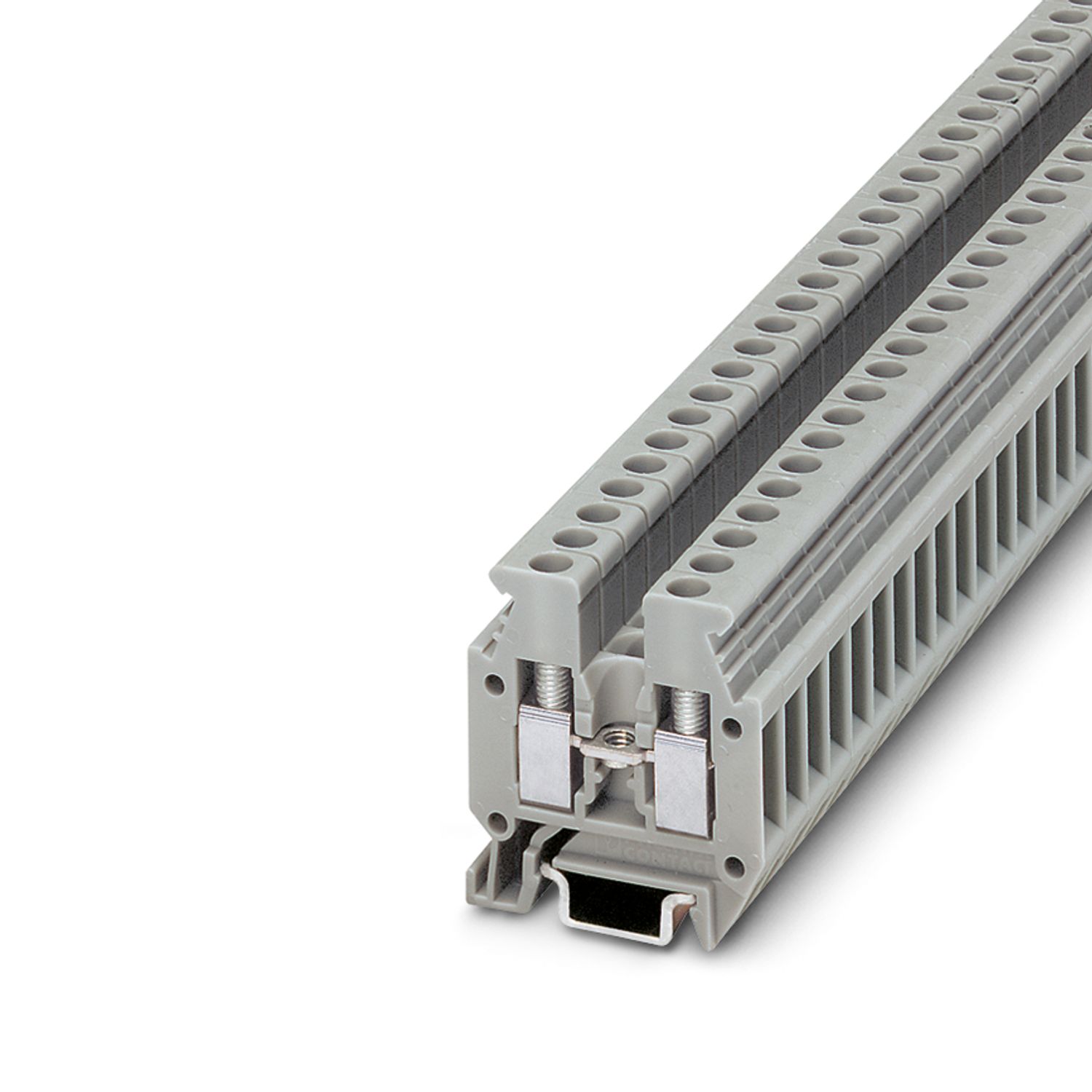

MBK 3/E-Z

-

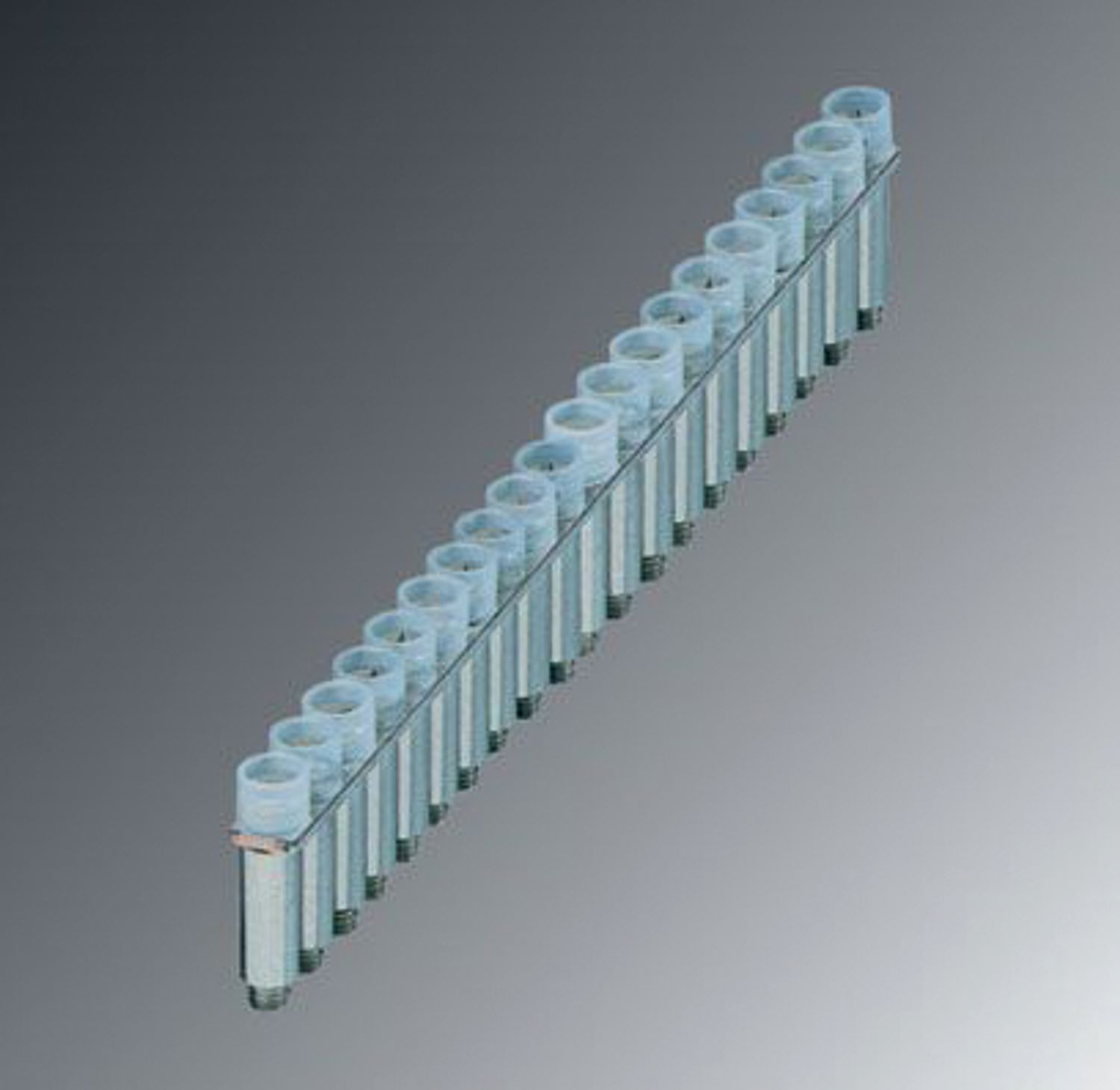

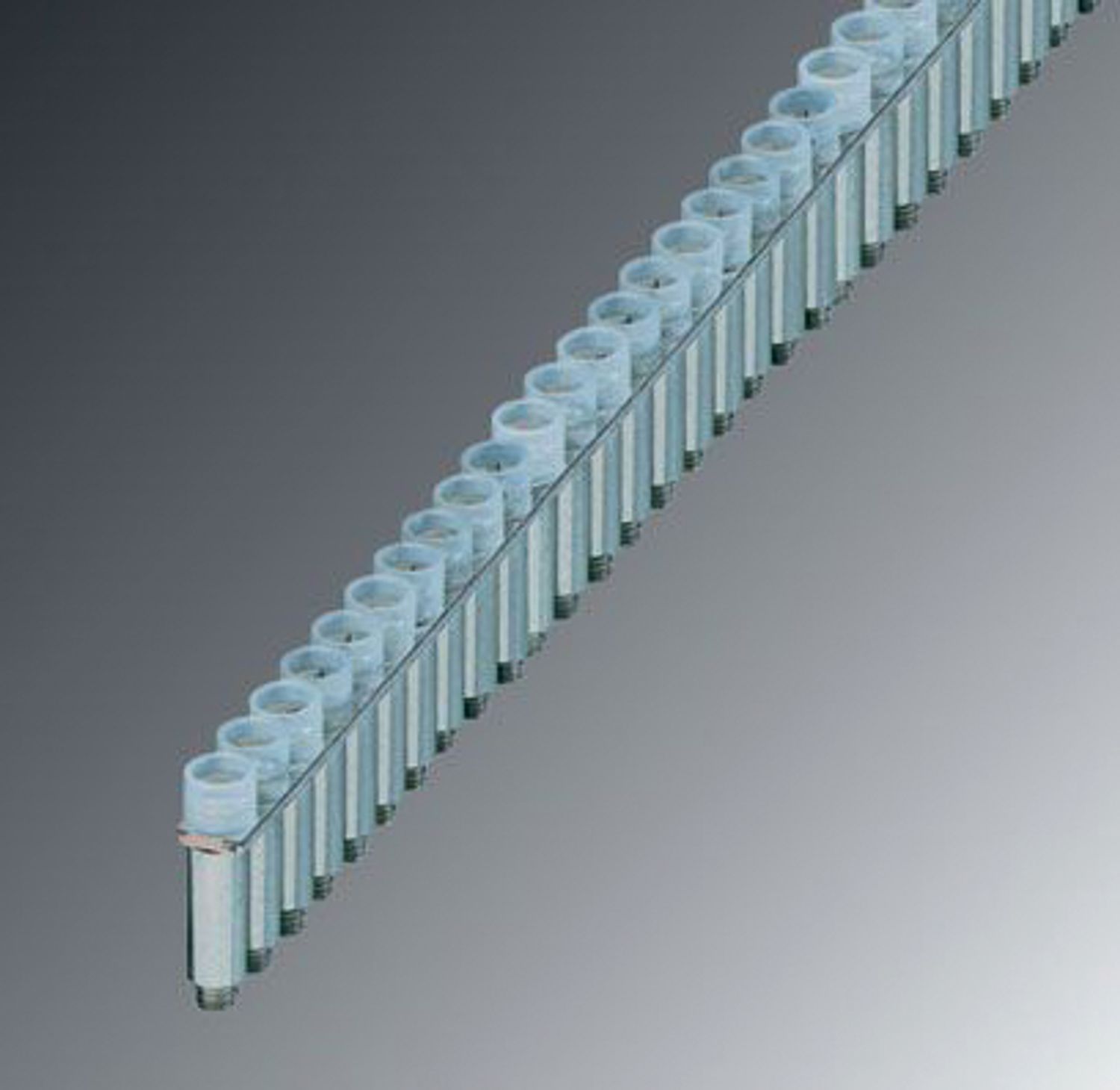

Mini feed-through terminal block

1413036

Mini feed-through terminal block, nom. voltage: 500 V, nominal current: 24 A, number of connections: 2, connection method: Screw connection, Rated cross section: 2.5 mm2, cross section: 0.2 mm2 - 4 mm2, mounting type: NS 15, color: gray

Product details

| Product type | Miniature terminal block |

| Number of connections | 2 |

| Number of rows | 1 |

| Potentials | 1 |

| Insulation characteristics | |

| Overvoltage category | III |

| Degree of pollution | 3 |

| Rated surge voltage | 6 kV |

| Maximum power dissipation for nominal condition | 0.77 W |

| Number of connections per level | 2 |

| Nominal cross section | 2.5 mm² |

| Connection method | Screw connection |

| Screw thread | M3 |

| Tightening torque | 0.6 ... 0.8 Nm |

| Stripping length | 8 mm |

| Internal cylindrical gage | A3 |

| Connection in acc. with standard | IEC 60947-7-1 |

| Conductor cross-section rigid | 0.2 mm² ... 4 mm² |

| Cross section AWG | 24 ... 12 (converted acc. to IEC) |

| Conductor cross-section flexible | 0.25 mm² ... 2.5 mm² |

| Conductor cross-section, flexible [AWG] | 24 ... 14 (converted acc. to IEC) |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 0.25 mm² ... 2.5 mm² |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 0.25 mm² ... 1.5 mm² |

| Cross-section with insertion bridge, rigid | 2.5 mm² |

| Cross-section with insertion bridge, flexible | 2.5 mm² |

| 2 conductors with same cross section, solid | 0.2 mm² ... 1 mm² |

| 2 conductors with same cross section, flexible | 0.2 mm² ... 1.5 mm² |

| 2 conductors with same cross section, flexible, with ferrule without plastic sleeve | 0.25 mm² ... 1.5 mm² |

| 2 conductors with the same cross section, flexible, with TWIN ferrule with plastic sleeve | 0.5 mm² ... 1 mm² |

| Nominal current | 24 A |

| Maximum load current | 32 A (with 4 mm² conductor cross-section) |

| Nominal voltage | 500 V |

| Nominal cross section | 2.5 mm² |

| Rated data (ATEX/IECEx) | |

| Identification | II 2 G Ex eb IIC Gb |

| Operating temperature range | -60 °C ... 105 °C |

| Ex-certified accessories | 1415021 D-MBK/E |

| 1205053 SZS 0,6X3,5 | |

| 1421633 E/MK | |

| List of bridges | Fixed bridge / FBRI 2-5 N / 3000227 |

| Fixed bridge / FBRI 3-5 N / 3000201 | |

| Fixed bridge / FBRI 5-5 N / 3000188 | |

| Fixed bridge / FBRI 6-5 N / 3000256 | |

| Fixed bridge / FBRI 10-5 N / 2770642 | |

| Fixed bridge / FBRI 20-5 N / 3000515 | |

| Bridge data | 22 A (2.5 mm²) |

| Ex temperature increase | 40 K (23.1 A / 2.5 mm²) |

| for bridging with bridge | 250 V |

| - At bridging between non-adjacent terminal blocks | 176 V |

| Rated insulation voltage | 250 V |

| output | (Permanent) |

| Ex level General | |

| Rated voltage | 275 V |

| Rated current | 21 A |

| Maximum load current | 27.5 A |

| Contact resistance | 0.5 mΩ |

| Ex connection data General | |

| Torque range | 0.6 Nm ... 0.8 Nm |

| Nominal cross section | 2.5 mm² |

| Rated cross section AWG | 14 |

| Connection capacity rigid | 0.2 mm² ... 4 mm² |

| Connection capacity AWG | 24 ... 12 |

| Connection capacity flexible | 0.2 mm² ... 2.5 mm² |

| Connection capacity AWG | 24 ... 14 |

| 2 conductors with same cross section, solid | 0.2 mm² ... 1.5 mm² |

| 2 conductors with the same cross-section AWG rigid | 24 ... 16 |

| 2 conductors with same cross section, stranded | 0.2 mm² ... 1.5 mm² |

| 2 conductors with the same cross-section AWG flexible | 24 ... 16 |

| Width | 5.2 mm |

| End cover width | 1 mm |

| Height | 28 mm |

| Depth | 26.2 mm |

| Color | gray (RAL 7042) |

| Flammability rating according to UL 94 | V2 |

| Insulating material group | I |

| Insulating material | PA |

| Static insulating material application in cold | -40 °C |

| Relative insulation material temperature index (Elec., UL 746 B) | 125 °C |

| Surge voltage test | |

| Test voltage setpoint | 7.3 kV |

| Result | Test passed |

| Temperature-rise test | |

| Requirement temperature-rise test | Increase in temperature ≤ 45 K |

| Result | Test passed |

| Short-time withstand current 2.5 mm² | 0.3 kA |

| Short-time withstand current 4 mm² | 0.48 kA |

| Result | Test passed |

| Power-frequency withstand voltage | |

| Test voltage setpoint | 1.89 kV |

| Result | Test passed |

| Mechanical data | |

| Open side panel | Yes |

| Mechanical strength | |

| Result | Test passed |

| Attachment on the carrier | |

| DIN rail/fixing support | NS 15 |

| Test force setpoint | 1 N |

| Result | Test passed |

| Test for conductor damage and slackening | |

| Rotation speed | 10 (+/- 2) rpm |

| Revolutions | 135 |

| Conductor cross-section/weight | 0.2 mm² / 0.2 kg |

| 2.5 mm² / 0.7 kg | |

| 4 mm² / 0.9 kg | |

| Result | Test passed |

| Needle-flame test | |

| Time of exposure | 30 s |

| Result | Test passed |

| Oscillation/broadband noise | |

| Specification | DIN EN 50155 (VDE 0115-200):2018-05 |

| Spectrum | Long life test category 2, bogie-mounted |

| Frequency | f1 = 5 Hz to f2 = 250 Hz |

| ASD level | 6.12 (m/s²)²/Hz |

| Acceleration | 3.12g |

| Test duration per axis | 5 h |

| Test directions | X-, Y- and Z-axis |

| Result | Test passed |

| Shocks | |

| Pulse shape | Half-sine |

| Acceleration | 30g |

| Shock duration | 18 ms |

| Number of shocks per direction | 3 |

| Test directions | X-, Y- and Z-axis (pos. and neg.) |

| Result | Test passed |

| Ambient conditions | |

| Ambient temperature (operation) | -40 °C ... 110 °C (Operating temperature range incl. self-heating; for max. short-term operating temperature, see RTI Elec.) |

| Ambient temperature (storage/transport) | -25 °C ... 60 °C (for a short time, not exceeding 24 h, -60 °C to +70 °C) |

| Ambient temperature (assembly) | -5 °C ... 70 °C |

| Ambient temperature (actuation) | -5 °C ... 70 °C |

| Permissible humidity (operation) | 20 % ... 90 % |

| Permissible humidity (storage/transport) | 30 % ... 70 % |

| Connection in acc. with standard | IEC 60947-7-1 |

| Mounting type | NS 15 |

| Item number | 1413036 |

| Packing unit | 50 pc |

| Minimum order quantity | 50 pc |

| Sales key | BE1261 |

| Product key | BE1261 |

| GTIN | 4017918021115 |

| Weight per piece (including packing) | 4,806 g |

| Weight per piece (excluding packing) | 4,407 g |

| Customs tariff number | 85369010 |

| Country of origin | CN |

ECLASS

| ECLASS-13.0 | 27250101 |

ETIM

| ETIM 8.0 | EC000897 |

UNSPSC

| UNSPSC 21.0 | 39121400 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes |

| Exemption | 6(c) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-50

An article-related China RoHS declaration table can be found in the download area for the respective article under "Manufacturer declaration". For all articles with EFUP-E, no China RoHS declaration table issued and required.

|

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | Lead (CAS: 7439-92-1) |

Compatible products

Note: Applying some accessories below might limit this product.

-

-

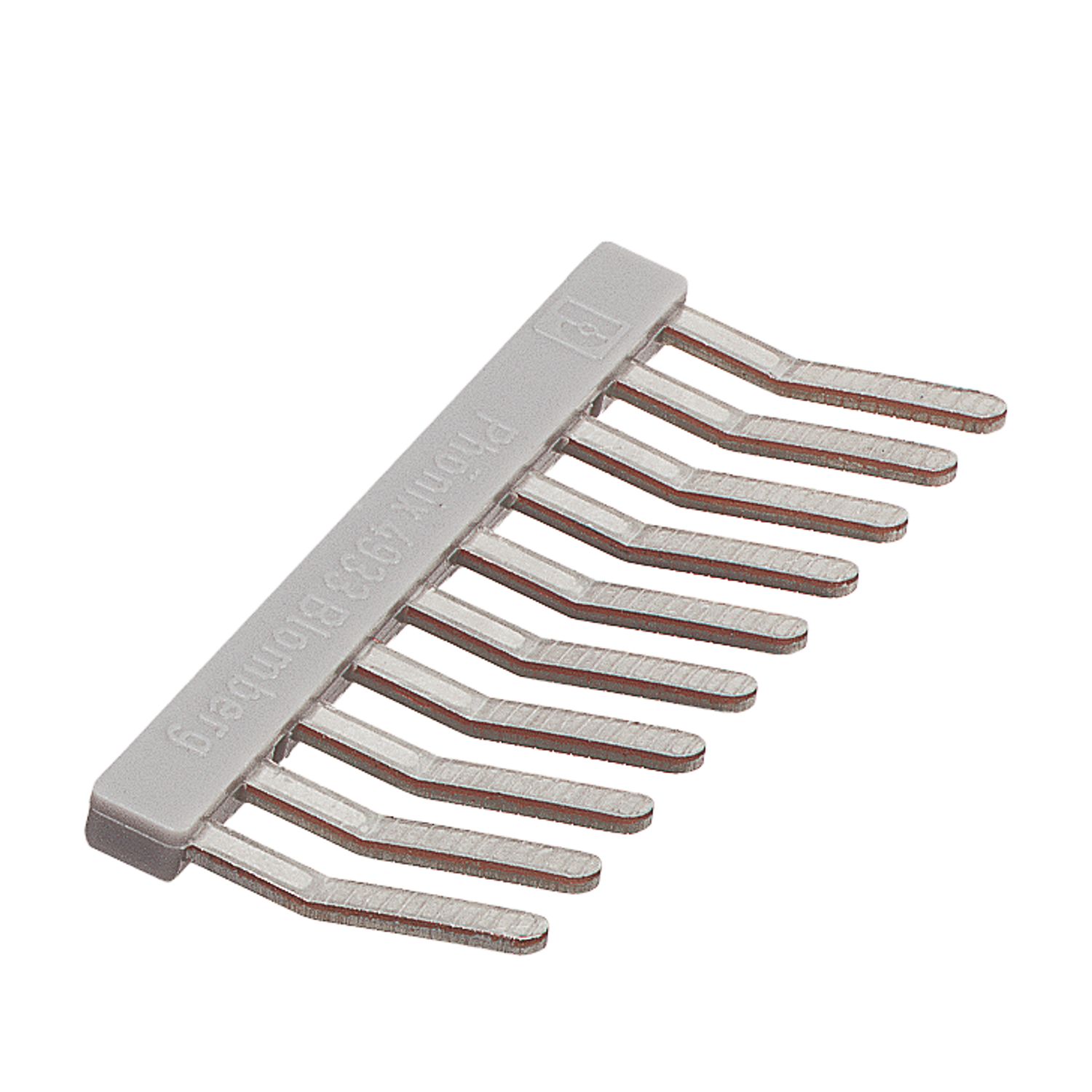

EBL 10- 5 - Insertion bridge 2303132

-

SBRN 2-7 - Bridge bar 1413230

-

FBRI 2-5 N - Fixed bridge 3000227

-

FBRI 3-5 N - Fixed bridge 3000201

-

FBRI 4-5 N - Fixed bridge 3000191

-

FBRI 5-5 N - Fixed bridge 3000188

-

FBRI 6-5 N - Fixed bridge 3000256

-

FBRI 7-5 N - Fixed bridge 3000269

-

FBRI 8-5 N - Fixed bridge 3000272

-

FBRI 9-5 N - Fixed bridge 3000285

-

FBRI 12-5 N - Fixed bridge 3000434

-

FBRI 16-5 N - Fixed bridge 3000476

-

FBRI 20-5 N - Fixed bridge 3000515

-

FBRI 40-5 N - Fixed bridge 3006823

-

D-MBK/E - End cover 1415021

-

FB-150 METER - Fixed bridge 0201595

-

RPS - Reducing plug 0201647

-

TS-KK 3 - Separating plate 2770215

-

ATP-MBK - Partition plate 1413227

-

SBS 5:UNBEDRUCKT - Marker card 1007219

-

SZS 0,6X3,5 - Screwdriver 1205053

-

NS 15 UNPERF 2000MM VPE 10 - DIN rail, unperforated 1401695

-

NS 15 PERF 2000MM VPE 10 - DIN rail perforated 1401682

-

NS 15 AL PERF 2000MM VPE 10 - DIN rail perforated 1401763

-

NS 15 WH PERF 2000MM-VPE 10 - DIN rail perforated 1204096

-

ZB 5 :UNBEDRUCKT - Zack marker strip 1050004

-

ZB 5 CUS - Zack marker strip 0824962

-

ZB 5,LGS:L1-N,PE - Zack marker strip 1050415

-

UC-TM 5 - Marker for terminal blocks 0818108

-

UC-TM 5 CUS - Marker for terminal blocks 0824581

-

UCT-TM 5 - Marker for terminal blocks 0828734

-

UCT-TM 5 CUS - Marker for terminal blocks 0829595

-

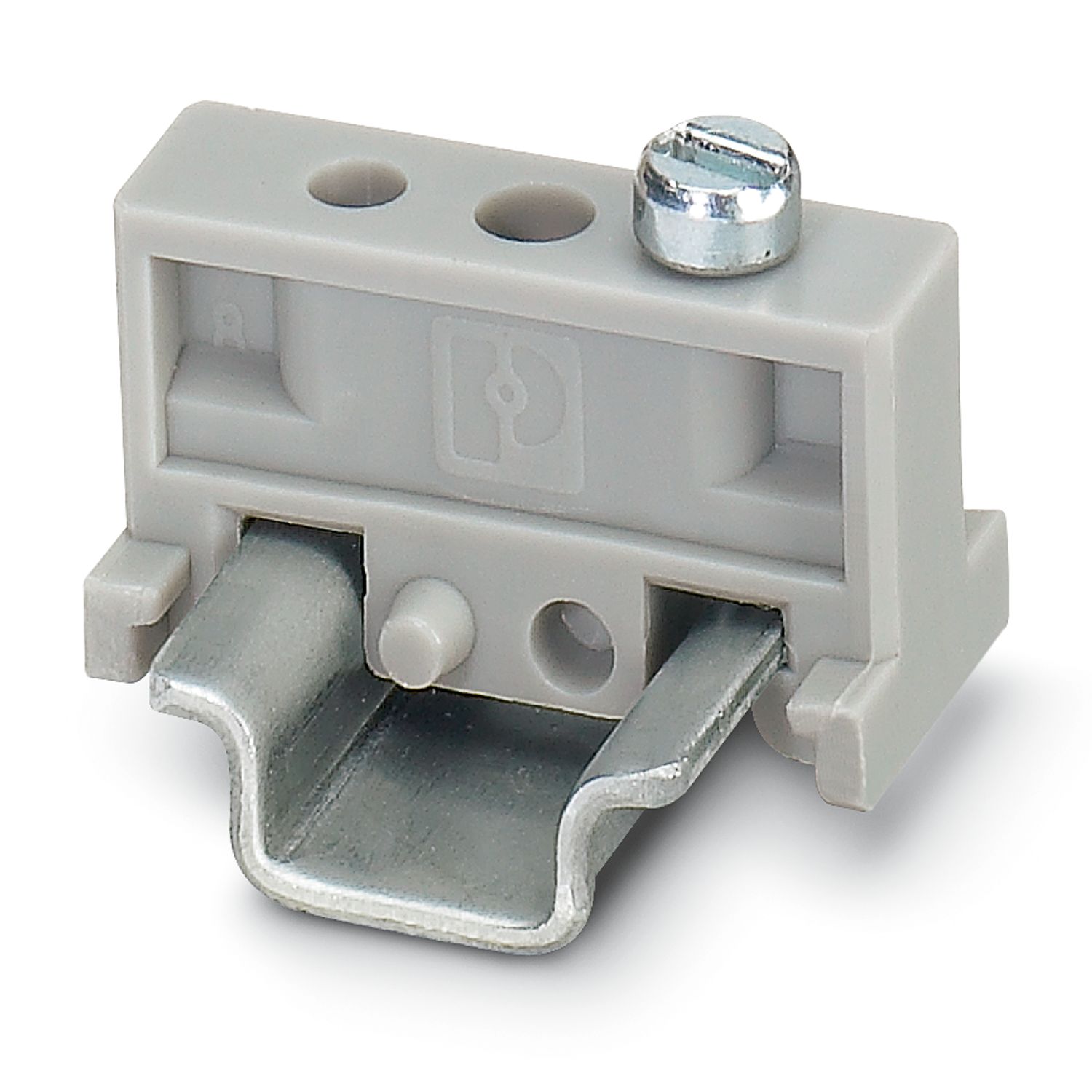

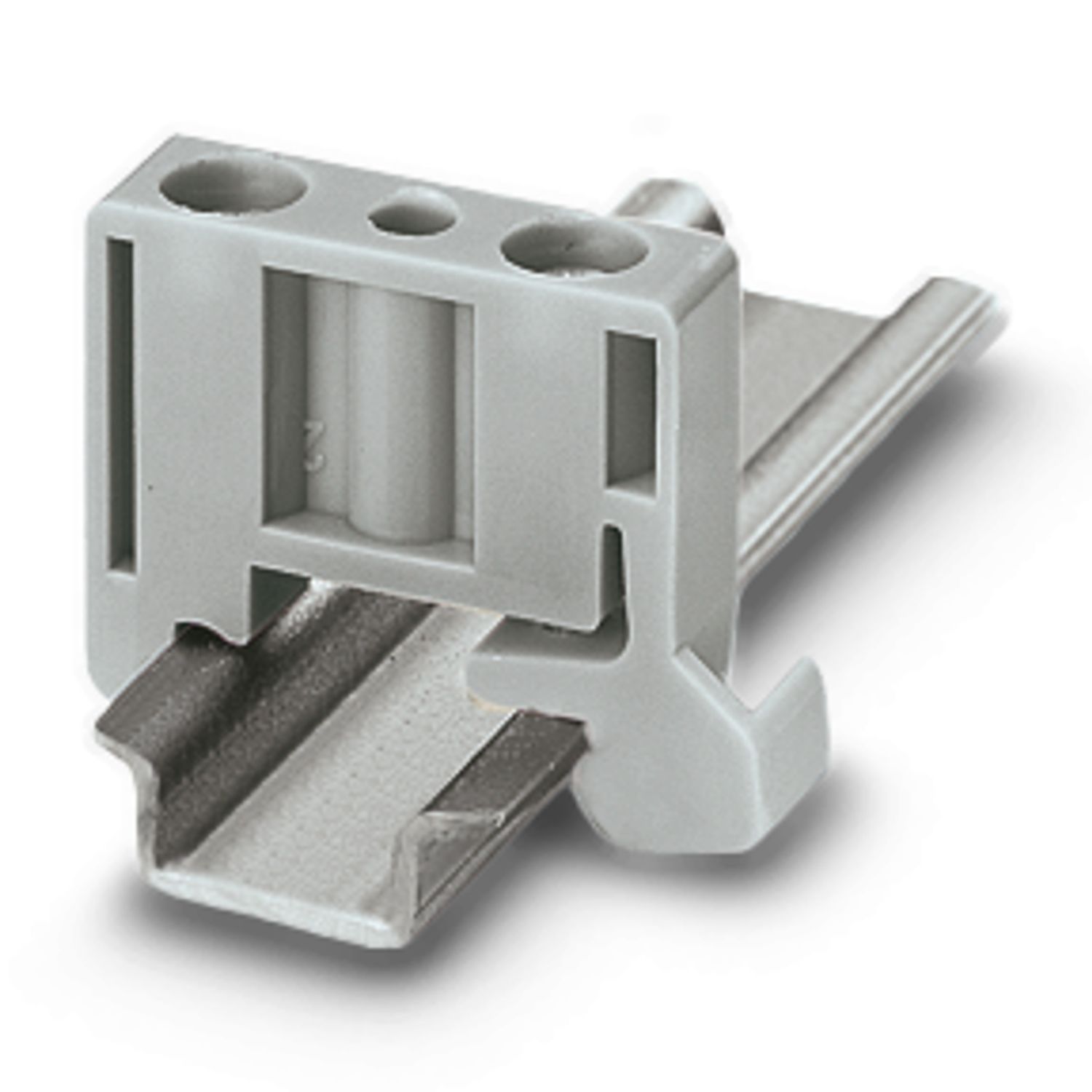

E/MBK - End bracket 1401637

-

E/MK - End bracket 1421633

-

E/MK 1 - End bracket 1421659

-

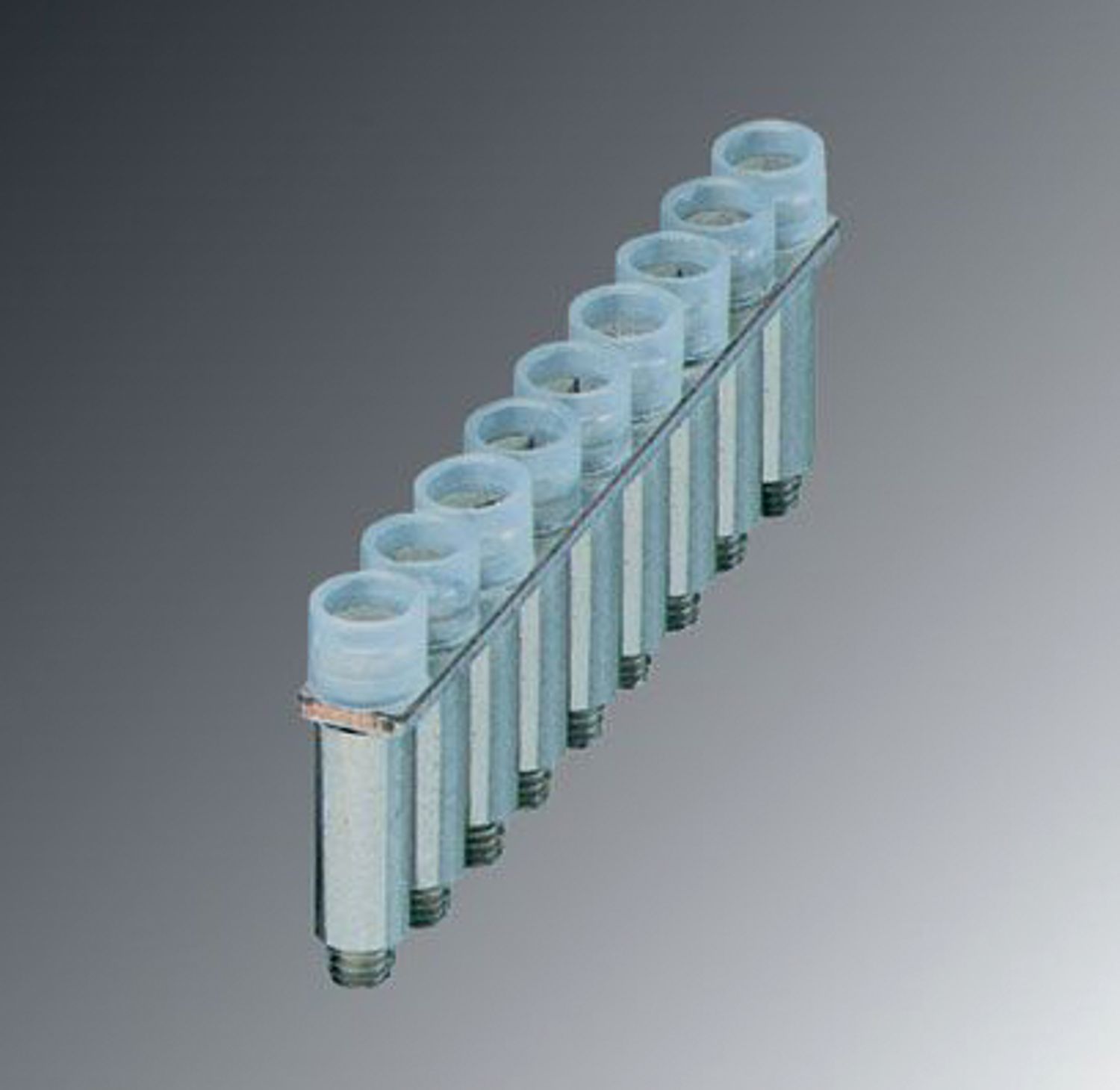

PSBJ 3/13/4 - Test plug strip 0201304

-

PSB 3/10/4 - Test plug strip 0601292

Your advantages

Separating disks, partition plates, and test sockets complete the range of accessories

Clear arrangement thanks to marking of all terminal points

Space saving thanks to compact design and mounting option on a 15 mm DIN rail

Easy potential distribution thanks to standardized plug-in bridges

PHOENIX CONTACT B.V.

Hengelder 56, 6902 PA Zevenaar, Postbus 246, 6900 AE Zevenaar