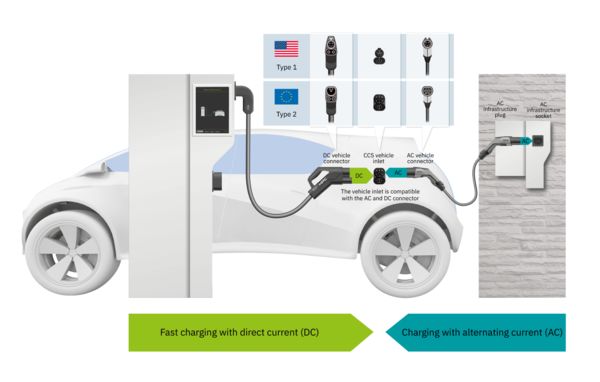

The vehicle is charged with AC power from a household outlet. Voltages up to 250 V may be applied in single-phase grids, and up to 480 V in three-phase grids. The maximum charging current is 16 A. There is no communication between the vehicle and the charging point. Fuse protection via a residual current device (RCD) is a mandatory requirement. Because this is not always guaranteed in older installations, Phoenix Contact advises against this charging mode.