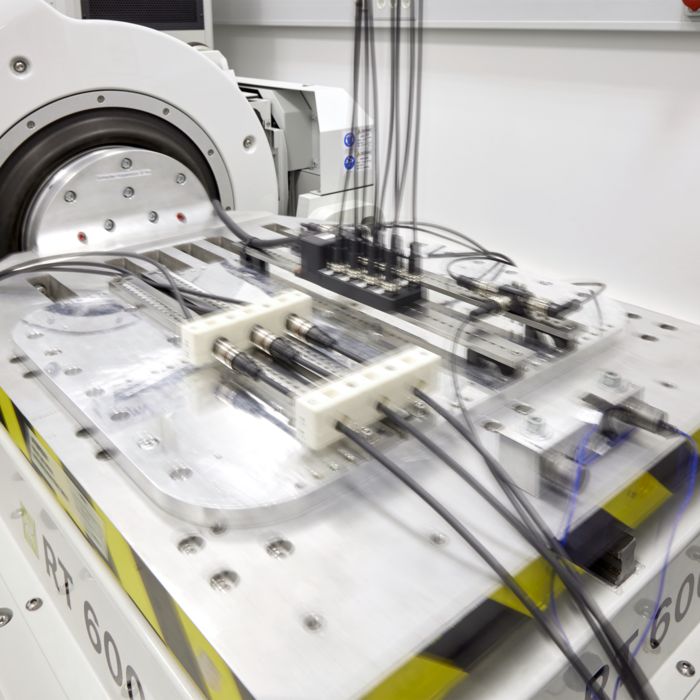

360° view of the M12 push-pull connections

With plug-and-produce, M12 push-pull connectors enable reliable connection even in confined spaces. The adjacent 3D view illustrates how this connection works.

With the M12 push-pull fast-locking system, Phoenix Contact is providing a robust connection concept for device and field cabling. The push-pull system ensures cross-manufacturer plug-in compatibility and particularly easy insertion – convenient, safe, and easy.

With plug-and-produce, M12 push-pull connectors enable reliable connection even in confined spaces. The adjacent 3D view illustrates how this connection works.

With the cross-manufacturer locking system, plugging is now reliable and convenient – even in confined spaces. You will reduce installation times by up to 80 percent compared to screw connections.

The M12 Duo contour allows flexible field wiring with proven M12 screw connectors or the new push-pull fast-connection technology. An easy push-pull device integration is even possible for existing M12 solutions.

The new M12 push-pull concept with countersunk M12 ports allows flush integration into the housing. Through the higher packing density your device designs become more compact.

Realize extensions in the field easily: You can realize flying leads with connectors with push-pull internal and external locking.

With M12 push-pull connectors designed for assembly, you can determine flexible cable lengths. The easy and tool-free Push-Lock connection enables convenient on-site wiring.

The consistently standardized push-pull product range guarantees worldwide availability. Cross-manufacturer compatibility with the IEC 61076-2-010 standardization.

M12 push-pull provides reliable protection against dust and water in accordance with IEC 60529. The connectors and devices are tested in accordance with IPX5 and IPX7 requirements. During these tests, the test objects must withstand jet water of 12.5 L/min. for >3 minutes and are immersed for 30 minutes in 1 m-deep water without any damage.

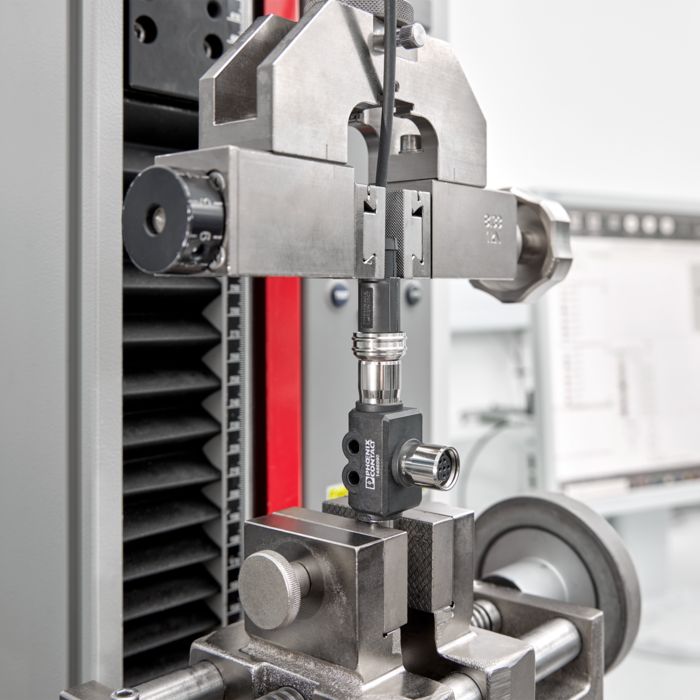

Push-pull connectors are subjected to vibrations and shocks. We simulate these interferences on the vibrating table. During this, contact interruptions of >1 μs are not permitted.

To test the tensile load capacity in accordance with IEC 60512-13-2, M12 push-pull connectors must withstand a tensile force of 300 N over 60 s. Neither the connector nor the cable may become damaged during this test. In addition, the locking mechanism of the connector must not come loose. Finally, it must still be easy to unlock the plug-in connection.

During the rotation test in accordance with IEC 60998-2-1, a vertically fixed M12 push-pull connector is connected to a mating connector. A 5 kg test weight is suspended from the end of the conductor. The conductor is moved around its own axis 150 times and must not become damaged as a result. In addition, the locking mechanism of the connector must not be released during the test, but must be able to be unlocked without problems at the end of the test.

For test part 2 in accordance with UL 2238a, the push-pull locking system is subjected to a 360° rotation with a load of ≥13.7 N. As in the other test for the locking mechanism, there must be no damage to the connector or cable. The locking mechanism of the connector must not be released during the test, but must be able to be unlocked at the end of the test.