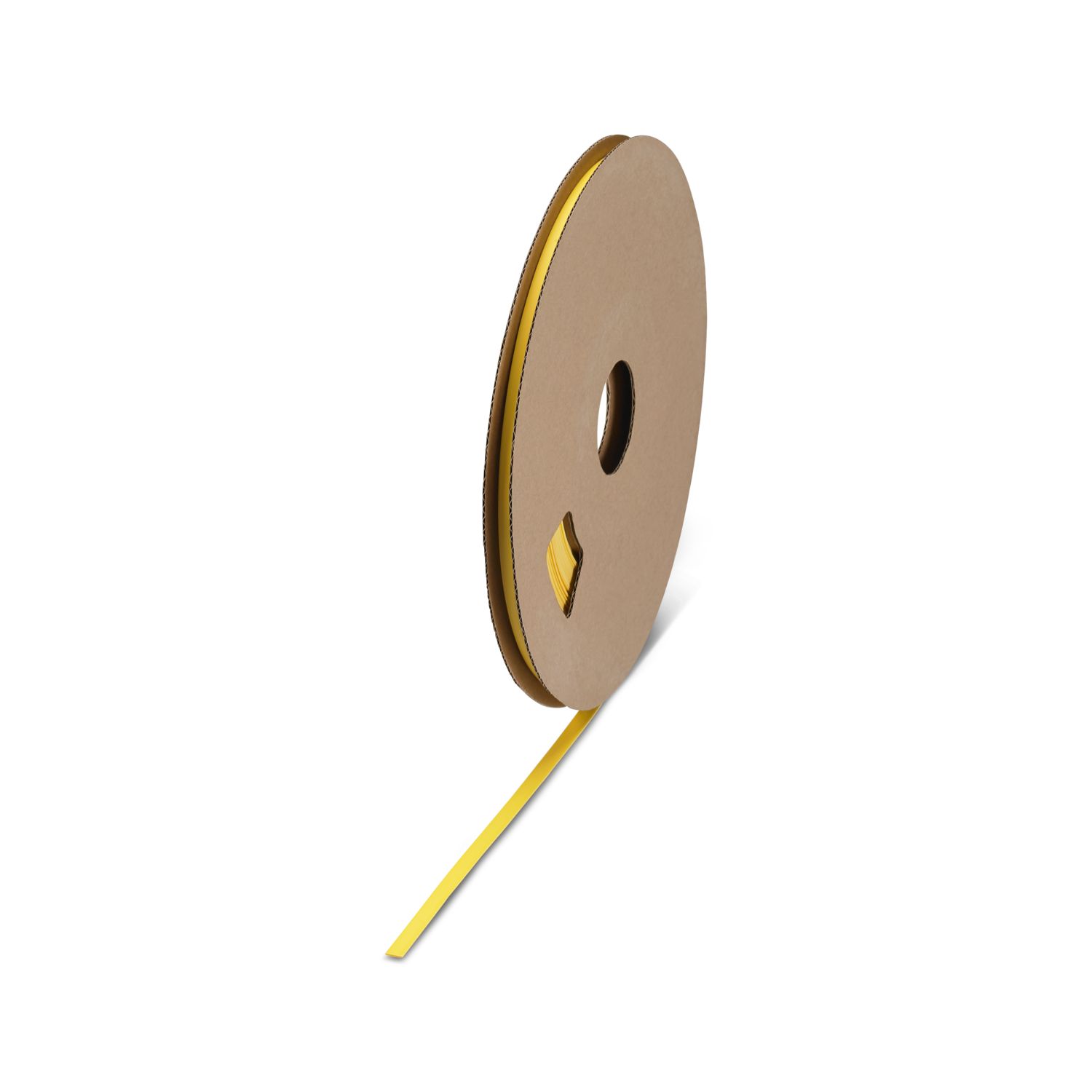

The shrink sleeves in the E-WMS... product family are designed for automated processing with the THERMOMARK E.SLEEVE applicator. The continuous format of the material means that individual marker lengths can be realized. After the printing and application process, you have the option of shrinking the marked shrink sleeves by applying heat manually and thus fixing them on the cable/wire.

E-WMS 3,2 (EX5)R YE

-

Shrink sleeve

1221584

Product details

| Note on application | For the THERMOMARK ROLL and THERMOMARK ROLL 2.0 roll printers, this material can only be processed with an external media hub. |

| Material information | The specified minimum wire diameter of the shrink sleeve refers to its use as a marking material and does not guarantee any insulation characteristics once shrunk. Depending on the processed material batch, as well as the storage and processing conditions, the maximum insertable wire diameter may be reduced. |

| Product type | Shrink sleeve |

| Area of application | KOMAX: M1650 TUBE |

| Marking | |

| Number of individual labels | 1 |

| Length of roll | 30.00 m |

| Height | 6.25 mm |

| RoHS compliant | yes |

| Color | yellow (RAL 1018) |

| Material | Polyolefine |

| Base element material | polyolefine |

| Shrink rate | 3:1 |

| Shrink temperature | > 85 °C |

| External cable diameter | 1 mm ... 3.2 mm |

| Test for substances that would hinder coating with paint or varnish | |

| Result | Test passed |

| Specification | DIN EN ISO 1518-1:2019-10 (following) |

| Requirements | ≥ 5 N |

| Result | Test passed |

| Tesafilm test | |

| Specification | DIN EN ISO 2409:2013 (following) |

| Result | Test passed |

| UV resistance | |

| Specification | ISO 4892-2:2013-03 (following) |

| Result | Test passed |

| Test duration | 96 h |

| Procedure | Artificial irradiation. |

| Temperature resistance | |

| Specification | ANSI/UL 969-2018:03 (following) |

| Test duration | 240 h |

| Rating 125 °C (150 °C) | Test passed |

| Wipe resistance of inscriptions | |

| Specification | DIN EN 61010-1 (VDE 0411-01):2020-03 |

| DIN EN 62208 (VDE 0660-511):2012-06 (in parts) | |

| Isopropyl [CAS No. 67-63-0] |

Test passed |

| n-Hexane [CAS No. 110-54-3] |

Test passed |

| Water + Petroleum ether [CAS No. 64742-82-1] |

Test passed |

| Sodium hydroxide 0.1 mol/l [CAS No. 1310-73-2] |

Test passed |

| Ethanol (99 %) [CAS No. 64-17-5] |

Test passed |

| Acetone (99 %) [CAS No. 67-64-1] |

Test passed |

| Specification | ISO 175:2010 (following) |

| Test duration | 168 h |

| Sodium hydroxide 0.1 mol/l [CAS No. 1310-73-2] |

Test passed |

| Ethanol (99 %) [CAS No. 64-17-5] |

Test passed |

| Acetone (99 %) [CAS No. 67-64-1] |

Test passed |

| Diesel [CAS No. 68476-34-6] |

Test passed |

| IRM 901 | Test passed |

| IRM 902 | Test passed |

| Testing in a condensation changing climate in the presence of sulfur dioxide | |

| Specification | DIN 50018:2013-05 |

| Result | Test passed |

| Climate level | AHT 1.0 S |

| Cycles | 2 |

| Salt spray test | |

| Specification | DIN EN 60068-2-11:2000-02 |

| Result | Test passed |

| Test duration | 96 h |

| Ambient conditions | |

| Ambient temperature (operation) | -55 °C ... 125 °C |

| Recommended ambient temperature (storage/transport) | 23 °C |

| Recommended humidity (storage/transport) | 50 % |

| Shelf life | 5 years |

| Wipe resistance | DIN EN 61010-1 (VDE 0411-1) |

| Mounting type | slide-on |

| Item number | 1221584 |

| Packing unit | 1 pc |

| Minimum order quantity | 1 pc |

| Sales key | BG2 |

| Product key | BG2216 |

| GTIN | 4063151309831 |

| Weight per piece (including packing) | 299 g |

| Weight per piece (excluding packing) | 299 g |

| Customs tariff number | 39173200 |

| Country of origin | CN |

ECLASS

| ECLASS-13.0 | 27281102 |

| ECLASS-15.0 | 27281102 |

ETIM

| ETIM 9.0 | EC001530 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes (No exemptions) |

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | No substance above 0.1 wt% |

Compatible products

-

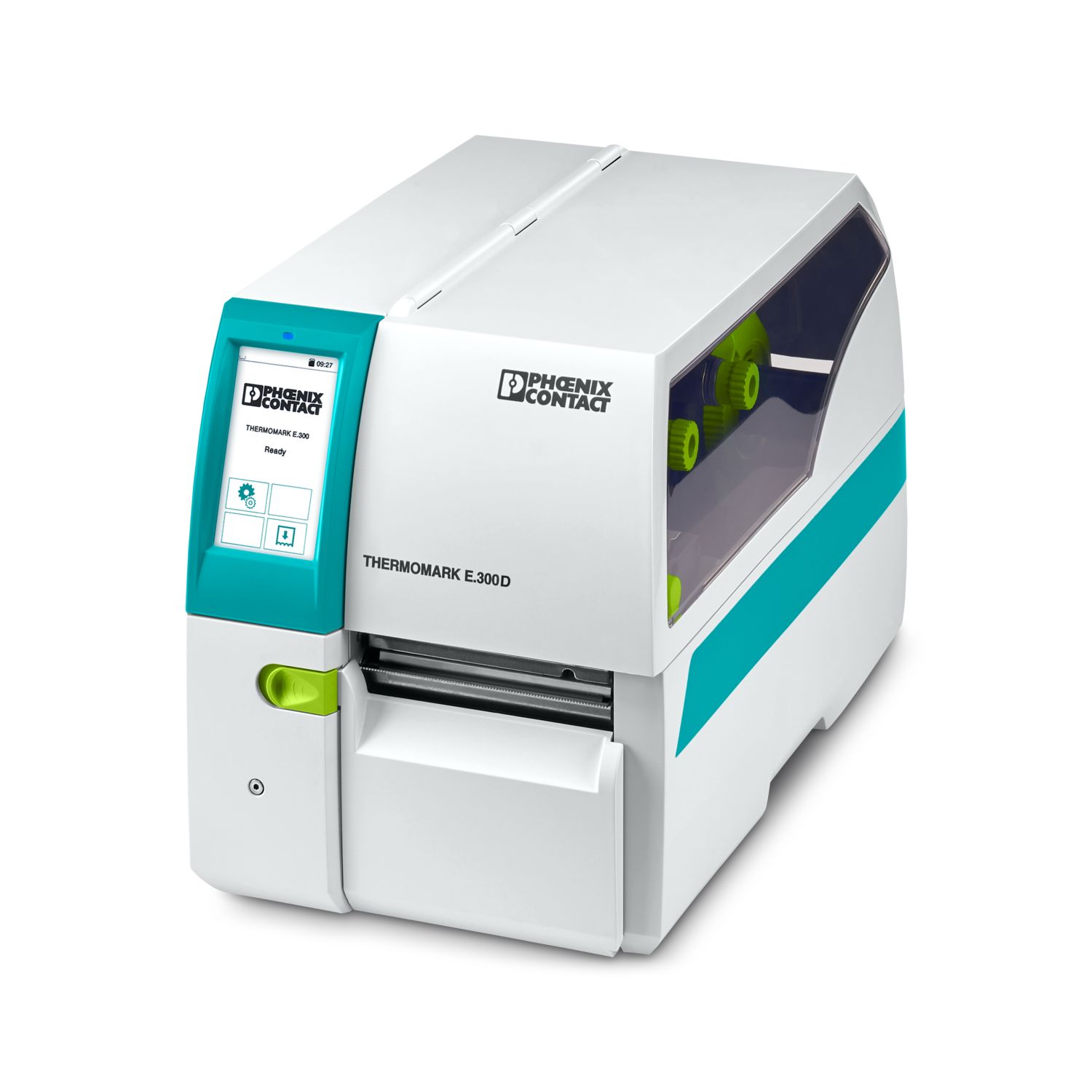

THERMOMARK E.300 - Thermal transfer printer 1285306

-

THERMOMARK E.300 D - Thermal transfer printer 1004303

-

THERMOMARK E.600 - Thermal transfer printer 1285310

-

THERMOMARK E.600 D - Thermal transfer printer 1004304

-

THERMOMARK E.300 DOUBLE - Thermal transfer printer 1472379

-

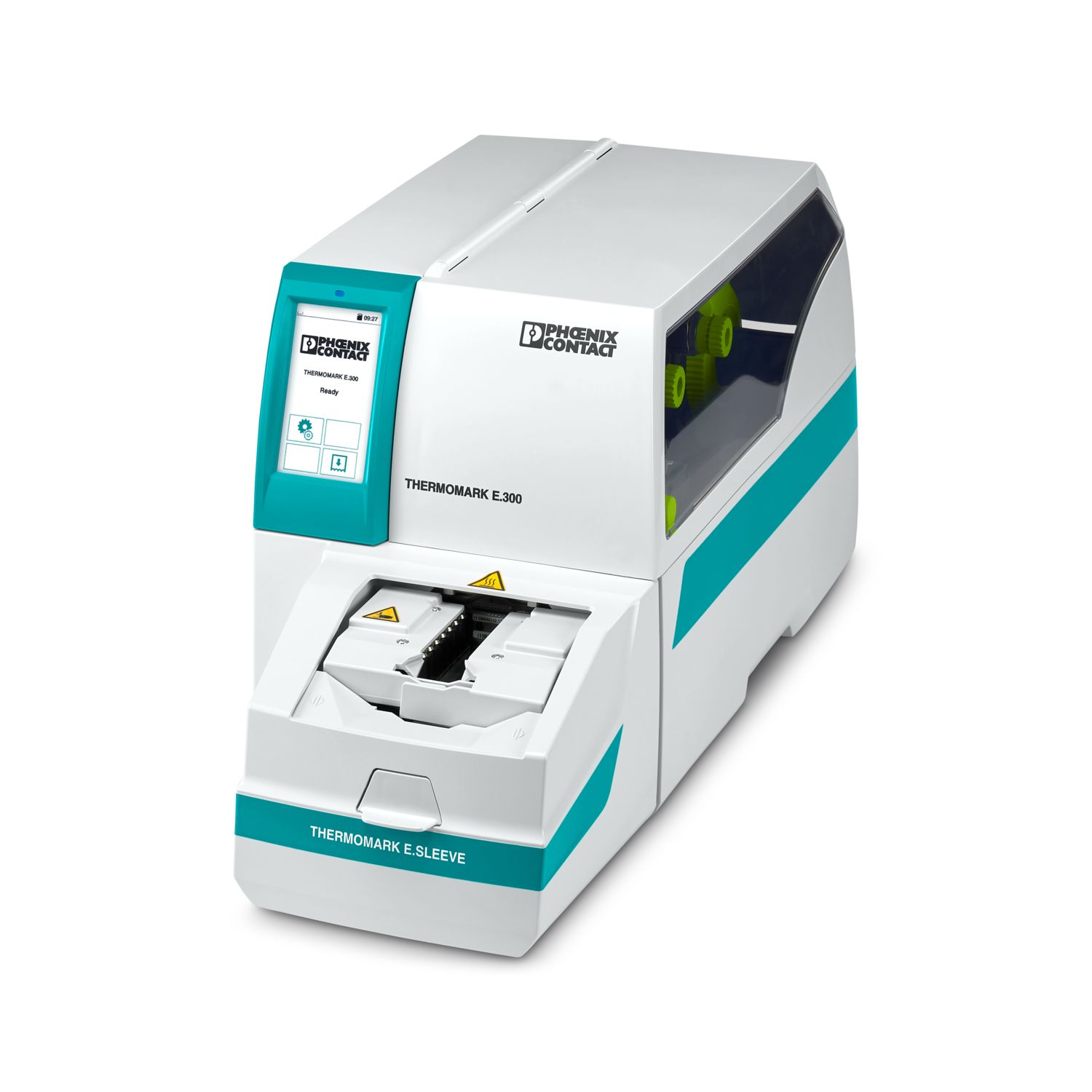

THERMOMARK E.SLEEVE - Applicator 1192932

-

THERMOMARK E.SLEEVE SET - Applicator set 1287049

-

TM-RIBBON 40 BK 105 - Ink ribbon 1259008

-

TM E.WIRE/E.SLEEVE-PR - Pressure roller 1259203

-

TM E.300/E.600-TEAR OFF PLATE - Demolition plate 1263118

-

TM E.300/E.600-FRONT COVER - Front plate 1285305

-

THERMOMARK ROLL-ERH - Media hub 5146448

-

THERMOMARK-ERH 500 - Media hub 5146309

Your advantages

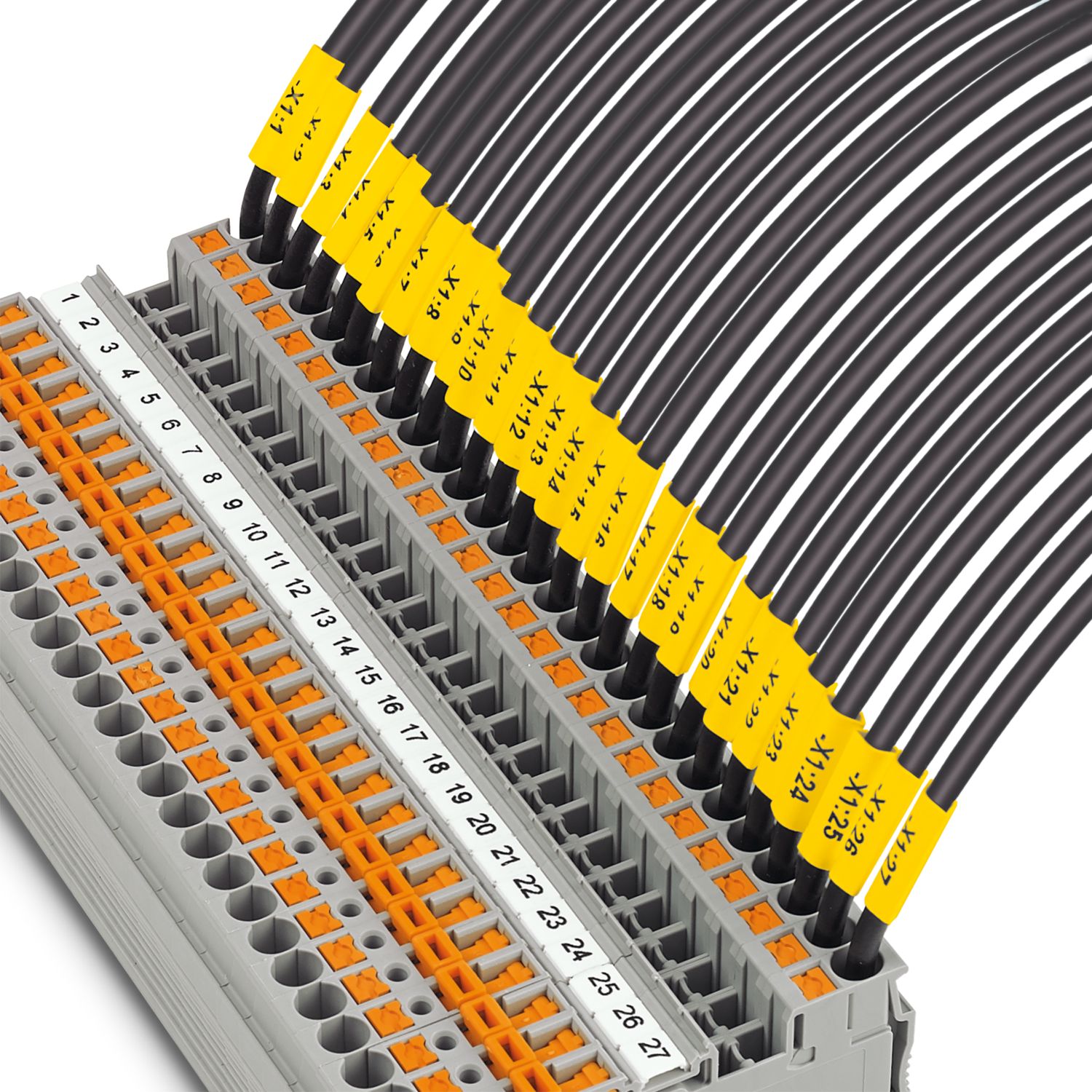

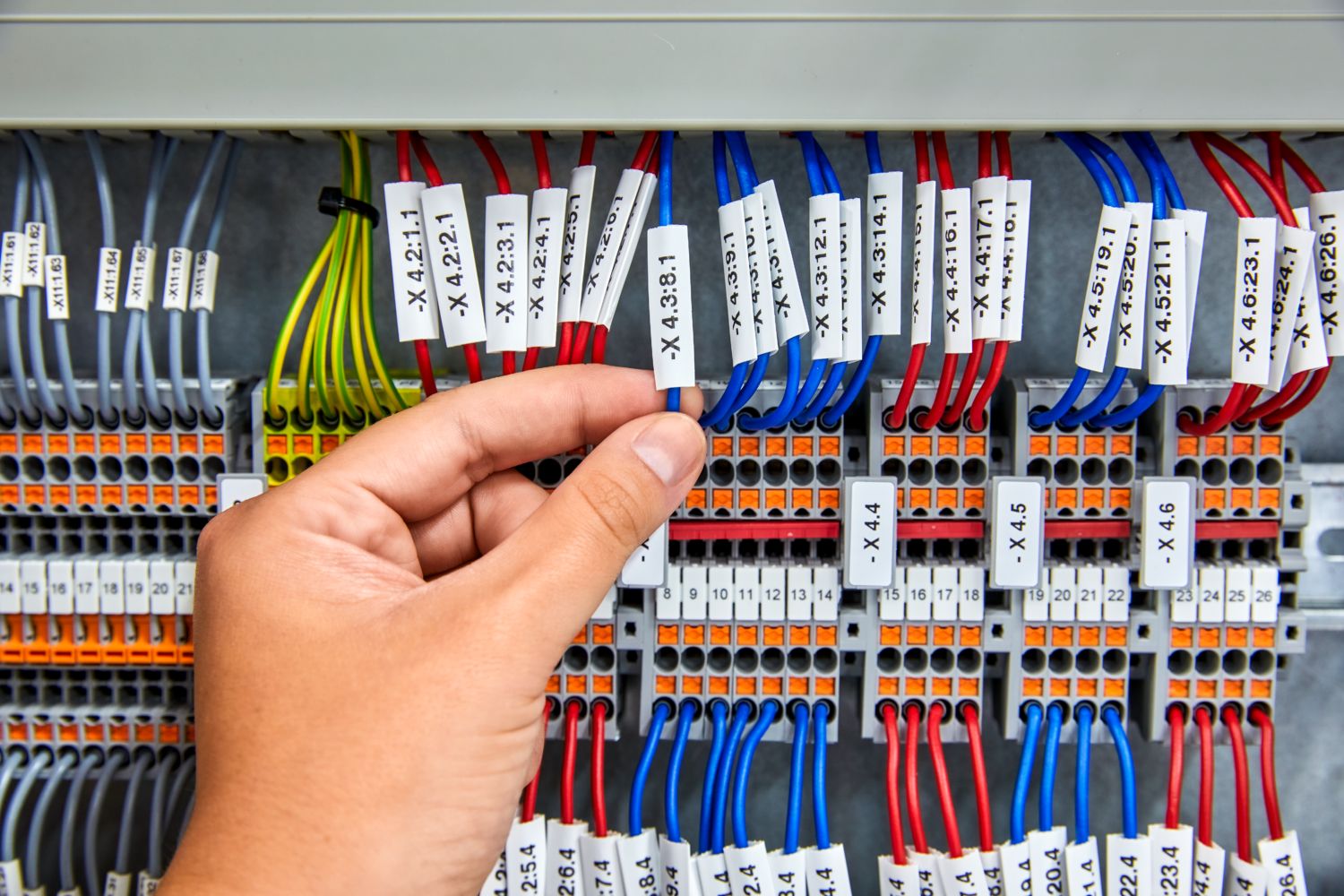

Permanent and captive identification of single-core wires, wires, cables, pneumatic hoses, and other cylindrical objects

High flexibility, as individual marker lengths ranging from 15 mm ... 51 mm (0.59" ... 2.0") can be realized

As an option, the sleeves can be shrunk by applying heat manually to fix the sleeve in position

High diameter coverage with a shrink ratio of 3:1

Widely used and proven worldwide in control cabinet and machine building, the oil and gas industry, and the railway industry

Can be used in the tube printing module M1650 Tube from KOMAX

Frequently searched

Phoenix Contact UAB

Svitrigailos str. 11M, 03228 Vilnius