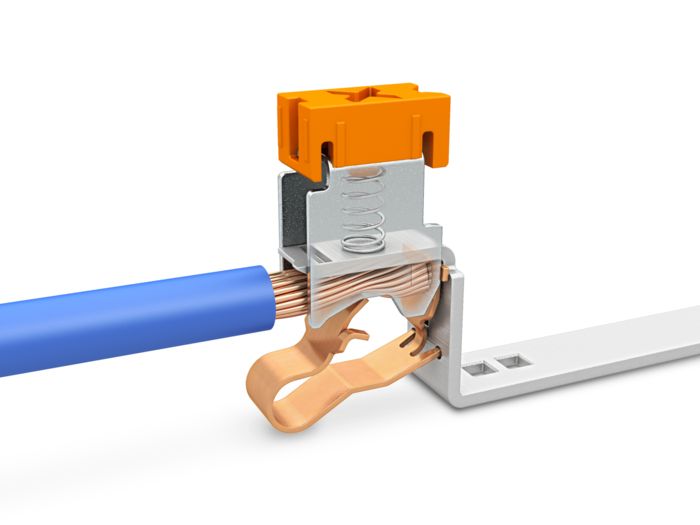

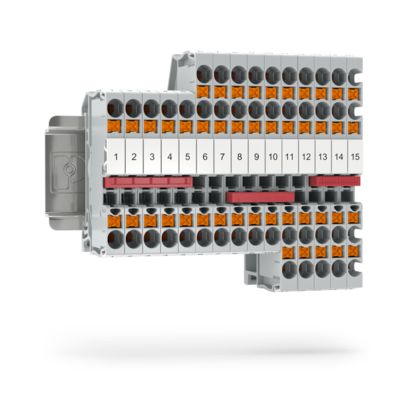

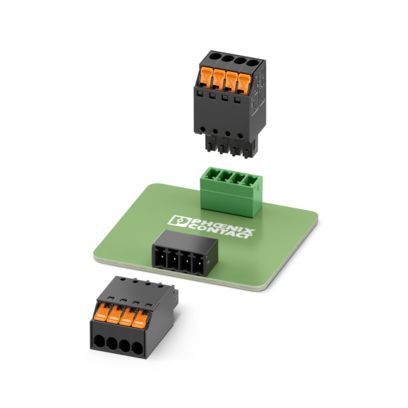

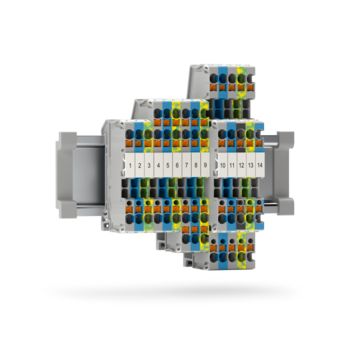

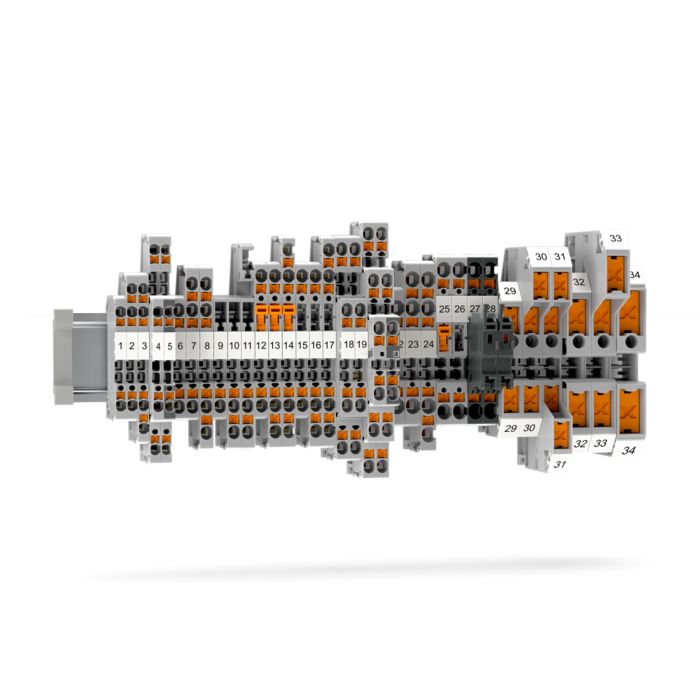

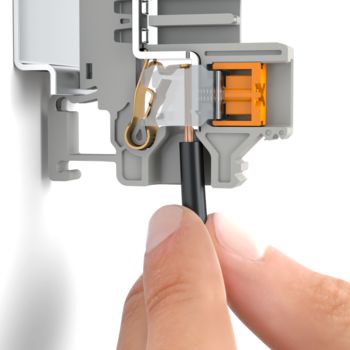

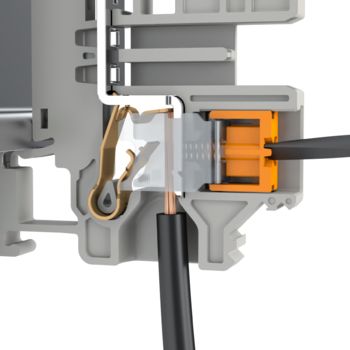

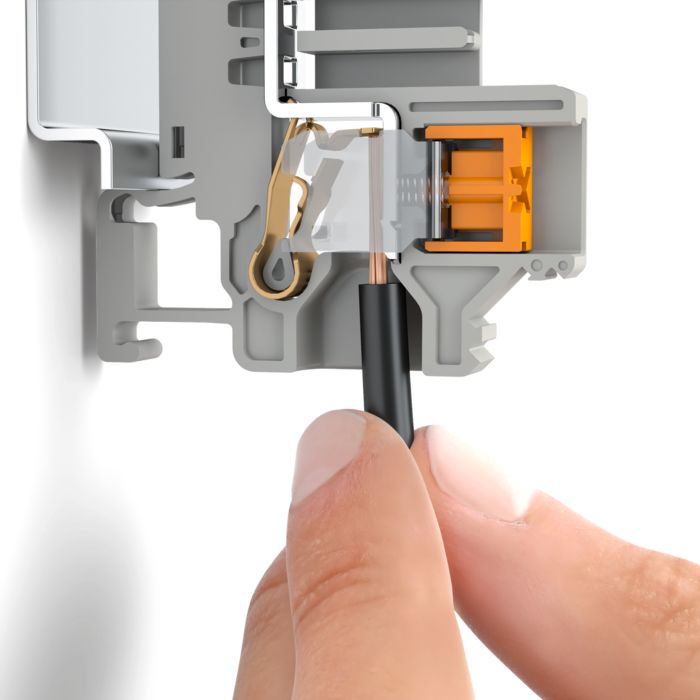

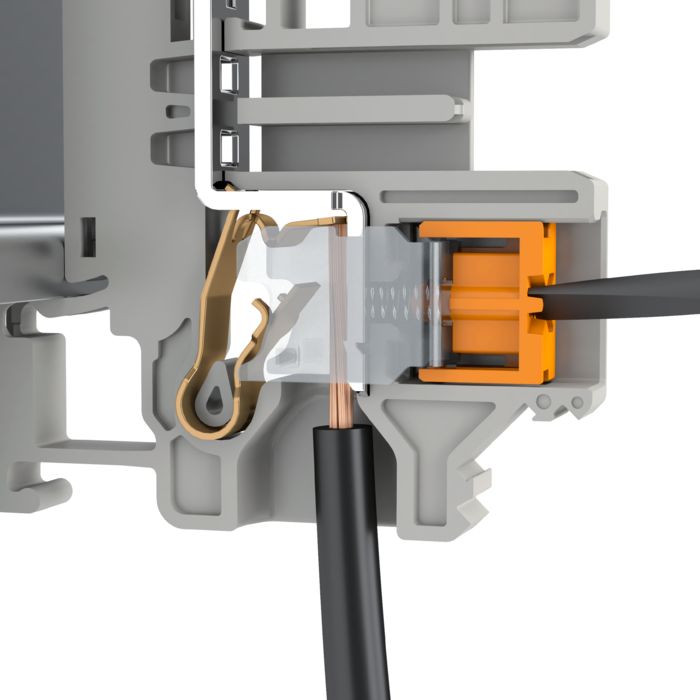

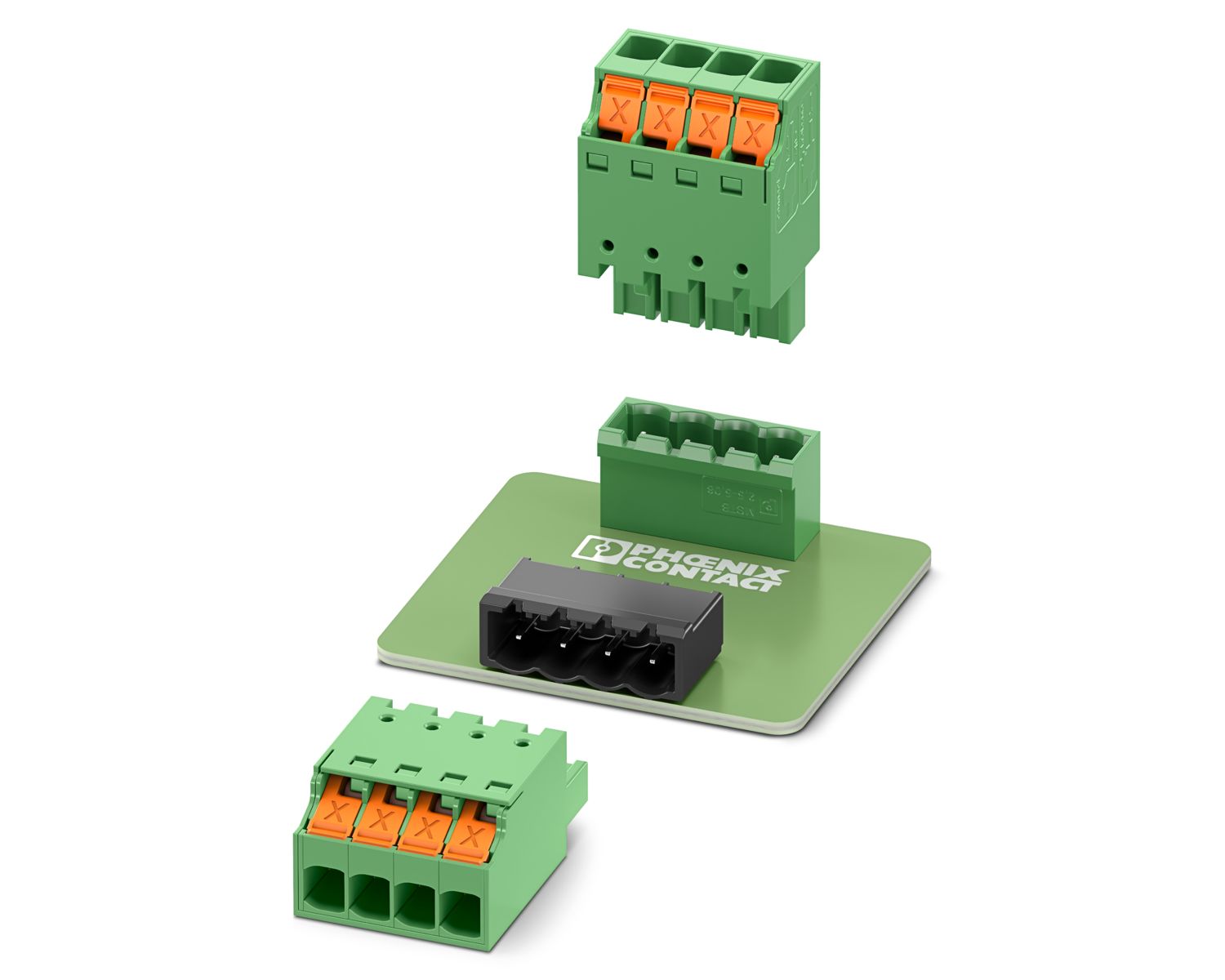

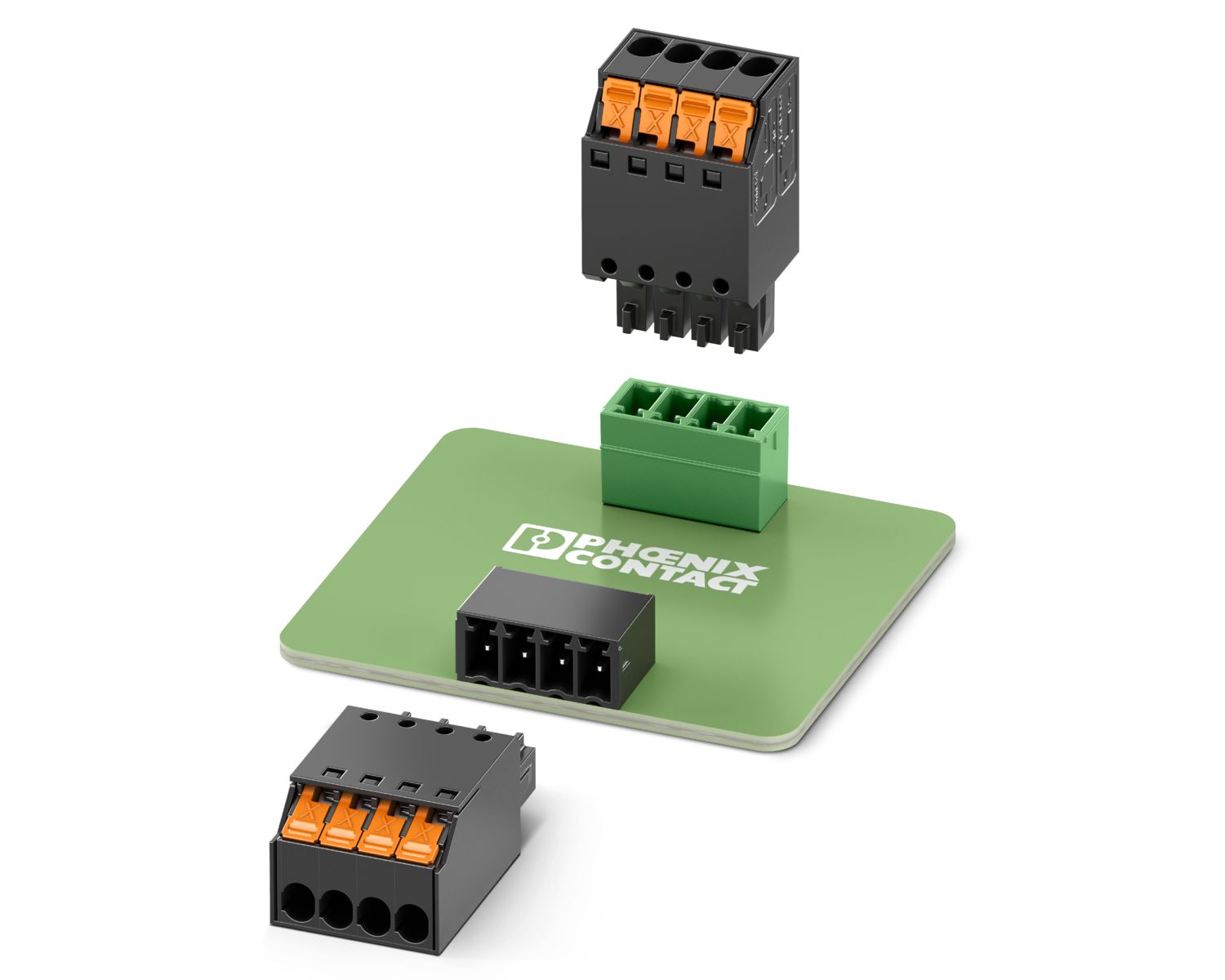

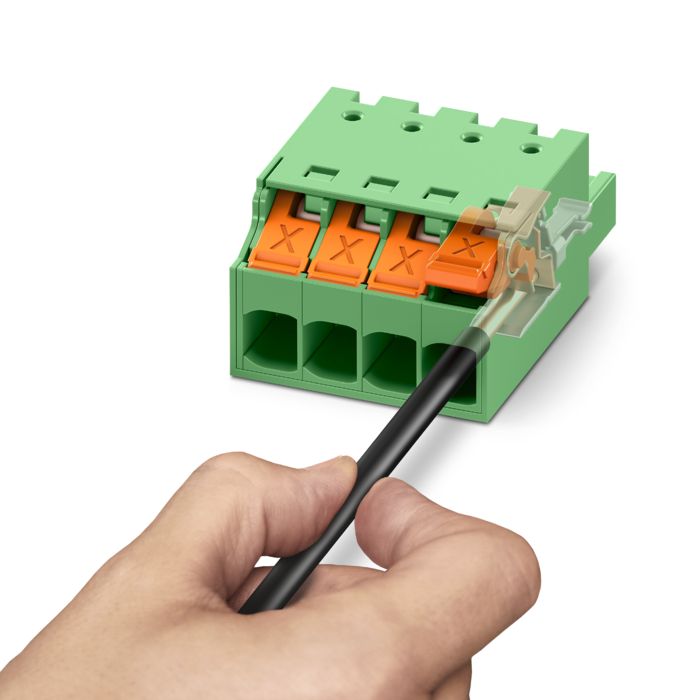

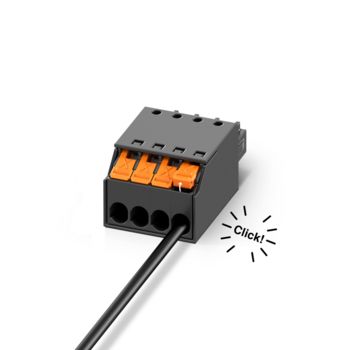

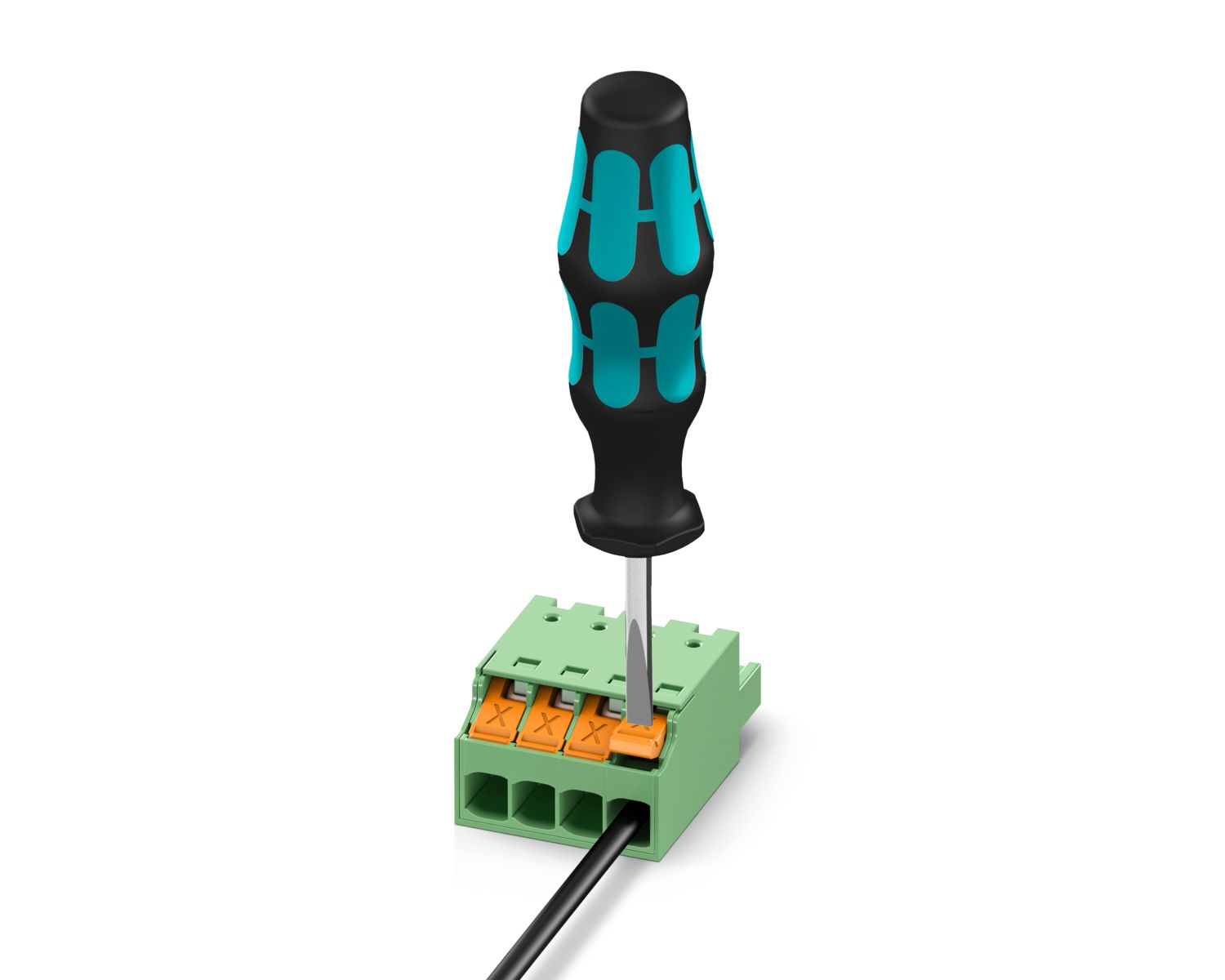

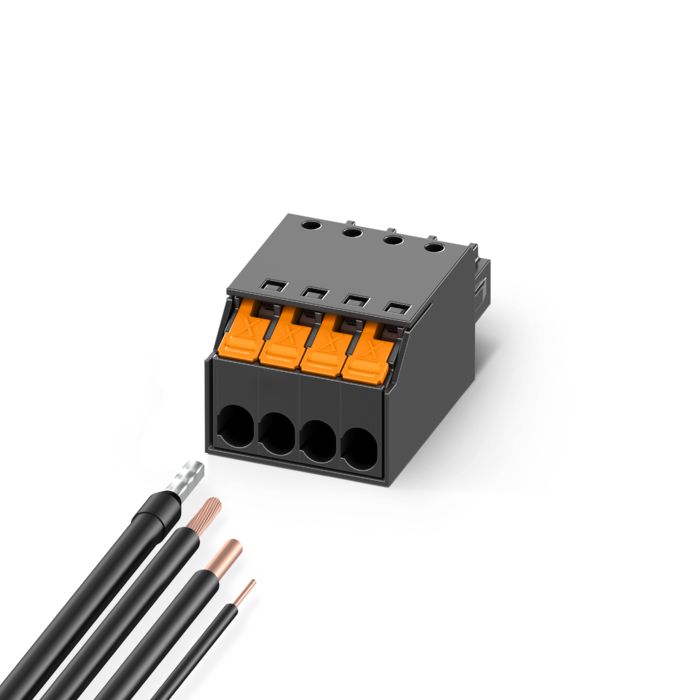

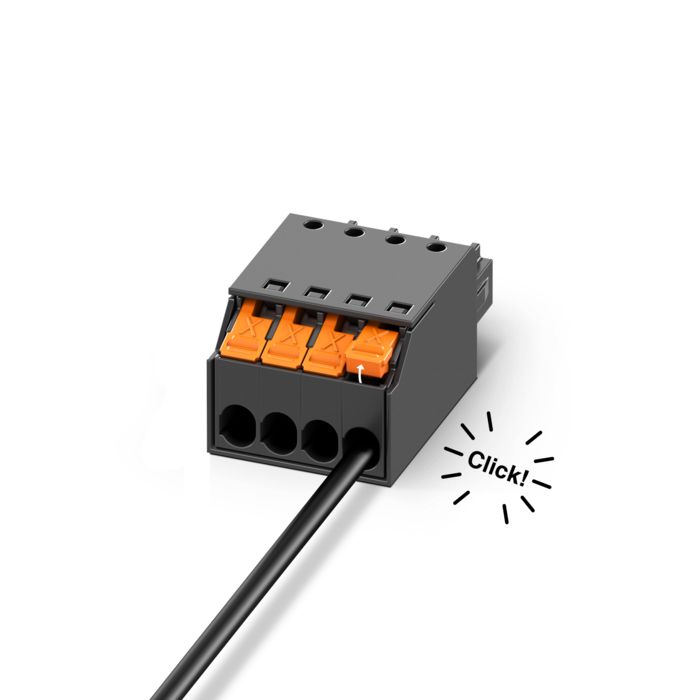

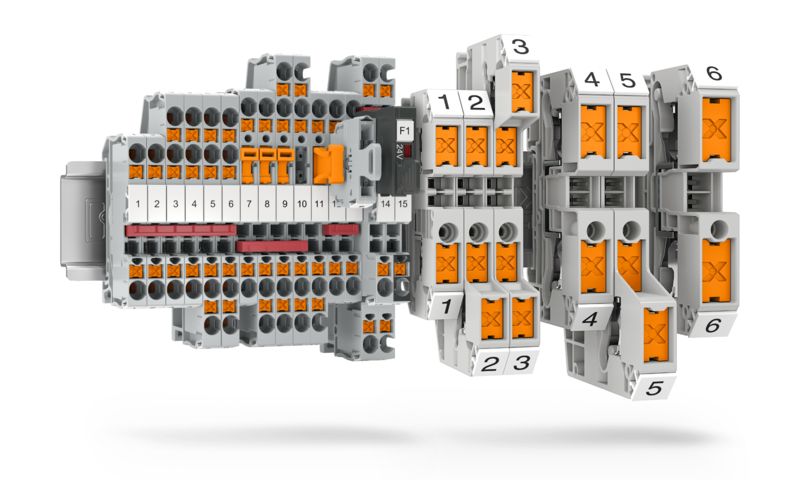

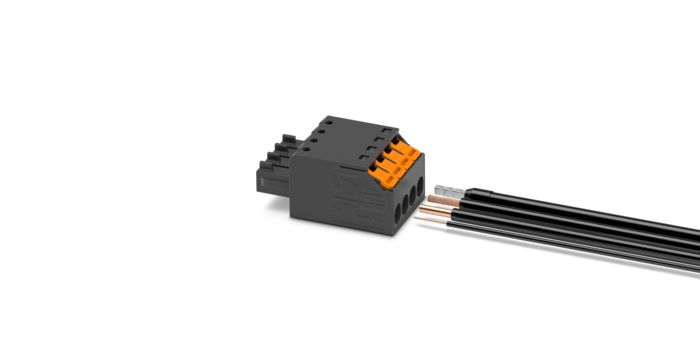

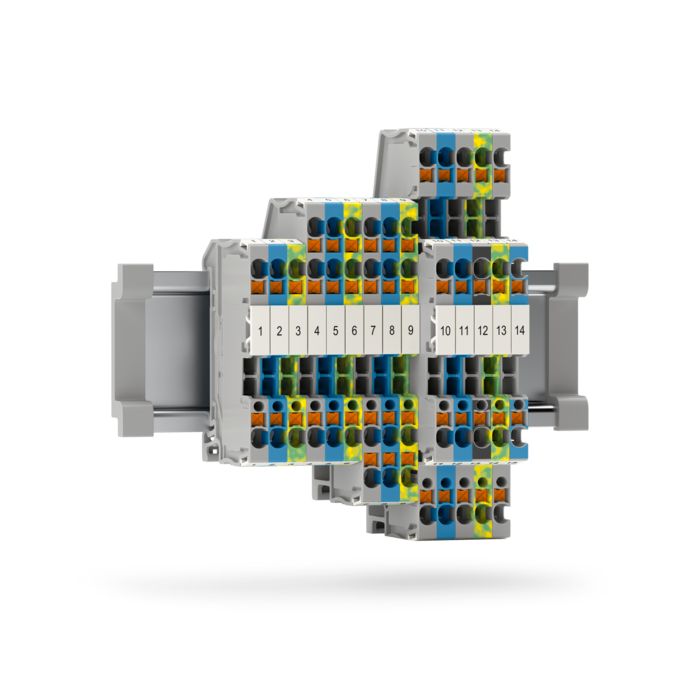

The new XT 1,5 terminal blocks add a compact solution to the Push-X portfolio. Designed for conductor cross-sections from 0.34 to 2.5 mm², they enable the tool-free wiring of all conductor types. Even flexible conductors from just 0.34 mm² trigger the connection without the need for a ferrule. The pitch width of 4.2 mm ensures increased ease of use and deliberately sets it apart from the standard 3.5 mm version on the market. Initial customer feedback confirms this decision.