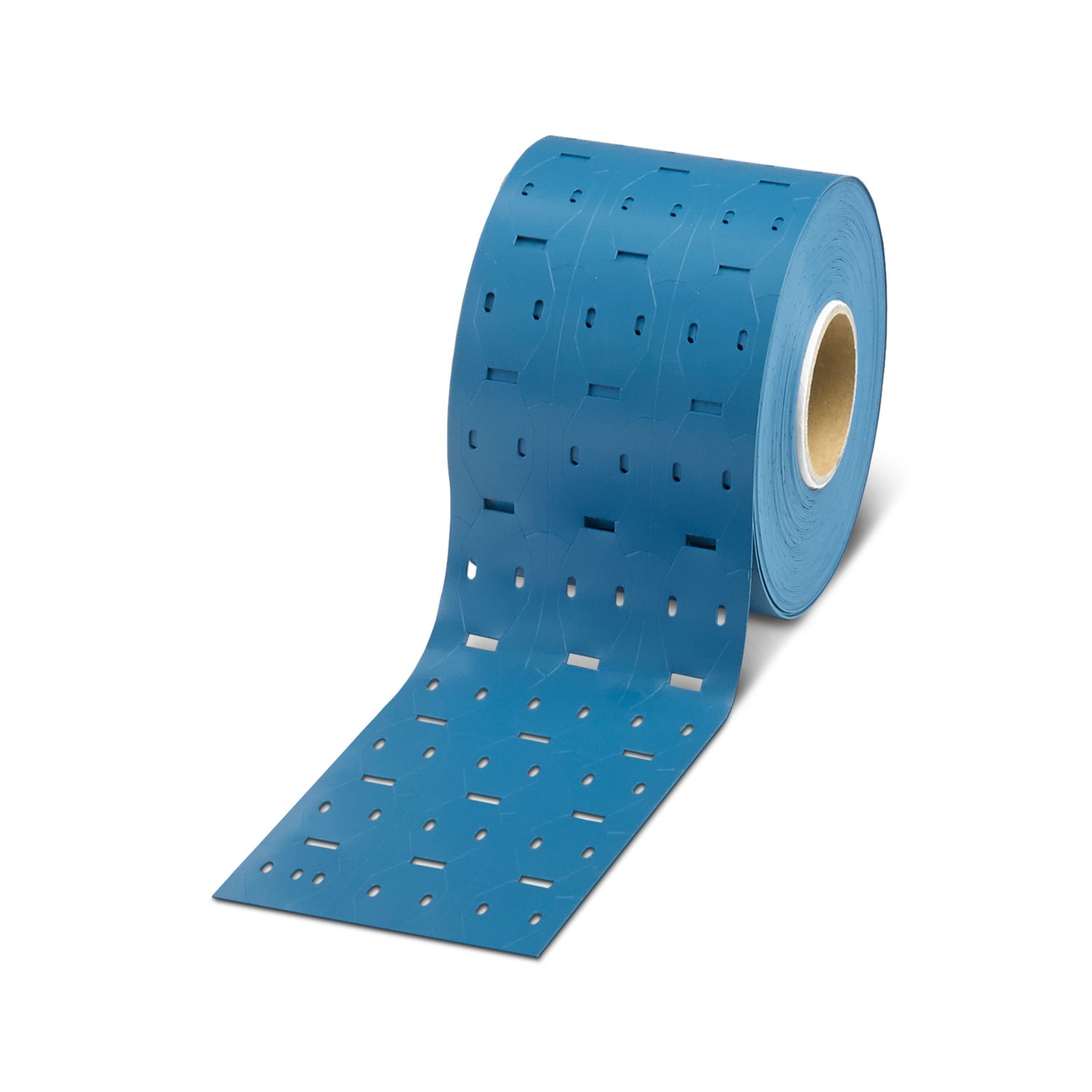

WMTB HF-D (30X10)R BU

-

Detectable cable markers

1255591

Detectable cable markers, Roll, blue, unlabeled, can be labeled with: THERMOMARK E.300 (D)/600 (D), THERMOMARK ROLL 2.0, THERMOMARK ROLL, THERMOMARK ROLL X1, THERMOMARK ROLLMASTER 300/600, mounting type: Assembly with cable ties, cable diameter: ≥ 6 mm, Number of individual labels: 1000, text field height: 10 mm, text field width: 30 mm

Product details

| General | Due to the differing detection properties of metal detectors, the installer/end user must check suitability for the actual application |

| Note on application | The composition of the WMTB HF-D (...x..)R BU complies with the Code of Federal Regulations, Food and Drugs (FDA), 21 CFR CH 1. Based on the provided sample material, the WMTB HF-D rating plates can therefore safely be used for the identification of food processing machines. Direct contact of the products with the food is not intended. |

| Note on application | In accordance with Regulation (EU) No. 10/2011, the WMTB HF-D (…x…)R BU rating plates can be safely used for the identification of food processing machines. |

| Product type | Conductor marking |

| Area of application | Food and beverage industry |

| Type | Roll |

| Product property | detectable |

| Marking | |

| Number of individual labels | 1000 |

| Number of individual labels per row | 3 |

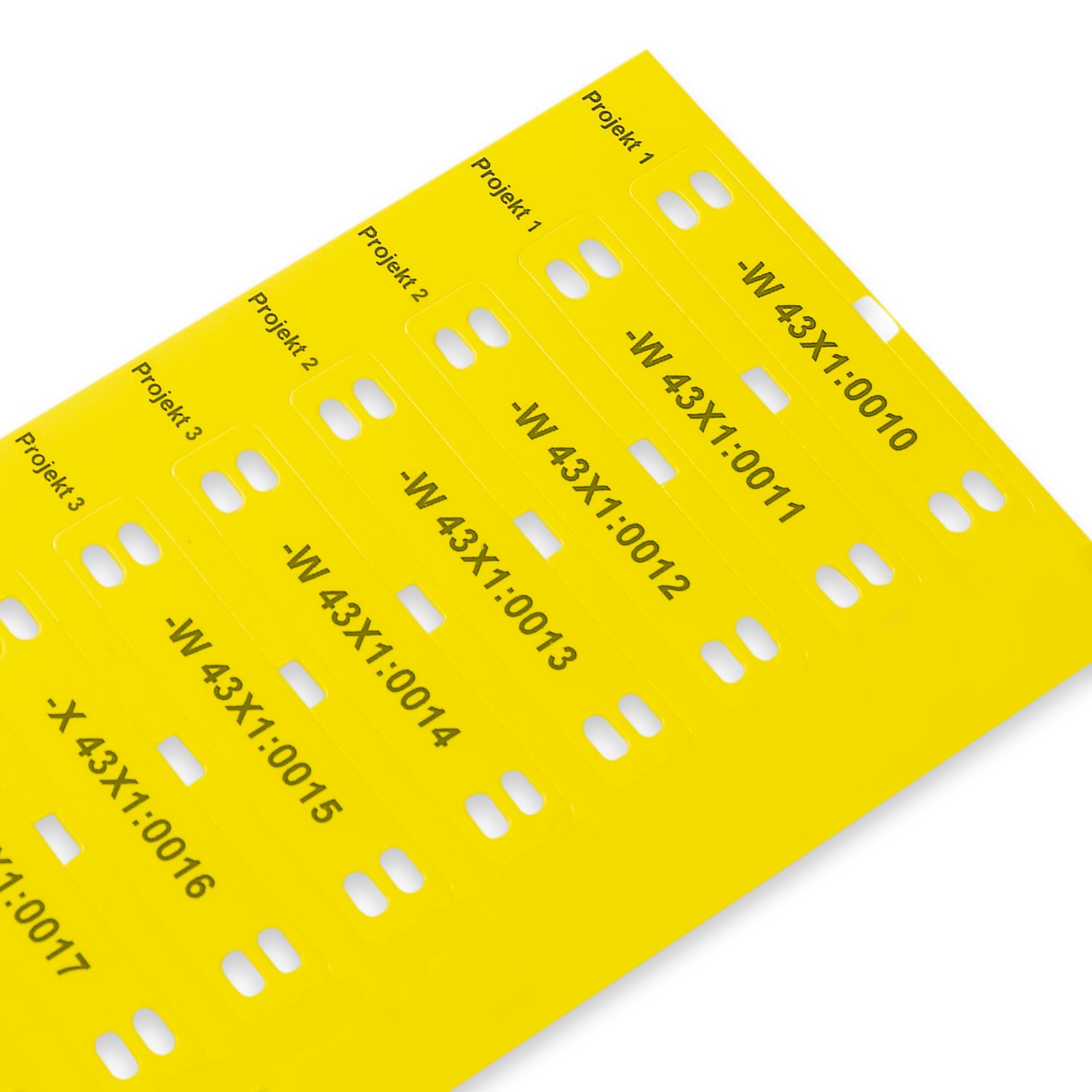

| Identification technology | Thermal transfer for rolls |

| Width | 10 mm |

| Length | 30 mm |

| Text field | |

| Text field width | 30 mm |

| Text field height | 10 mm |

| RoHS compliant | yes |

| Color | blue (RAL 5015) |

| Material | TPU |

| Flammability rating according to UL 94 | HB |

| Components | halogen-free |

| External cable diameter | ≥ 6.00 mm |

| Test for substances that would hinder coating with paint or varnish | |

| Result | Test passed |

| Test for substances that would hinder coating with paint or varnish | |

| Result | Test passed |

| Scratch test for the determining scratch resistance | |

| Specification | DIN EN ISO 1518-1:2019-10 (following) |

| Requirements | ≥ 5 N |

| Result | Test passed |

| Tesafilm test | |

| Specification | DIN EN ISO 2409:2013 (following) |

| Result | Test passed |

| UV resistance | |

| Specification | ISO 4892-2:2013-03 (following) |

| Result | Test passed |

| Test duration | 96 h |

| Specification | DIN EN 60068-2-2:2008-05 (following) |

| Result | Test passed |

| Procedure | Test Bb |

| Duration | 96 h |

| Temperature for testing | 105 °C |

| Temperature resistance | |

| Specification | ANSI/UL 969-2018:03 (following) |

| Test duration | 240 h |

| Rating 125 °C (150 °C) | Test passed |

| Wipe resistance of inscriptions | |

| Specification | DIN EN 61010-1 (VDE 0411-01):2020-03 |

| DIN EN 62208 (VDE 0660-511):2012-06 (in parts) | |

| Isopropyl [CAS No. 67-63-0] |

Test passed |

| n-Hexane [CAS No. 110-54-3] |

Test passed |

| Water + Petroleum ether [CAS No. 64742-82-1] |

Test passed |

| Sodium hydroxide 0.1 mol/l [CAS No. 1310-73-2] |

Test passed |

| Ethanol (99 %) [CAS No. 64-17-5] |

Test passed |

| Acetone (99 %) [CAS No. 67-64-1] |

Test passed |

| Specification | ISO 175:2010 (following) |

| Test duration | 168 h |

| Sodium hydroxide 0.1 mol/l [CAS No. 1310-73-2] |

Test passed |

| Ethanol (99 %) [CAS No. 64-17-5] |

Test passed |

| Diesel [CAS No. 68476-34-6] |

Test passed |

| IRM 901 | Test passed |

| IRM 902 | Test passed |

| Testing in a condensation changing climate in the presence of sulfur dioxide | |

| Specification | DIN 50018:2013-05 |

| Result | Test passed |

| Climate level | AHT 1.0 S |

| Cycles | 2 |

| Salt spray test | |

| Specification | DIN EN 60068-2-11:2000-02 |

| Result | Test passed |

| Test duration | 96 h |

| Ambient conditions | |

| Ambient temperature (operation) | -25 °C ... 105 °C |

| Recommended ambient temperature (storage/transport) | 23 °C |

| Recommended humidity (storage/transport) | 50 % (Storage in a dry and dark place in the original packaging is recommended) |

| Wipe resistance | DIN EN 61010-1 (VDE 0411-1) |

| Mounting type | Assembly with cable ties |

| Item number | 1255591 |

| Packing unit | 1 pc |

| Minimum order quantity | 1 pc |

| Sales key | BG2311 |

| Product key | BG2311 |

| GTIN | 4063151363307 |

| Weight per piece (including packing) | 890,4 g |

| Weight per piece (excluding packing) | 22,22 g |

| Customs tariff number | 39204910 |

| Country of origin | DK |

ECLASS

| ECLASS-13.0 | 27281102 |

ETIM

| ETIM 9.0 | EC001530 |

UNSPSC

| UNSPSC 21.0 | 39131500 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes (No exemptions) |

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | No substance above 0.1 wt% |

Compatible products

-

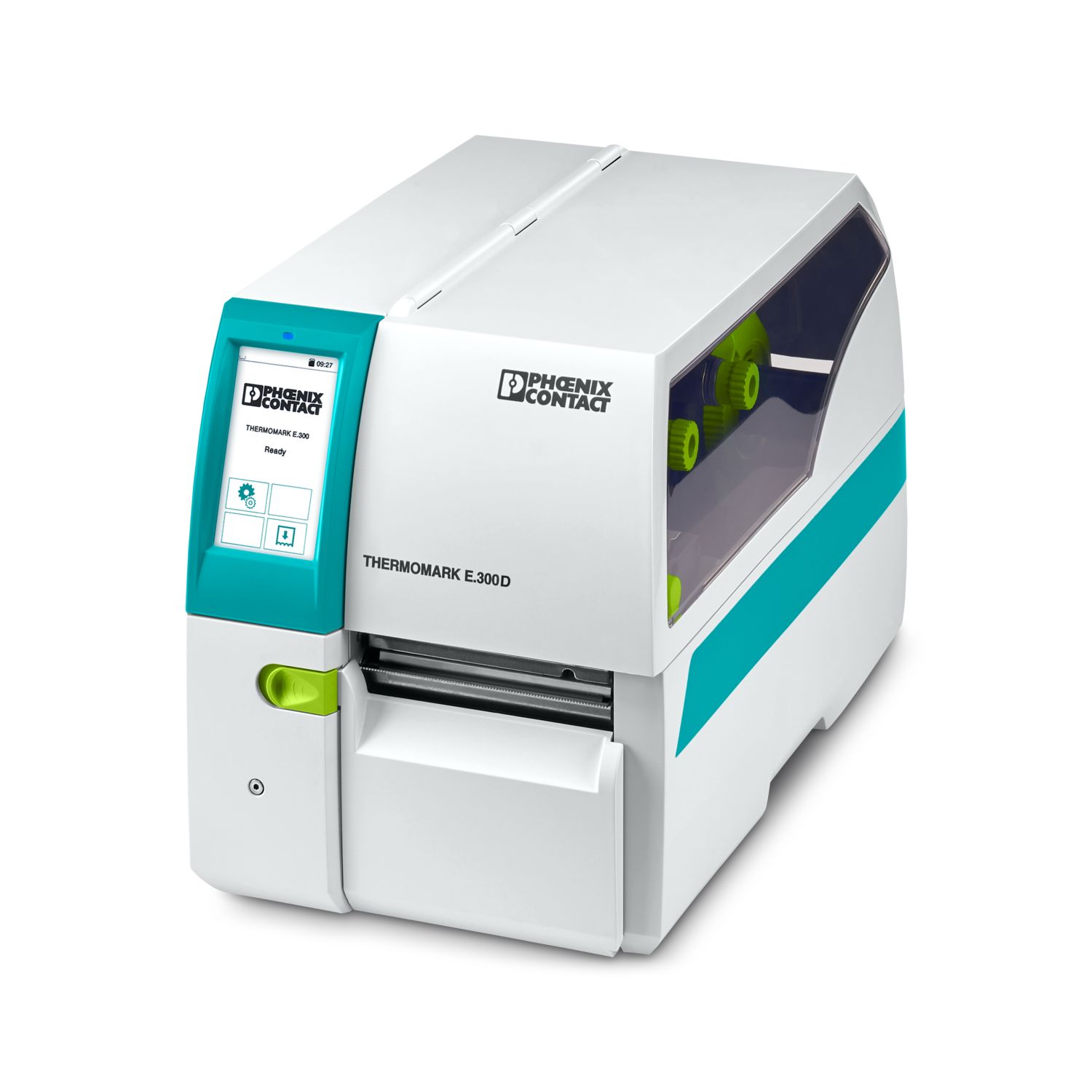

THERMOMARK E.300 - Thermal transfer printer 1285306

-

THERMOMARK E.300 D - Thermal transfer printer 1004303

-

THERMOMARK E.600 - Thermal transfer printer 1285310

-

THERMOMARK E.600 D - Thermal transfer printer 1004304

-

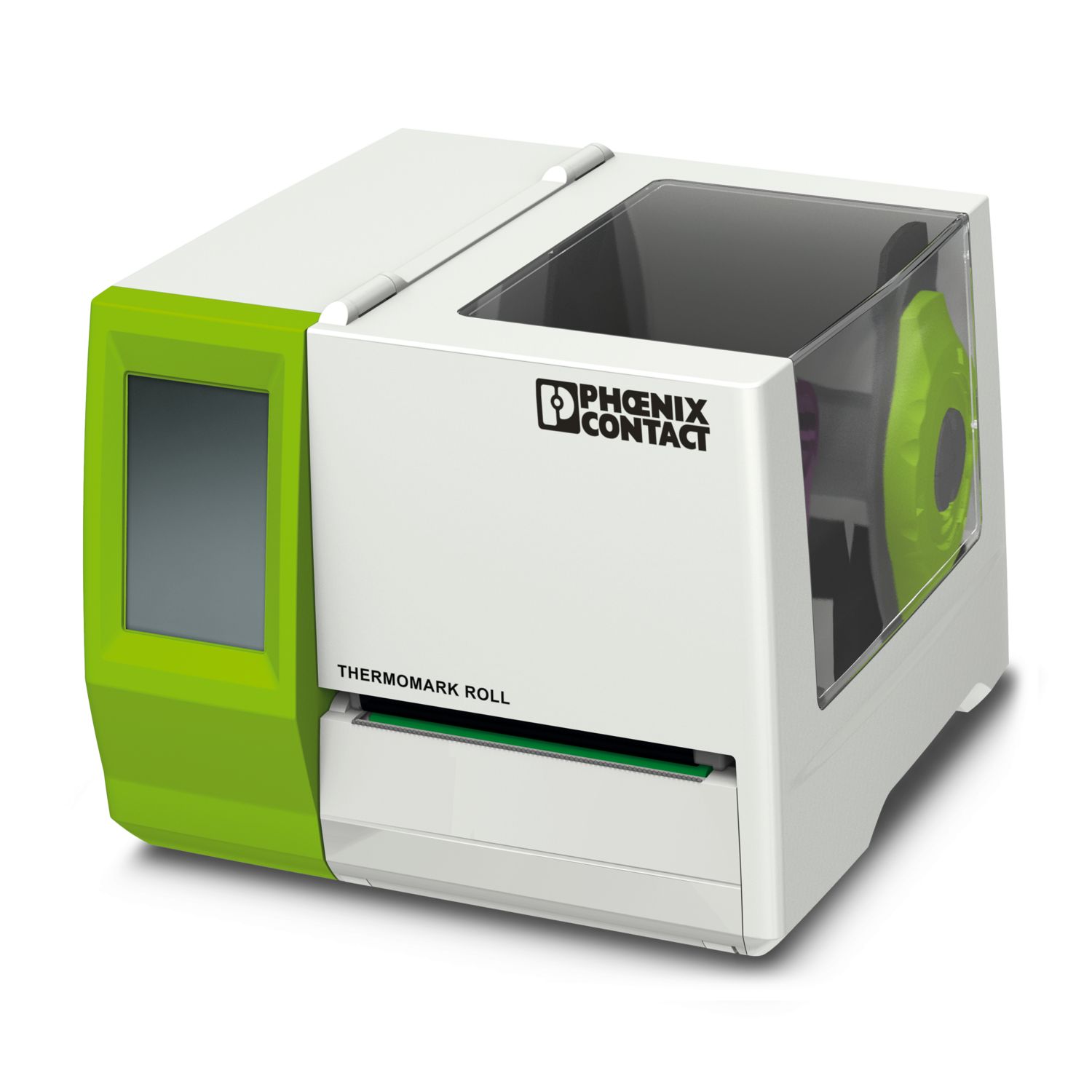

THERMOMARK ROLL 2.0 - Thermal transfer printer 1085260

-

THERMOMARK E.300 DOUBLE - Thermal transfer printer 1472379

-

TM-RIBBON 105 BK 106 - Ink ribbon 1255597

-

WT-ID HF 2,5X98 BU - Cable tie 3240794

-

WT-ID HF 3,5X140 BU - Cable tie 3240795

-

WT-ID HF 3,5X200 BU - Cable tie 3240796

-

WT-ID HF 4,5X200 BU - Cable tie 3240797

-

WT-ID HF 4,5X290 BU - Cable tie 3240798

-

WT-ID HF 7,5X365 BU - Cable tie 3240800

-

THERMOMARK ROLLMASTER 300 - Thermal transfer printer 0804501

-

THERMOMARK ROLLMASTER 600 - Thermal transfer printer 0804663

-

THERMOMARK ROLL - Thermal transfer printer 5146477

Your advantages

WMTB HF-D … detectable cable marker for identification of various cables and wires in controller, system, and control cabinet building in the food industry

The halogen-free wire and cable markers can be detected inductively

When combined with the TM-RIBBON 105 BK 106 ink ribbon, the printing is highly resistant to solvents, aggressive cleaning agents, acetone, and ethanol

The highly flexible material adapts to the conductors and cables

The material used has been tested and approved by ISEGA for use in the food industry

Frequently searched

PHOENIX CONTACT nv/sa

Minervastraat 10-12, 1930 Zaventem