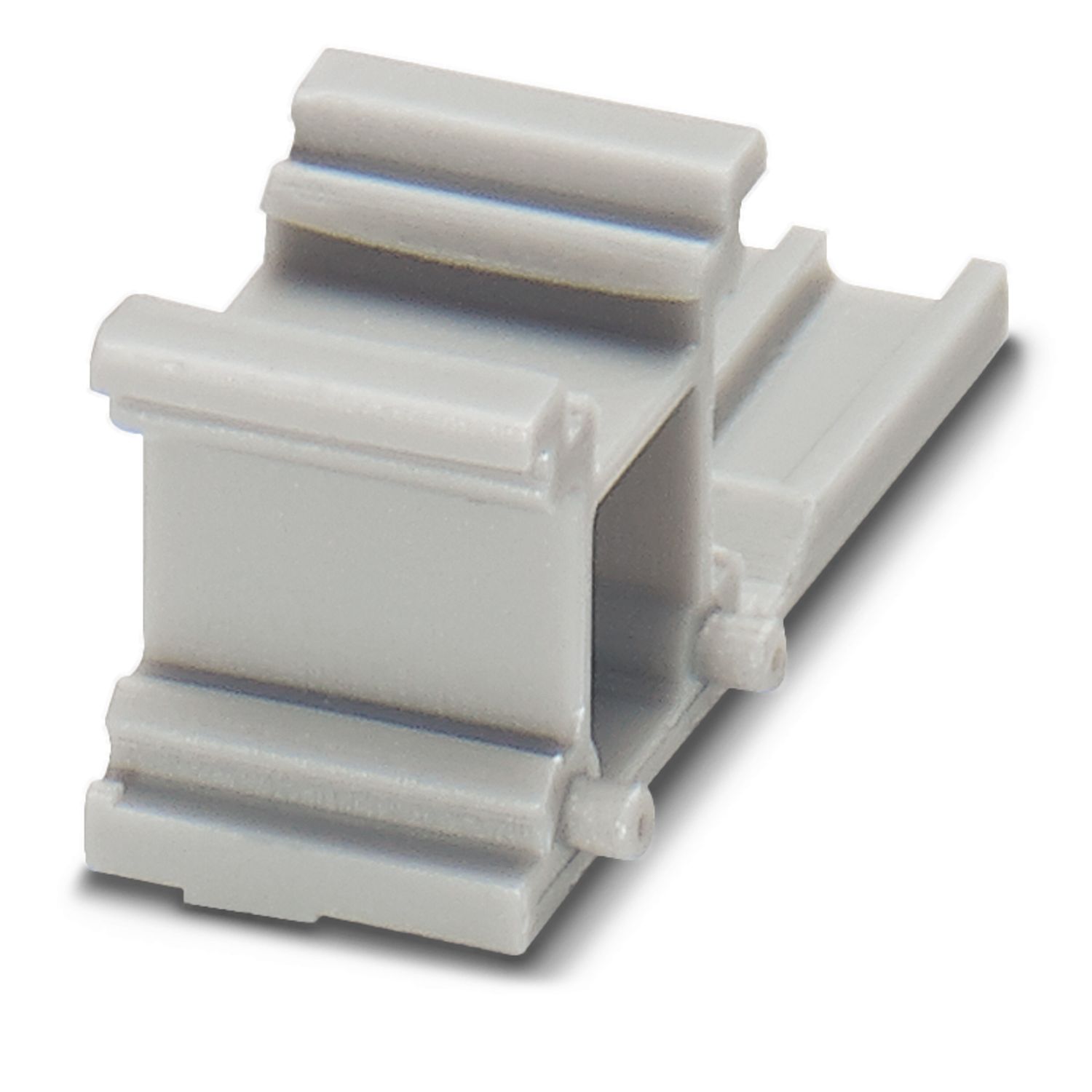

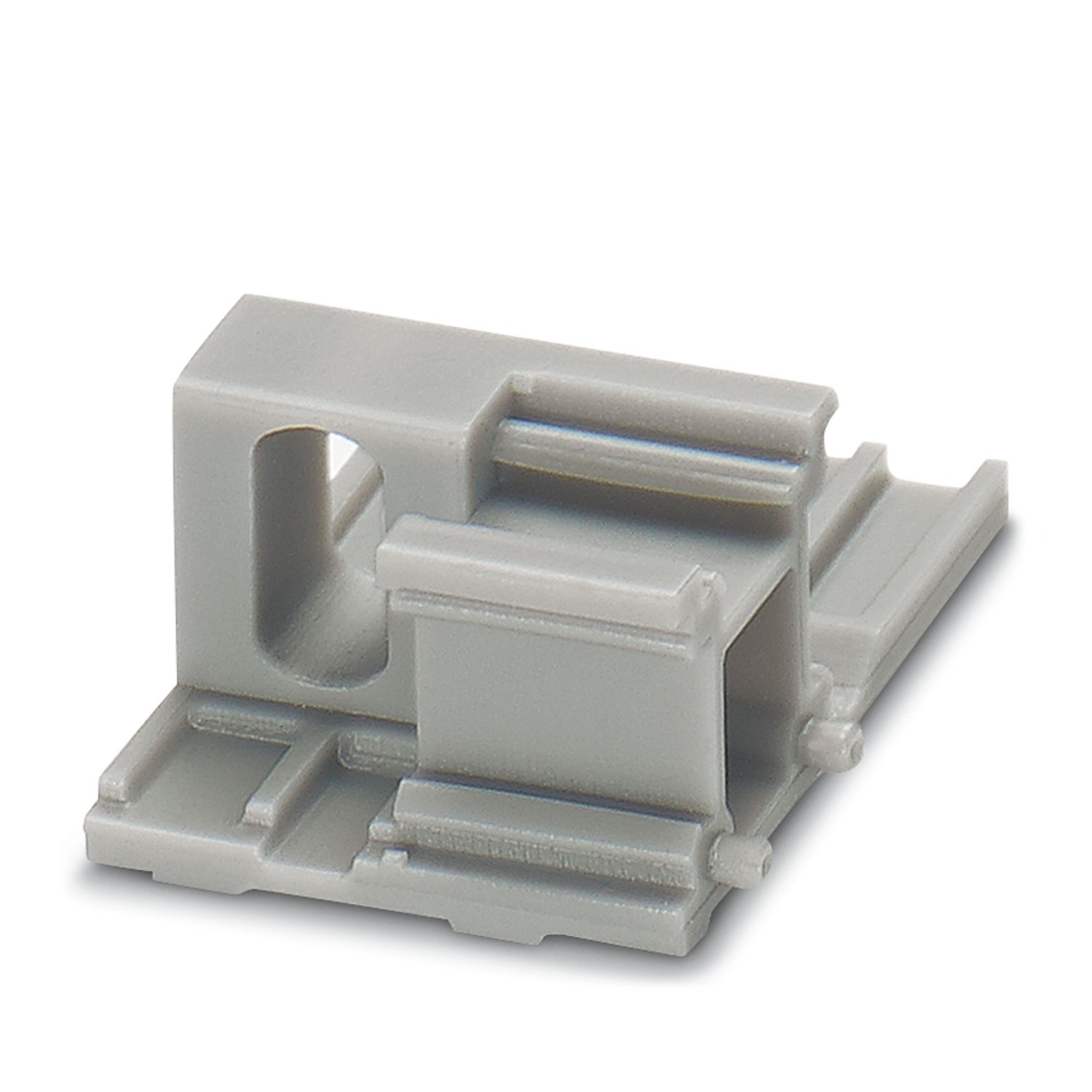

PTMC 1,5-1 /GY

-

Marshalling patchboard

1454577

Marshalling patchboard, nom. voltage: 500 V, nominal current: 17.5 A, connection method: Push-in connection, Rated cross section: 1.5 mm2, cross section: 0.14 mm2 - 2.5 mm2, mounting: for snapping onto a DIN rail adapter, for snapping onto a cover flange, color: gray

Product details

| Number of positions | 1 |

| Number of connections | 2 |

| Number of rows | 1 |

| Insulation characteristics | |

| Overvoltage category | III |

| Degree of pollution | 3 |

| Rated surge voltage | 6 kV |

| Maximum power dissipation for nominal condition | 0.56 W |

| Number of connections per level | 2 |

| Nominal cross section | 1.5 mm² |

| Rated cross section AWG | 16 |

| Connection method | Push-in connection |

| Stripping length | 8 mm ... 10 mm |

| Internal cylindrical gage | A1 |

| B1 | |

| Connection in acc. with standard | IEC 60947-7-1 |

| Conductor cross-section rigid | 0.14 mm² ... 2.5 mm² |

| Cross section AWG | 26 ... 16 (converted acc. to IEC) |

| Conductor cross-section flexible | 0.14 mm² ... 1.5 mm² |

| Conductor cross-section, flexible [AWG] | 26 ... 18 (converted acc. to IEC) |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 0.14 mm² ... 1.5 mm² |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 0.14 mm² ... 1.5 mm² |

| Nominal cross section | 1.5 mm² |

| Nominal current | 17.5 A |

| Maximum load current | 21 A (with a 2.5 mm² conductor cross-section) |

| Nominal voltage | 500 V |

| Connection cross sections directly pluggable | |

| Conductor cross-section rigid | 0.34 mm² ... 2.5 mm² |

| Conductor cross-section, rigid [AWG] | 20 ... 16 (converted acc. to IEC) |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 0.34 mm² ... 1.5 mm² |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 0.34 mm² ... 1.5 mm² |

| Width | 6.3 mm |

| Height | 30 mm |

| Depth | 11 mm |

| Color | gray (RAL 7042) |

| Flammability rating according to UL 94 | V0 |

| Insulating material group | I |

| Insulating material | PA |

| Static insulating material application in cold | -60 °C |

| Relative insulation material temperature index (Elec., UL 746 B) | 130 °C |

| Fire protection for rail vehicles (DIN EN 45545-2) R22 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R23 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R24 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R26 | HL 1 - HL 3 |

| Surface flammability NFPA 130 (ASTM E 162) | passed |

| Specific optical density of smoke NFPA 130 (ASTM E 662) | passed |

| Smoke gas toxicity NFPA 130 (SMP 800C) | passed |

| Surge voltage test | |

| Test voltage setpoint | 7.3 kV |

| Result | Test passed |

| Temperature-rise test | |

| Requirement temperature-rise test | Increase in temperature ≤ 45 K |

| Result | Test passed |

| Short-time withstand current 1.5 mm² | 0.18 kA |

| Short-time withstand current 2.5 mm² | 0.3 kA |

| Result | Test passed |

| Power-frequency withstand voltage | |

| Test voltage setpoint | 1.89 kV |

| Result | Test passed |

| Mechanical data | |

| Open side panel | No |

| Mechanical strength | |

| Result | Test passed |

| Test for conductor damage and slackening | |

| Rotation speed | 10 rpm |

| Revolutions | 135 |

| Conductor cross-section/weight | 0.14 mm² / 0.2 kg |

| 1.5 mm² / 0.4 kg | |

| 2.5 mm² / 0.7 kg | |

| Result | Test passed |

| Aging | |

| Temperature cycles | 192 |

| Result | Test passed |

| Needle-flame test | |

| Time of exposure | 30 s |

| Result | Test passed |

| Oscillation/broadband noise | |

| Specification | DIN EN 50155 (VDE 0115-200):2022-06 |

| Spectrum | Long life test category 1, class B, body mounted |

| Frequency | f1 = 5 Hz to f2 = 150 Hz |

| ASD level | 0.964 (m/s²)²/Hz |

| Acceleration | 5.72g |

| Test duration per axis | 5 h |

| Test directions | X-, Y- and Z-axis |

| Result | Test passed |

| Shocks | |

| Specification | DIN EN 50155 (VDE 0115-200):2022-06 |

| Pulse shape | Half-sine |

| Acceleration | 5g |

| Shock duration | 30 ms |

| Number of shocks per direction | 3 |

| Test directions | X-, Y- and Z-axis (pos. and neg.) |

| Result | Test passed |

| Ambient conditions | |

| Ambient temperature (operation) | -60 °C ... 105 °C (max. short-term operating temperature RTI Elec.) |

| Ambient temperature (storage/transport) | -25 °C ... 60 °C (for a short time, not exceeding 24 h, -60 °C to +70 °C) |

| Ambient temperature (assembly) | -5 °C ... 70 °C |

| Ambient temperature (actuation) | -5 °C ... 70 °C |

| Permissible humidity (storage/transport) | 30 % ... 70 % |

| Connection in acc. with standard | IEC 60947-7-1 |

| Mounting type | for snapping onto a DIN rail adapter |

| for snapping onto a cover flange |

| Item number | 1454577 |

| Packing unit | 10 pc |

| Minimum order quantity | 10 pc |

| Sales key | ***** |

| Product key | BE6212 |

| GTIN | 4063151843656 |

| Weight per piece (including packing) | 2.36 g |

| Weight per piece (excluding packing) | 2.3 g |

| Customs tariff number | 85369010 |

| Country of origin | CN |

ECLASS

| ECLASS-13.0 | 27250190 |

| ECLASS-15.0 | 27250190 |

ETIM

| ETIM 9.0 | EC002848 |

UNSPSC

| UNSPSC 21.0 | 39121400 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes (No exemptions) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-E

No hazardous substances above the limits

|

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | No substance above 0.1 wt% |

Compatible products

-

-

DF-PTMC-U - Flange cover 3270401

-

DF-PTMC-NS - Adapter 3270403

-

DF-PTMC-ZB - Marker adapter 3270410

-

SZF 0-0,4X2,5 - Screwdriver 1204504

-

ST-BW 0 - Actuation tool 1200135

-

RPS - Reducing plug 0201647

-

ZB 10:UNBEDRUCKT - Zack marker strip 1053001

-

ZB 10 CUS - Zack marker strip 0824941

-

ZB10,LGS:FORTL.ZAHLEN - Zack marker strip 1053014

-

ZB10,QR:FORTL.ZAHLEN - Zack marker strip 1053027

-

ZB10,LGS:L1-N,PE - Marker for terminal blocks 1053412

-

ZB10,LGS:U-N - Marker for terminal blocks 1053438

-

UC-TM 10 - Marker for terminal blocks 0818069

-

UC-TM 10 CUS - Marker for terminal blocks 0824605

-

UCT-TM 10 - Marker for terminal blocks 0829142

-

UCT-TM 10 CUS - Marker for terminal blocks 0829623

-

ZBF10:UNBEDRUCKT - Zack Marker strip, flat 0809997

-

ZBF10 CUS - Zack Marker strip, flat 0825031

-

ZBF10,LGS:FORTL.ZAHLEN - Zack Marker strip, flat 0810009

-

ZBF10,QR:FORTL.ZAHLEN - Zack Marker strip, flat 0810025

-

UC-TMF 10 - Marker for terminal blocks 0818124

-

UC-TMF 10 CUS - Marker for terminal blocks 0824662

-

UCT-TMF 10 - Marker for terminal blocks 0829204

-

UCT-TMF 10 CUS - Marker for terminal blocks 0829679

-

TMT 10 R - Marker for terminal blocks 0816210

-

TMT 10 R CUS - Marker for terminal blocks 0824500

-

MPS-MT - Test plug 0201744

-

MPS-IH WH - Insulating sleeve 0201663

-

MPS-IH RD - Insulating sleeve 0201676

-

MPS-IH BU - Insulating sleeve 0201689

-

MPS-IH YE - Insulating sleeve 0201692

-

MPS-IH GN - Insulating sleeve 0201702

-

MPS-IH GY - Insulating sleeve 0201728

-

MPS-IH BK - Insulating sleeve 0201731

Your advantages

High contact quality thanks to push-in technology as a replacement for Wire-Wrap®, TERMI-POINT®, etc.

Individual color assignment of cable and terminal point to ensure error-free, safe operation

Color configuration possible according to VDE 0812, VDE 0815, DIN 47100 or unlimited.

Tool-free wiring in a confined space thanks to compact size

Individual setup thanks to modular principle

Suitable for DIN rail mounting and panel cutouts with corresponding accessories

PHOENIX CONTACT (SEA) Pte Ltd

80 Bendemeer Road, #09-01A | #10-02 (Reception), Singapore 339949