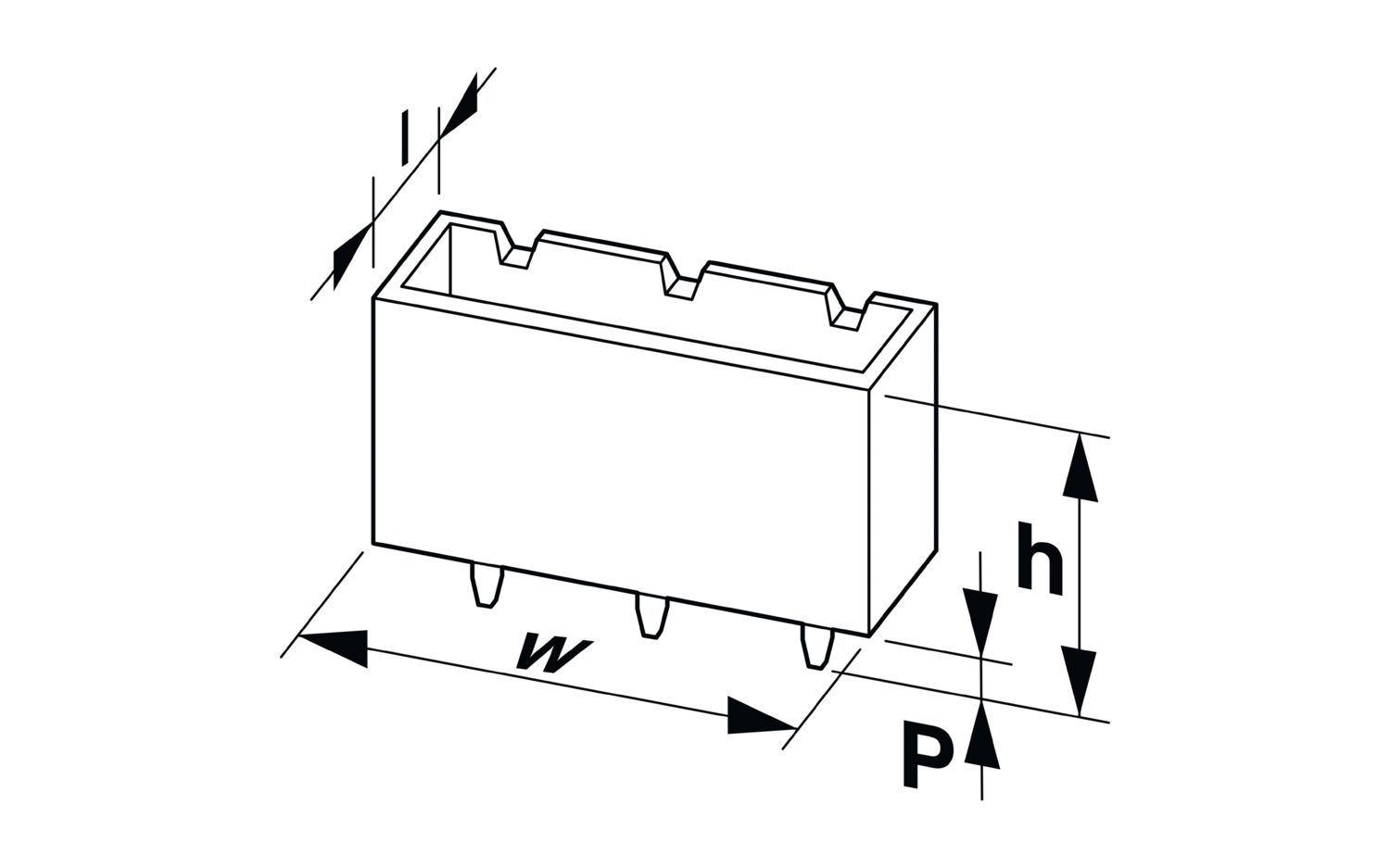

PCB headers, nominal cross section: 16 mm2, color: green, nominal current: 76 A, rated voltage (III/2): 1000 V, contact surface: Ag, contact connection type: Socket, number of potentials: 4, number of rows: 1, number of positions: 4, number of connections: 4, product range: IPCV 16/..-GF, pitch: 10.16 mm, mounting: Wave soldering, pin layout: Linear pinning, solder pin [P]: 4 mm, number of solder pins per potential: 3, plug-in system: COMBICON PC 16, Pin connector pattern alignment: Standard, locking: Screw locking mechanism, mounting method: Threaded flange, type of packaging: packed in cardboard