PT 2,5-4L/2P-FS

-

Flange

3012312

Flange, width: 5.2 mm, height: 125 mm, color: gray

Product details

| Product type | Flange |

| Conductor cross-section flexible ultrasound-compressed | 0.34 mm² ... 4 mm² |

| Conductor cross-section, flexible [AWG] ultrasound-compressed | 22 ... 12 (converted acc. to IEC) |

| Width | 5.2 mm |

| End cover width | 2.2 mm |

| Height | 125 mm |

| Depth on NS 35/7,5 | 59 mm |

| Depth on NS 35/15 | 66.5 mm |

| Color | gray (RAL 7042) |

| Flammability rating according to UL 94 | V0 |

| Insulating material | PA |

| Static insulating material application in cold | -60 °C |

| Relative insulation material temperature index (Elec., UL 746 B) | 130 °C |

| Fire protection for rail vehicles (DIN EN 45545-2) R22 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R23 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R24 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R26 | HL 1 - HL 3 |

| Surface flammability NFPA 130 (ASTM E 162) | passed |

| Specific optical density of smoke NFPA 130 (ASTM E 662) | passed |

| Smoke gas toxicity NFPA 130 (SMP 800C) | passed |

| Surge voltage test | |

| Result | Test passed |

| Temperature-rise test | |

| Requirement temperature-rise test | Increase in temperature ≤ 45 K |

| Result | Test passed |

| Short-time withstand current 2.5 mm² | 0.3 kA |

| Result | Test passed |

| Power-frequency withstand voltage | |

| Test voltage setpoint | 1.89 kV |

| Result | Test passed |

| Mechanical strength | |

| Result | Test passed |

| Attachment on the carrier | |

| Result | Test passed |

| Test for conductor damage and slackening | |

| Rotation speed | 10 rpm |

| Revolutions | 135 |

| Conductor cross-section/weight | 0.14 mm² / 0.2 kg |

| 2.5 mm² / 0.7 kg | |

| 4 mm² / 0.9 kg | |

| Result | Test passed |

| Aging | |

| Temperature cycles | 192 |

| Result | Test passed |

| Needle-flame test | |

| Time of exposure | 30 s |

| Result | Test passed |

| Oscillation/broadband noise | |

| Specification | DIN EN 50155 (VDE 0115-200):2022-06 |

| Spectrum | Long life test category 1, class B, body mounted |

| Frequency | f1 = 5 Hz to f2 = 150 Hz |

| ASD level | 0.964 (m/s²)²/Hz |

| Acceleration | 0.58g |

| Test duration per axis | 5 h |

| Test directions | X-, Y- and Z-axis |

| Result | Test passed |

| Shocks | |

| Specification | DIN EN 50155 (VDE 0115-200):2022-06 |

| Pulse shape | Half-sine |

| Acceleration | 5g |

| Shock duration | 30 ms |

| Number of shocks per direction | 3 |

| Test directions | X-, Y- and Z-axis (pos. and neg.) |

| Result | Test passed |

| Ambient conditions | |

| Ambient temperature (operation) | -60 °C ... 105 °C (max. short-term operating temperature RTI Elec.) |

| Ambient temperature (storage/transport) | -25 °C ... 60 °C (for a short time, not exceeding 24 h, -60 °C to +70 °C) |

| Ambient temperature (assembly) | -5 °C ... 70 °C |

| Ambient temperature (actuation) | -5 °C ... 70 °C |

| Permissible humidity (storage/transport) | 30 % ... 70 % |

| Item number | 3012312 |

| Packing unit | 10 pc |

| Minimum order quantity | 10 pc |

| Sales key | BE224Z |

| Product key | BE224Z |

| GTIN | 4046356645959 |

| Weight per piece (including packing) | 13,5 g |

| Weight per piece (excluding packing) | 13,2 g |

| Customs tariff number | 85389099 |

| Country of origin | PL |

ECLASS

| ECLASS-13.0 | 27250302 |

| ECLASS-15.0 | 27250302 |

ETIM

| ETIM 9.0 | EC001041 |

UNSPSC

| UNSPSC 21.0 | 39121400 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes (No exemptions) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-E

No hazardous substances above the limits

|

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | No substance above 0.1 wt% |

Compatible products

Note: Applying some accessories below might limit this product.

-

-

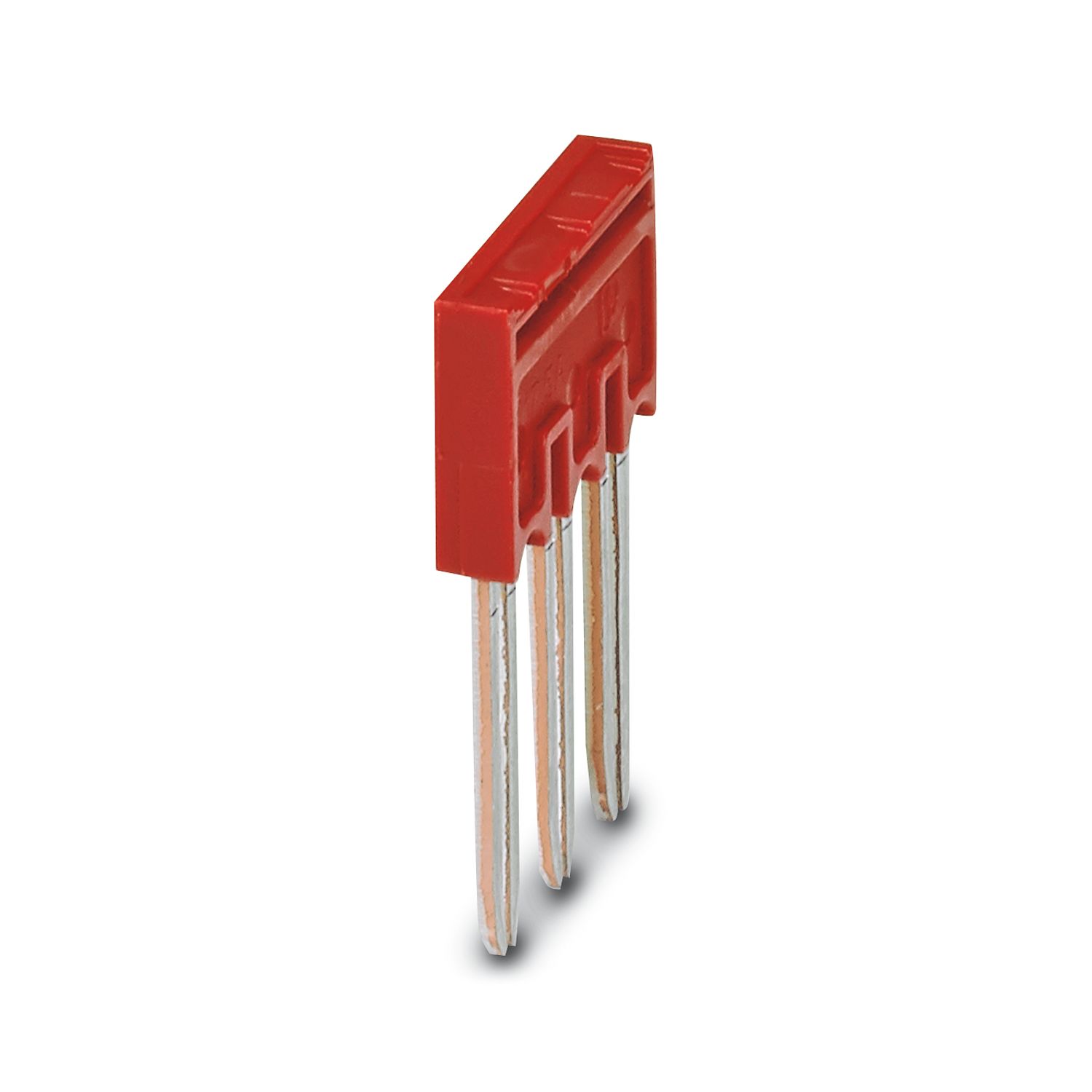

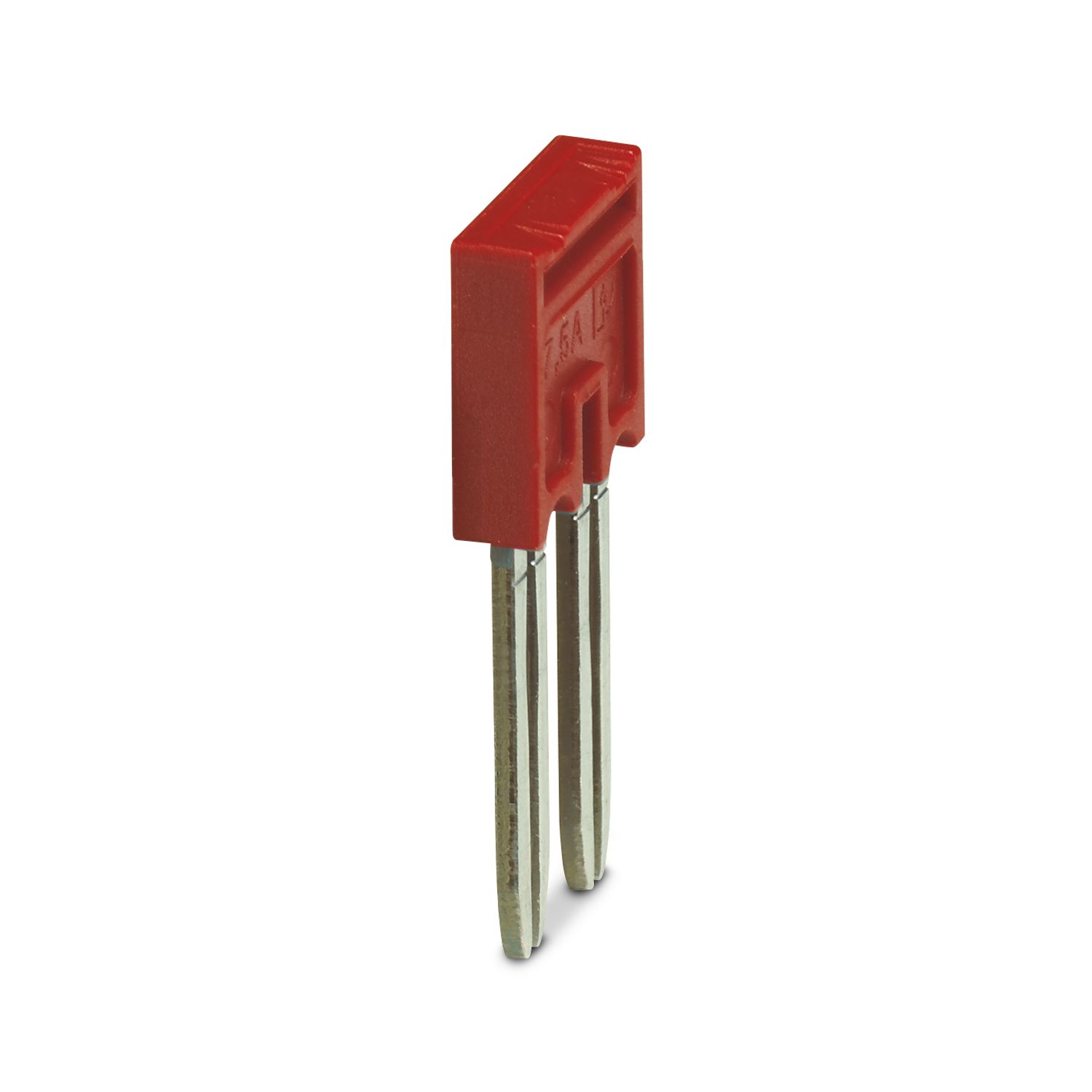

FBSR 3-5 - Plug-in bridge 3001591

-

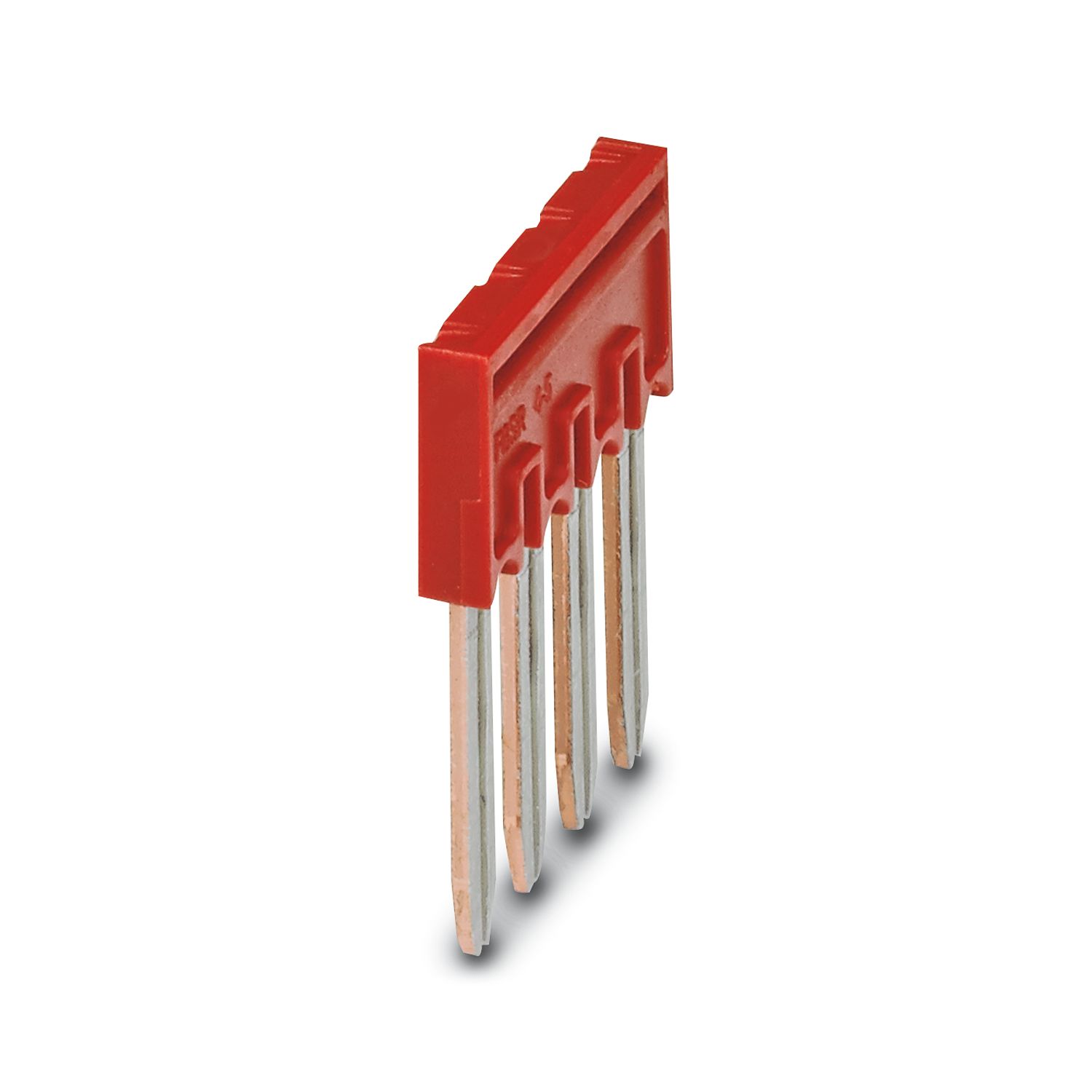

FBSR 4-5 - Plug-in bridge 3001592

-

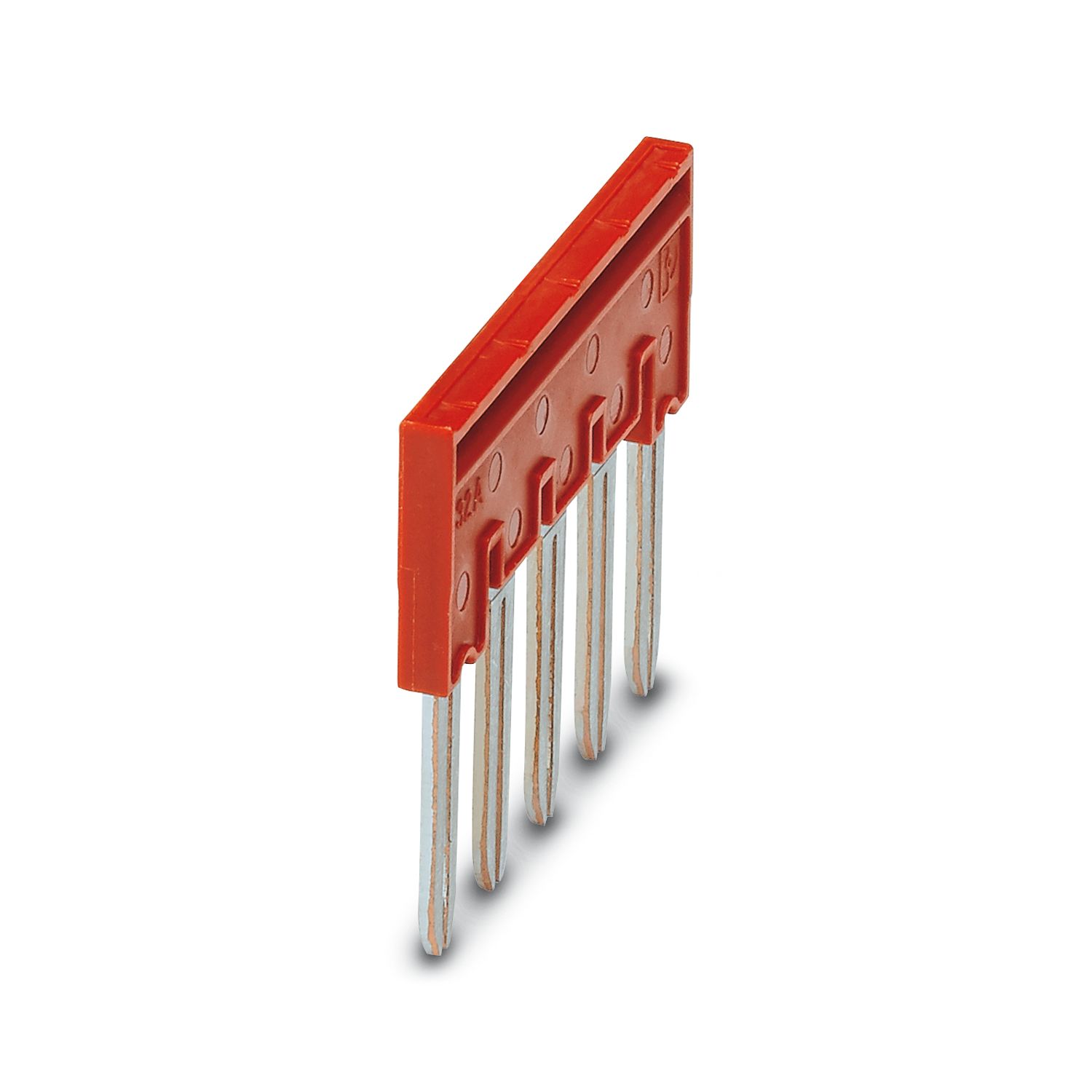

FBSR 5-5 - Plug-in bridge 3001593

-

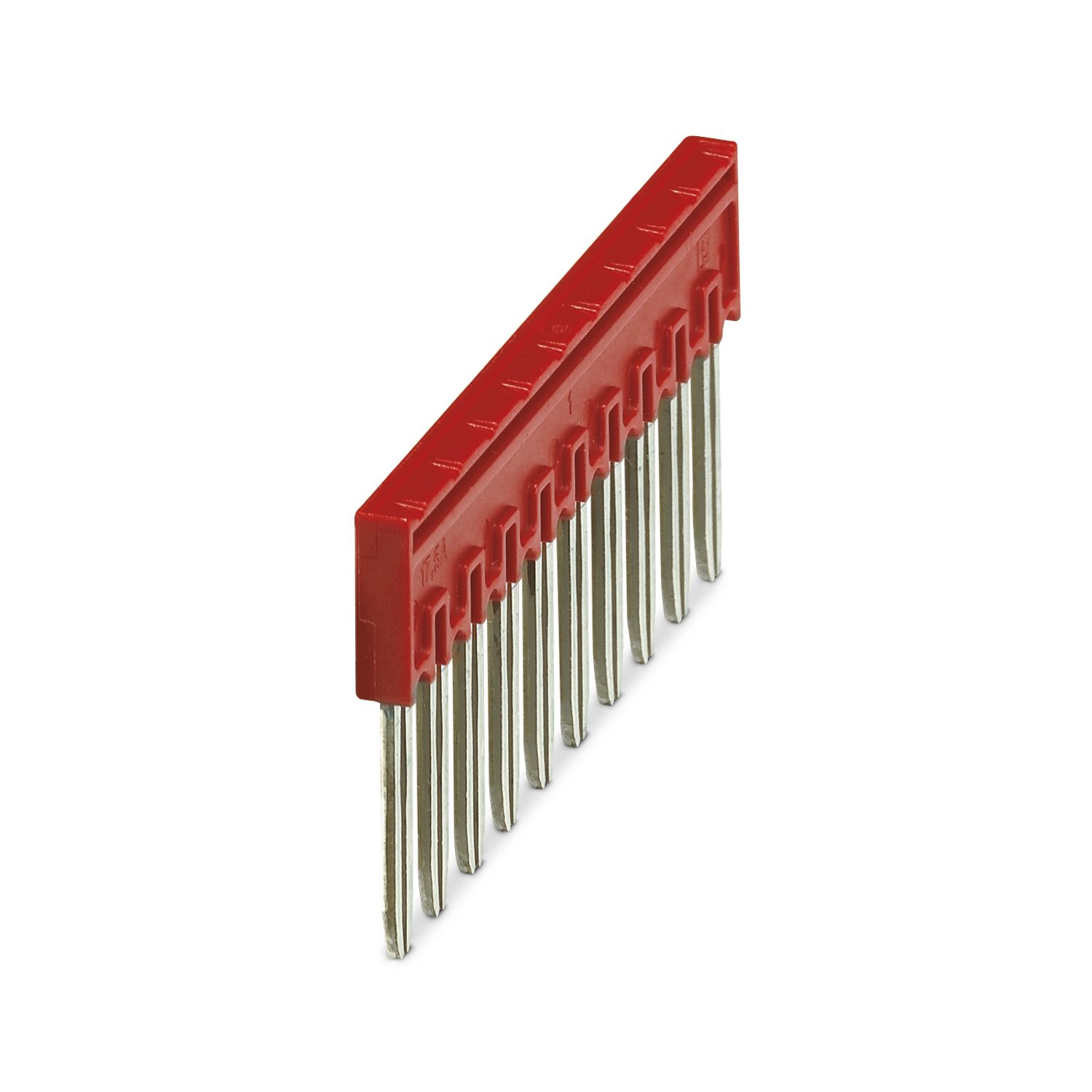

FBSR 10-5 - Plug-in bridge 3033710

-

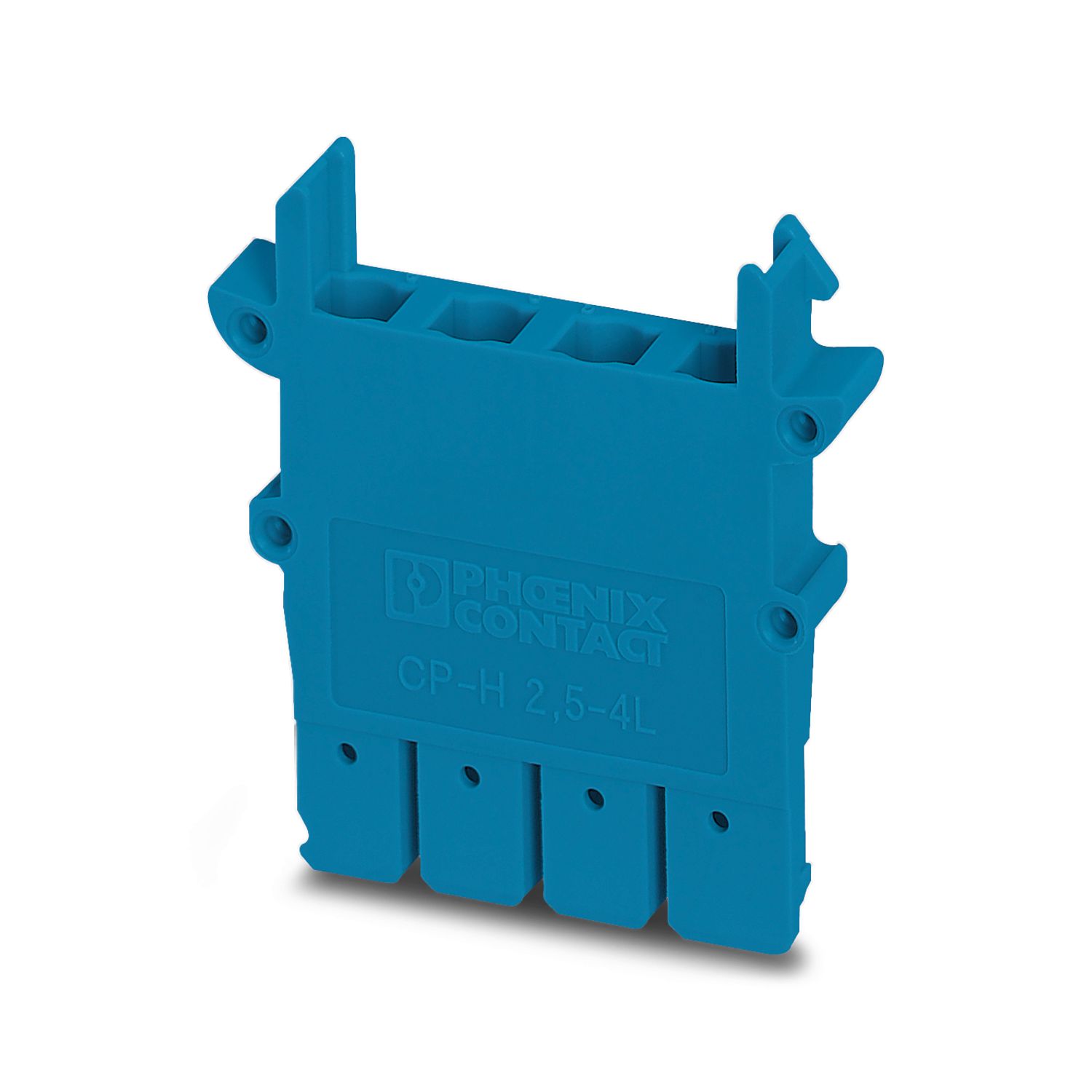

CP-H 2,5-4L BU - Connector housing 3012322

-

AP-CP-H CM - Cover profile 3000801

-

AP-CP-H METER - Cover profile 3012315

-

CEC 2,5 - Filler plug 3062757

-

WS PT 2,5 - Warning label 1029026

-

WS-DIO PT 2,5 - Warning label 1029037

-

DFS-CP-H 2,5-4L - Flange cover 3012317

-

DFS-CP 2,5-4L - Flange cover 3012321

-

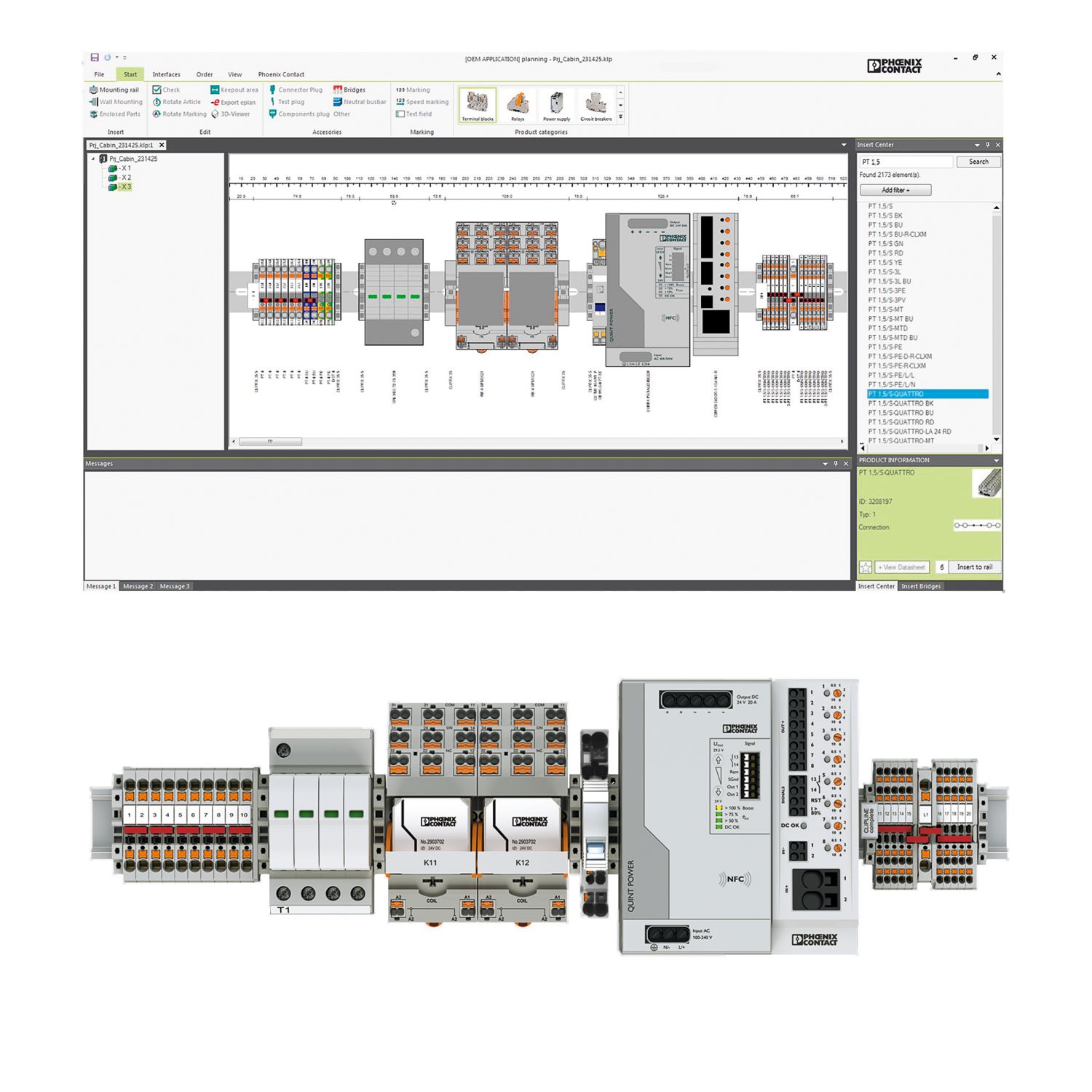

PROJECT COMPLETE - Software 1050453

Your advantages

In addition to the testing option in the double function shaft, all terminal blocks provide an additional test pick-off

The compact design and front connection enable wiring in a confined space

The Push-in connection terminal blocks are characterized by the system features of the CLIPLINE complete system and by easy and tool-free wiring of conductors with ferrules or solid conductors

PHOENIX CONTACT nv/sa

Minervastraat 10-12, 1930 Zaventem