Our solutions for marine automation

Rely on certified solutions from Phoenix Contact for use above and below deck. Whether cargo ships, cruise ships, special purpose ships, yachts, or ferries: Phoenix Contact supplies tailor-made solutions based on a comprehensive range of products. From simple applications to complex system solutions, our products ensure smooth control and data transmission in all application areas. Regardless of via which medium: high-performance and reliable solutions – even for harsh conditions and which are tested and verified in accordance with all the relevant marine approvals.

Your advantages

- Collect, process, visualize, and use data intelligently

- Easy integration possibilities of all common maritime communication protocols

- Tested quality: certified in accordance with DNV, ABS, LR, RINA, EN 60945, and IEC 62443

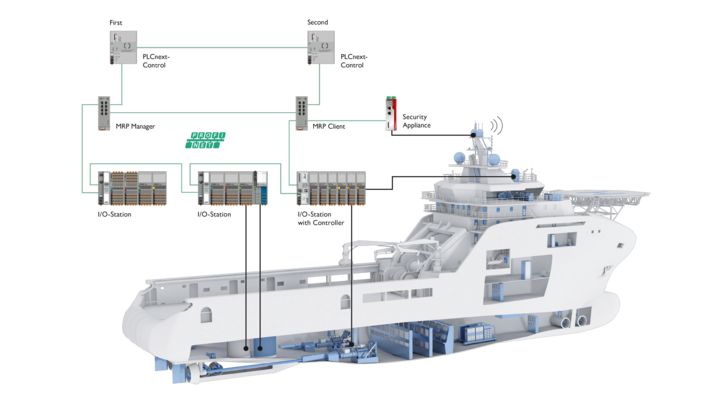

Redundancy ensures the failsafe performance of your essential services

Redundant alerting and monitoring Increase your operational safety with comprehensive solutions

Systems such as ship’s engines, power generation, rudder systems, or fire detection are part of the essential services on board. If they fail, there is a danger to the crew and the ship.

In order to be notified promptly regarding critical situations, redundant alerting and monitoring based on robust control and network technology are installed. In addition to the essential services, the system also reports on general conditions such as the level of the ballast water or fuel tanks and drinking water supplies.

Redundant automation systems, networks, and visualizations are implemented based on the open PLCnext automation platform. The portfolio will be extended with comprehensive solutions for performance monitoring which, along with the software, also include the necessary security routers and cloud solutions for the entire fleet. Applicable maritime certifications for the relevant components complete our range.

Solutions for the engine room

Solutions for the engine room System redundancy for highly available and efficient operation of all essential systems in the engine room

Reliable control of the engine room is essential for smooth operation of the vessel. With redundant systems based on PROFINET, Phoenix Contact ensures the safe and high-availability operation of motors and drives. The PLCnext Engineer software ensures easy programming with high-level languages in accordance with IEC 61131 and reliably forwards the acquired values from the controller to the control room.

Loading dock automation

High-availability automation for the hydraulics Determine the status of various items quickly and easily

Automated hydraulics are required for the fast loading and unloading of freight. This avoids long downtimes in port.

In order to ensure the safety of personnel on board, it must also be possible to open and close loading ramps reliably at all times. Phoenix Contact can provide you with redundant control systems for this.

Whether Modbus/RTU, Modbus/TCP, CANopen®, NMEA, or 4 … 20 mA: Phoenix Contact offers modular and open interface solutions for your application.

For stern ramps, hatch and ramp covers, doors, and movable car decks, use solutions from Phoenix Contact to ensure high-availability communication between the decentral systems and the control room. This means that, in the event of an emergency, all systems can be operated without having to switch to manual operation.

Monitoring the level of storage and cargo tanks

Reliable tank and ballast water management Solutions for level monitoring

Ensure a stable position of the ship on the high sea. Reliable monitoring of the level of storage and cargo tanks is indispensable for this.

Phoenix Contact offers a stand-alone system to prevent the overfilling of tanks.

Two control units form a redundant system: a preliminary alarm at 95% signals that the fill rate has been reduced. The main alarm at 98% indicates that filling has been stopped.

Automation solutions for heave compensation

Solutions for heave compensation Automation of dynamic positioning on the high seas

With an automation solution based on applicative system redundancy, you can make sure that the heave compensation always ensures the correct position of the ship. This is necessary, for example, when dynamic positioning is no longer sufficient in very high seas.

Secure communication in the network is ensured by mGuard security routers and VPN technology.

Products

Years of experience and industry-specific expertise result in outstanding solutions for your industry.

Technologies

Comprehensive expertise in all relevant technologies for your maritime application