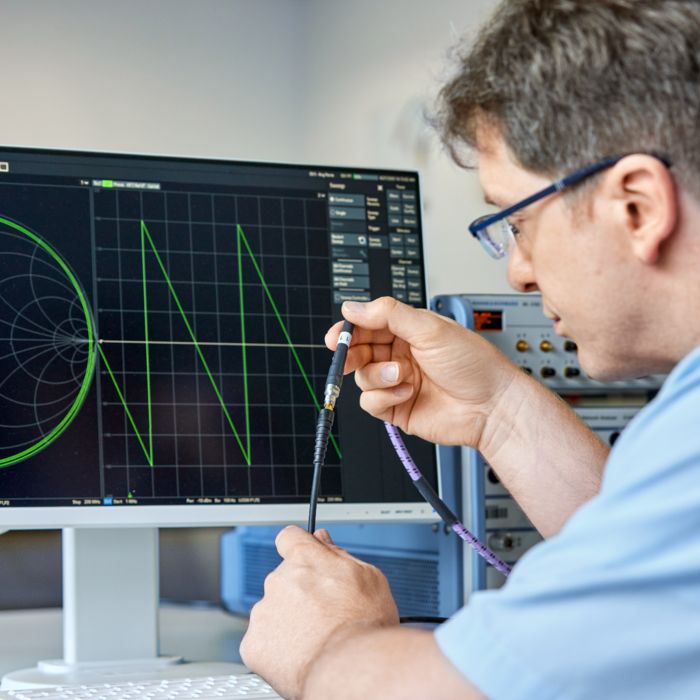

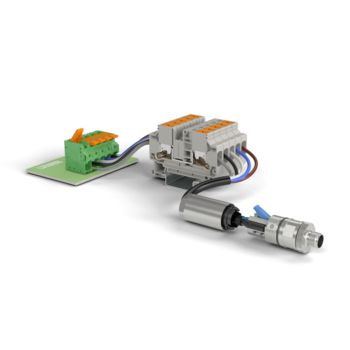

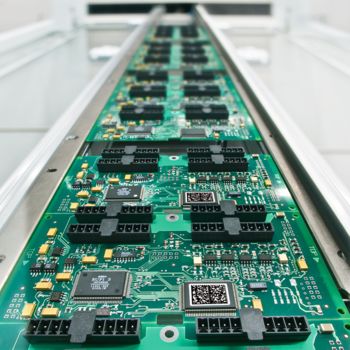

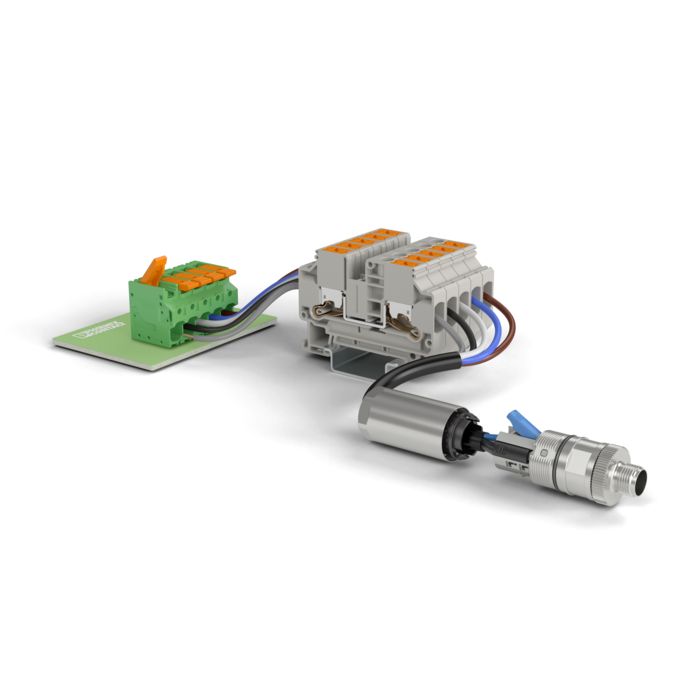

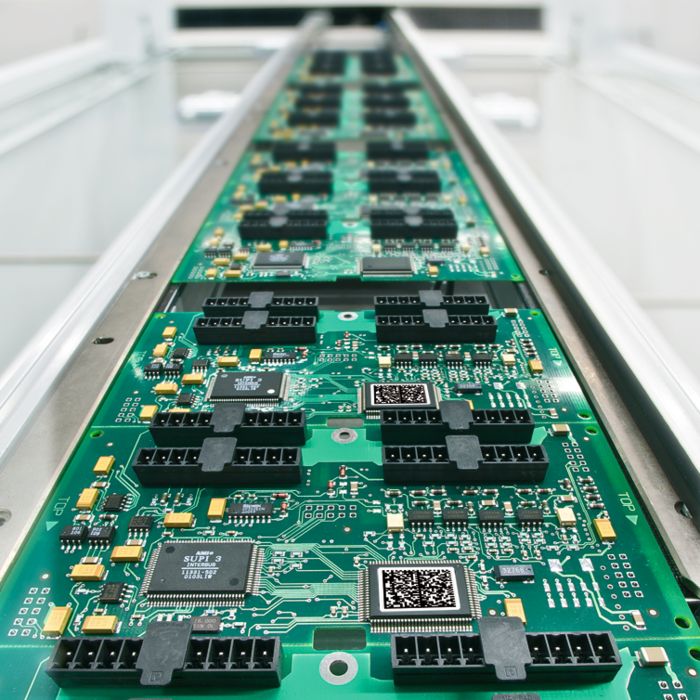

With our extensive portfolio of connectors for data transmission, you always have the right connection. And it is quite easy, since Phoenix Contact is your single-source provider for all device interfaces. In our great variety of designs, codings, and pin assignments you will easily find your consistent solution for copper or FO cabling.