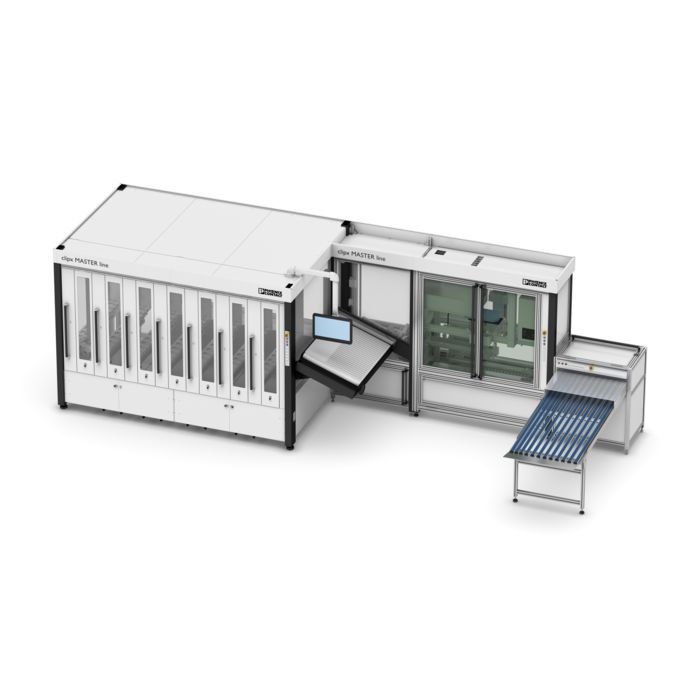

Fully automated production of terminal strips with the clipx MASTER line

Maximum efficiency through fully automated assembly and marking

Optimize your production processes in control cabinet building with our clipx MASTER line for the fully automated production of terminal strips, including marking. Following the fully automated assembly of the DIN rails, the entire terminal strip is then laser marked without interrupting the process. The information required for production is issued directly from the engineering process. With these features, the clipx MASTER line contributes significantly to the process optimization and implementation of automated production processes in control cabinet building.

Your advantages

- Increased efficiency and productivity through fully automated production without process interruptions

- Minimized errors through data transfer from engineering

- Significant time savings during marking by using terminal blocks with integrated markers

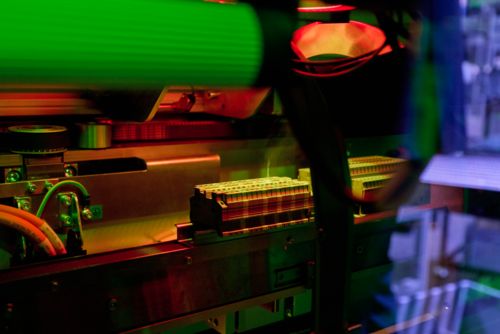

- High marking quality and precision due to laser marking

Your automation solution for efficient terminal strip production

The comprehensive clipx MASTER line production process includes component mounting and the subsequent marking. Key advantages of our system include the fully automated transport between the individual work steps and the parallel execution of mounting and marking processes, which reduces production times to a minimum. Using Phoenix Contact terminal blocks from the CLXM and CLM product families with integrated markers and setup-optimized packaging can increase efficiency during mounting and marking.

The clipx MASTER line helps to make processes in terminal strip production more efficient and cost-effective, and also helps to significantly reduce manual intervention.

Our clipx MASTER line in detail

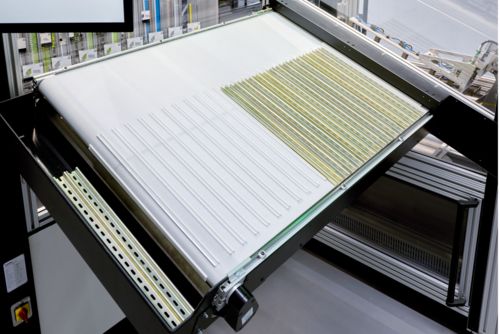

Range for automated production

Our terminal blocks from the CLXM and CLM product families with integrated markers are ideally suited to automated terminal strip production. With setup-optimized packaging, filling and refilling processes are completed quickly.

The use of terminal blocks with markers already attached saves a great deal of time. Manual tasks including as separating out, assigning, and snapping on individual markers during the marking process are no longer necessary.