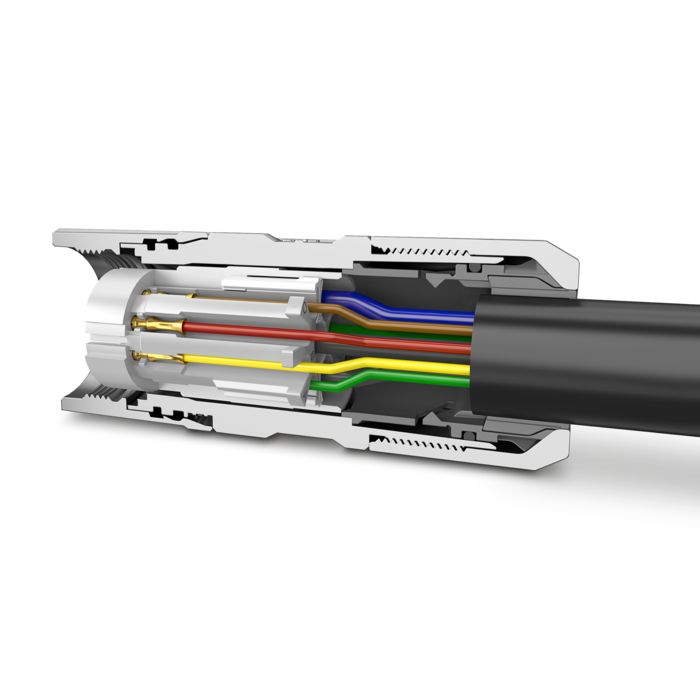

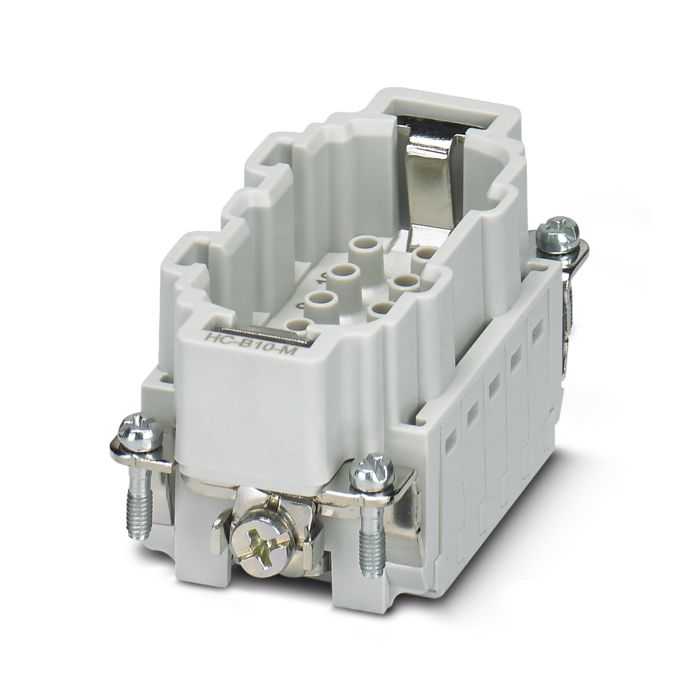

Crimp connectors from the respective connector series can be combined with almost all headers of the associated series. A special feature is the low installed height as compared to other connection technologies. The plug-in direction is parallel to the conductor axis. Versions are available with or without screw or latching flange, and with or without pull-out aid.