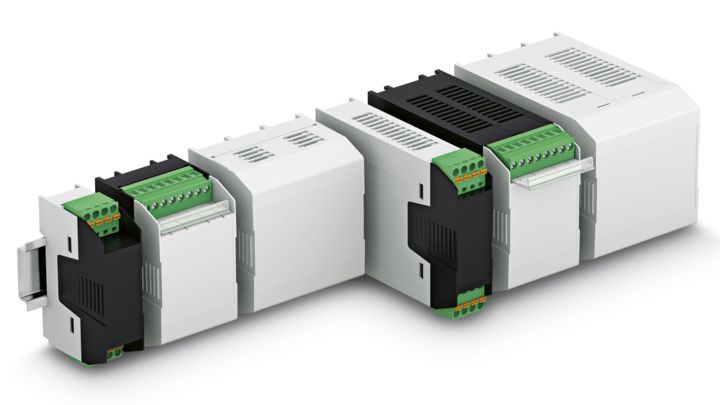

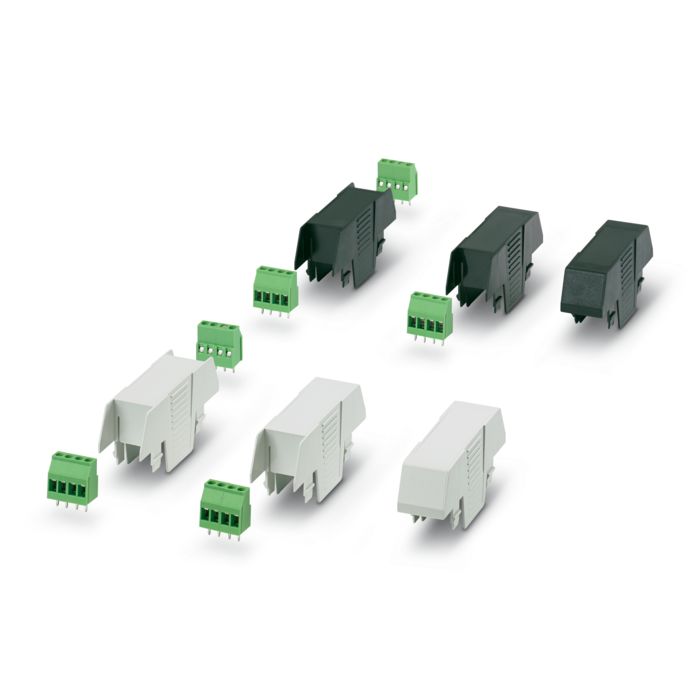

Versatility, the main principle behind the EH series, is also carried over to the cover design. The open terminal compartment provides flexibility for PCB connection technology. Three cover versions are available for individual PCB connections. Choose between covers with terminal compartment open on one or both sides or a closed cover.