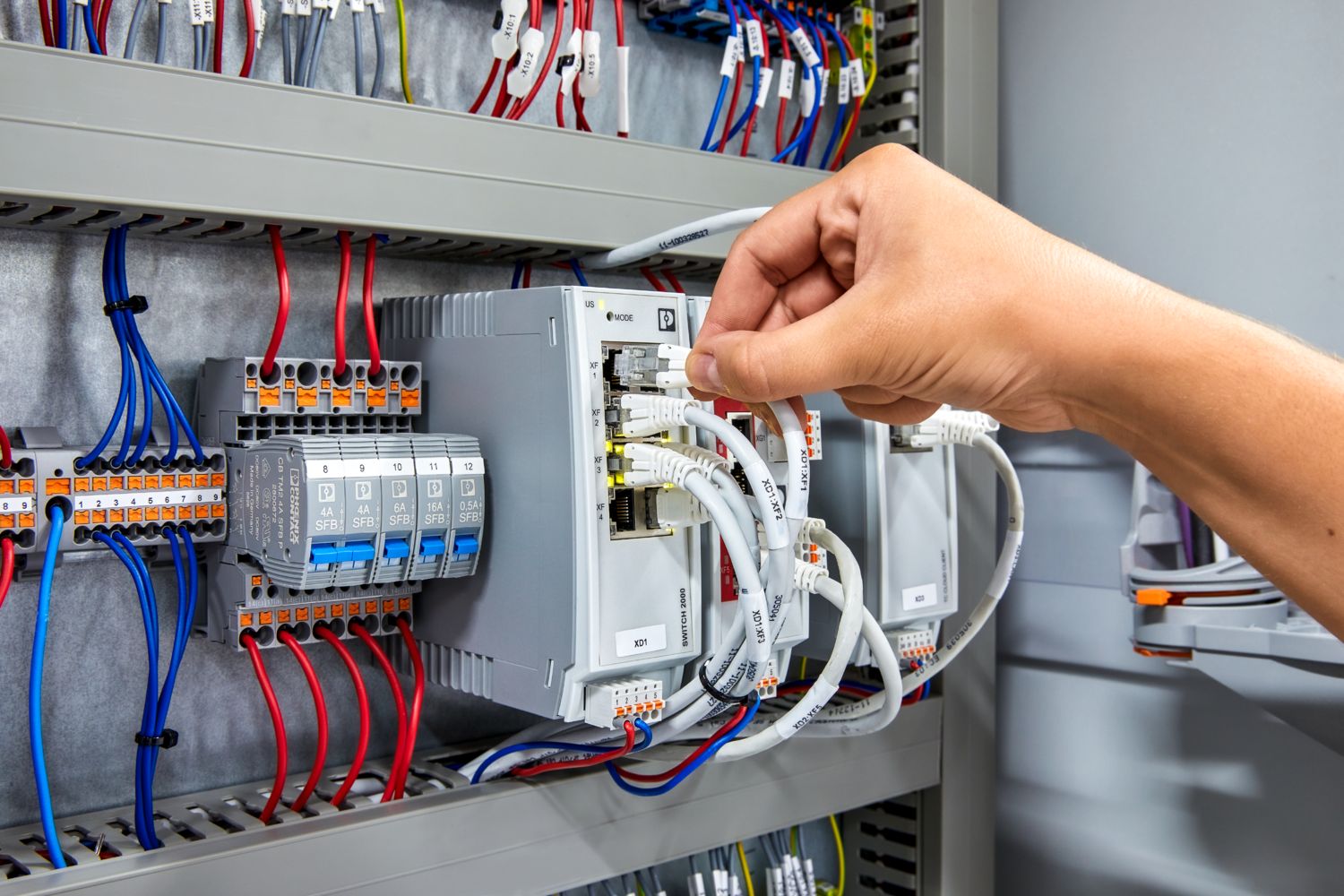

The self-laminating wrap-around labels in the E-WML... product family are designed for automated processing with the THERMOMARK E.WRAP applicator. After the printing and applying process, the markers adhere to the cable at a permanently defined position and the protective laminate protects the markers against dirt and abrasion. As the labels wrap tightly around the wires, they do not create any additional volume, so the wires can also be pulled through cable ducts, for example.

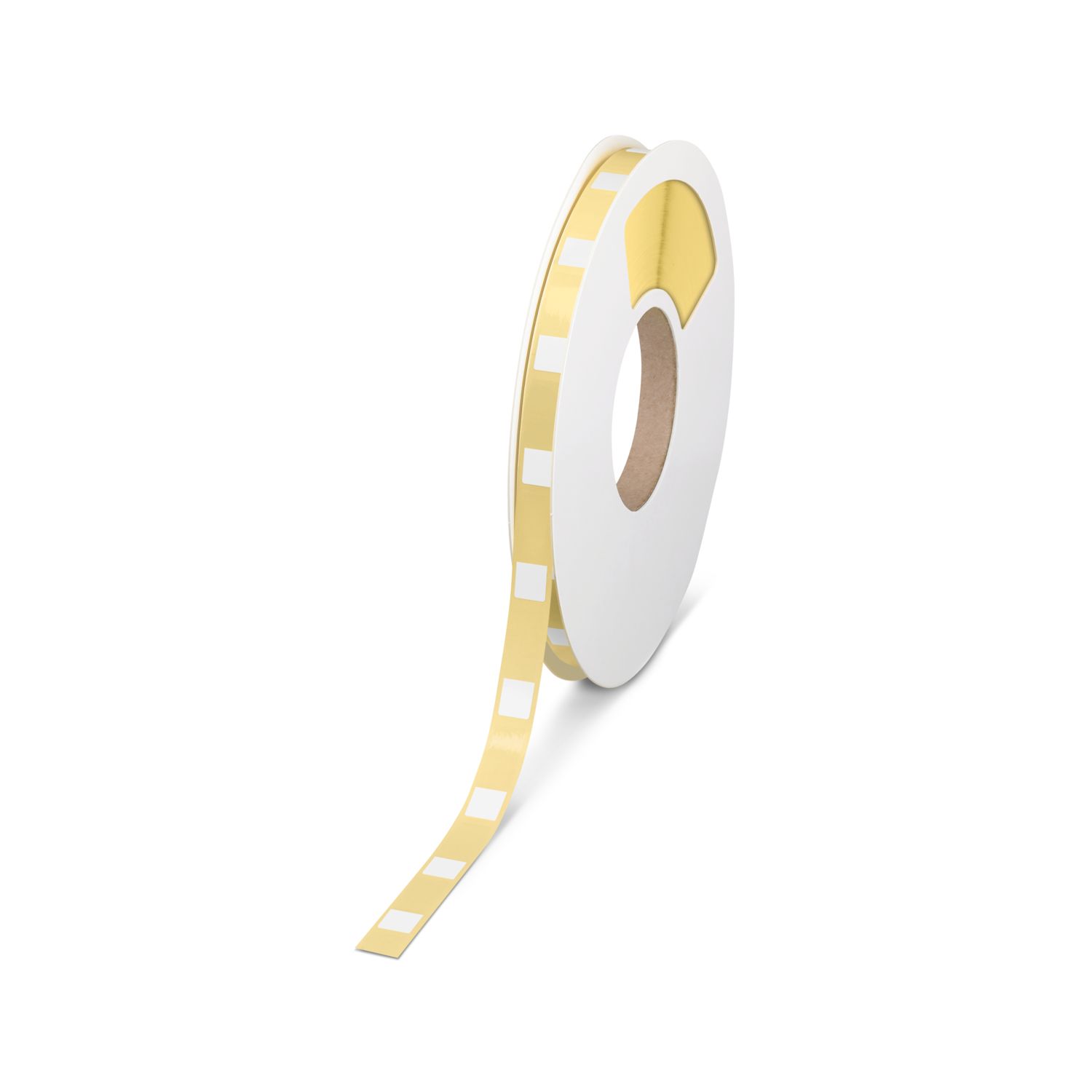

E-WML 8 (13X13)R

-

Wire-wrap label

1199671

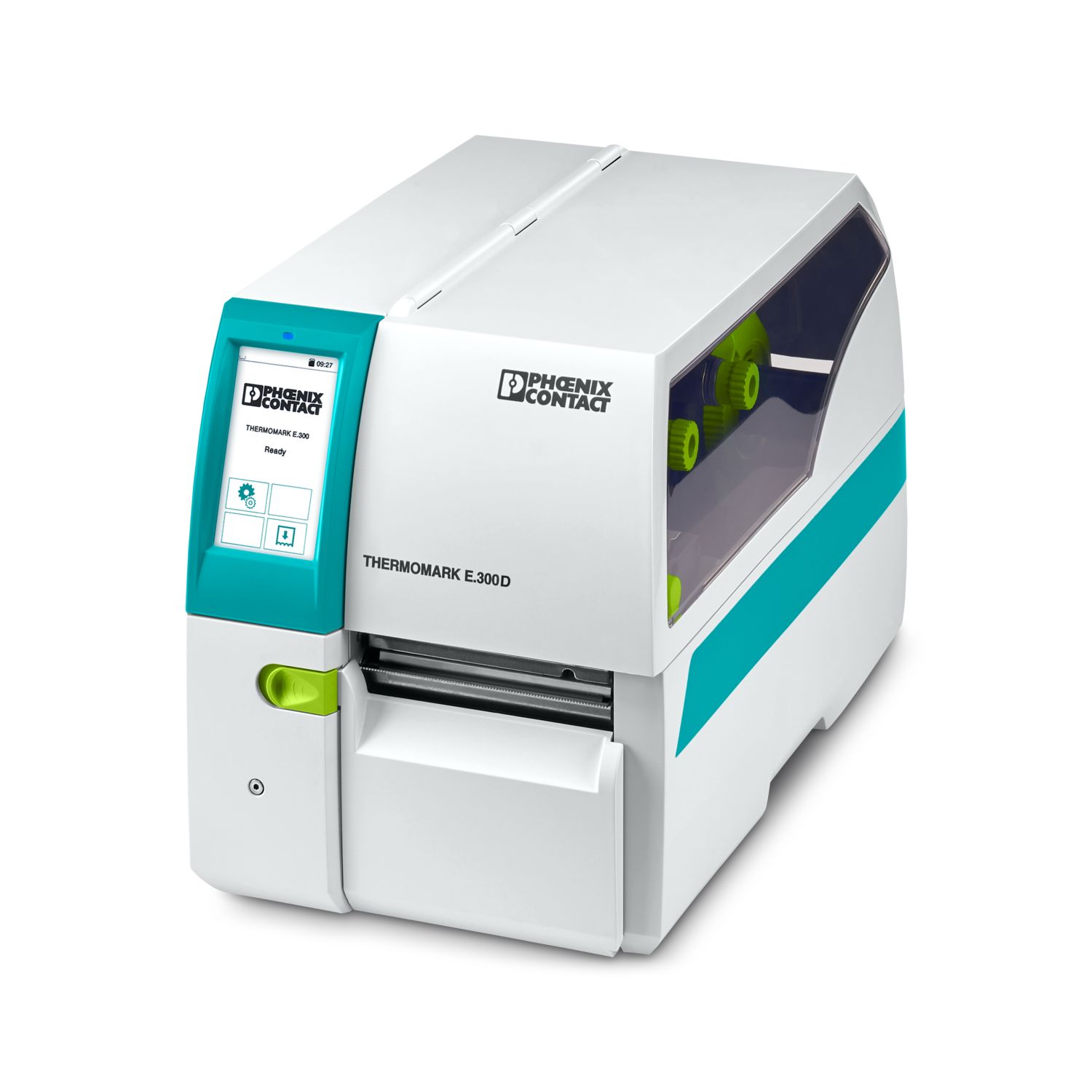

Wire-wrap label, Roll, white, unmarked, can be labeled with: THERMOMARK E.WRAP, cable diameter range: 4 ... 8.1 mm, mounting type: adhesive, Number of individual labels: 4000, text field height: 12.7 mm, text field width: 12.7 mm

Product details

Compatible products

Your advantages

For indoor and outdoor applications: high resistance to dirt and abrasion due to the protective laminate

Firmly defined positioning of labels thanks to the adhesive system

Broad diameter range with many different applications inside and outside the control cabinet

The wrap-around labels do not create any additional volume, so the cable can also be pulled through cable ducts, for example

Tight, bubble-free fit on the cable thanks to automatic winding

For cylindrical objects, single wires, and cables