Energy-efficient building operation in the Industry Solution Center Realize sustainable and safe building operation with our monitoring and control solutions for room automation and primary systems.

Customer profile

Phoenix Contact

Building 4 comprises 18,000 m² and features modern architecture with a lot of glass and a large atrium that spans all floors.

The building’s open character is also reflected in its infrastructure, the room automation, and the flexibly designed working areas.

The challenge

Individual building use and high operating costs

The ongoing operating costs, such as electricity, heating, and maintenance costs, account for around 80% of the total lifecycle costs of the building.

The solution

Efficient energy management and optimized supply processes

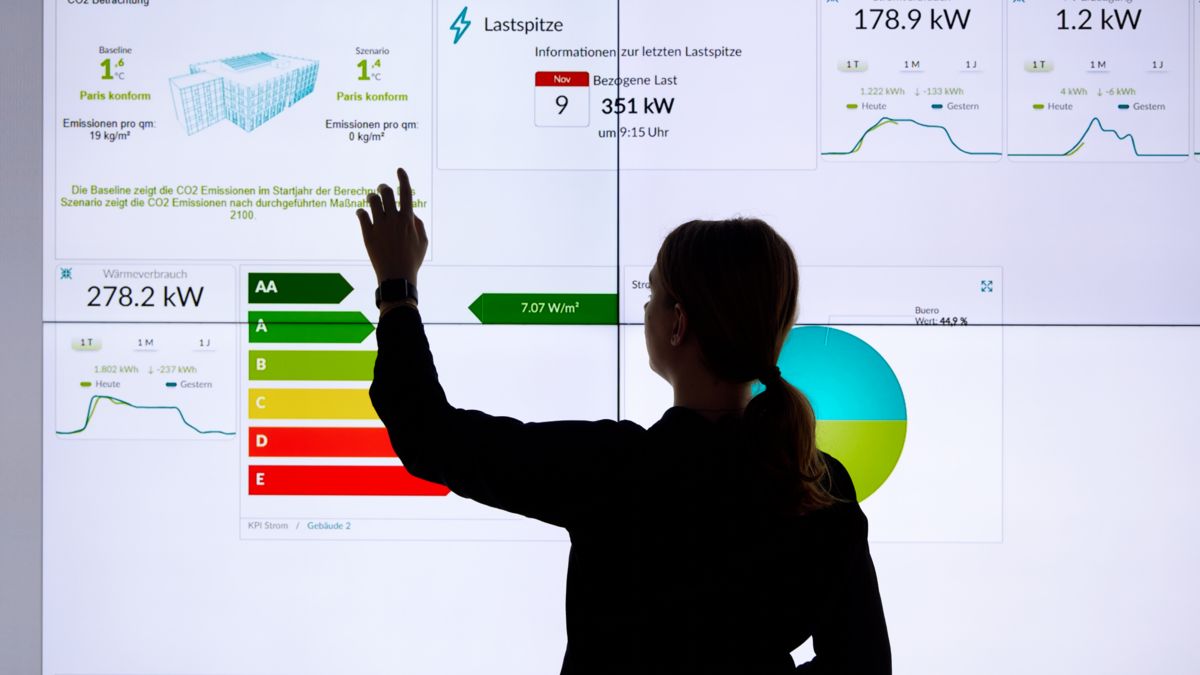

Efficient energy management and an optimum supply process have been achieved through the intelligent networking of power generation, energy consumption, and energy storage in combination with the heating and cooling circuit. The four office and production buildings at the site are supplied with energy via a ring concept, in which all generators, loads, and storage systems are interconnected.

Two combined heat and power plants cover around 60% of the auxiliary power consumption. The waste heat generated by these plants is used to heat and cool the buildings. The active load management uses a stored control strategy to ensure that peak loads are not exceeded. For this reason, the new building 4 does not need its own separate supply.

Nearly all ventilation systems are equipped with heat recovery. With an output of 160 KWp, the photovoltaic system on the roof is also actively integrated into the electrical power supply system. The aim is to use this renewable energy for the charging stations for electric cars, among other things.

Connecting the building services management system with active energy management

When it came time to realize the building technology, the Facility Management team decided to use components and systems from Phoenix Contact’s own product range. It is based on the Emalytics building management system, which connects the building services management system to the active energy management system. The higher-level system receives the field level data from 27 ILC 2050 BI controllers. The Niagara framework-based controller acts as a smart device that standardizes all the data from the trades and transfers it to the Emalytics building services management system.

Both the classic sensors and actuators as well as the new, intelligent IP-based field devices can be quickly and easily integrated into the system. Based on the recorded information, Emalytics facilitates the predictive maintenance of the installed devices. For example, unusual data can alert the operator to future faults. Emalytics analyzes the characteristic values of the spark plugs of the motors installed in the combined heat and power plant and, if necessary, recommends preventive replacement. This significantly increases the runtime of the combined heat and power plants.

Location-independent control and monitoring of properties

Furthermore, the ILC 2050 BI supports all established building technology standards such as BACnet IP, BACnet MS/TP, M-Bus, KNX/TP, SNMP, and oBIX. Corresponding modules in the Inline I/O portfolio can be used to connect common bus systems such as DALI, Modbus/TCP, and Modbus/RTU. The protocol-independent integration of the field devices into the ILC 2050 BI controller greatly simplifies the engineering and cabling work involved.

The building management system makes it possible to easily control and monitor the various properties from any location. Moreover, existing buildings can be easily integrated into the new system. This provides numerous benefits for the operator, who can now compare locations or set up a communication platform for all properties, for example. It is possible to improve the supply processes for all buildings based on the existing data, which results in more efficient management of the properties.

Your advantages

- Efficient energy management through the intelligent networking of power generation, energy consumption, and energy storage

- Location-independent control and monitoring of properties

- Optimized efficiency of supply processes

Contact

Products

Still haven’t found the right product?

Feel free to contact us. We will consult with you to find the ideal solution together.

Summary

Energy-efficient building operation

Rotermund Ingenieurgesellschaft mbH & Co. KG specializes in optimizing building operations, calculating lifecycle costs, and benchmarking the usage costs of buildings. The company carried out a competitive analysis for Phoenix Contact on the basis of a benchmark from a wide range of building types with a gross floor area of 85,000 m². The results demonstrated that the Bad Pyrmont site is at the lower end of the cost group. This was achieved through innovative concepts in the area of building infrastructure and technical and commercial building management, as well as efficient supply and disposal cost design.