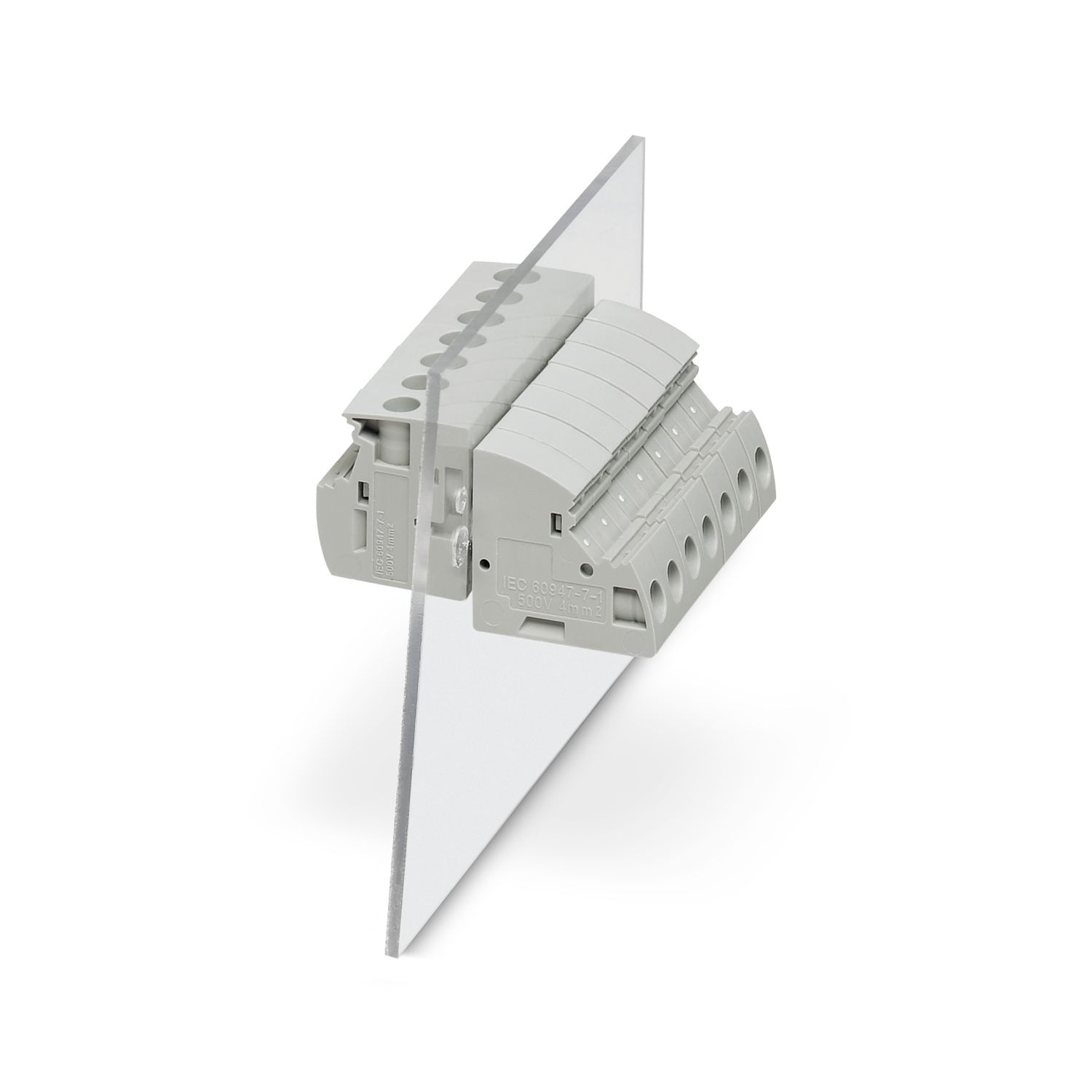

UWV 4 GNYE

-

Panel feed-through terminal block

1733096

Panel feed-through terminal block, connection method: Screw connection with tension sleeve, Screw connection with tension sleeve, number of positions: 1, load current: 32 A, cross section: 0.2 mm2 - 6 mm2, connection direction of the conductor to plug-in direction: -90 °, width: 8.1 mm, color: yellow

Product details

| Product type | Panel feed-through terminal block |

| Product family | UW 4 |

| Number of positions | 1 |

| Pitch | 8.1 mm |

| Properties | |

| Nominal current IN | 32 A |

| Nominal voltage UN | 320 V |

| Rated voltage (III/3) | 320 V |

| Rated surge voltage (III/3) | 4 kV |

| Connection technology | |

| Connector system | UW 4 |

| Nominal cross section | 4 mm² |

| Conductor connection exterior | |

| Connection method | Screw connection with tension sleeve |

| Connection direction of the conductor to plug-in direction | -90 ° |

| Conductor cross-section rigid | 0.2 mm² ... 6 mm² |

| Conductor cross-section flexible | 0.2 mm² ... 4 mm² |

| Conductor cross-section flexible, with ferrule without plastic sleeve | 0.25 mm² ... 4 mm² |

| Conductor cross-section, flexible, with ferrule, with plastic sleeve | 0.25 mm² ... 4 mm² |

| 2 conductors with same cross section, solid | 0.2 mm² ... 1.5 mm² |

| 2 conductors with same cross section, flexible | 0.2 mm² ... 1.5 mm² |

| 2 conductors with same cross section, flexible, with ferrule without plastic sleeve | 0.25 mm² ... 1.5 mm² |

| 2 conductors with the same cross section, flexible, with TWIN ferrule with plastic sleeve | 0.5 mm² ... 2.5 mm² |

| Internal cylindrical gage | A4 |

| Stripping length | 9 mm |

| Tightening torque | 0.6 Nm ... 0.8 Nm |

| Conductor connection interior | |

| Connection method | Screw connection with tension sleeve |

| Connection direction of the conductor to plug-in direction | 0 ° |

| Conductor cross-section rigid | 0.2 mm² ... 6 mm² |

| Conductor cross-section flexible | 0.2 mm² ... 4 mm² |

| Conductor cross-section flexible, with ferrule without plastic sleeve | 0.25 mm² ... 4 mm² |

| Conductor cross-section, flexible, with ferrule, with plastic sleeve | 0.25 mm² ... 4 mm² |

| 2 conductors with same cross section, solid | 0.2 mm² ... 1.5 mm² |

| 2 conductors with same cross section, flexible | 0.2 mm² ... 1.5 mm² |

| 2 conductors with same cross section, flexible, with ferrule without plastic sleeve | 0.25 mm² ... 1.5 mm² |

| 2 conductors with the same cross section, flexible, with TWIN ferrule with plastic sleeve | 0.5 mm² ... 2.5 mm² |

| Internal cylindrical gage | A4 |

| Stripping length | 9 mm |

| Tightening torque | 0.6 Nm ... 0.8 Nm |

| Panel thickness | 1 mm...4 mm |

| Material data - contact | |

| Note | WEEE/RoHS-compliant, free of whiskers according to IEC 60068-2-82/JEDEC JESD 201 |

| Contact material | Cu alloy |

| Surface characteristics | tin-plated |

| Material data - housing | |

| Color (Housing) | yellow (1018) |

| Insulating material | PA |

| Insulating material group | I |

| CTI according to IEC 60112 | 600 |

| Flammability rating according to UL 94 | V0 |

| Glow wire flammability index GWFI according to EN 60695-2-12 | 850 |

| Glow wire ignition temperature GWIT according to EN 60695-2-13 | 775 |

| Temperature for the ball pressure test according to EN 60695-10-2 | 125 °C |

| Safety note | |

| Safety note | • Only electrically qualified personnel may install and operate the product. To recognize and prevent danger, the qualified personnel must be familiar with the basics of electrical engineering. |

| • Observe the technical data provided here and refer to the documents listed under “Downloads”. The download area contains important information, such as installation notes, technical drawings, and 3D data. | |

| • The cable entry funnel is not safe to touch. Never connect or disconnect the terminal when it is energized. Take appropriate steps to ensure touch protection. | |

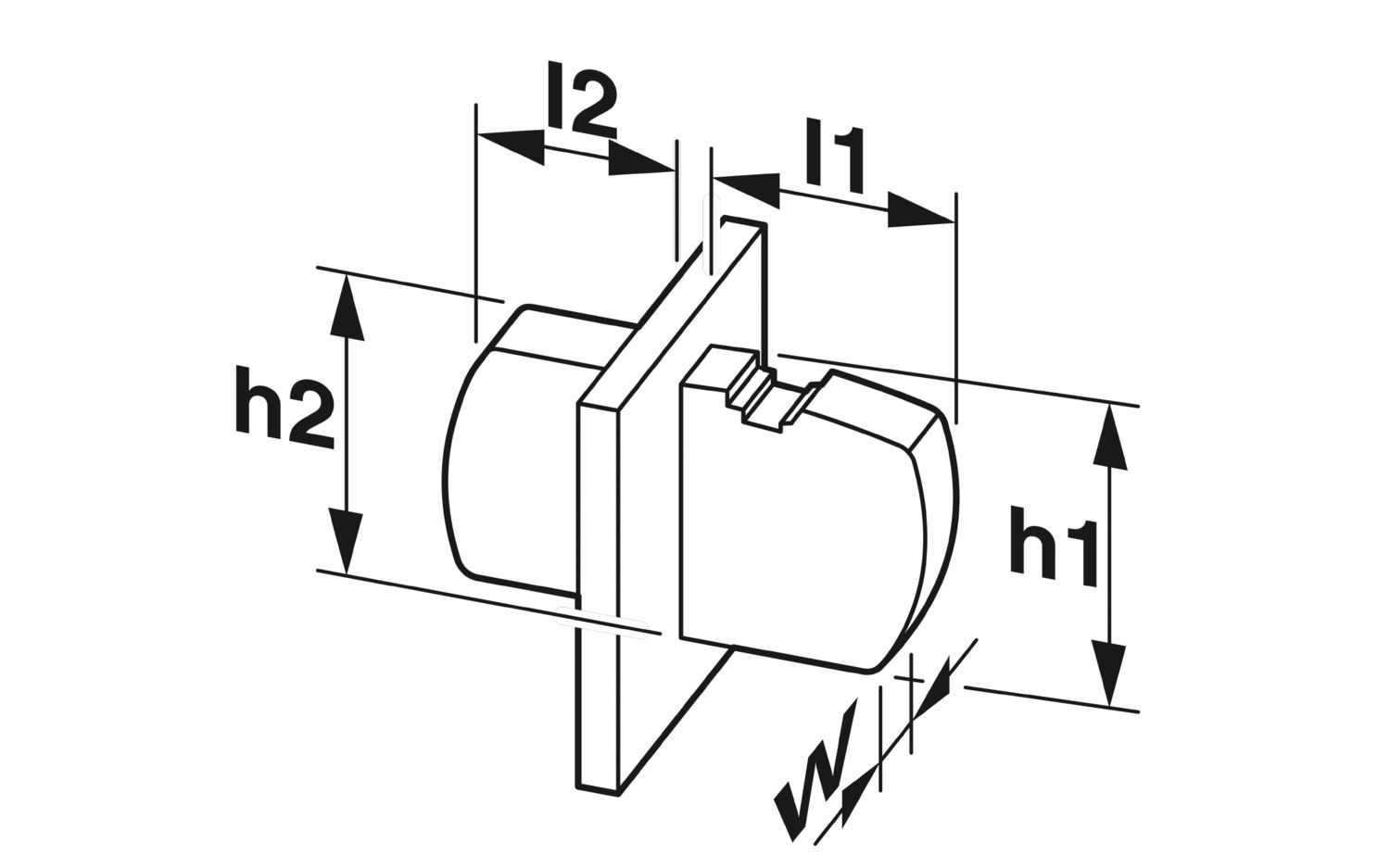

| Dimensional drawing |

|

| Pitch | 8.1 mm |

| Width [w] | 8.1 mm |

| External dimensions | |

| Height [h1] | 25.3 mm |

| Length [l1] | 26.78 mm |

| Internal dimensions | |

| Height [h2] | 24.78 mm |

| Length [l2] | 20.72 mm |

| Test for conductor damage and slackening | |

| Specification | IEC 60947-7-1:2009-04 |

| Result | Test passed |

| Pull-out test | |

| Specification | IEC 60947-7-1:2009-04 |

| Conductor cross-section/conductor type/tractive force setpoint/actual value | 0.25 mm² / solid / > 10 N |

| 0.25 mm² / flexible / > 10 N | |

| 6 mm² / solid / > 80 N | |

| 4 mm² / flexible / > 60 N | |

| Temperature-rise test | |

| Specification | IEC 60947-7-1:2009-04 |

| Requirement temperature-rise test | Increase in temperature ≤ 45 K |

| Short-time withstand current | |

| Specification | IEC 60947-7-1:2009-04 |

| Air clearances and creepage distances | 1. Insulation coordination | |

| Application | without spacer plate |

| Specification | IEC 60947-7-1:2009-04 |

| Insulating material group | I |

| Comparative tracking index (IEC 60112) | CTI 600 |

| Rated insulation voltage (III/3) | 320 V |

| Rated surge voltage (III/3) | 4 kV |

| minimum clearance value - non-homogenous field (III/3) | 3 mm |

| minimum creepage distance (III/3) | 4 mm |

| Air clearances and creepage distances | 2. Insulation coordination | |

| Application | with spacer plate |

| Specification | IEC 60947-7-1:2009-04 |

| Insulating material group | I |

| Comparative tracking index (IEC 60112) | CTI 600 |

| Rated insulation voltage (III/3) | 500 V |

| Rated surge voltage (III/3) | 6 kV |

| minimum clearance value - non-homogenous field (III/3) | 5.5 mm |

| minimum creepage distance (III/3) | 6.3 mm |

| Vibration test | |

| Specification | IEC 60068-2-6:2007-12 |

| Frequency | 10 - 150 - 10 Hz |

| Sweep speed | 1 octave/min |

| Amplitude | 0.35 mm (10 Hz ... 60.1 Hz) |

| Acceleration | 5g (60.1 Hz ... 150 Hz) |

| Test duration per axis | 2.5 h |

| Test directions | X-, Y- and Z-axis |

| Glow-wire test | |

| Specification | IEC 60695-2-11:2014-02 |

| Temperature | 960 °C |

| Time of exposure | 30 s |

| Shocks | |

| Specification | IEC 60068-2-27:2008-02 |

| Pulse shape | Semi-sinusoidal |

| Acceleration | 30g |

| Shock duration | 18 ms |

| Test directions | X-, Y- and Z-axis (pos. and neg.) |

| Ambient conditions | |

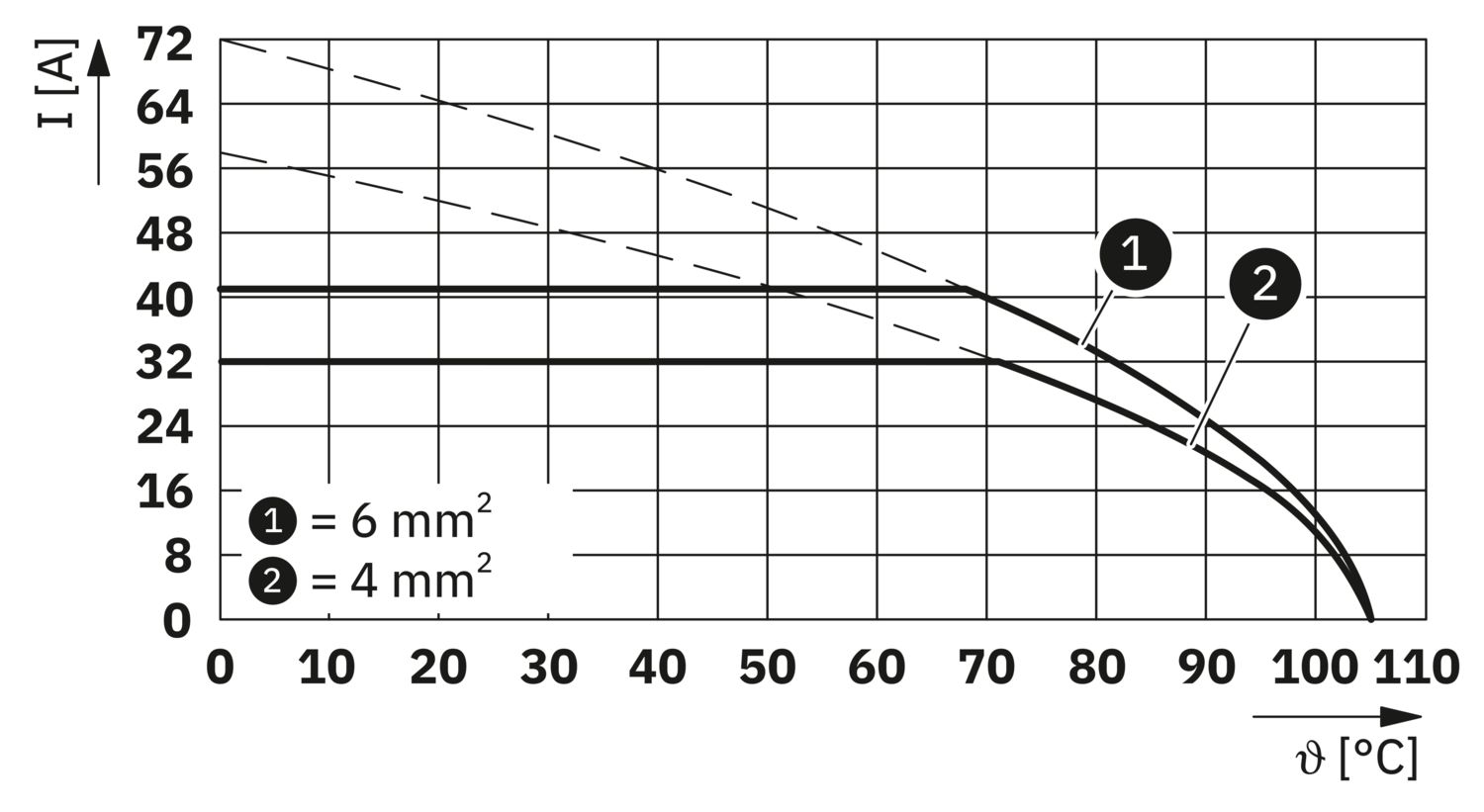

| Ambient temperature (operation) | -40 °C ... 105 °C (Depending on the current carrying capacity/derating curve) |

| Ambient temperature (storage/transport) | -40 °C ... 70 °C |

| Relative humidity (storage/transport) | 30 % ... 70 % |

| Ambient temperature (assembly) | -5 °C ... 100 °C |

| Type of packaging | packed in cardboard |

| Item number | 1733096 |

| Packing unit | 50 pc |

| Minimum order quantity | 50 pc |

| Note | Made to order (non-returnable) |

| Product key | AA1ADD |

| GTIN | 4067923291577 |

| Weight per piece (including packing) | 10.98 g |

| Weight per piece (excluding packing) | 10.94 g |

| Country of origin | CN |

ECLASS

| ECLASS-13.0 | 27141134 |

| ECLASS-15.0 | 27141134 |

ETIM

| ETIM 9.0 | EC001283 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes |

| Exemption | 6(c) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-50

An article-related China RoHS declaration table can be found in the download area for the respective article under "Manufacturer declaration". For all articles with EFUP-E, no China RoHS declaration table issued and required.

|

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | Lead (CAS: 7439-92-1) |

Compatible products

Your advantages

Well-known connection principle allows worldwide use

Low temperature rise, thanks to maximum contact force

Tool-free snap-in principle enables easy mounting on the device panel

Automatic panel thickness compensation enables universal use

PHOENIX CONTACT Trading LLC

Riyadh Moon Tower, 7586 King Fahed Branch Road, Ar Rahmaniyah, ZIP Code: 12341-4119, Riyadh, Kingdom of Saudi Arabia