Voestalpine Signaling: Safety in rail transport with Push-in terminal blocks

Voestalpine Signaling Overview

- Voestalpine Signaling Siershahn GmbH specializes in operational safety in rail transport.

- High rail transport safety levels require top-class components.

- To enable the quick installation of safety systems in railway lines and reliable data transmission, the company relies on Push-in direct-connection technology from Phoenix Contact.

- In addition to contact and operator safety, this technology also enables Voestalpine to benefit from potential savings with regard to processing.

Customer profile

When it comes to safety in rail transport, the hot box detection system for train axles from Voestalpine Signaling plays a vital role. The provider of diagnostic and monitoring systems is a subsidiary of Austrian company Voestalpine AG and also specializes in the detection of dangling parts or parts protruding from the train profile.

Rudolf Mühlenbein from Voestalpine Signaling relies on terminal blocks with Push-in Technology

Application

“The contactless acquisition of mechanical and physical data on the rail vehicle frame, as well as the ability to draw the correct conclusions from the prepared results requires comprehensive technical know-how,” explains Rudolf Mühlenbein, who works in the R&D department at Voestalpine in Siershahn. Copper wire, FO, or radio transmits the data from the sensors to the transformer house containing the control cabinets for the evaluation device.

Depending on the system level, e.g., for alarm systems, Voestalpine products must be approved by the Federal Railway Authority (Eisenbahn Bundesamt – EBA) prior to installation. “For this reason as well, we are very interested in reliable contacts across all of our electronics and electrical installations,” says Mühlenbein. Due to the strict requirements on the part of the Rail Authority, Voestalpine develops all its sensors and evaluation devices as well as firmware and software autonomously. Development and testing costs are correspondingly high.

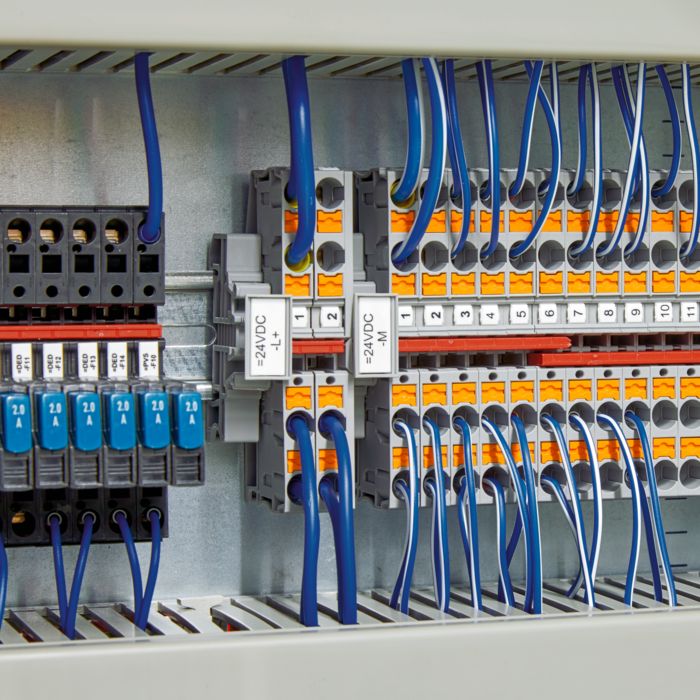

Components with Push-in connection technology for internal and external connections

Solution

“To avoid wasting time with all the electrical switching processes performed during the testing and simulations, we chose Phoenix Contact Push-in direct-connection technology,” Mühlenbein explains. “This connection technology saves us a great deal of time and helps us implement more test cycles.”

For all electrical structures through to ready-to-use systems, Voestalpine consistently uses pre-assembled conductors with ferrules. “As we predominantly work with smaller cross-sections, the Push-in connection technology makes installation at our site and at the final destination, as well as later maintenance and servicing, easier and error-free,” says Mühlenbein. “Especially because our systems are shipped and commissioned worldwide.”

The orange push buttons protect the spring contacts against damage

The orange push button elements are especially helpful at the terminal blocks where the contact can be opened with any pointed or screwdriver-type tool. For one, the terminal points are clearly identifiable. And for another, they also prevent confusion with other connection technology, such as the accidental contact of live parts during actuation. Even without pretreatment, the conductors can be connected to the push-in terminal blocks.

When the rail vehicles pass sensors and transformer houses, high vibrations are produced. Therefore, Mühlenbein places great value on the vibration resistance of installed components. Phoenix Contact subjects all terminal blocks, regardless of connection technology, to vibration testing in accordance with DIN EN 50155 (German railway standard) degree of severity. During these tests, performed at frequencies up to 150 Hz in all directions on the components, no contact interruptions greater than one microsecond are permitted.

Summary

High rail transport safety levels also requires that electro-technical components be reliable. “The selection of Phoenix Contact Push-in direct-connection technology was a good decision for us,” Mühlenbein summarizes. “Because, all in all, this technology offers us not only contact and operator safety, but also the necessary savings potential with regard to time-saving processing. Therefore, we consistently only use products with this type of connection technology in future designs. Furthermore, we prefer that our control cabinet manufacturers also use this technology.”