-

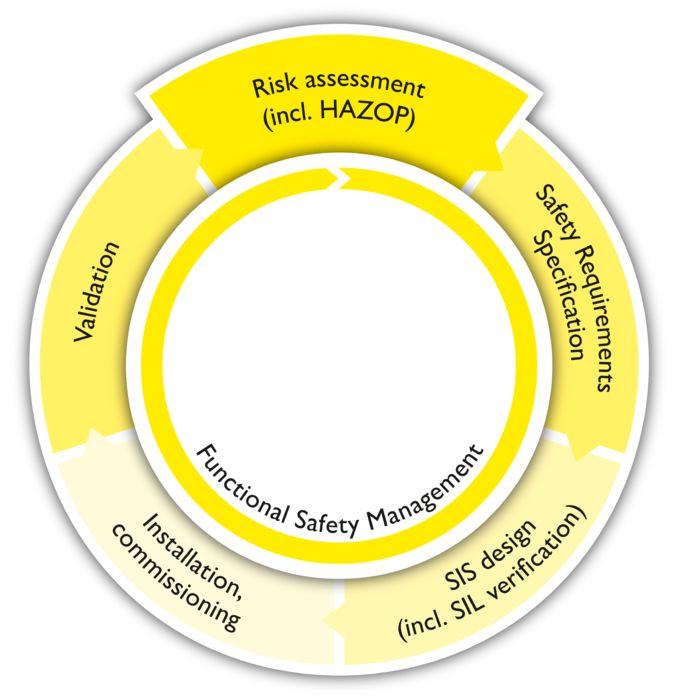

Safety planning

Planning of the activities that are required for achieving functional safety (FS) of the system, including verification and validation. -

Risk assessment

Systematic identification and evaluation of all risks and establishment of measures to be taken for adequate risk reduction. -

Assigning protection layers

Assigning the planned measures to individual protection levels and establishing the required SIL for safety functions. -

Functional safety management

Establishing a management system for controlling the safety lifecycle and for resource planning. -

Evaluating functional safety

Recurring assessment of whether the safety planning and functional safety management were applied correctly.