LS-EMLP (180X180) WH

-

Device marker

0804346

Device marker, Sheet, white, unmarked, can be labeled with: TOPMARK NEO, TOPMARK LASER, mounting type: adhesive, Number of individual labels: 1, text field height: 180 mm, text field width: 180 mm

Product details

| Note on application | During laser cutting, combustion residues can occur on the material. If they cannot be removed dry, we recommend damp cleaning with “Clean 80” from Eckart Signplastics GmbH. |

| Product type | Gerätemarker |

| Marking | |

| Number of individual labels | 1 |

| Identification technology | Direct laser marking |

| Width | 180.00 mm |

| Height | 180.00 mm |

| Depth | 0.85 mm |

| Foil strength | 800 µm |

| Adhesive strength | 50 µm |

| Adhesive | Acrylic |

| Color | white (RAL 9010) |

| Base element material | ABS |

| Components | free from silicone and halogen |

| Test for substances that would hinder coating with paint or varnish | |

| Result | Test passed |

| Test for substances that would hinder coating with paint or varnish | |

| Result | Test passed |

| Specification | EN ISO 1518-1:2023 (following) |

| Requirements | ≥ 5 N |

| Result | Test passed |

| Tesafilm test | |

| Specification | DIN EN ISO 2409:2020-12 (following) |

| Result | Test passed |

| UV resistance | |

| Specification | ISO 4892-2:2013-03 (following) |

| Result | Test passed |

| Test duration | 96 h |

| Procedure | Artificial irradiation. |

| Weathering-resistance | |

| Specification | DIN EN ISO 4892-2:2021-11 |

| Result | Test passed |

| Test duration | 6000 h |

| Procedure | A |

| Temperature resistance | |

| Specification | ANSI/UL 969-2018:03 (following) |

| Test duration | 240 h |

| Wipe resistance of inscriptions | |

| Specification | DIN EN 61010-1 (VDE 0411-01):2020-03 |

| DIN EN 62208 (VDE 0660-511):2012-06 (in parts) | |

| Isopropyl [CAS No. 67-63-0] |

Test passed |

| n-Hexane [CAS No. 110-54-3] |

Test passed |

| Water + Petroleum ether [CAS No. 64742-82-1] |

Test passed |

| Sodium hydroxide 0.1 mol/l [CAS No. 1310-73-2] |

Test passed |

| Ethanol (99 %) [CAS No. 64-17-5] |

Test passed |

| Specification | ISO 175:2010 (following) |

| Test duration | 168 h |

| Sodium hydroxide 0.1 mol/l [CAS No. 1310-73-2] |

Test passed |

| Diesel [CAS No. 68476-34-6] |

Test passed |

| IRM 901 | Test passed |

| IRM 902 | Test passed |

| Testing in a condensation changing climate in the presence of sulfur dioxide | |

| Specification | EN ISO 22479:2022-06 |

| Result | Test passed |

| Procedure | Method B |

| Cycles | 2 |

| Salt spray test | |

| Specification | DIN EN 60068-2-11:2000-02 |

| Result | Test passed |

| Test duration | 96 h |

| Ambient conditions | |

| Ambient temperature (operation) | -20 °C ... 60 °C |

| Recommended ambient temperature (storage/transport) | 23 °C |

| Recommended humidity (storage/transport) | 50 % (Storage in a dry and dark place in the original packaging is recommended) |

| Shelf life | 1 Year |

| Wipe resistance | DIN EN 61010-1 (VDE 0411-1) |

| Mounting type | adhesive |

| Item number | 0804346 |

| Packing unit | 10 pc |

| Minimum order quantity | 10 pc |

| Sales key | BG241D |

| Product key | BG241D |

| GTIN | 4055626306056 |

| Weight per piece (including packing) | 40.42 g |

| Weight per piece (excluding packing) | 40.42 g |

| Customs tariff number | 39203000 |

| Country of origin | DE |

ECLASS

| ECLASS-13.0 | 27281103 |

| ECLASS-15.0 | 27281103 |

ETIM

| ETIM 9.0 | EC001288 |

UNSPSC

| UNSPSC 21.0 | 39131500 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes (No exemptions) |

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | No substance above 0.1 wt% |

Compatible products

Your advantages

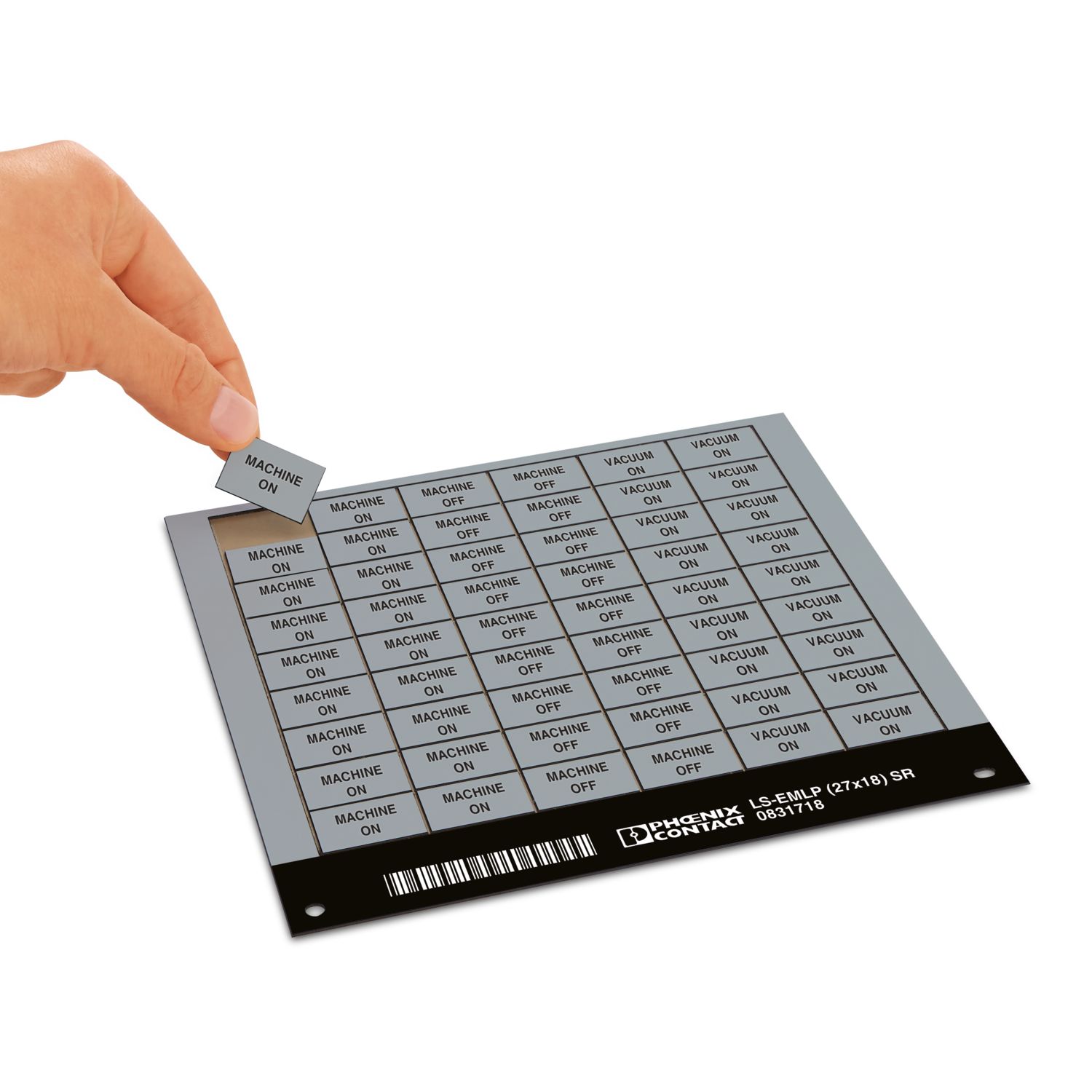

Stick-on device marking

Individually configurable equipment marking in proven laser sheet format for optimum positioning in the marking device

Very high contrast due to the white top layer with black marking

PHOENIX CONTACT PTY Ltd.

Level 12 1PSQ, 169 Macquarie Street, Parramatta NSW 2150