EAC

Approval ID: RU C-DE.BL08.B.00644cULus Recognized

Approval ID: E60425| Nominal voltage UN | Nominal current IN | Cross section AWG | Cross section mm2 | |

|---|---|---|---|---|

| B | ||||

| 600 V | 28 A | 24 - 10 | ||

| C | ||||

| 600 V | 28 A | 24 - 10 | ||

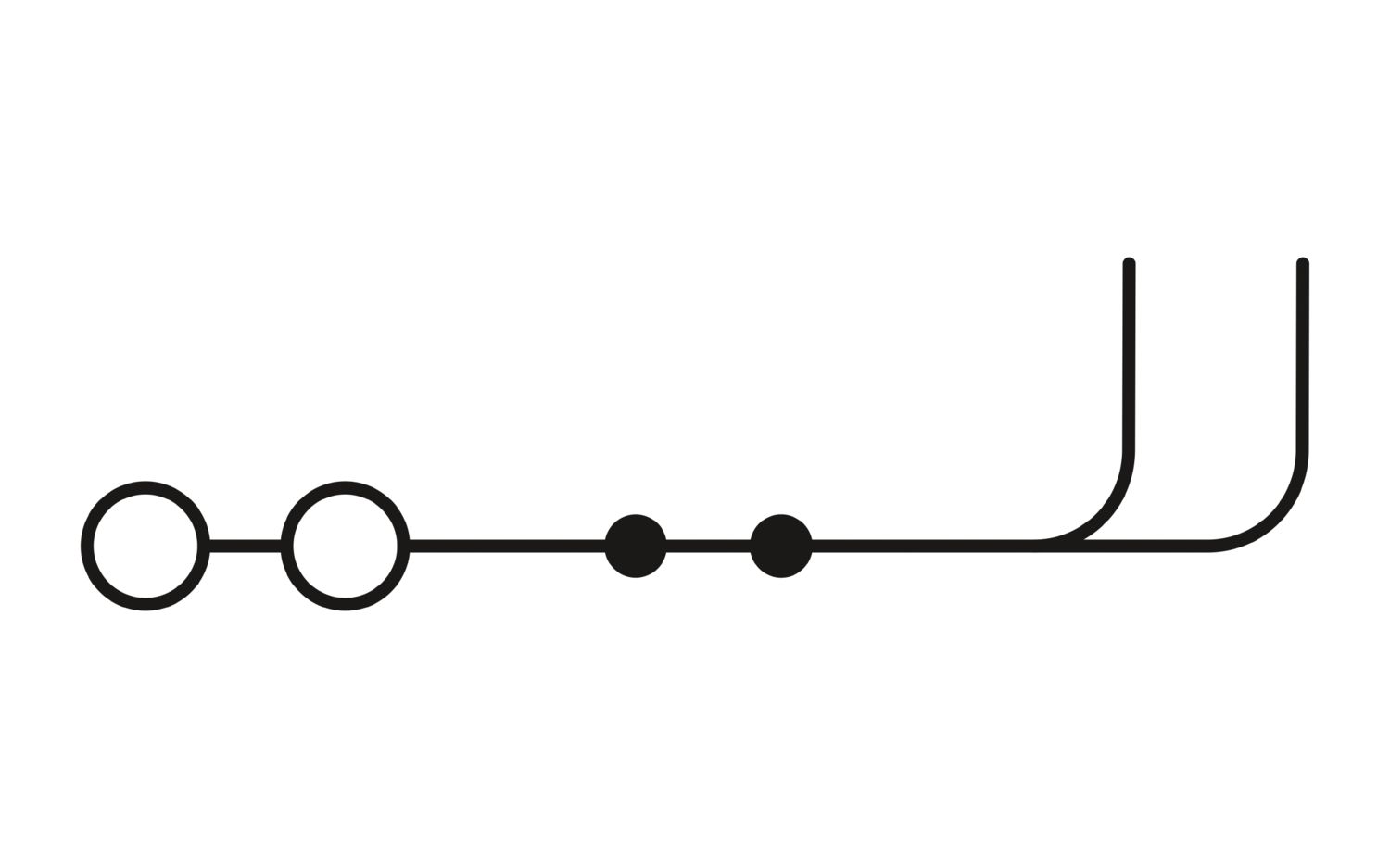

Feed-through terminal block, The max. load current must not be exceeded by the total current of all connected conductors.

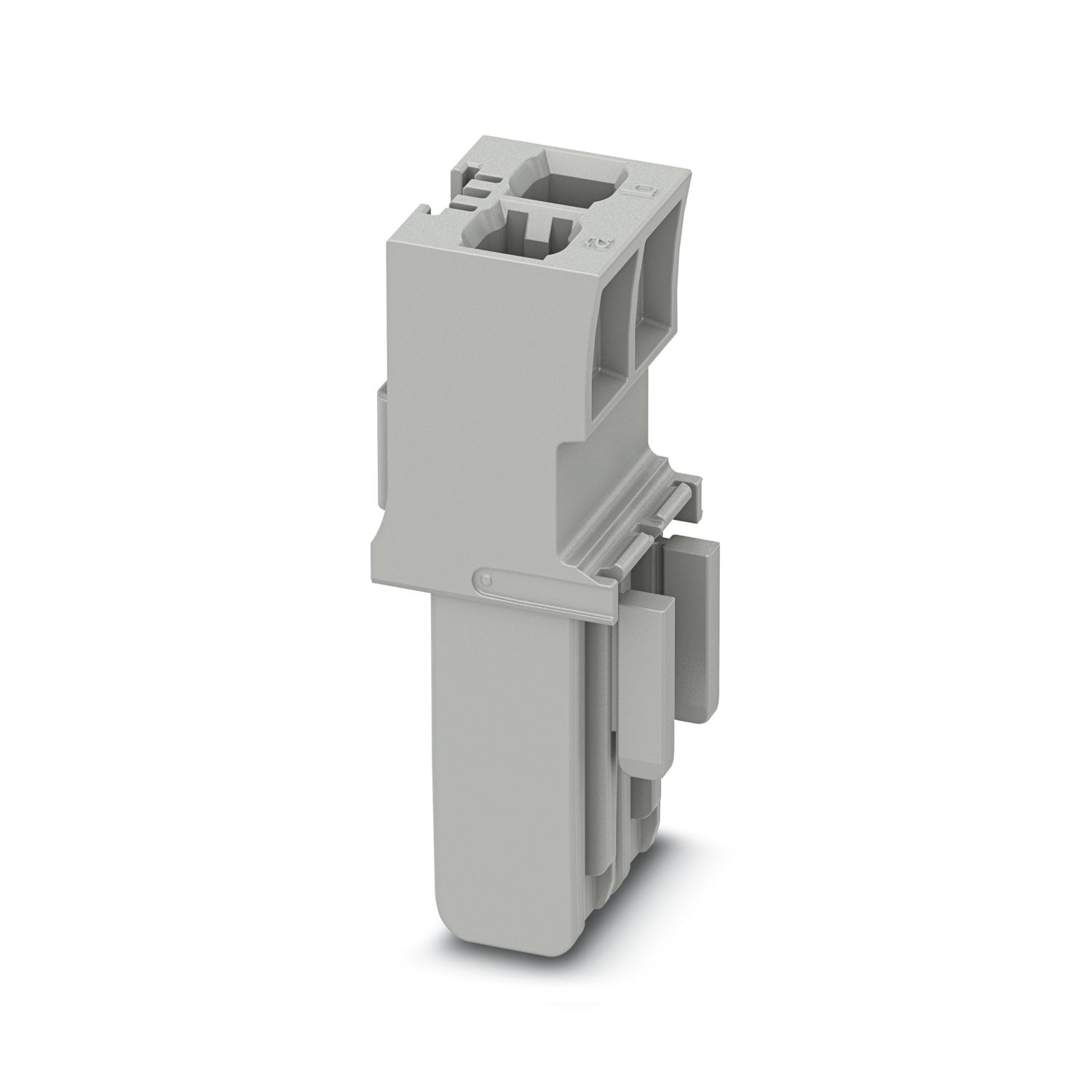

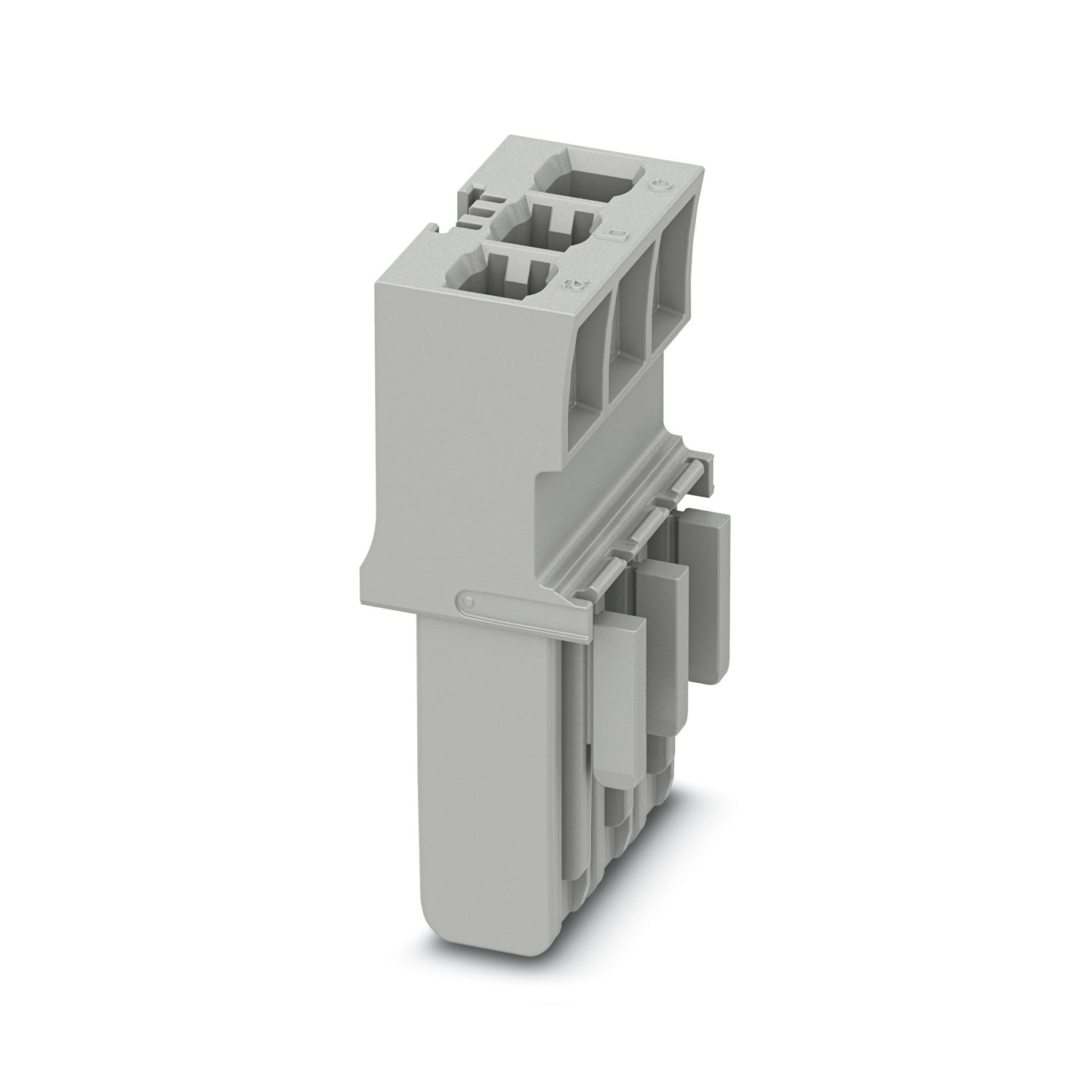

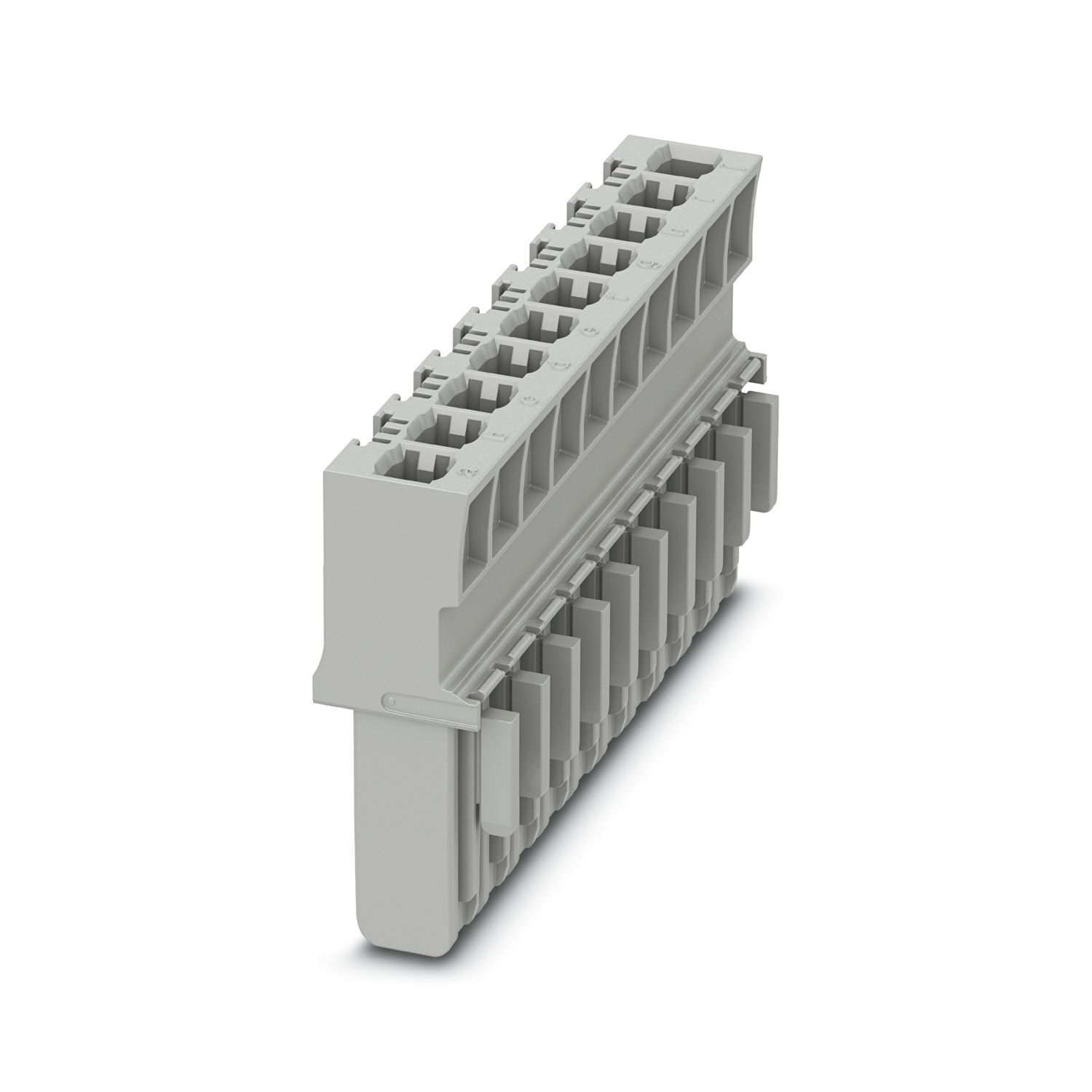

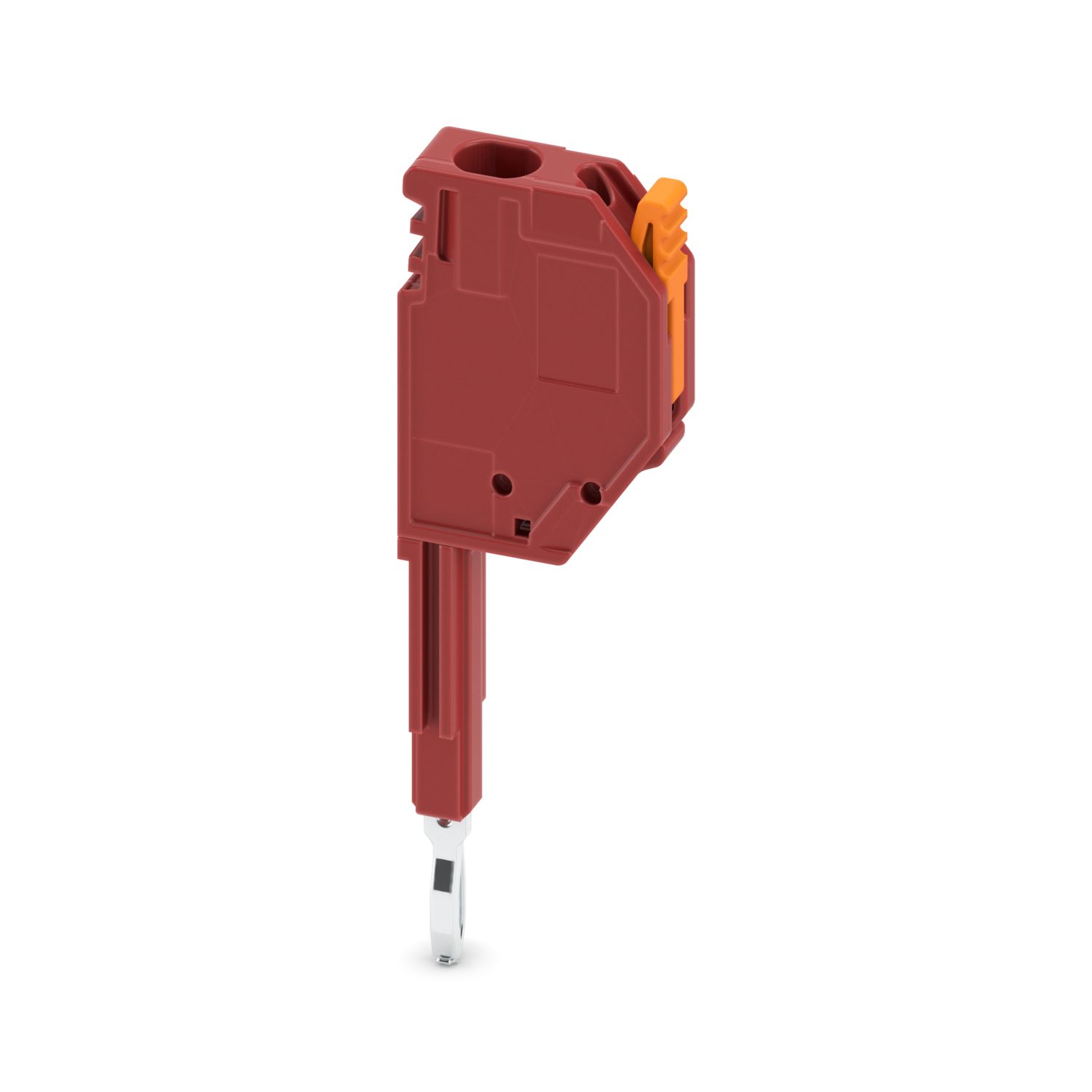

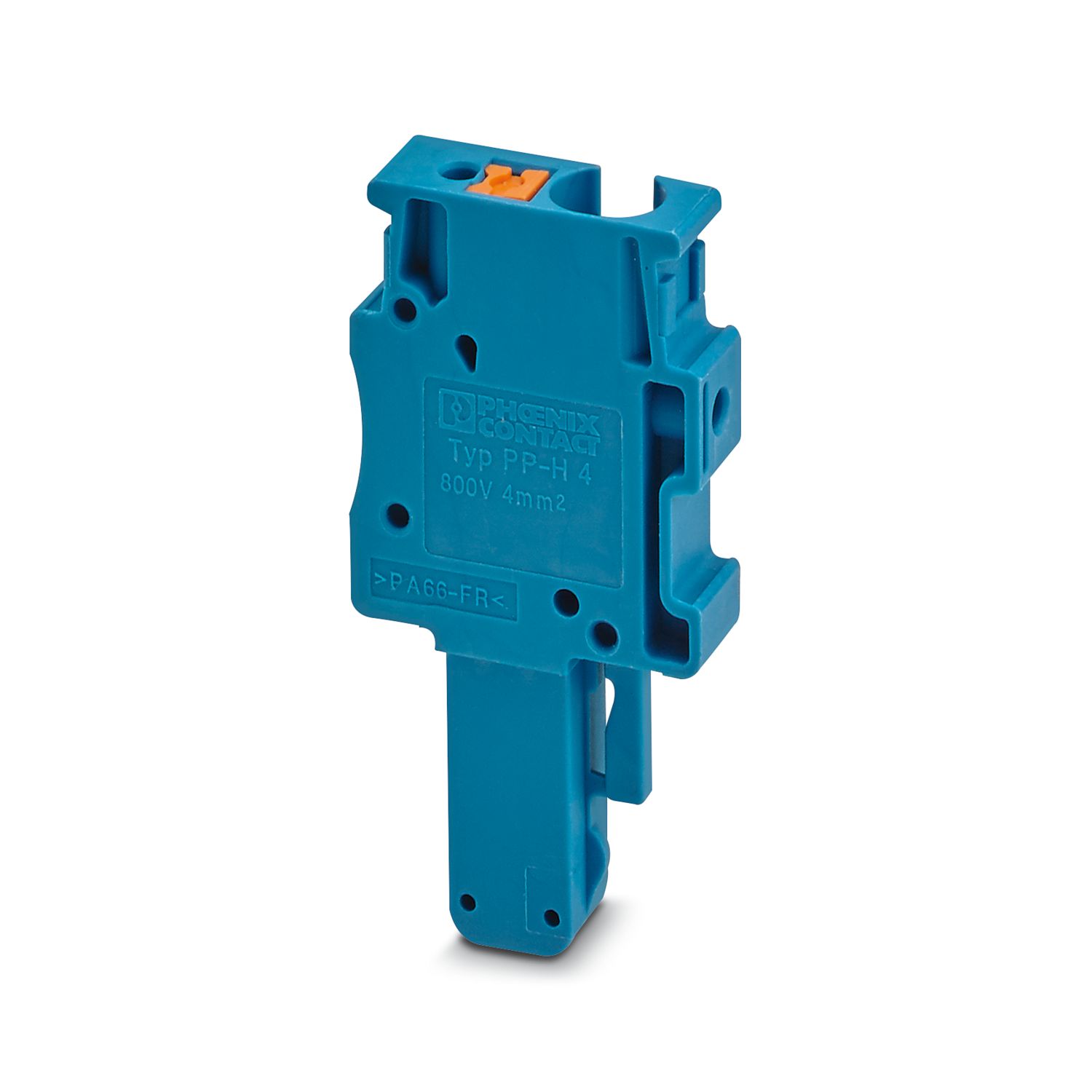

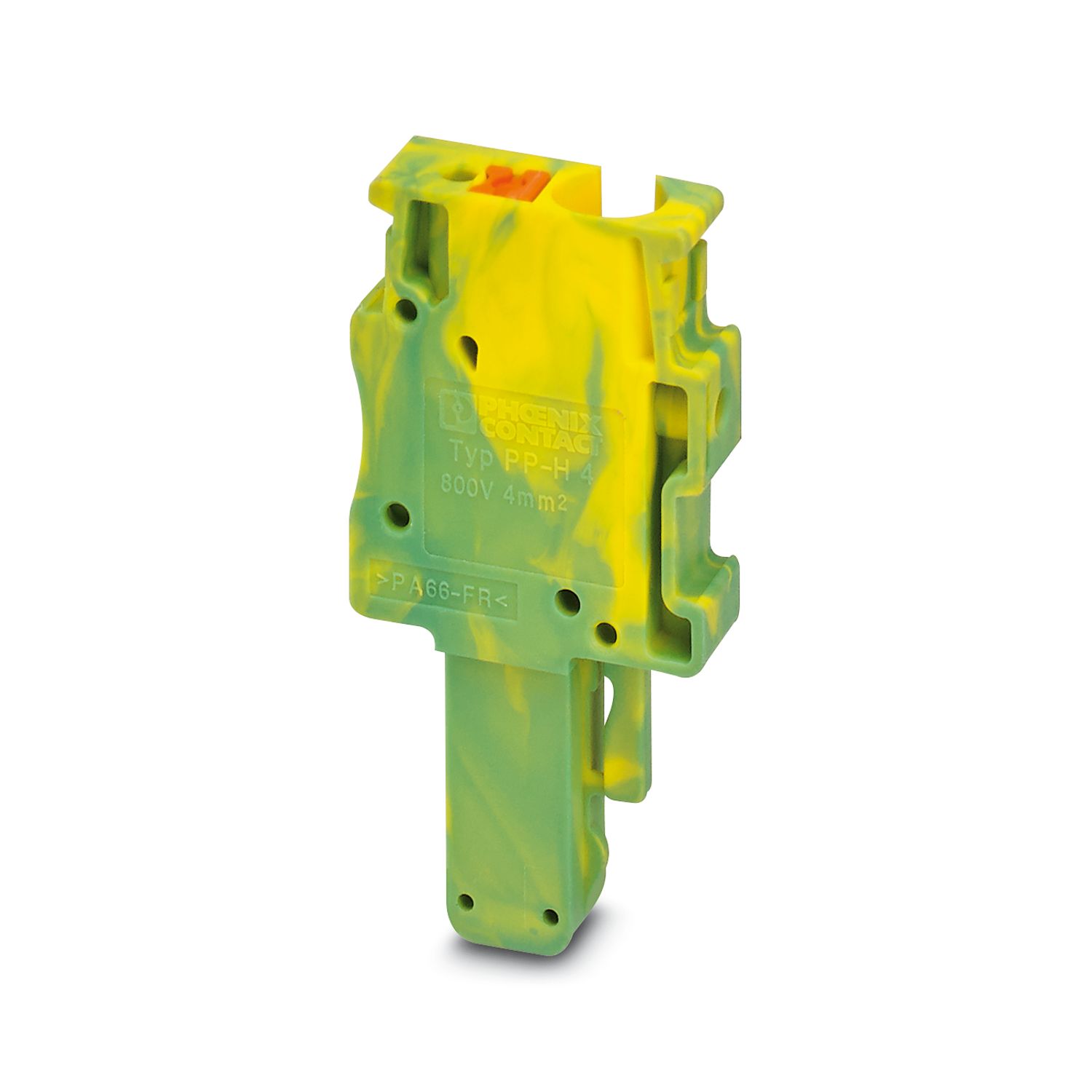

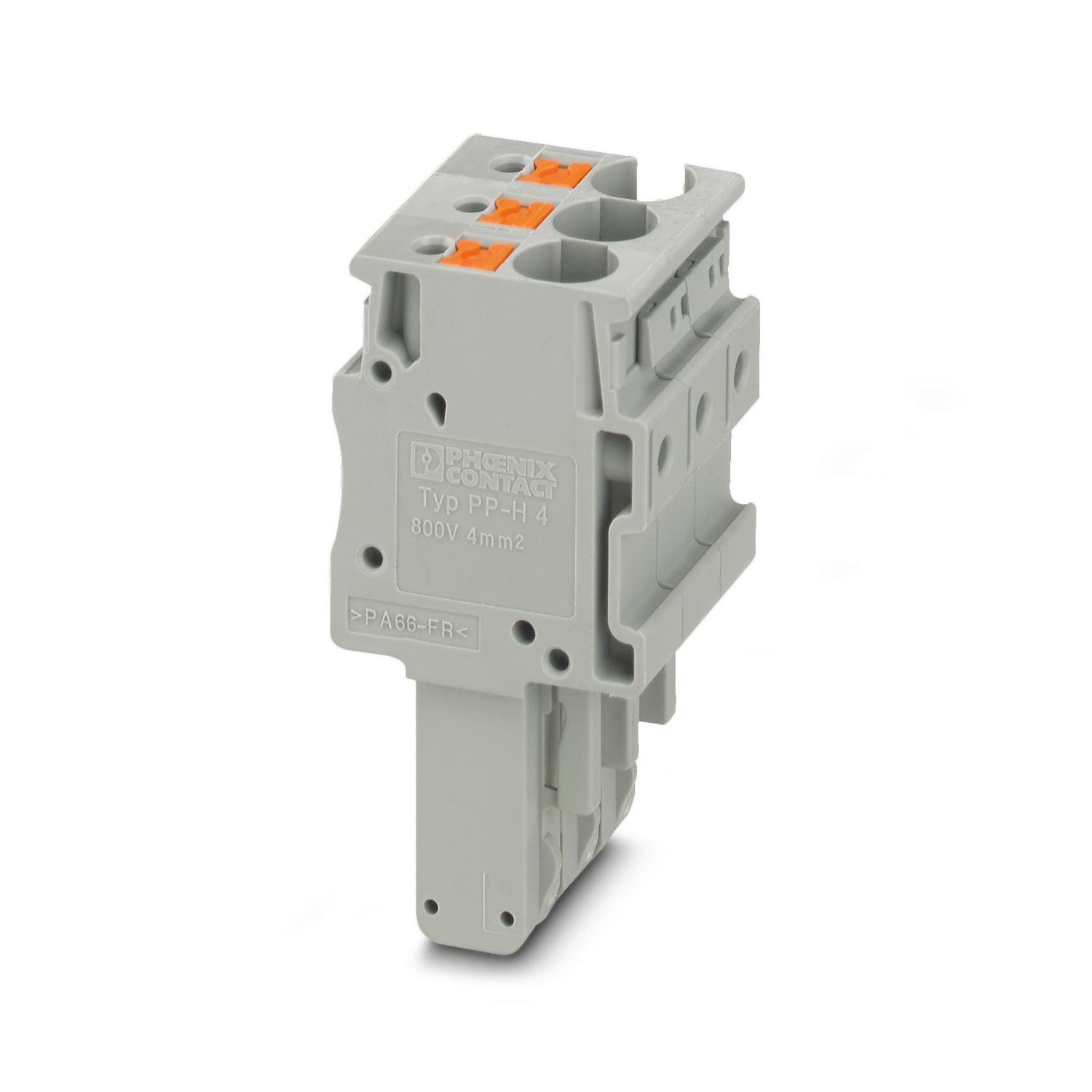

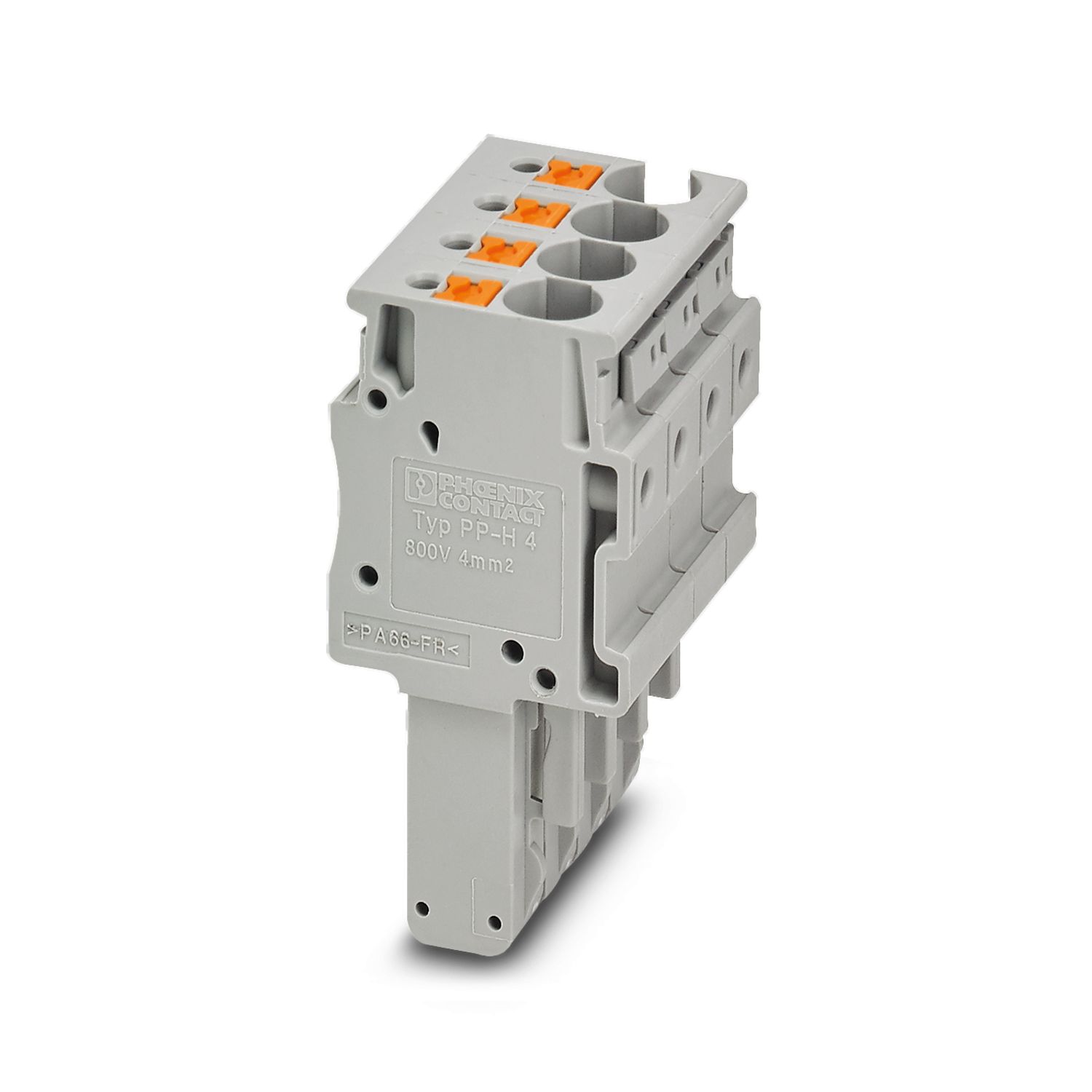

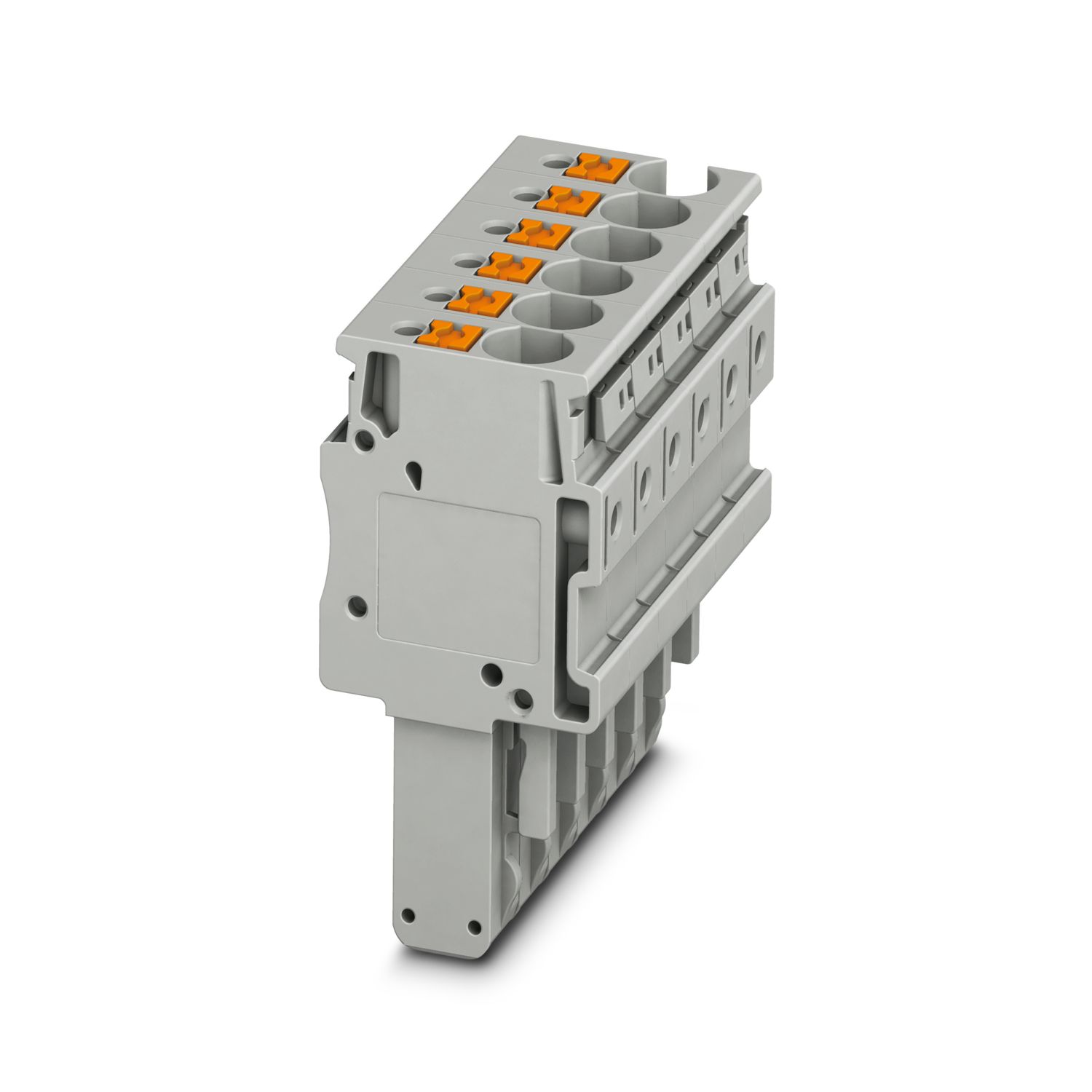

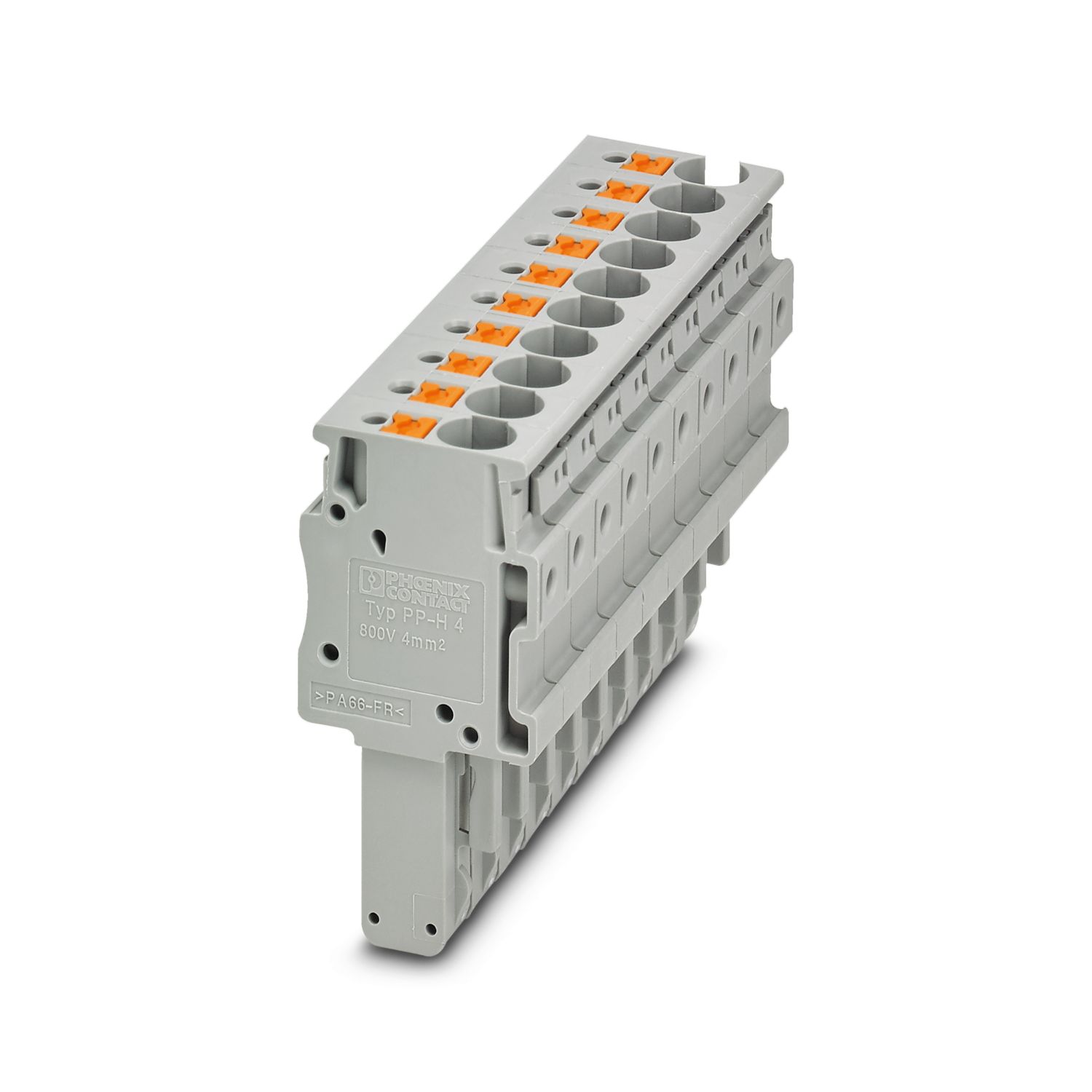

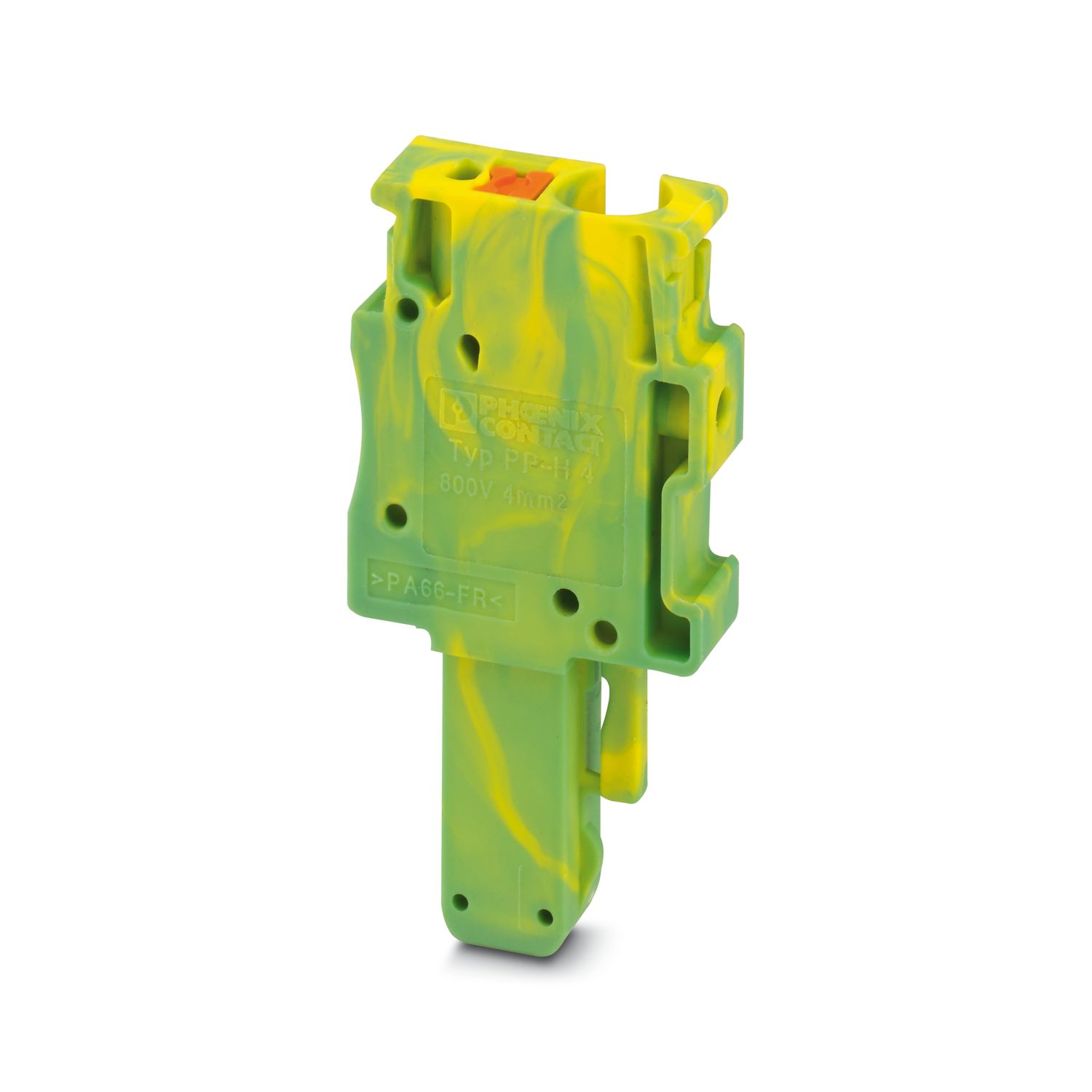

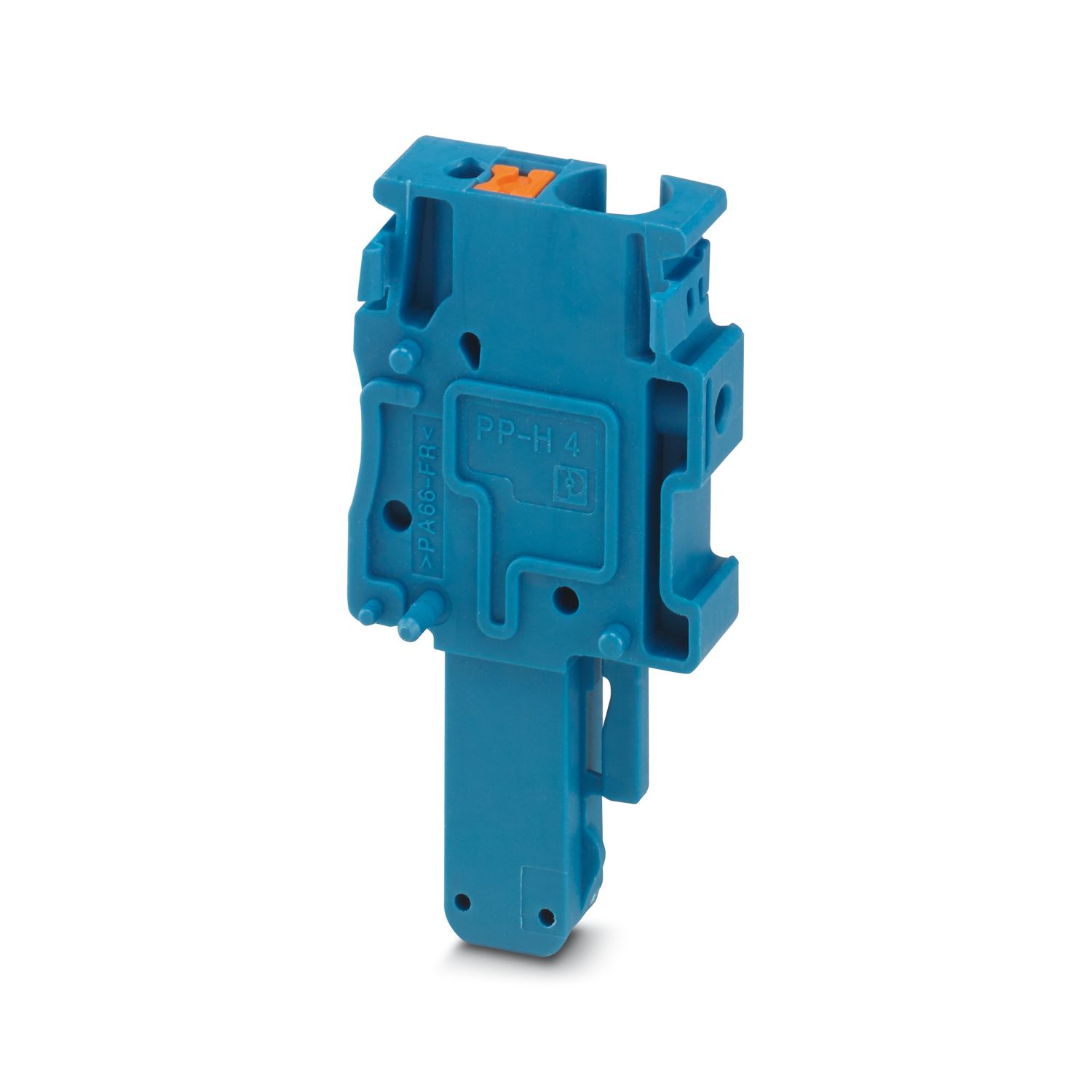

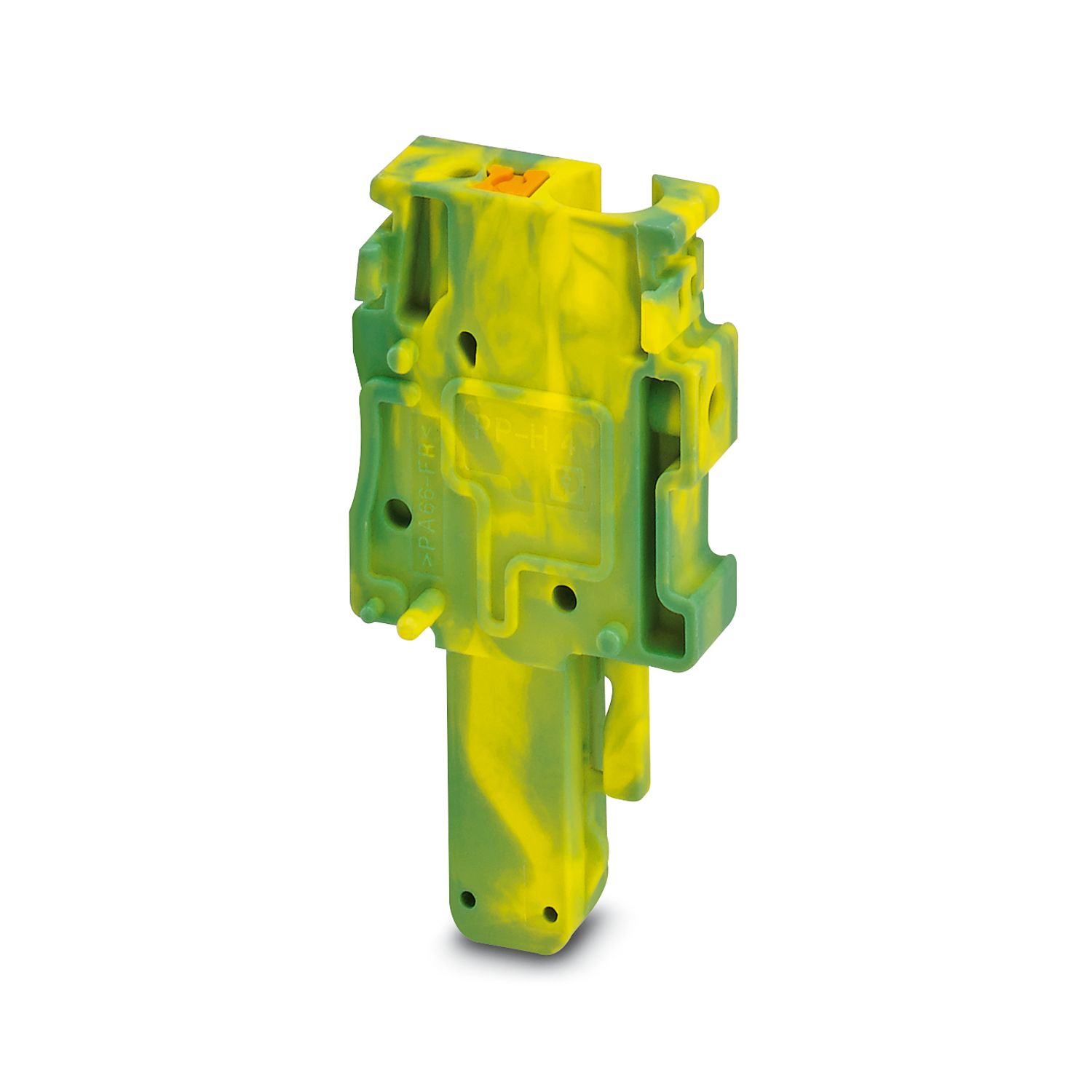

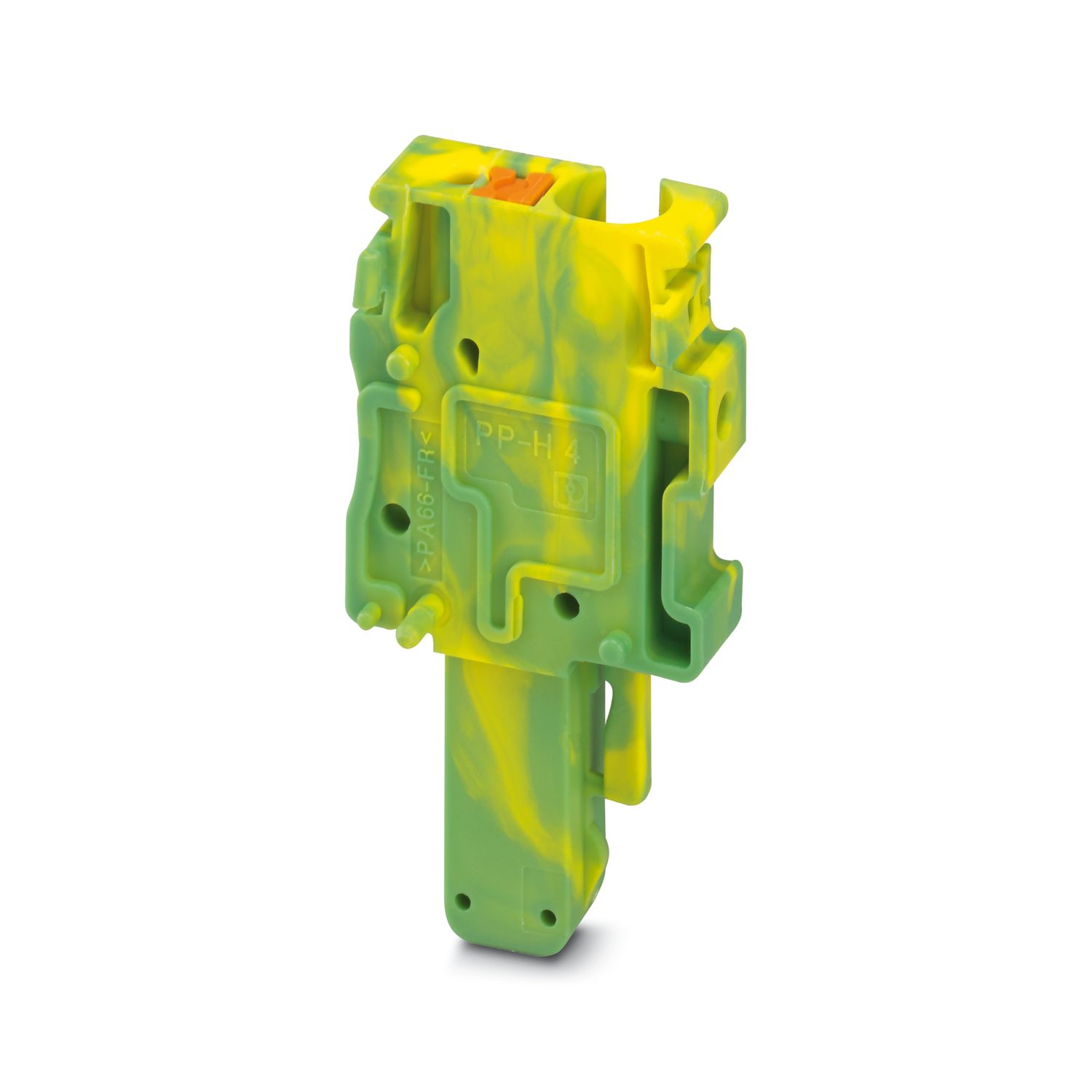

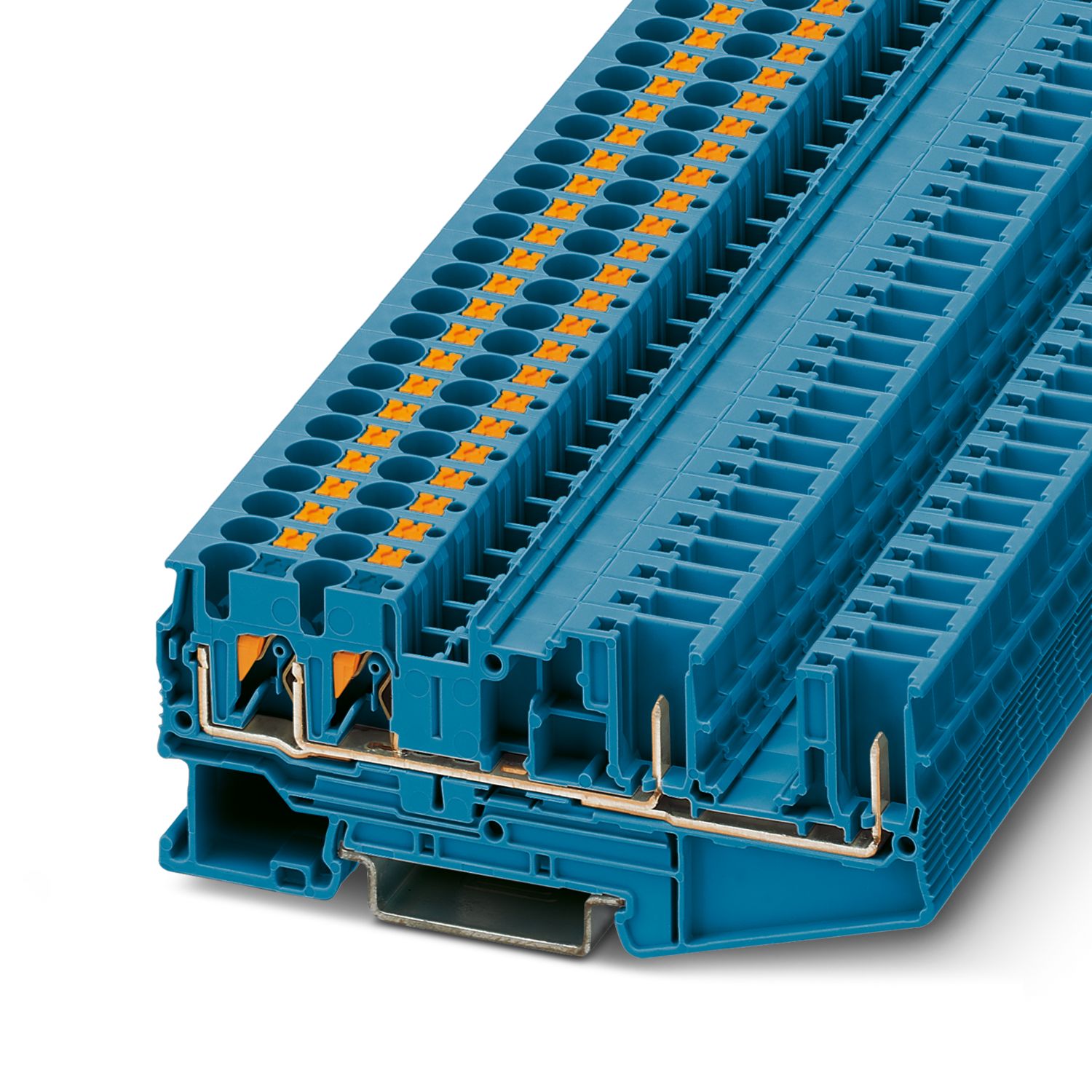

Current and voltage are determined by the plug used., nom. voltage: 800 V, nominal current: 32 A, connection method: Push-in / plug connection, Rated cross section: 4 mm2, cross section: 0.2 mm2 - 6 mm2, mounting: NS 35/7,5, NS 35/15, color: blue

| General | The max. load current must not be exceeded by the total current of all connected conductors. Current and voltage are determined by the plug used. |

| Number of connections | 4 |

| Number of rows | 1 |

| Potentials | 1 |

| Insulation characteristics | |

| Overvoltage category | III |

| Degree of pollution | 3 |

| Rated surge voltage | 8 kV |

| Maximum power dissipation for nominal condition | 1.02 W |

| Number of connections per level | 4 |

| Nominal cross section | 4 mm² |

| Connection method | Push-in / plug connection |

| Stripping length | 10 mm ... 12 mm |

| Internal cylindrical gage | A4 |

| Connection in acc. with standard | IEC 60947-7-1 |

| Conductor cross-section rigid | 0.2 mm² ... 6 mm² |

| Cross section AWG | 24 ... 10 (converted acc. to IEC) |

| Conductor cross-section flexible | 0.2 mm² ... 6 mm² |

| Conductor cross-section, flexible [AWG] | 24 ... 10 (converted acc. to IEC) |

| Conductor cross-section flexible ultrasound-compressed | 0.34 mm² ... 6 mm² |

| Conductor cross-section, flexible [AWG] ultrasound-compressed | 22 ... 10 (converted acc. to IEC) |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 0.25 mm² ... 4 mm² |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 0.25 mm² ... 4 mm² |

| 2 conductors with the same cross section, flexible, with TWIN ferrule with plastic sleeve | 0.5 mm² ... 1 mm² |

| Nominal current | 32 A |

| Maximum load current | 36 A (with 6 mm² conductor cross-section, rigid) |

| Nominal voltage | 800 V |

| Nominal cross section | 4 mm² |

| Connection cross sections directly pluggable | |

| Conductor cross-section rigid | 0.5 mm² ... 6 mm² |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 0.5 mm² ... 4 mm² |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 0.5 mm² ... 4 mm² |

| Width | 6.2 mm |

| End cover width | 2.2 mm |

| Height | 92.1 mm |

| Depth on NS 35/7,5 | 36.5 mm |

| Depth on NS 35/15 | 44 mm |

| Color | blue (RAL 5015) |

| Flammability rating according to UL 94 | V0 |

| Insulating material group | I |

| Insulating material | PA |

| Static insulating material application in cold | -60 °C |

| Temperature index of insulation material (DIN EN 60216-1 (VDE 0304-21)) | 130 °C |

| Relative insulation material temperature index (Elec., UL 746 B) | 130 °C |

| Fire protection for rail vehicles (DIN EN 45545-2) R22 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R23 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R24 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R26 | HL 1 - HL 3 |

| Calorimetric heat release NFPA 130 (ASTM E 1354) | 28 MJ/kg |

| Surface flammability NFPA 130 (ASTM E 162) | passed |

| Specific optical density of smoke NFPA 130 (ASTM E 662) | passed |

| Smoke gas toxicity NFPA 130 (SMP 800C) | passed |

| Surge voltage test | |

| Test voltage setpoint | 9.8 kV |

| Result | Test passed |

| Short-time withstand current 4 mm² | 0.48 kA |

| Result | Test passed |

| Power-frequency withstand voltage | |

| Test voltage setpoint | 2 kV |

| Result | Test passed |

| Mechanical data | |

| Open side panel | Yes |

| Attachment on the carrier | |

| DIN rail/fixing support | NS 35 |

| Test force setpoint | 1 N |

| Result | Test passed |

| Service life | |

| Insertion/withdrawal cycles | 100 |

| Needle-flame test | |

| Time of exposure | 30 s |

| Result | Test passed |

| Oscillation/broadband noise | |

| Specification | DIN EN 50155 (VDE 0115-200):2008-03 |

| Spectrum | Long life test category 1, class B, body mounted |

| Frequency | f1 = 5 Hz to f2 = 150 Hz |

| ASD level | 0.964 (m/s²)²/Hz |

| Acceleration | 0.58g |

| Test duration per axis | 5 h |

| Test directions | X-, Y- and Z-axis |

| Result | Test passed |

| Shocks | |

| Specification | DIN EN 50155 (VDE 0115-200):2008-03 |

| Pulse shape | Half-sine |

| Acceleration | 5g |

| Shock duration | 30 ms |

| Number of shocks per direction | 3 |

| Test directions | X-, Y- and Z-axis (pos. and neg.) |

| Result | Test passed |

| Ambient conditions | |

| Ambient temperature (operation) | -60 °C ... 100 °C (max. operating temperature range including self-heating, see derating curve) |

| Ambient temperature (storage/transport) | -25 °C ... 60 °C (for a short time, not exceeding 24 h, -60 °C to +70 °C) |

| Ambient temperature (assembly) | -5 °C ... 70 °C |

| Ambient temperature (actuation) | -5 °C ... 70 °C |

| Permissible humidity (operation) | 20 % ... 90 % |

| Permissible humidity (storage/transport) | 30 % ... 70 % |

| Connection in acc. with standard | IEC 60947-7-1 |

| Mounting type | NS 35/7,5 |

| NS 35/15 |

| Item number | 3212000 |

| Packing unit | 50 pc |

| Minimum order quantity | 50 pc |

| Sales key | A1 - Terminal Strips |

| Product key | BE2241 |

| GTIN | 4046356482929 |

| Weight per piece (including packing) | 13,146 g |

| Weight per piece (excluding packing) | 13,146 g |

| Customs tariff number | 85369010 |

| Country of origin | PL |

| ECLASS-13.0 | 27250117 |

| ECLASS-15.0 | 27250117 |

| ETIM 9.0 | EC000897 |

| UNSPSC 21.0 | 39121400 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes (No exemptions) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-E

No hazardous substances above the limits

|

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | No substance above 0.1 wt% |