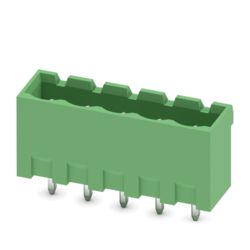

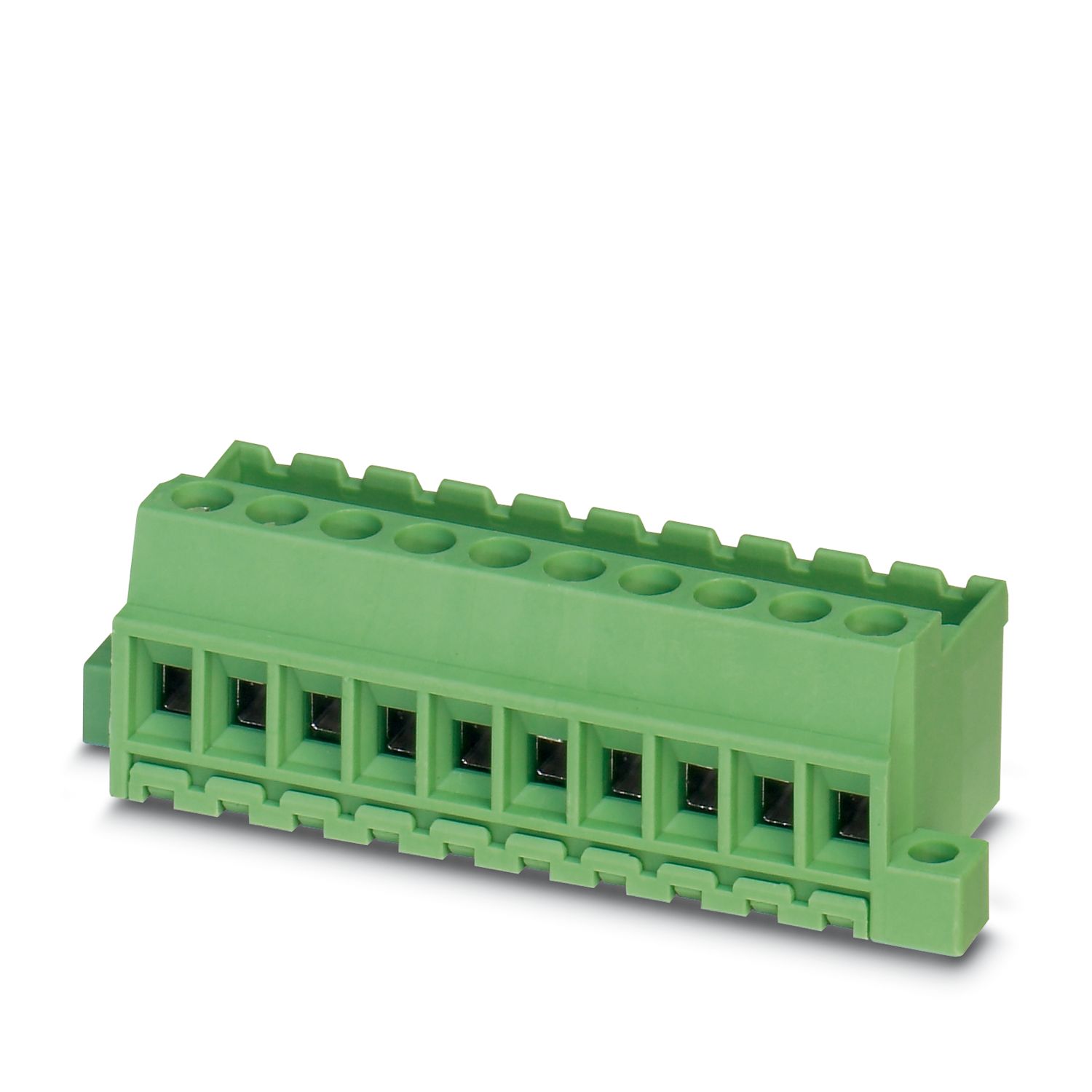

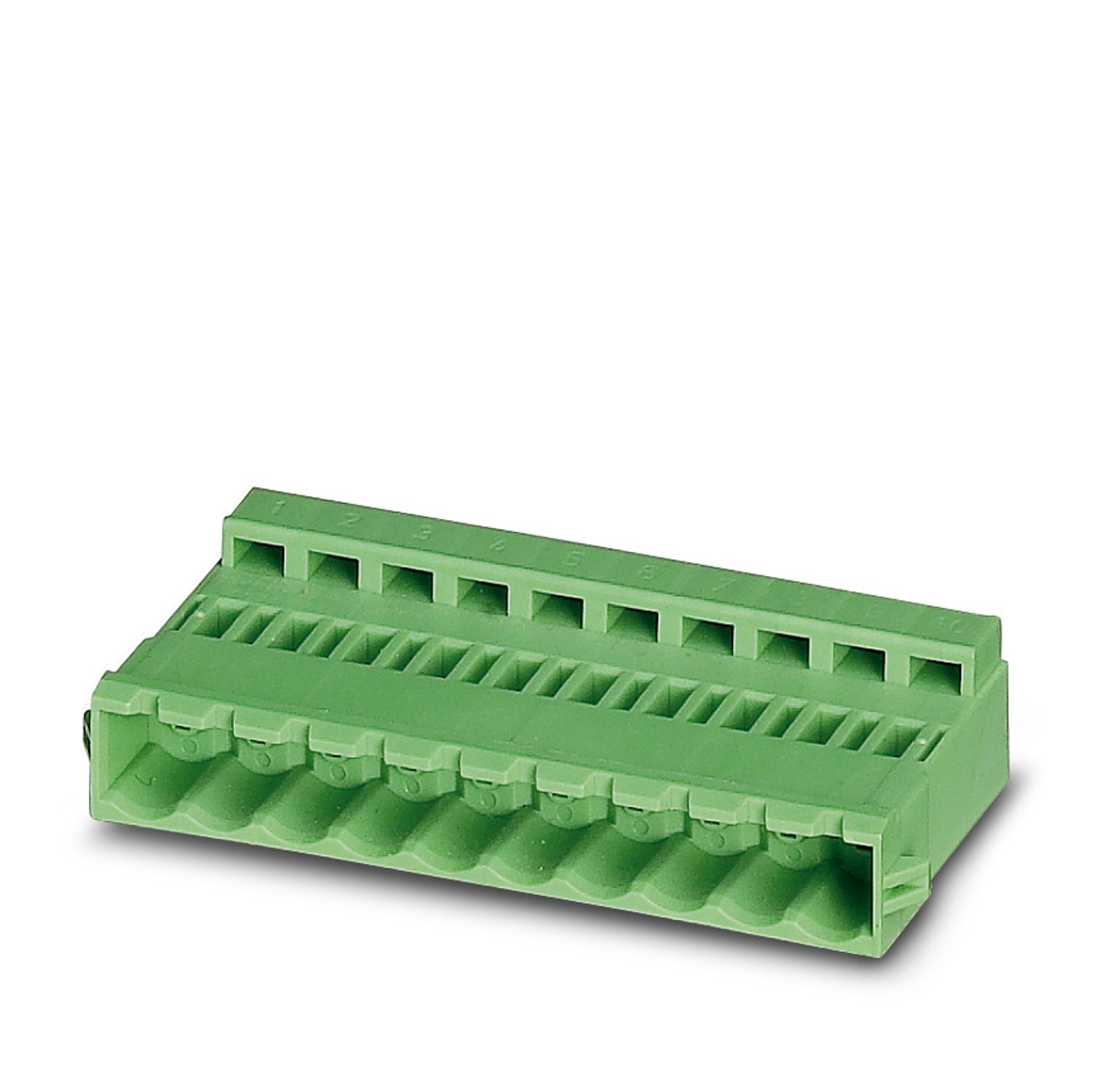

FRONT-MSTB 2,5/ 5-ST-5,08OGSO1

-

PCB connector

1736522

PCB connector, nominal cross section: 2.5 mm2, color: orange, nominal current: 12 A, rated voltage (III/2): 320 V, contact surface: Sn, contact connection type: Socket, number of potentials: 5, number of rows: 1, number of positions: 5, number of connections: 5, product range: FRONT-MSTB 2,5/..-ST, pitch: 5.08 mm, connection method: Front screw connection, screw head form: L Slotted, conductor/PCB connection direction: 0 °, locking clip: - Locking clip, plug-in system: COMBICON MSTB 2,5, locking: without, mounting method: without, type of packaging: packed in cardboard

Product details

| Product type | PCB connector |

| Product family | FRONT-MSTB 2,5/..-ST |

| Product line | COMBICON Connectors M |

| Type | Standard |

| Number of positions | 5 |

| Pitch | 5.08 mm |

| Number of connections | 5 |

| Number of rows | 1 |

| Number of potentials | 5 |

| Mounting type | no |

| Properties | |

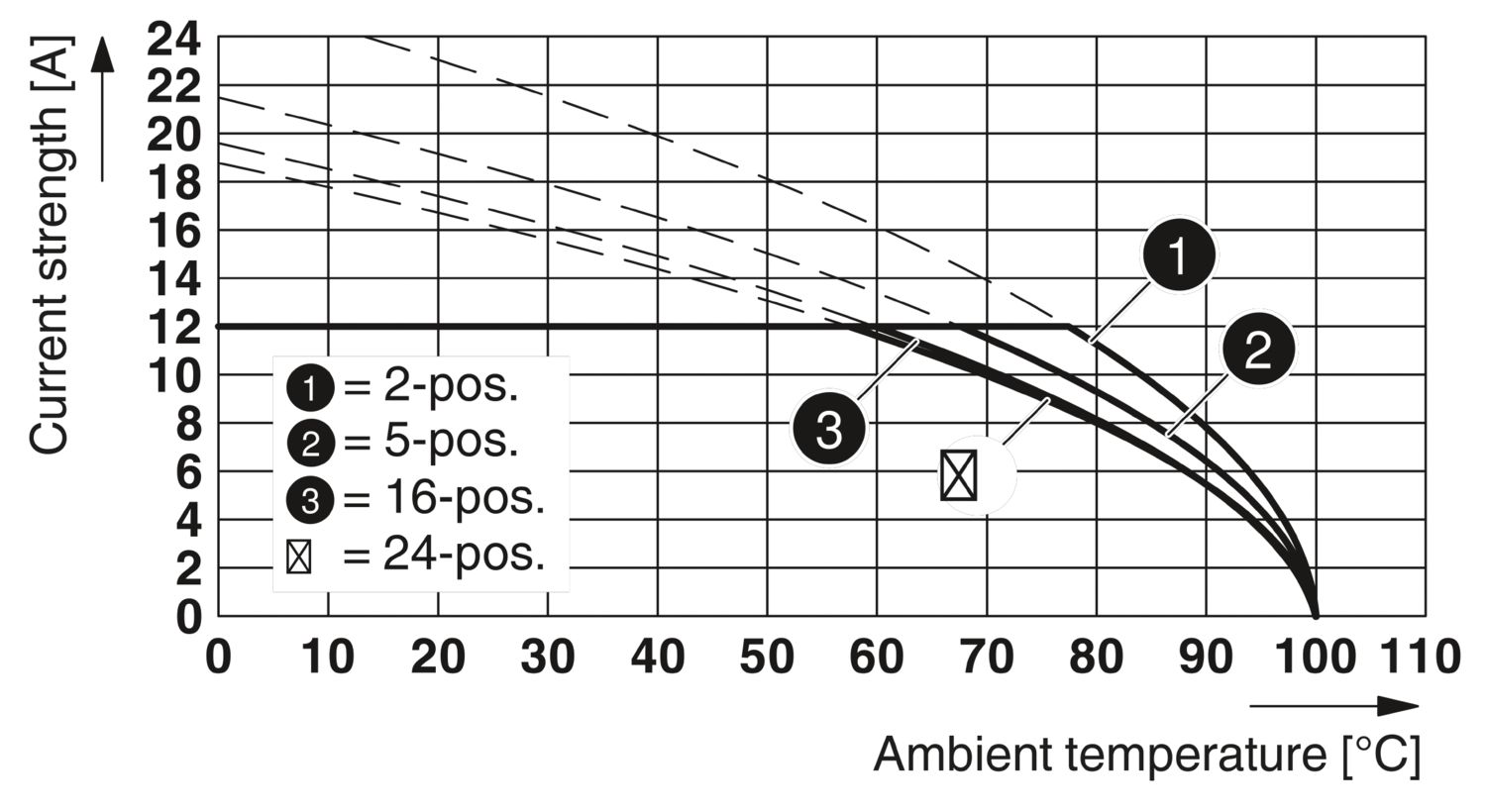

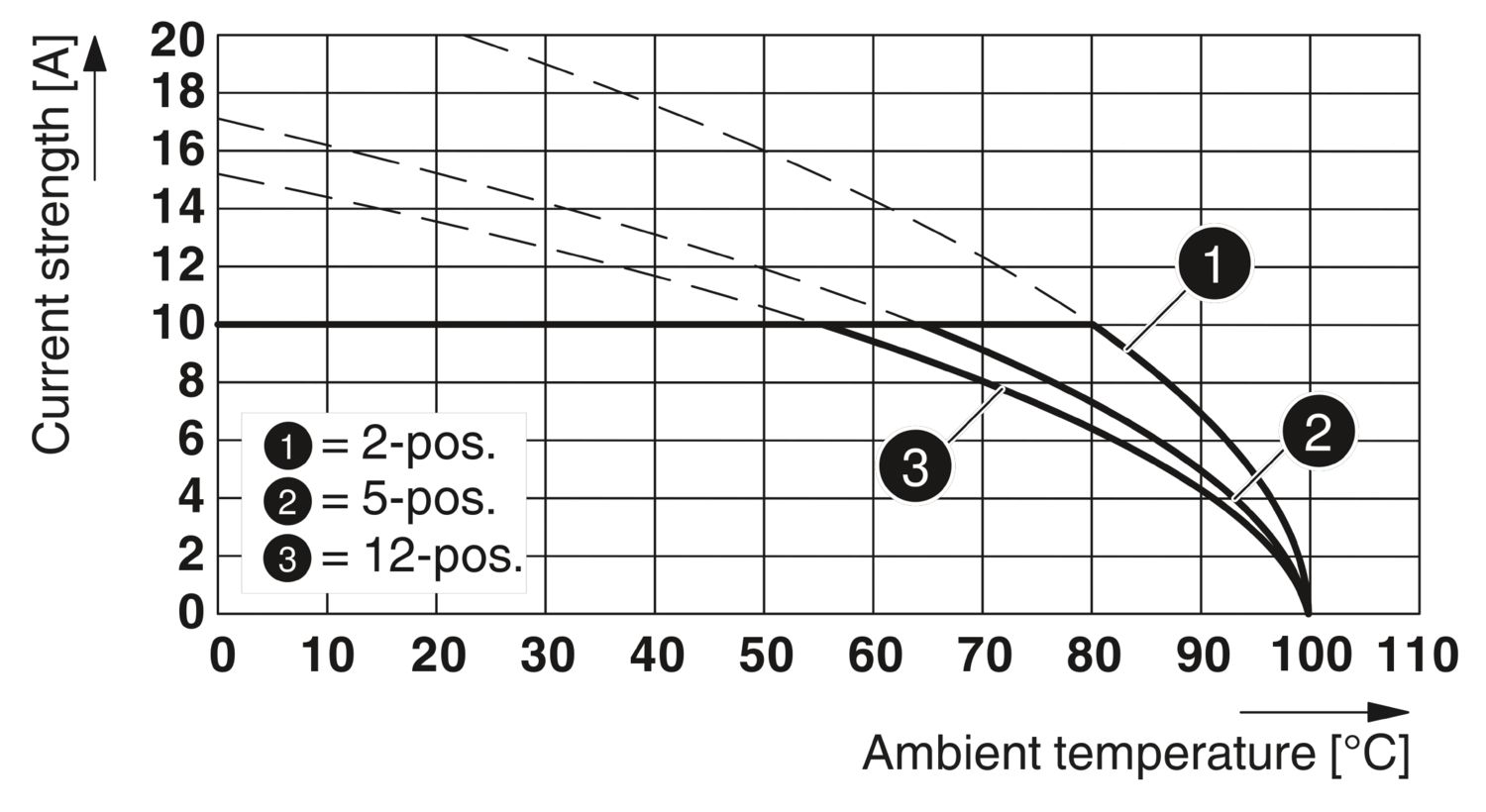

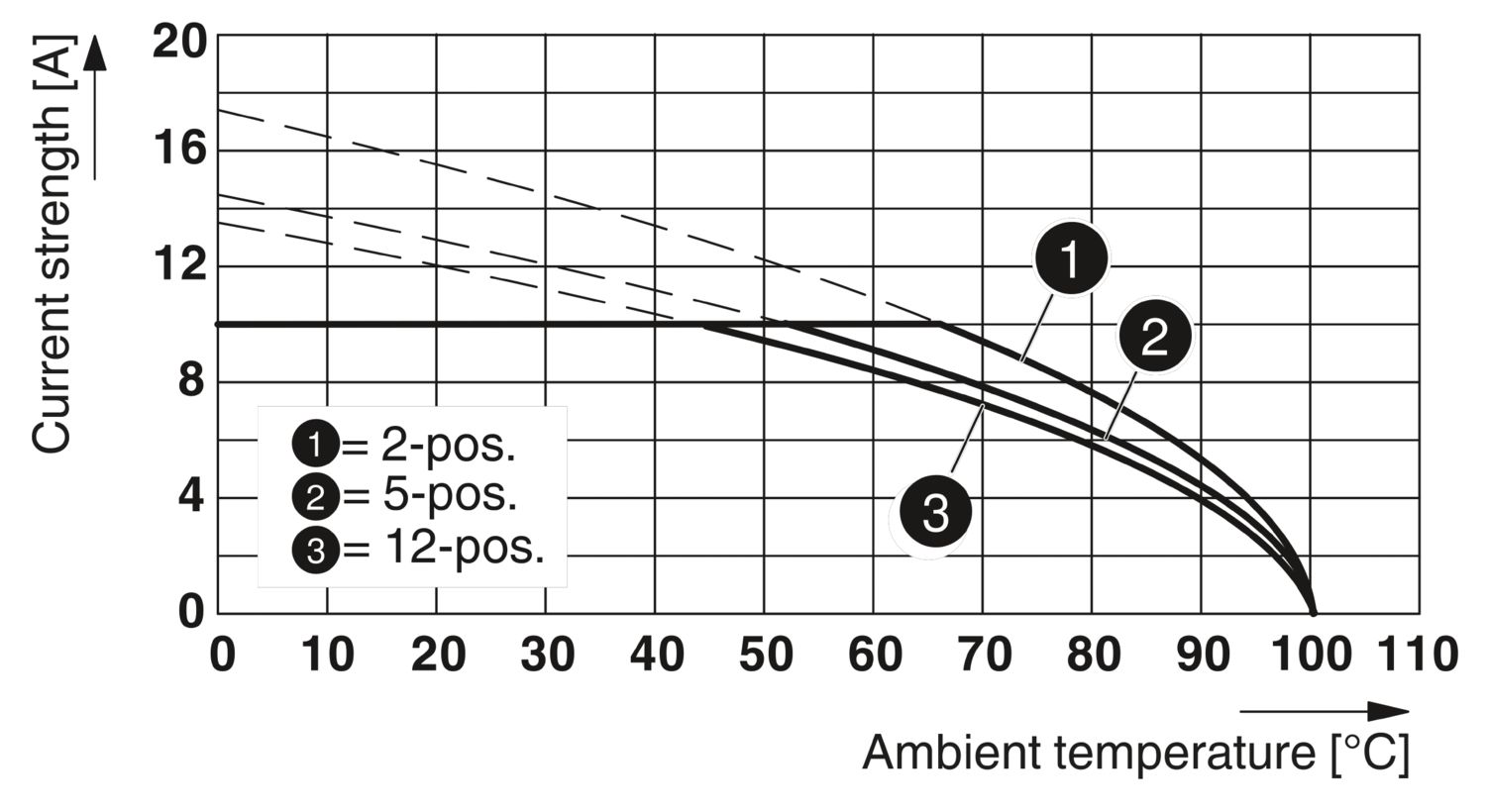

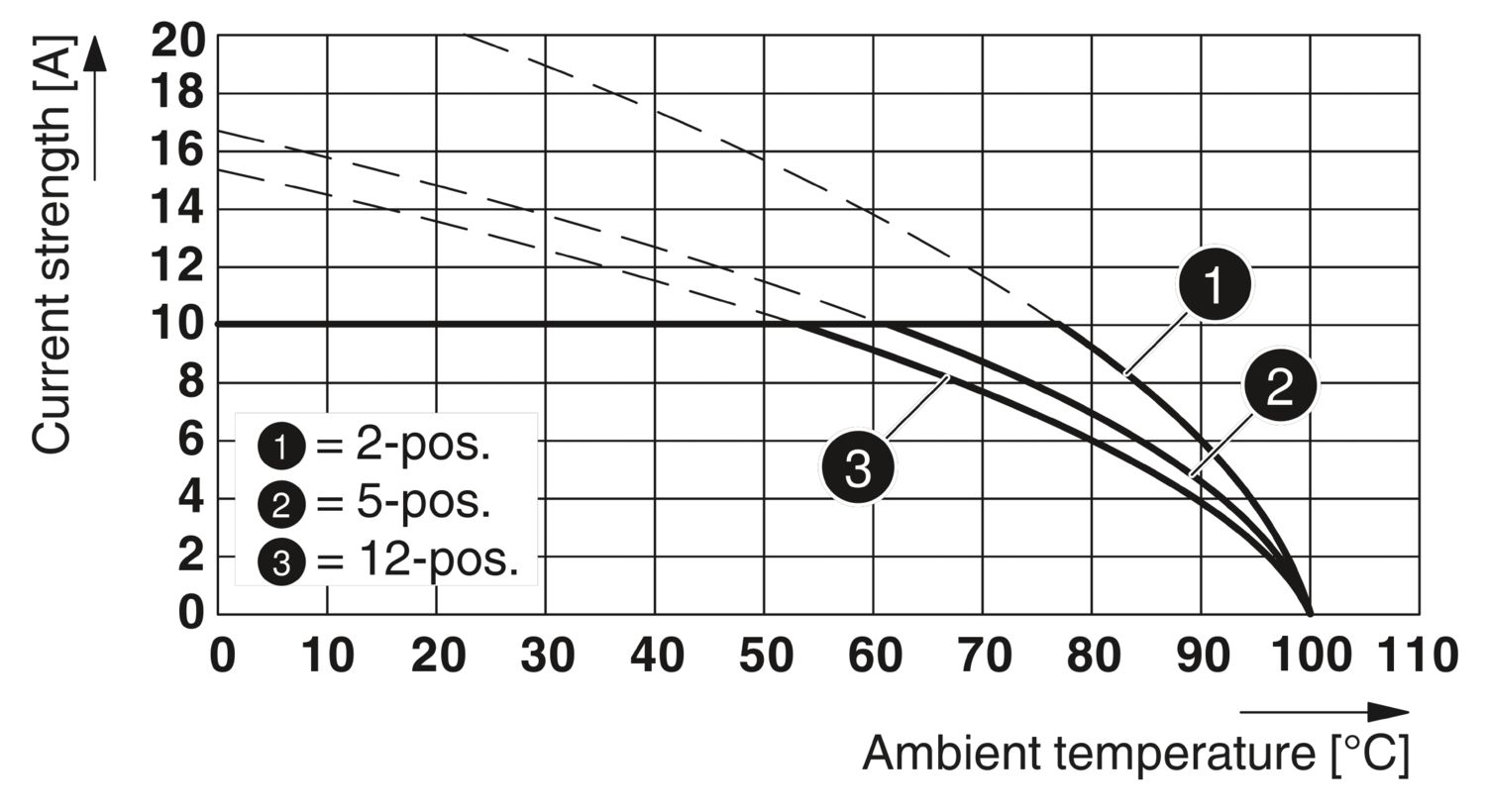

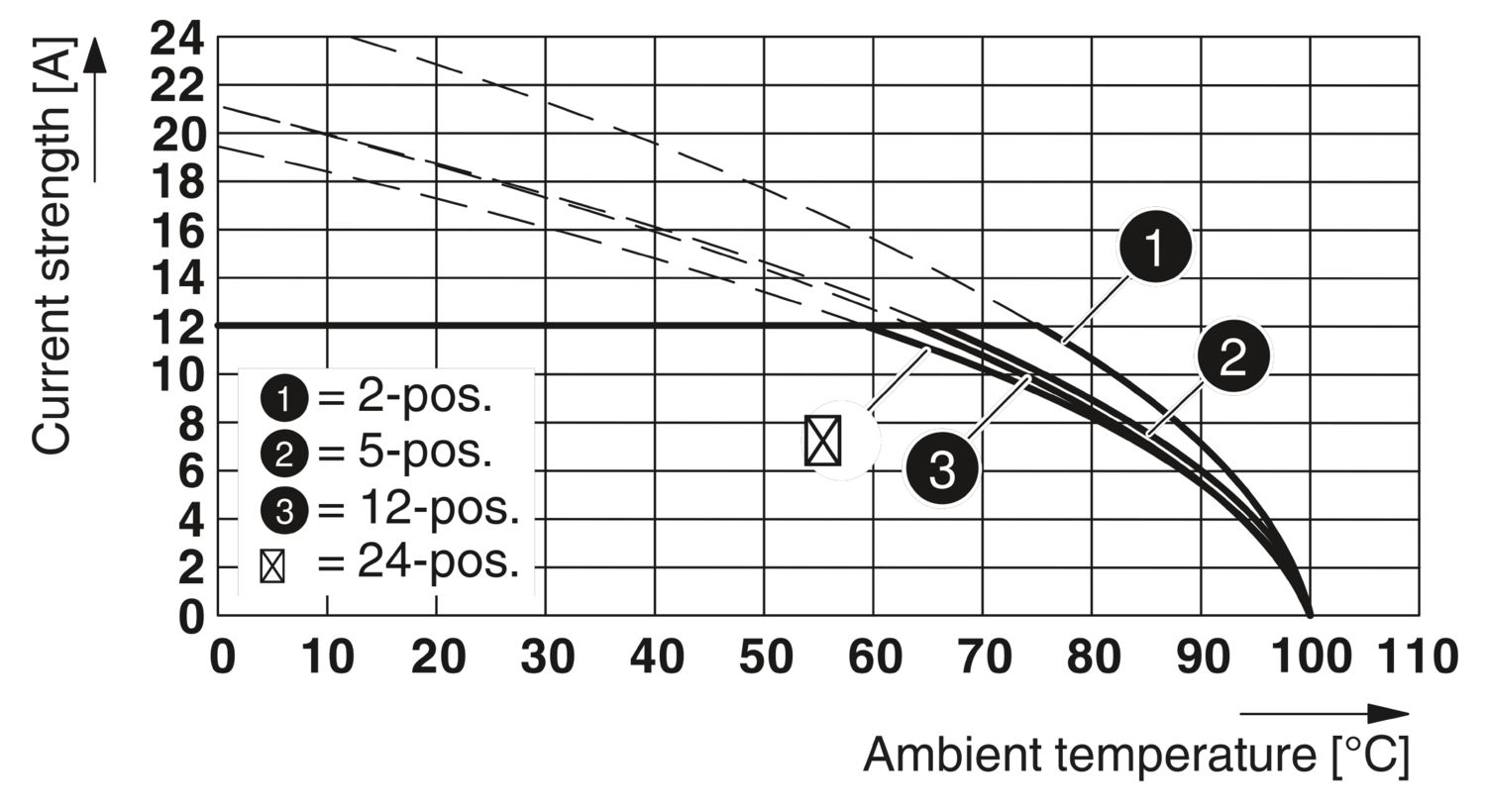

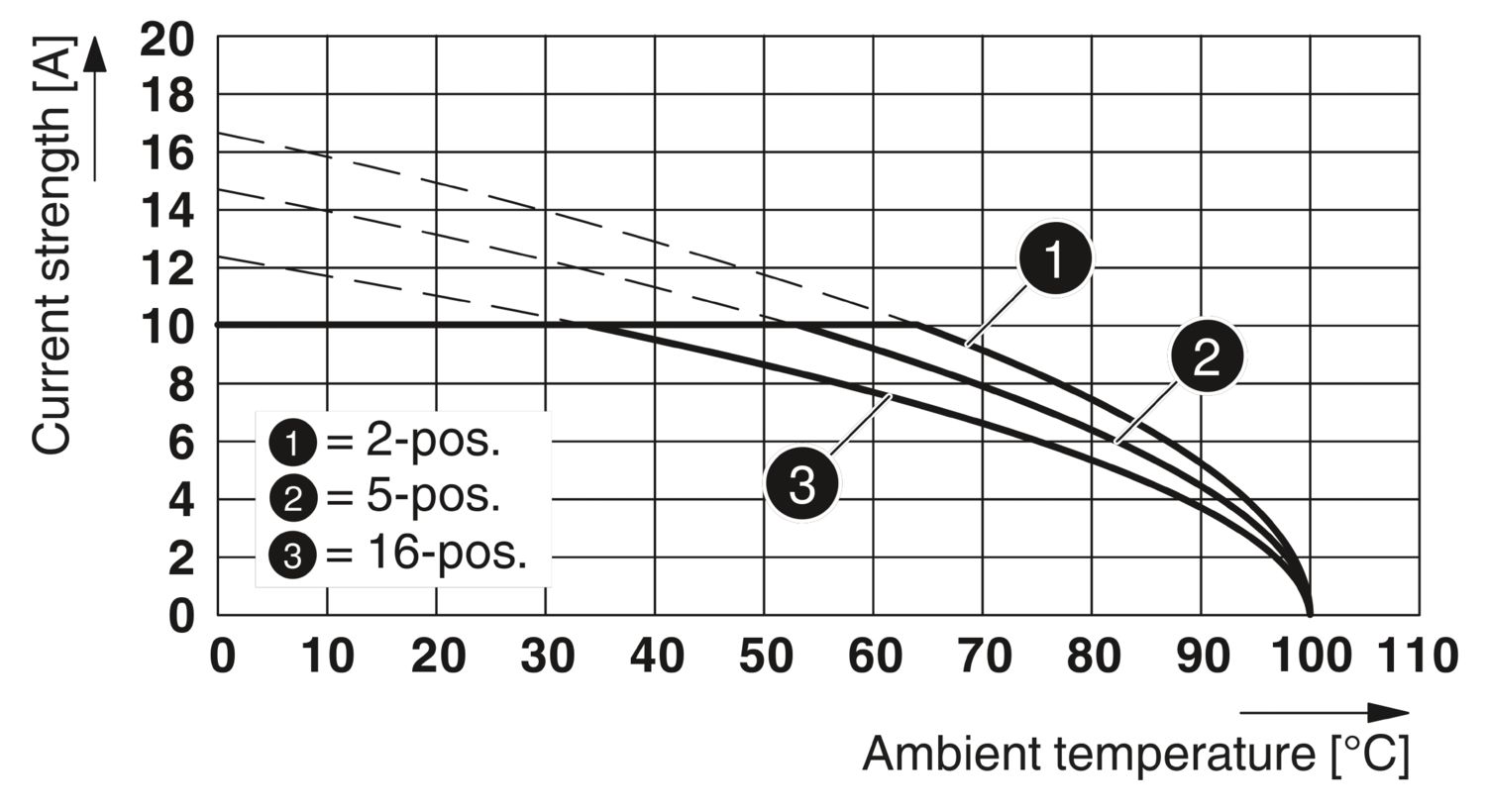

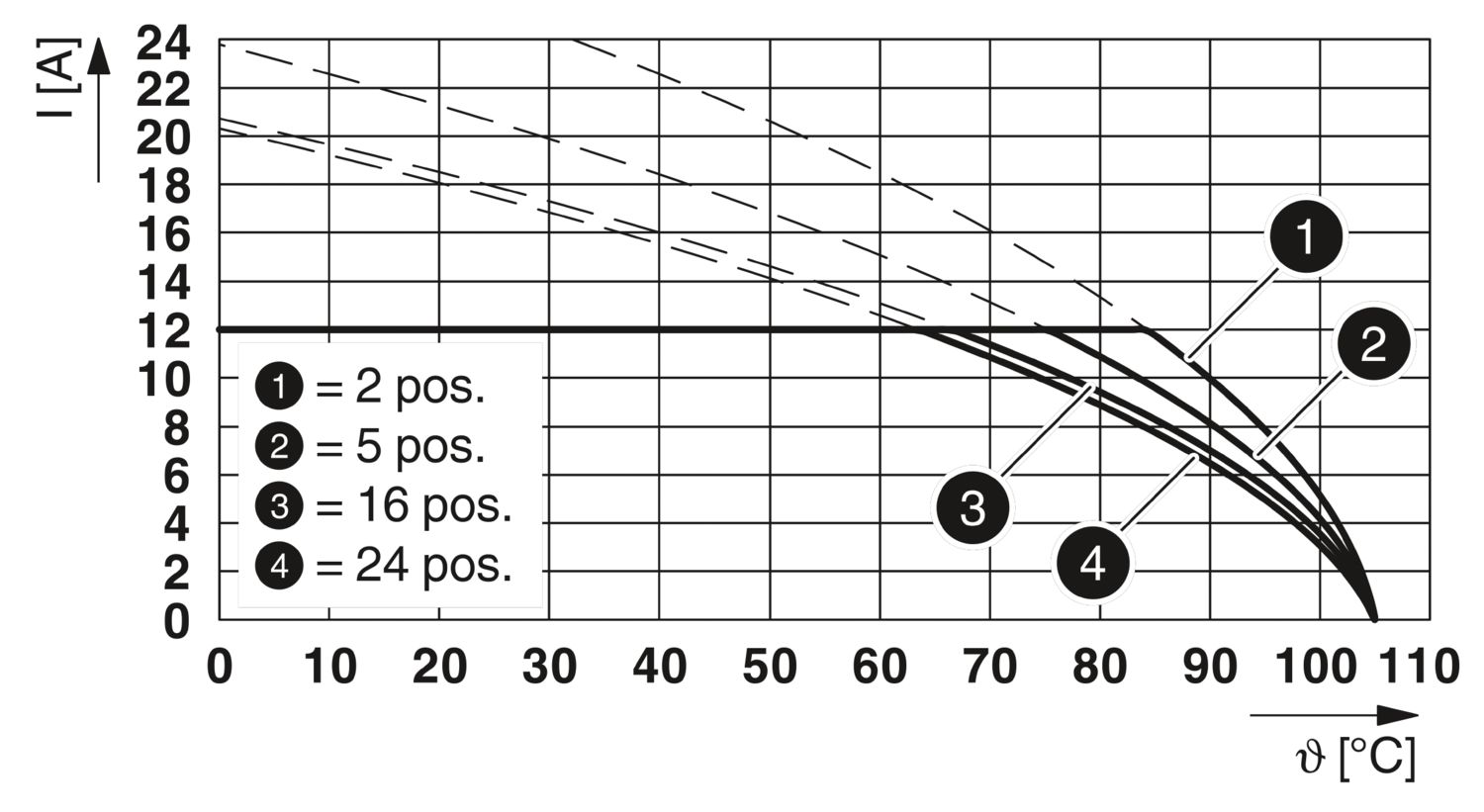

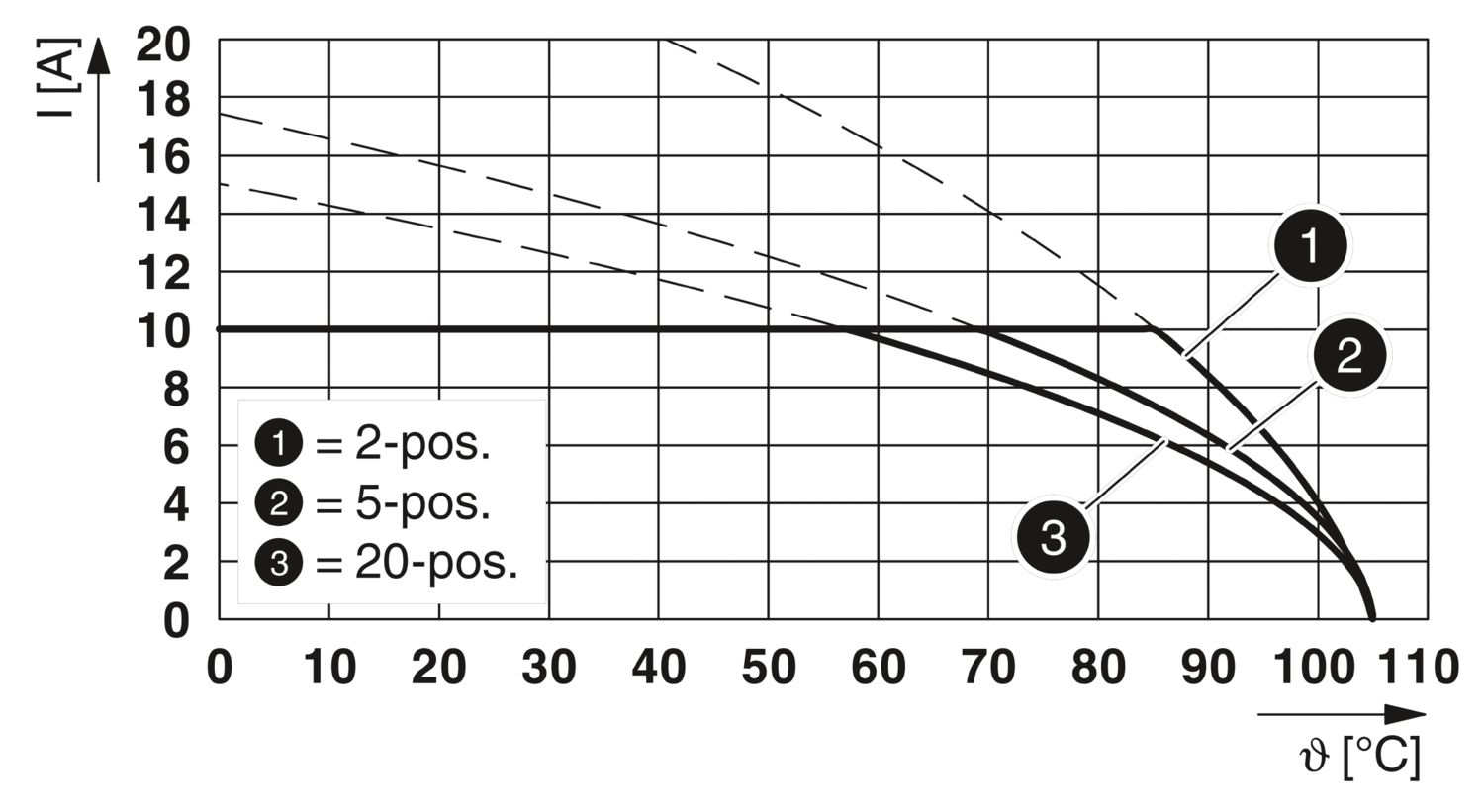

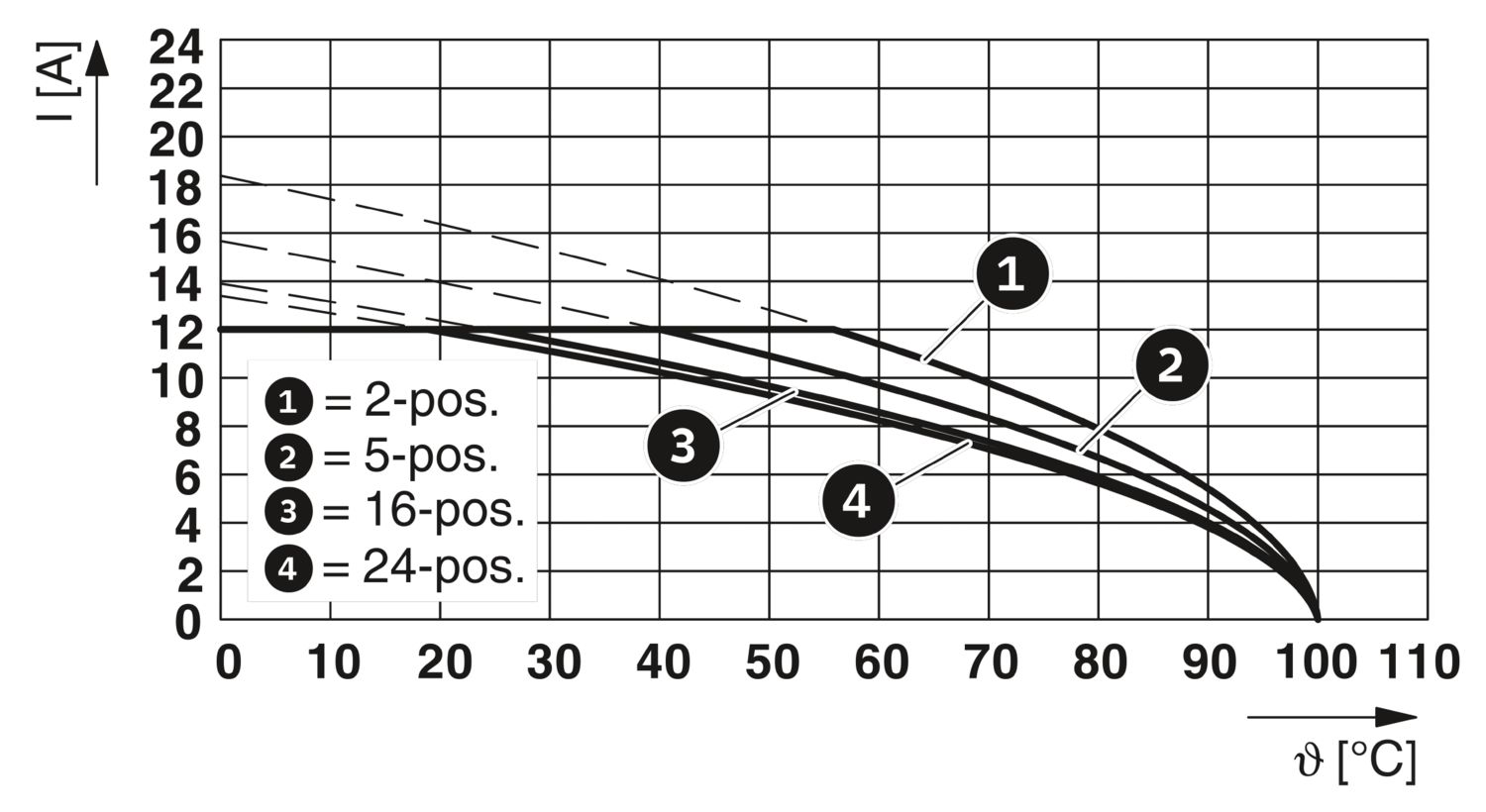

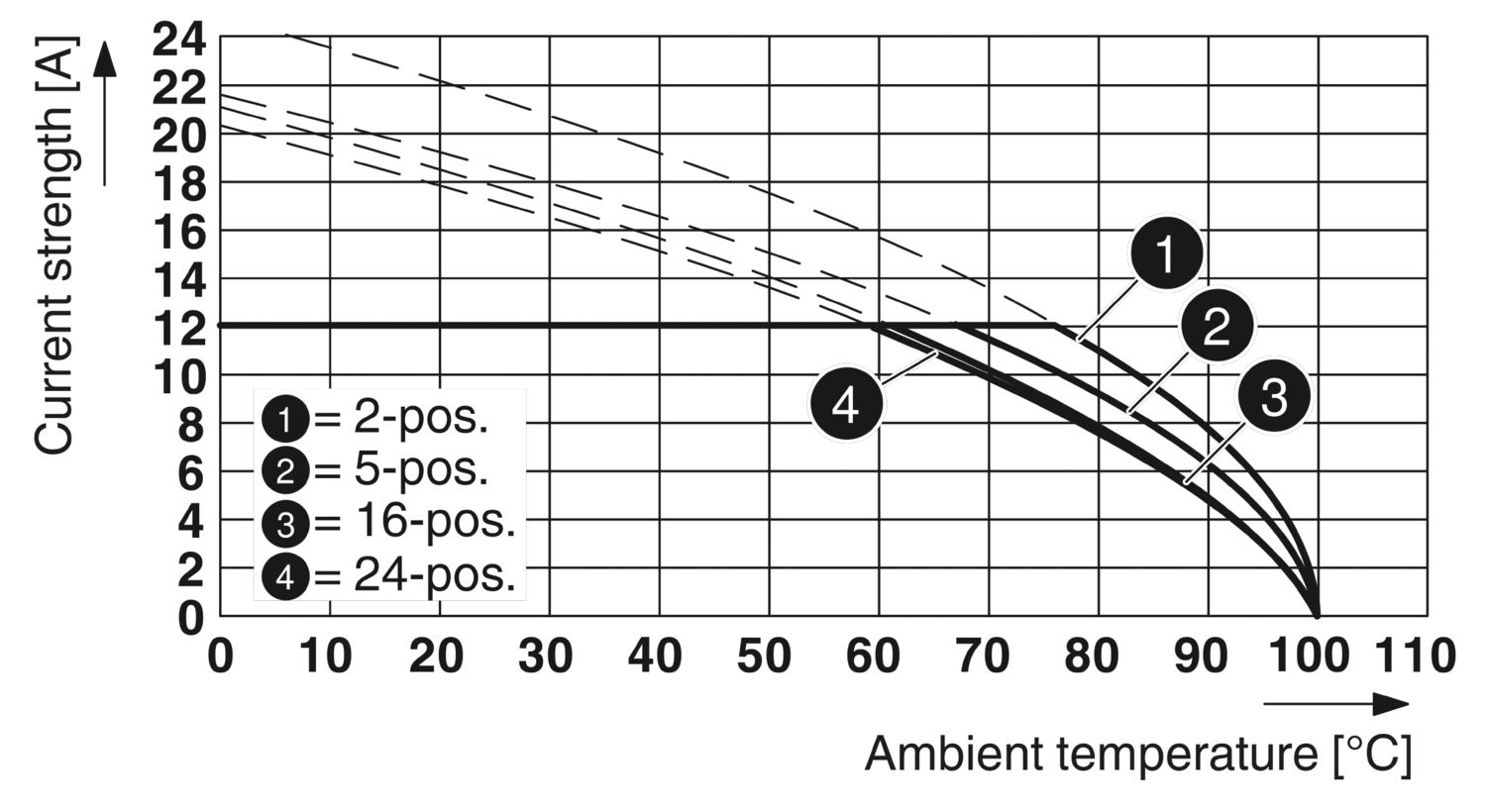

| Nominal current IN | 12 A |

| Nominal voltage UN | 320 V |

| Contact resistance | 1.5 mΩ |

| Rated voltage (III/3) | 250 V |

| Rated surge voltage (III/3) | 4 kV |

| Rated voltage (III/2) | 320 V |

| Rated surge voltage (III/2) | 4 kV |

| Rated voltage (II/2) | 630 V |

| Rated surge voltage (II/2) | 4 kV |

| Connection technology | |

| Type | Standard |

| Connector system | COMBICON MSTB 2,5 |

| Nominal cross section | 2.5 mm² |

| Contact connection type | Socket |

| Interlock | |

| Locking type | without |

| Mounting type | without |

| Conductor connection | |

| Connection method | Front screw connection |

| Conductor/PCB connection direction | 0 ° |

| Conductor cross-section rigid | 0.34 mm² ... 2.5 mm² |

| Conductor cross-section flexible | 0.2 mm² ... 2.5 mm² |

| Conductor cross-section AWG | 24 ... 12 |

| Conductor cross-section flexible, with ferrule without plastic sleeve | 0.25 mm² ... 2.5 mm² |

| Conductor cross-section, flexible, with ferrule, with plastic sleeve | 0.25 mm² ... 2.5 mm² |

| 2 conductors with same cross section, solid | 0.2 mm² ... 1 mm² |

| 2 conductors with same cross section, flexible | 0.2 mm² ... 1.5 mm² |

| 2 conductors with same cross section, flexible, with ferrule without plastic sleeve | 0.25 mm² ... 1 mm² |

| 2 conductors with the same cross section, flexible, with TWIN ferrule with plastic sleeve | 0.5 mm² ... 1.5 mm² |

| Cylindrical gauge a x b / diameter | 2.8 mm x 2.0 mm / 2.4 mm |

| Stripping length | 10 mm |

| Drive form screw head | Slotted (L) |

| Tightening torque | 0.5 Nm ... 0.6 Nm |

| Specifications for ferrules without insulating collar | |

| recommended crimping tool | 1212034 CRIMPFOX 6 |

| Specifications for ferrules with insulating collar | |

| recommended crimping tool | 1212034 CRIMPFOX 6 |

| Material data - contact | |

| Note | WEEE/RoHS-compliant, free of whiskers according to IEC 60068-2-82/JEDEC JESD 201 |

| Contact material | Cu alloy |

| Surface characteristics | hot-dip tin-plated |

| Metal surface terminal point (top layer) | Tin (4 - 8 µm Sn) |

| Metal surface contact area (top layer) | Tin (4 - 8 µm Sn) |

| Material data - housing | |

| Color (Housing) | orange (2003) |

| Insulating material | PA |

| Insulating material group | I |

| CTI according to IEC 60112 | 600 |

| Flammability rating according to UL 94 | V0 |

| Glow wire flammability index GWFI according to EN 60695-2-12 | 850 |

| Glow wire ignition temperature GWIT according to EN 60695-2-13 | 775 |

| Temperature for the ball pressure test according to EN 60695-10-2 | 125 °C |

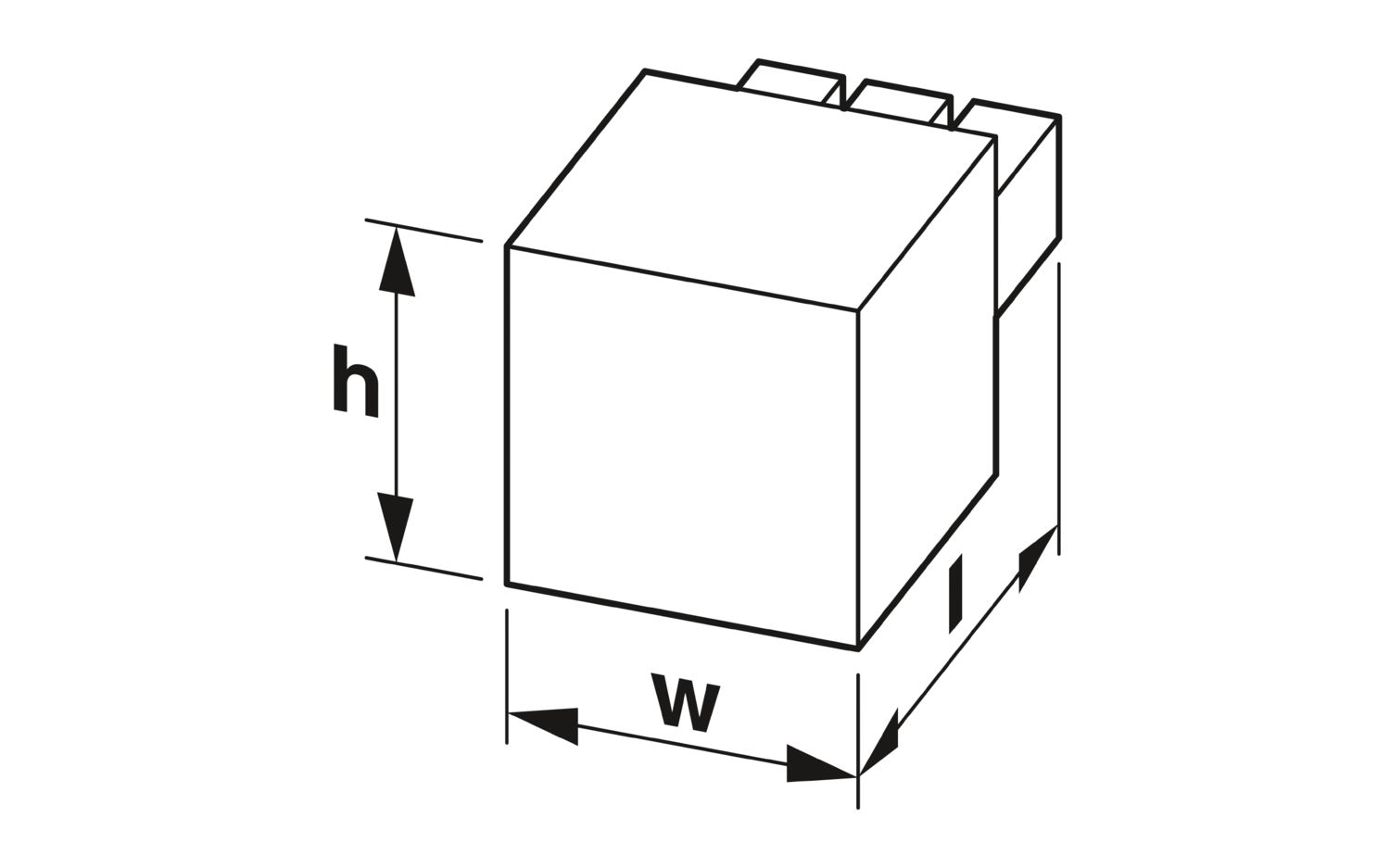

| Dimensional drawing |

|

| Pitch | 5.08 mm |

| Width [w] | 25.4 mm |

| Height [h] | 15 mm |

| Length [l] | 27.2 mm |

| Notes on operation | In accordance with IEC 61984, COMBICON connectors have no switching power (COC). During designated use, they must not be plugged in or disconnected when carrying voltage or under load. |

| Test for conductor damage and slackening | |

| Specification | IEC 60999-1:1999-11 |

| Result | Test passed |

| Pull-out test | |

| Specification | IEC 60999-1:1999-11 |

| Conductor cross-section/conductor type/tractive force setpoint/actual value | 0.34 mm² / solid / > 15 N |

| 0.2 mm² / flexible / > 10 N | |

| 2.5 mm² / solid / > 50 N | |

| 2.5 mm² / flexible / > 50 N | |

| Insertion and withdrawal forces | |

| Specification | IEC 60512-13-2:2006-02 |

| Result | Test passed |

| No. of cycles | 25 |

| Insertion strength per pos. approx. | 8 N |

| Withdraw strength per pos. approx. | 6 N |

| Torque test | |

| Specification | IEC 60999-1:1999-11 |

| Resistance of inscriptions | |

| Specification | IEC 60068-2-70:1995-12 |

| Result | Test passed |

| Polarization and coding | |

| Specification | IEC 60512-13-5:2006-02 |

| Result | Test passed |

| Visual inspection | |

| Specification | IEC 60512-1-1:2002-02 |

| Result | Test passed |

| Dimension check | |

| Specification | IEC 60512-1-2:2002-02 |

| Result | Test passed |

| Vibration test | |

| Specification | IEC 60068-2-6:2007-12 |

| Frequency | 10 - 150 - 10 Hz |

| Sweep speed | 1 octave/min |

| Amplitude | 0.35 mm (10 Hz ... 60.1 Hz) |

| Acceleration | 5g (60.1 Hz ... 150 Hz) |

| Test duration per axis | 2.5 h |

| Test directions | X-, Y- and Z-axis |

| Durability test | |

| Specification | IEC 60512-9-1:2010-03 |

| Impulse withstand voltage at sea level | 4.8 kV |

| Contact resistance R1 | 1.5 mΩ |

| Contact resistance R2 | 1.5 mΩ |

| Insertion/withdrawal cycles | 25 |

| Insulation resistance, neighboring positions | > 5 MΩ |

| Climatic test | |

| Specification | ISO 6988:1985-02 |

| Corrosive stress | 0.2 dm3 SO2 on 300 dm3/40 °C/1 cycle |

| Thermal stress | 100 °C/168 h |

| Power-frequency withstand voltage | 2.21 kV |

| Ambient conditions | |

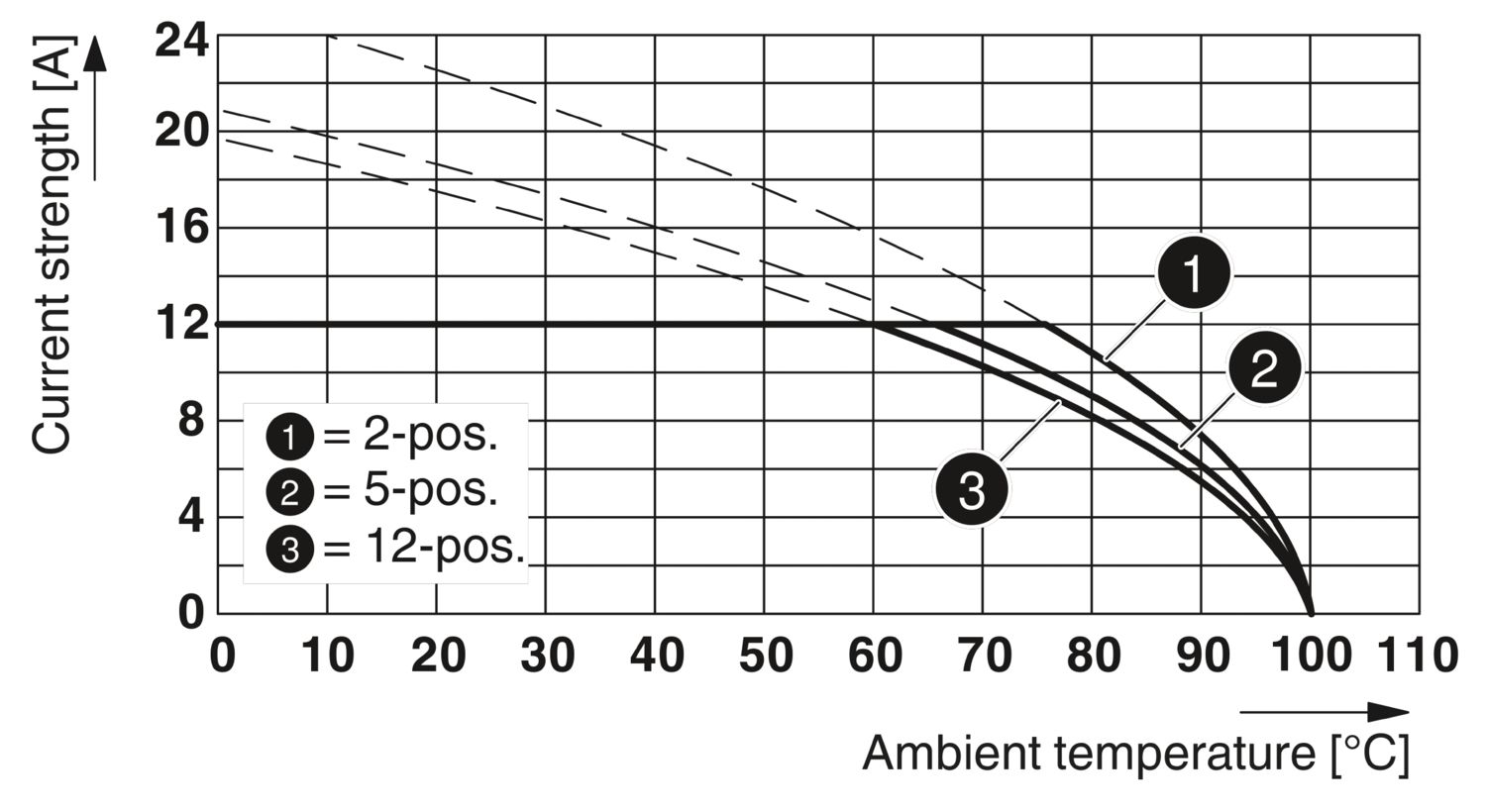

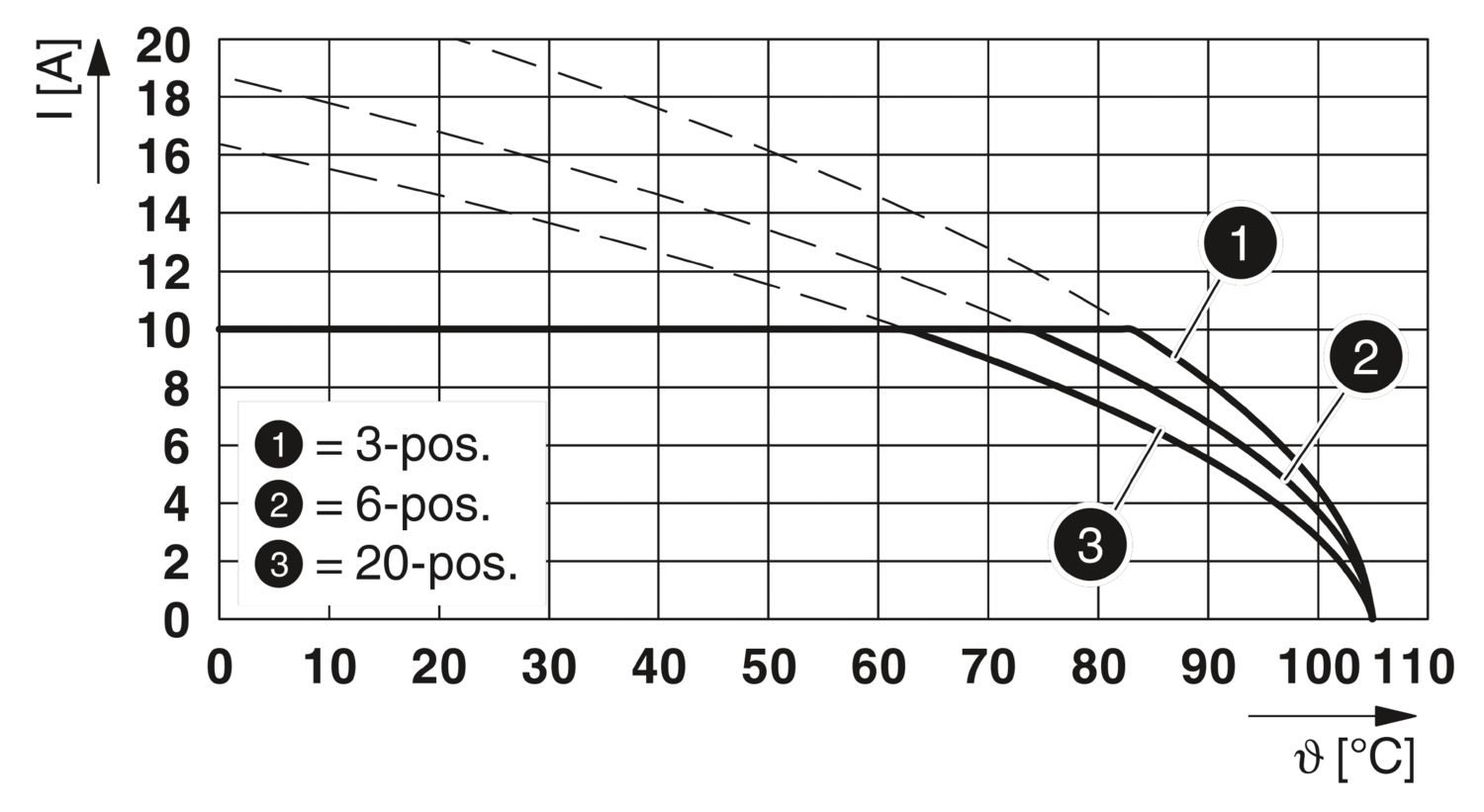

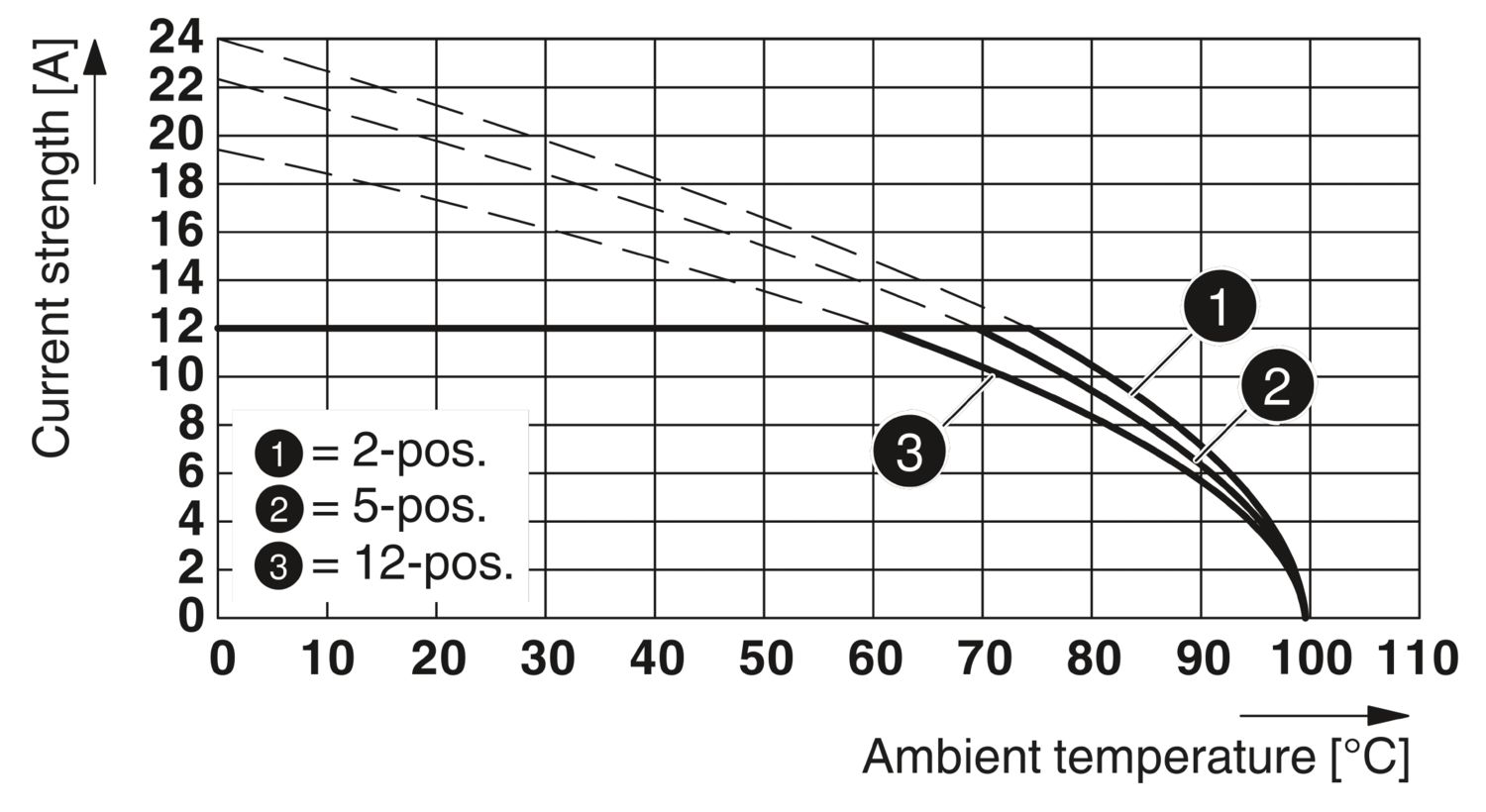

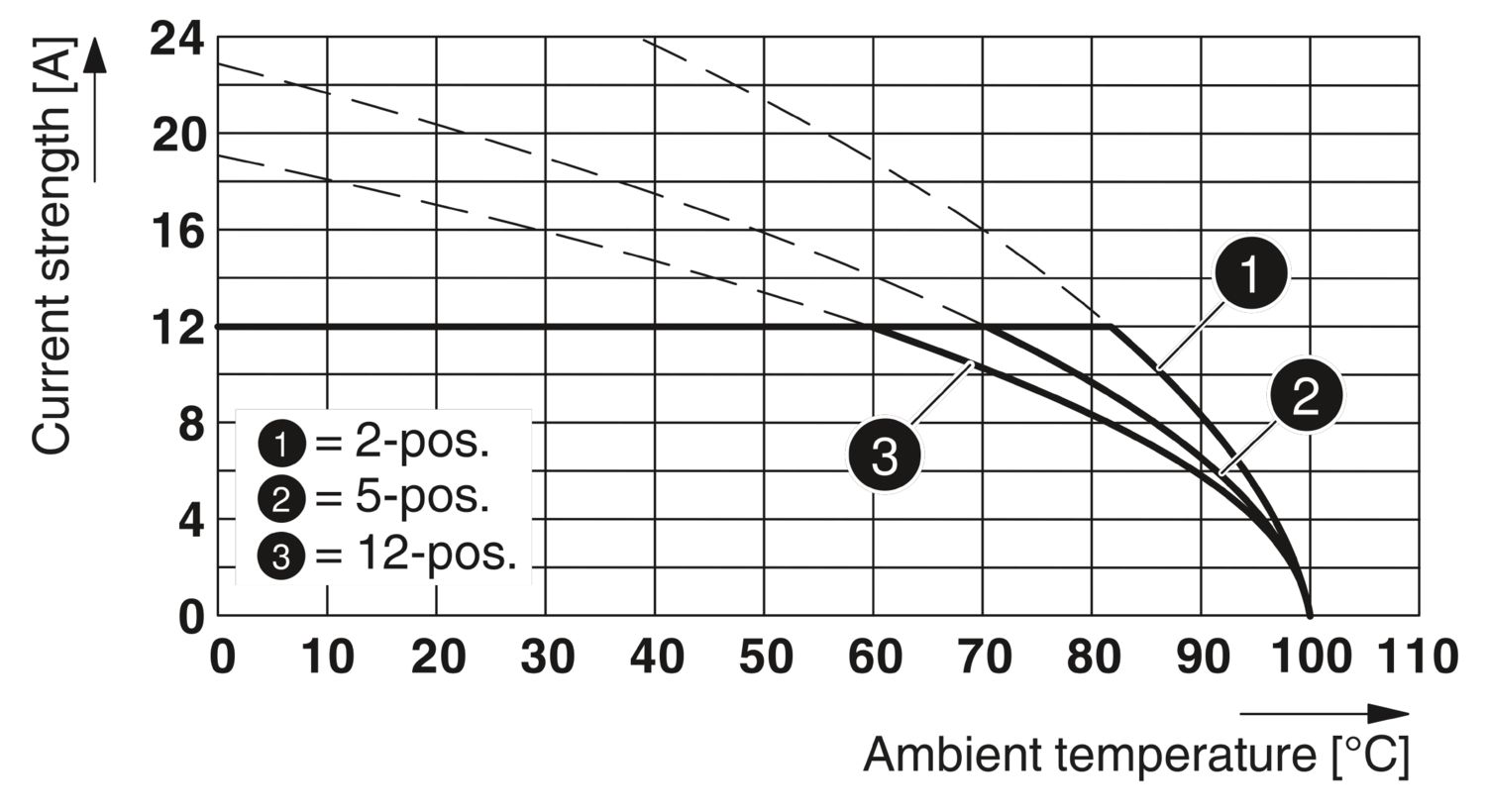

| Ambient temperature (operation) | -40 °C ... 100 °C (dependent on the derating curve) |

| Ambient temperature (storage/transport) | -40 °C ... 70 °C |

| Relative humidity (storage/transport) | 30 % ... 70 % |

| Ambient temperature (assembly) | -5 °C ... 100 °C |

| Thermal test | Test group C | |

| Specification | IEC 60512-5-1:2002-02 |

| Tested number of positions | 12 |

| Insulation resistance | |

| Specification | IEC 60512-3-1:2002-02 |

| Insulation resistance, neighboring positions | > 5 MΩ |

| Air clearances and creepage distances | | |

| Specification | IEC 60664-1:2007-04 |

| Insulating material group | I |

| Comparative tracking index (IEC 60112) | CTI 600 |

| Rated insulation voltage (III/3) | 250 V |

| Rated surge voltage (III/3) | 4 kV |

| minimum clearance value - non-homogenous field (III/3) | 3 mm |

| minimum creepage distance (III/3) | 3.2 mm |

| Rated insulation voltage (III/2) | 320 V |

| Rated surge voltage (III/2) | 4 kV |

| minimum clearance value - non-homogenous field (III/2) | 3 mm |

| minimum creepage distance (III/2) | 3 mm |

| Rated insulation voltage (II/2) | 630 V |

| Rated surge voltage (II/2) | 4 kV |

| minimum clearance value - non-homogenous field (II/2) | 3 mm |

| minimum creepage distance (II/2) | 3.2 mm |

| Type of packaging | packed in cardboard |

| Item number | 1736522 |

| Packing unit | 50 pc |

| Minimum order quantity | 50 pc |

| Note | Made to order (non-returnable) |

| Sales key | AACABA |

| Product key | AACABA |

| GTIN | 4017918215217 |

| Weight per piece (including packing) | 15,495 g |

| Weight per piece (excluding packing) | 14,967 g |

| Customs tariff number | 85366990 |

| Country of origin | DE |

ECLASS

| ECLASS-13.0 | 27460202 |

| ECLASS-15.0 | 27460202 |

ETIM

| ETIM 9.0 | EC002638 |

UNSPSC

| UNSPSC 21.0 | 39121400 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes (No exemptions) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-E

No hazardous substances above the limits

|

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | No substance above 0.1 wt% |

Compatible products

Note: Applying some accessories below might limit this product.

-

-

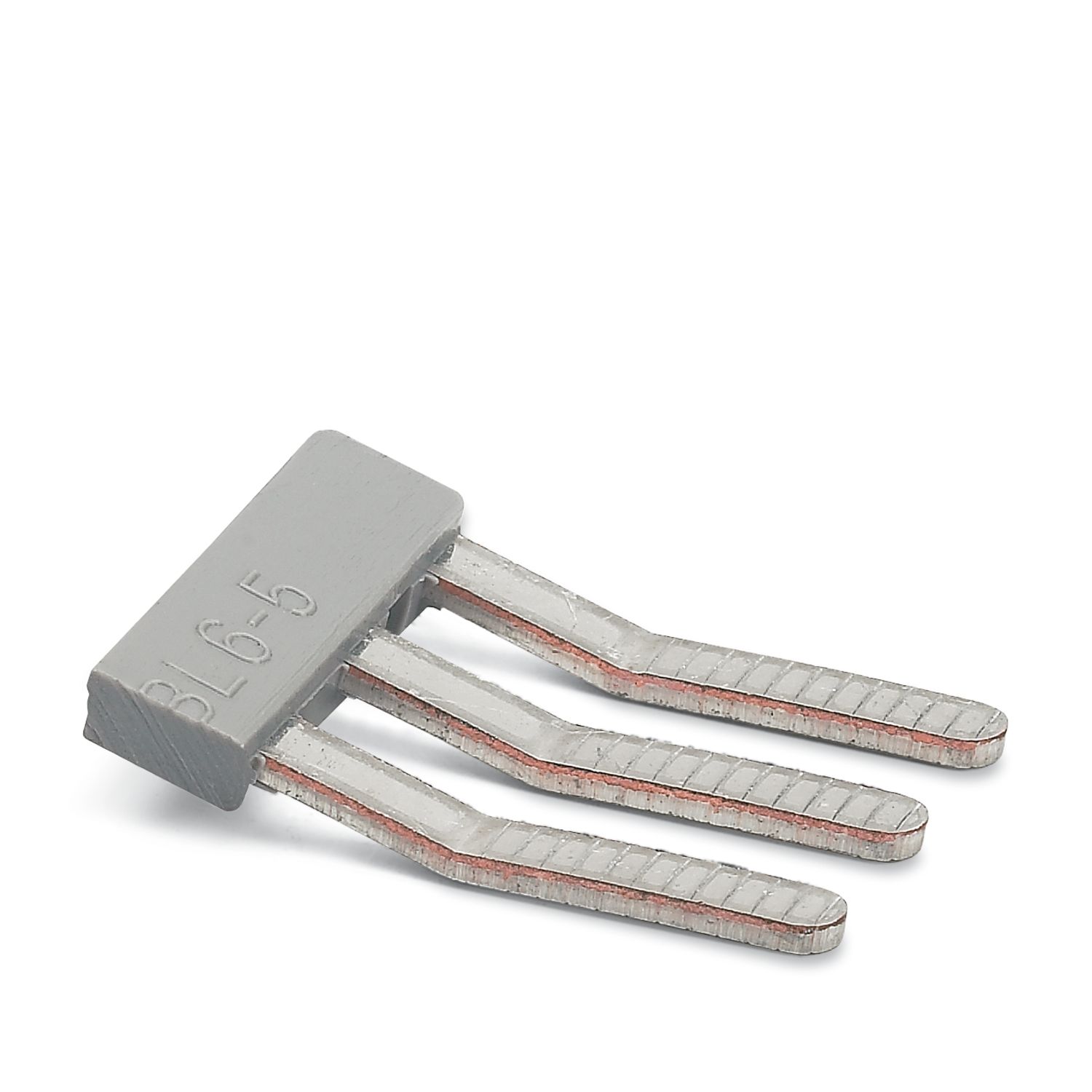

EBL 3- 5 - Insertion bridge 2303158

-

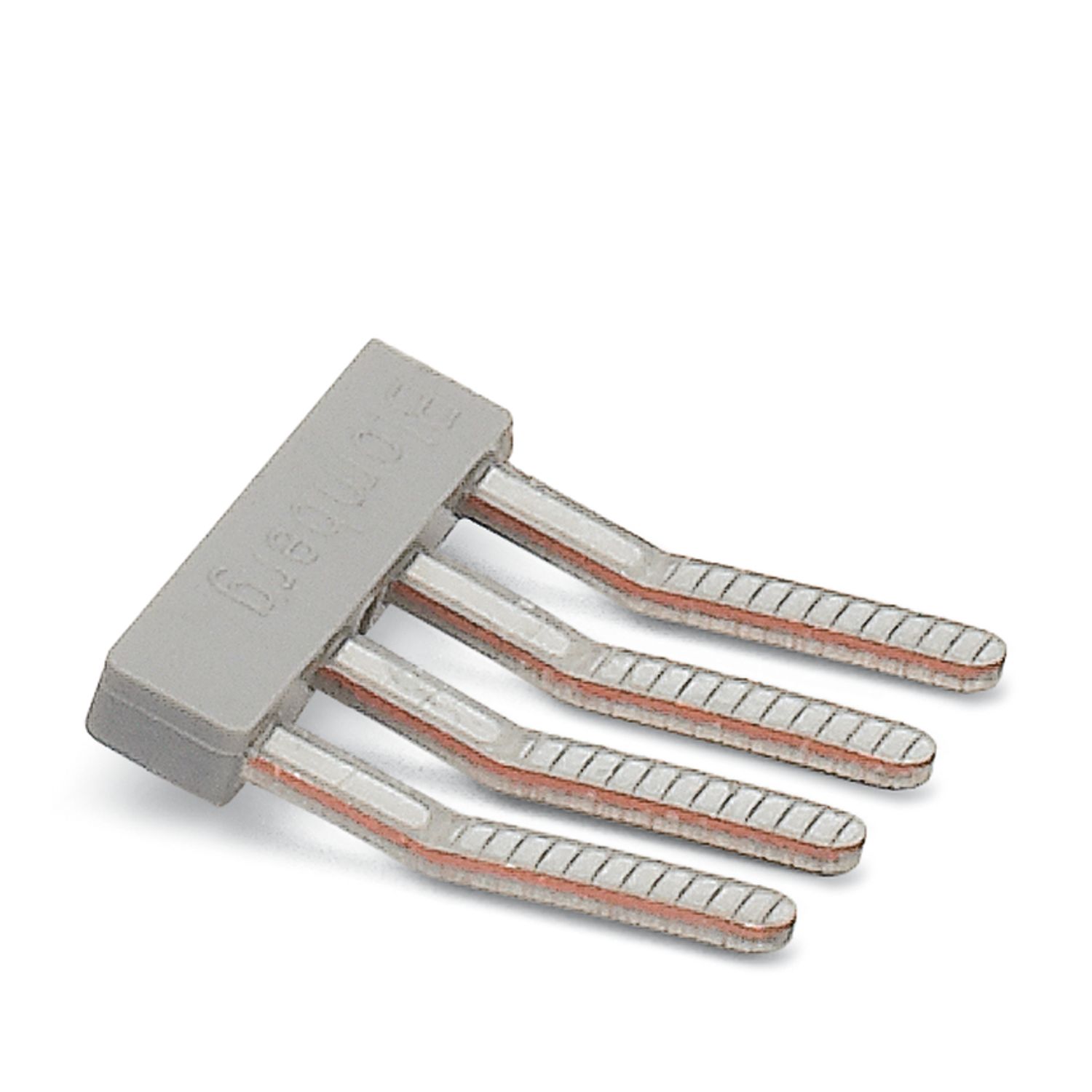

EBL 4- 5 - Insertion bridge 2303161

-

EBP 5- 5 - Insertion bridge 1733198

-

FRONT-MSTB-EW - Accessories 1763058

-

SZS 0,6X3,5 - Screwdriver 1205053

-

CP-MSTB - Coding profile 1734634

-

B-STIFT - Marker pen 1051993

-

UK 3-MVSTB-5,08 - Feed-through terminal block 3002076

-

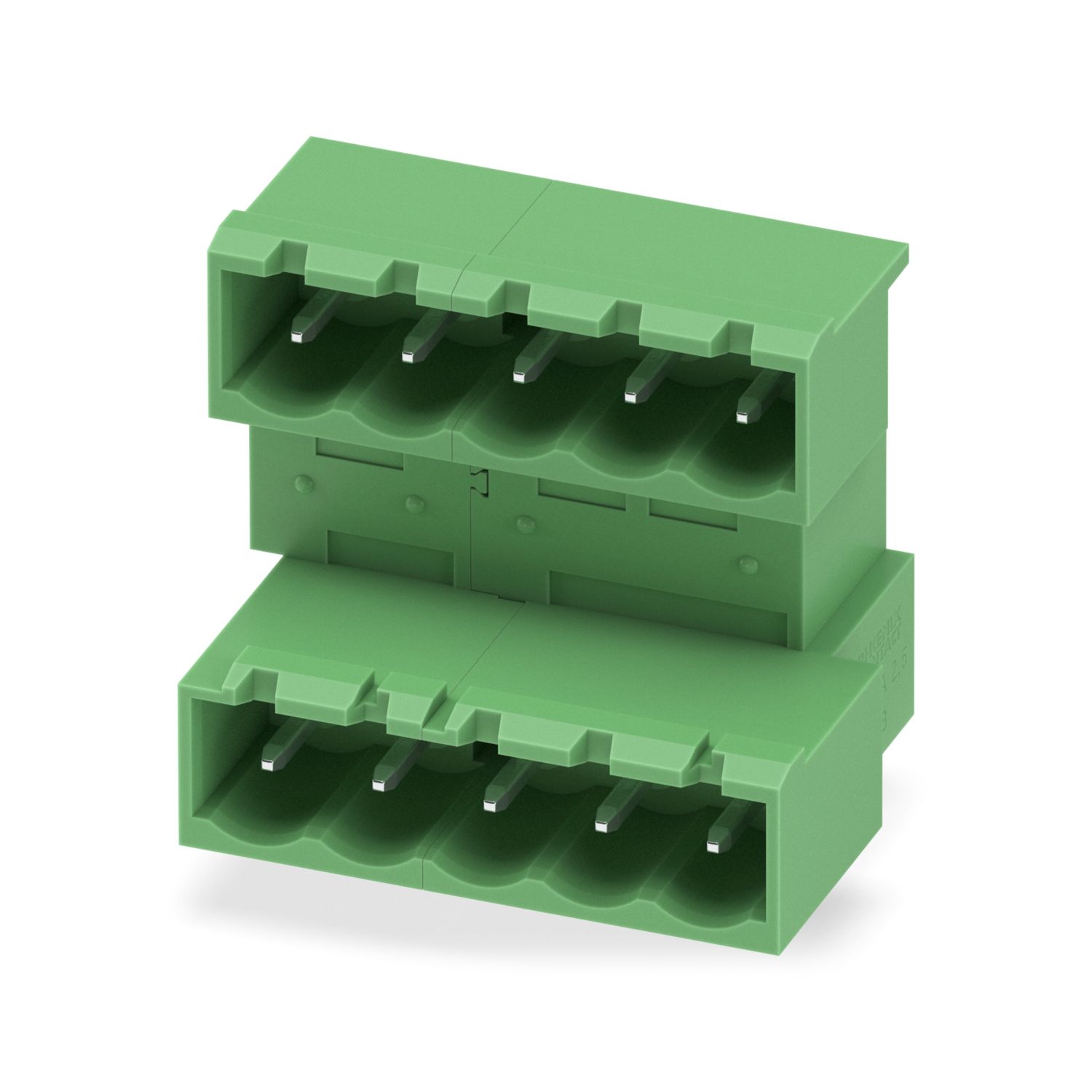

MVSTBU 2,5/ 5-GB-5,08 - PCB header 1788567

-

UKK 3-MSTB-5,08 - Double-level terminal block 2770888

-

UKK 3-MSTBVH-5,08 - Double-level terminal block 2770846

-

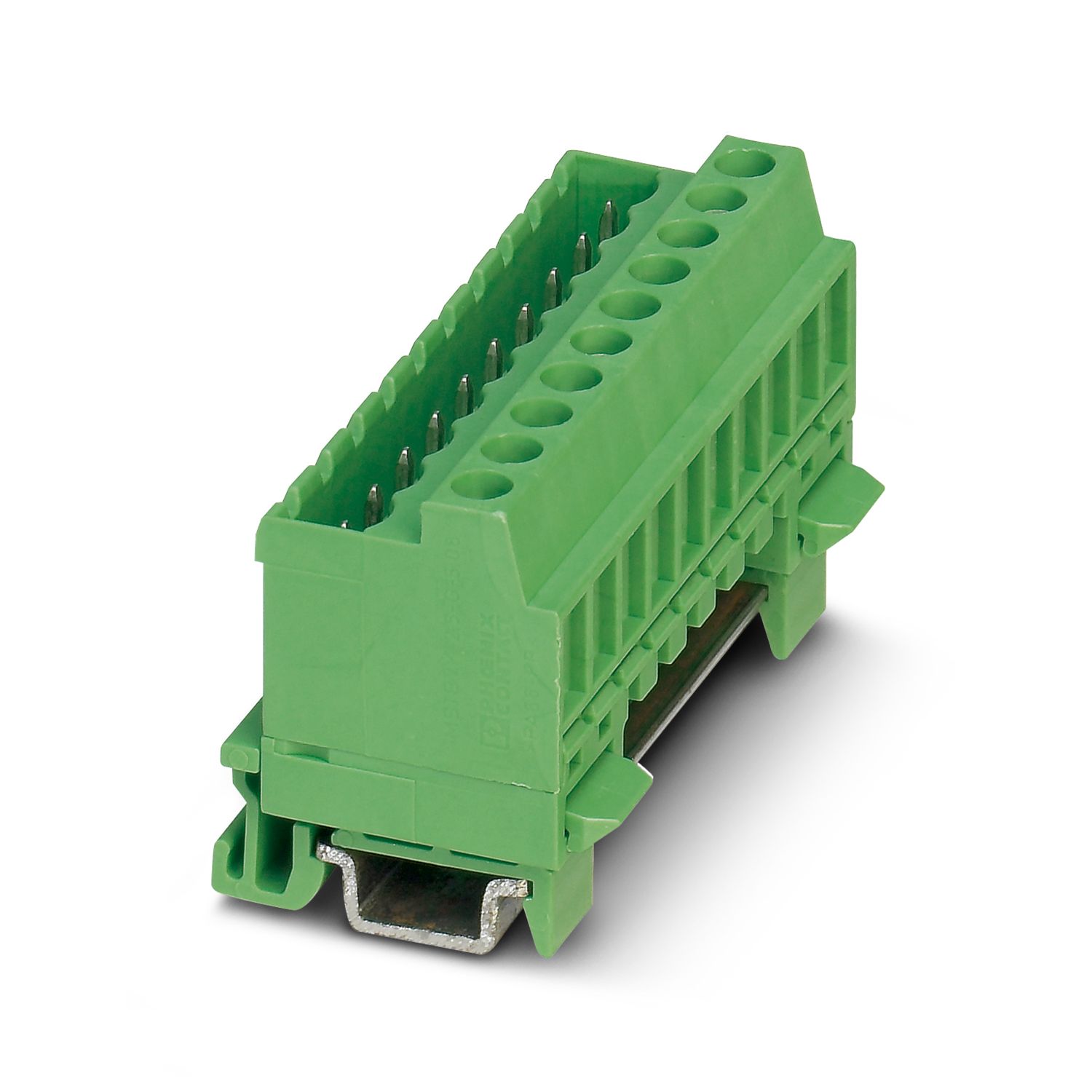

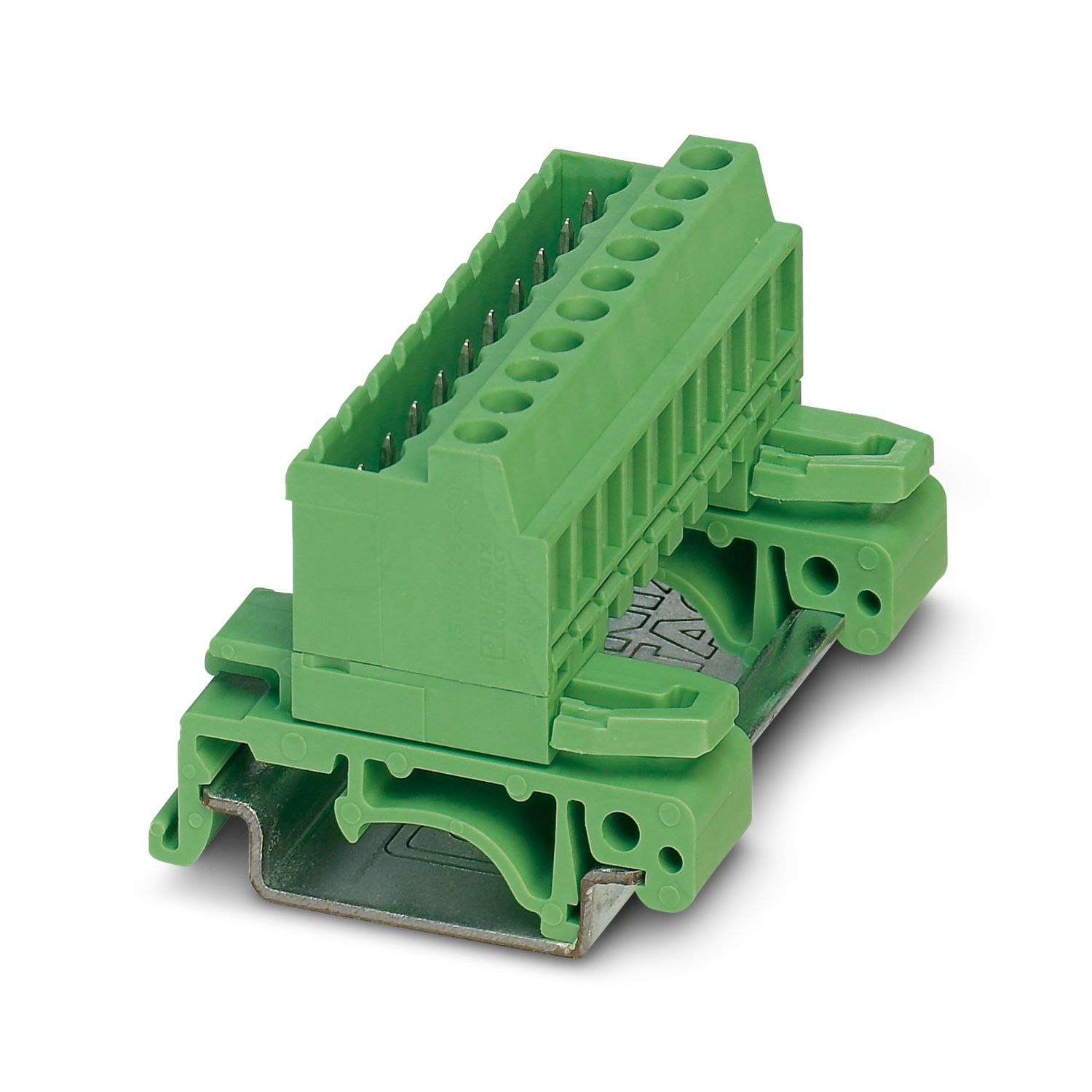

MSTBVK 2,5/ 5-G-5,08 - DIN rail connector 1788758

-

UMSTBVK 2,5/ 5-G-5,08 - DIN rail connector 1788143

-

MDSTBA 2,5/ 5-G-5,08 - PCB header 1842092

-

ICC 2,5/ 5-STZ-5,08 - PCB connector 1823875

Your advantages

Well-known connection principle allows worldwide use

Optimized for tight installation situations: operation and conductor connection from one direction

Low temperature rise, thanks to maximum contact force

Allows connection of two conductors

PHOENIX CONTACT B.V.

Hengelder 56, 6902 PA Zevenaar, Postbus 246, 6900 AE Zevenaar