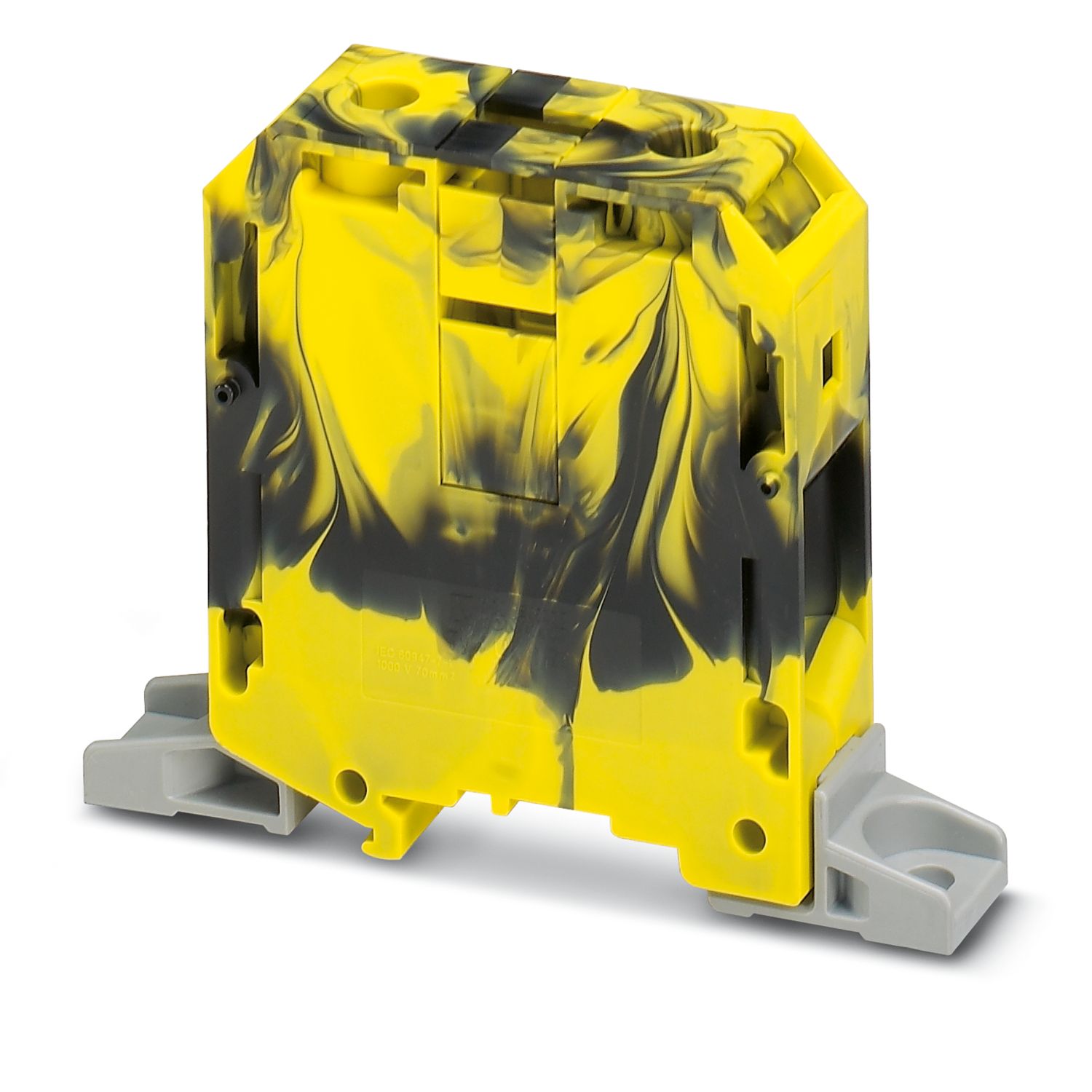

UKH 70-FE-F

-

High-current terminal block

3247058

High-current terminal block, nom. voltage: 1000 V, nominal current: 192 A, number of connections: 2, number of positions: 1, connection method: Screw connection, Rated cross section: 70 mm2, cross section: 16 mm2 - 70 mm2, mounting type: direct screw connection, color: black/yellow

Product details

| General | |

| Note | For a reliable contact of multi stranded conductors it is recommended to untwist multi stranded conductors. |

| Area of application | Railway industry |

| Machine building | |

| Plant engineering | |

| Number of positions | 1 |

| Number of connections | 2 |

| Number of rows | 1 |

| Potentials | 1 |

| Insulation characteristics | |

| Overvoltage category | III |

| Degree of pollution | 3 |

| Rated surge voltage | 8 kV |

| Maximum power dissipation for nominal condition | 6.27 W |

| Number of connections per level | 2 |

| Nominal cross section | 70 mm² |

| Level 1 above 1 below 1 | |

| Connection method | Screw connection |

| Screw thread | M8 |

| Tightening torque | 8 ... 10 Nm |

| Stripping length | 24 mm |

| Internal cylindrical gage | A11 |

| Connection in acc. with standard | IEC 60947-7-1 |

| Conductor cross-section rigid | 16 mm² ... 70 mm² |

| Cross section AWG | 4 ... 2/0 (converted acc. to IEC) |

| Conductor cross-section flexible | 25 mm² ... 70 mm² |

| Conductor cross-section, flexible [AWG] | 3 ... 2/0 (converted acc. to IEC) |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 16 mm² ... 70 mm² |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 16 mm² ... 70 mm² |

| 2 conductors with same cross section, solid | 16 mm² ... 25 mm² |

| 2 conductors with same cross section, flexible | 16 mm² ... 25 mm² |

| 2 conductors with same cross section, flexible, with ferrule without plastic sleeve | 16 mm² ... 25 mm² |

| Nominal current | 192 A |

| Maximum load current | 192 A (with 70 mm² conductor cross-section) |

| Nominal voltage | 1000 V |

| Note | Note: Product releases, connection cross sections and notes on connecting aluminum cables can be found in the download area. |

| Nominal cross section | 70 mm² |

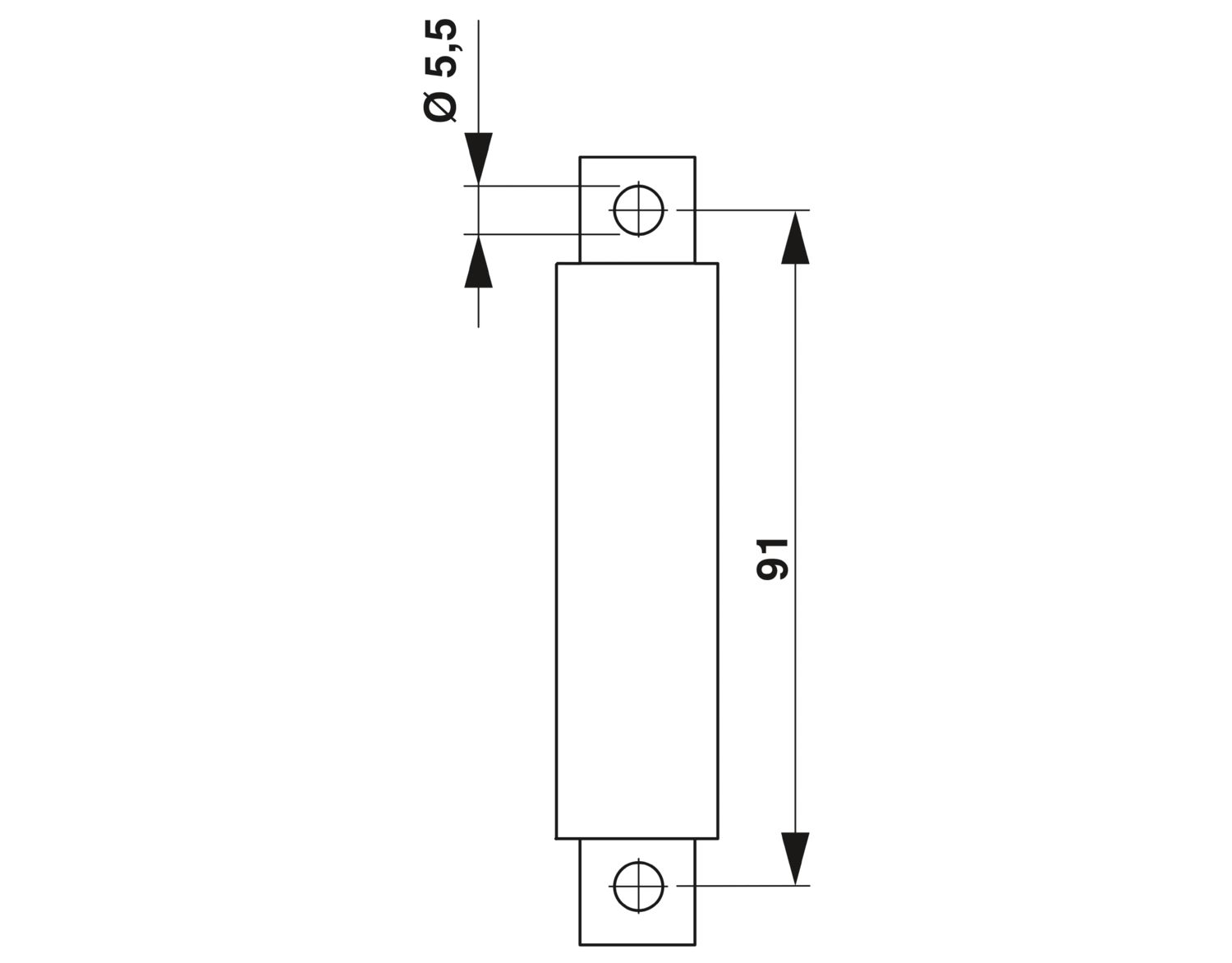

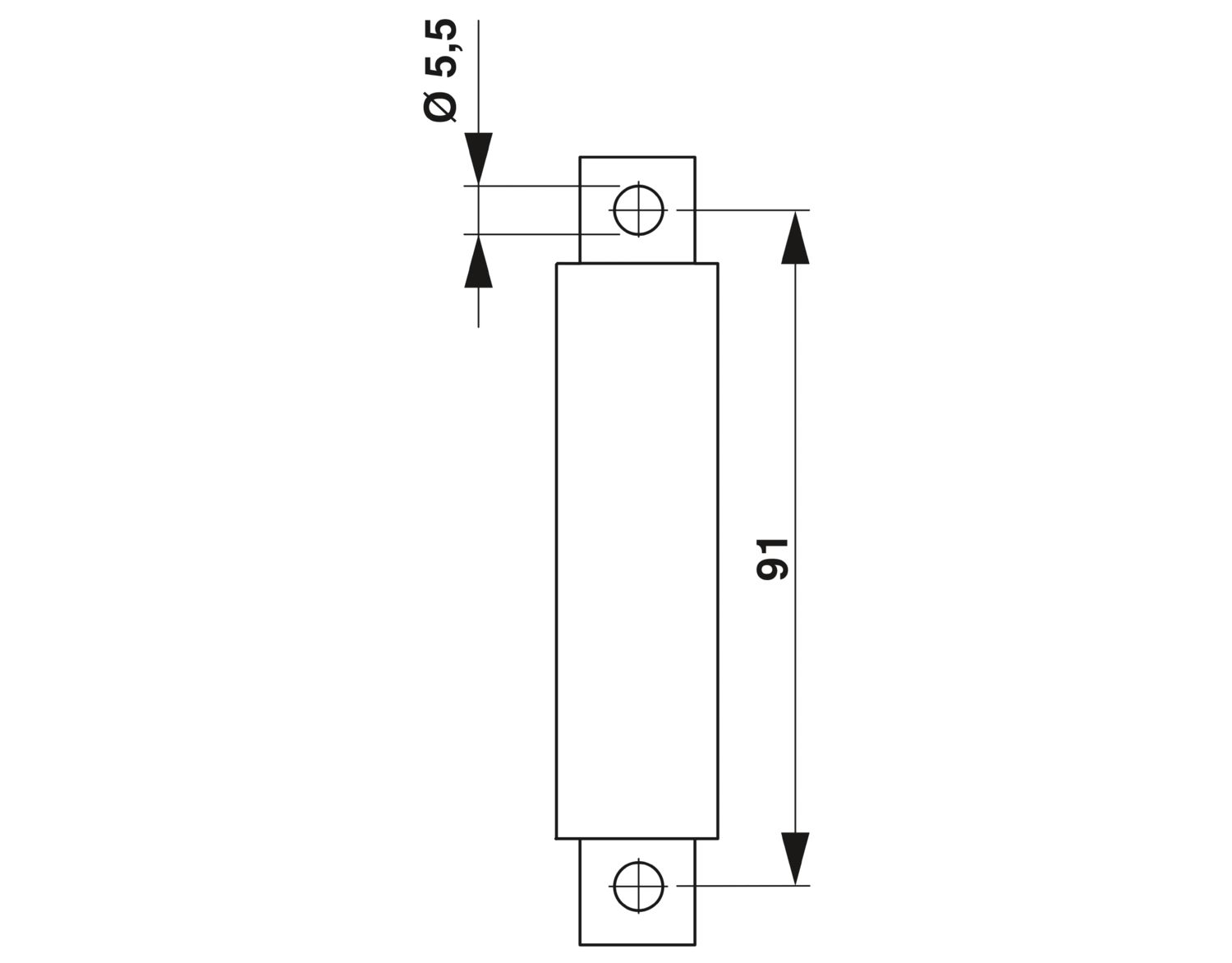

| Dimensional drawing |

|

| Width | 20.3 mm |

| Height | 80 mm |

| Color | black/yellow |

| Flammability rating according to UL 94 | V0 |

| Insulating material group | I |

| Insulating material | PA |

| Static insulating material application in cold | -60 °C |

| Relative insulation material temperature index (Elec., UL 746 B) | 130 °C |

| Fire protection for rail vehicles (DIN EN 45545-2) R22 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R23 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R24 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R26 | HL 1 - HL 3 |

| Surface flammability NFPA 130 (ASTM E 162) | passed |

| Specific optical density of smoke NFPA 130 (ASTM E 662) | passed |

| Smoke gas toxicity NFPA 130 (SMP 800C) | passed |

| Surge voltage test | |

| Test voltage setpoint | 9.8 kV |

| Result | Test passed |

| Short-time withstand current 70 mm² | 8.4 kA |

| Result | Test passed |

| Power-frequency withstand voltage | |

| Test voltage setpoint | 2.2 kV |

| Result | Test passed |

| Mechanical data | |

| Open side panel | No |

| Mechanical strength | |

| Result | Test passed |

| Attachment on the carrier | |

| Test force setpoint | 10 N |

| Result | Test passed |

| Test for conductor damage and slackening | |

| Conductor cross-section/weight | 25 mm² / 4.5 kg |

| 70 mm²/10.4 kg | |

| 95 mm²/14 kg | |

| Result | Test passed |

| Needle-flame test | |

| Time of exposure | 30 s |

| Result | Test passed |

| Oscillation/broadband noise | |

| Specification | DIN EN 50155 (VDE 0115-200):2008-03 |

| Spectrum | Long life test category 1, class B, body mounted |

| Frequency | f1 = 5 Hz to f2 = 150 Hz |

| ASD level | 1.857 (m/s²)²/Hz |

| Acceleration | 0.8g |

| Test duration per axis | 5 h |

| Test directions | X-, Y- and Z-axis |

| Result | Test passed |

| Shocks | |

| Specification | DIN EN 50155 (VDE 0115-200):2008-03 |

| Pulse shape | Half-sine |

| Acceleration | 5g |

| Shock duration | 30 ms |

| Number of shocks per direction | 3 |

| Test directions | X-, Y- and Z-axis (pos. and neg.) |

| Result | Test passed |

| Ambient conditions | |

| Ambient temperature (storage/transport) | -25 °C ... 60 °C (for a short time, not exceeding 24 h, -60 °C to +70 °C) |

| Ambient temperature (assembly) | -5 °C ... 70 °C |

| Ambient temperature (actuation) | -5 °C ... 70 °C |

| Permissible humidity (storage/transport) | 30 % ... 70 % |

| Connection in acc. with standard | IEC 60947-7-1 |

| Mounting type | direct screw connection |

| Item number | 3247058 |

| Packing unit | 10 pc |

| Minimum order quantity | 1 pc |

| Note | Made to order (non-returnable) |

| Sales key | BE |

| Product key | BE1311 |

| GTIN | 4046356707244 |

| Weight per piece (including packing) | 162.9 g |

| Weight per piece (excluding packing) | 162.9 g |

| Country of origin | Country of origin will be provided upon delivery. |

ETIM

| ETIM 8.0 | EC000897 |

UNSPSC

| UNSPSC 21.0 | 39121400 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes (No exemptions) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-E

No hazardous substances above the limits

|

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | No substance above 0.1 wt% |

Compatible products

Note: Applying some accessories below might limit this product.

-

-

FBI 3-20 N - Fixed bridge 3213205

-

AGK 10-UKH 50 - Pick-off terminal block 3001763

-

UKH 50 EP - Insertion profile 3009228

-

X-PEN 0,35 - Marker pen 0811228

-

SF-THEX 6-200 - Screwdriver 1212642

-

WS-2K - Warning label 1004513

-

WS-4K - Warning label 1004584

-

ZB 10:UNBEDRUCKT - Zack marker strip 1053001

-

ZB 10 CUS - Zack marker strip 0824941

-

ZB10,LGS:FORTL.ZAHLEN - Zack marker strip 1053014

-

ZB10,QR:FORTL.ZAHLEN - Zack marker strip 1053027

-

ZB10,LGS:L1-N,PE - Marker for terminal blocks 1053412

-

ZB10,LGS:U-N - Marker for terminal blocks 1053438

-

UC-TM 10 - Marker for terminal blocks 0818069

-

UC-TM 10 CUS - Marker for terminal blocks 0824605

-

UCT-TM 10 - Marker for terminal blocks 0829142

-

UCT-TM 10 CUS - Marker for terminal blocks 0829623

-

TMT 10 R - Marker for terminal blocks 0816210

-

TMT 10 R CUS - Marker for terminal blocks 0824500

Your advantages

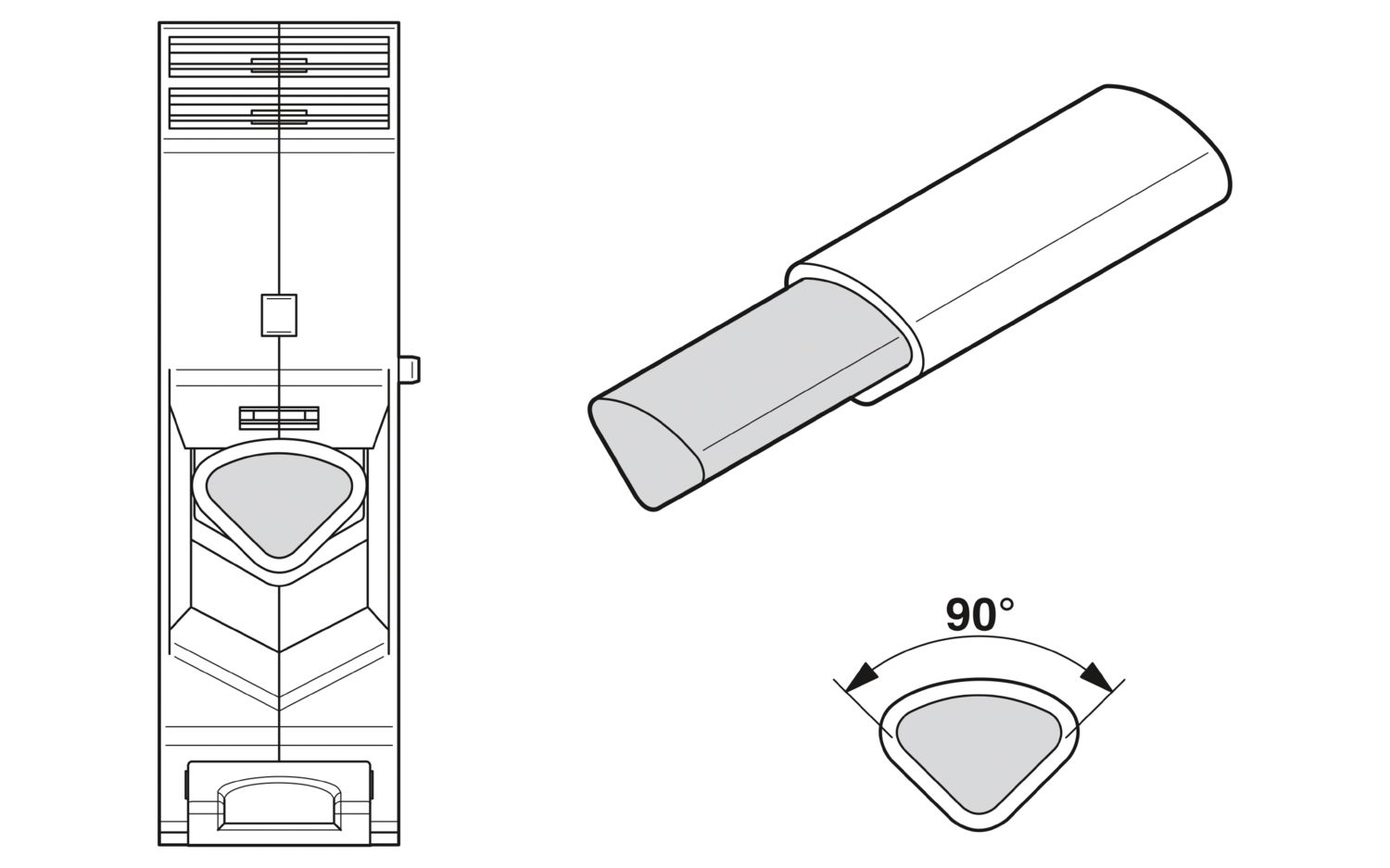

Reliable cable connection is ensured by three-point centering of the conductor in the prismatic sleeve base

Tested for railway applications

Screw locking by means of spring-loaded elements in the clamping part

Low contact resistance of the contact surface due to ribbing

PHOENIX CONTACT (Ireland) Ltd

C6 The Exchange, Calmount Park, Ballymount, Dublin 12, D12 XE18, Ireland