Mechanical wastewater pretreatment Our monitoring and control solutions for the first cleaning stage are designed to help you implement low-wear and low-maintenance operation of your wastewater treatment plant.

The challenge

Control how impurities are removed

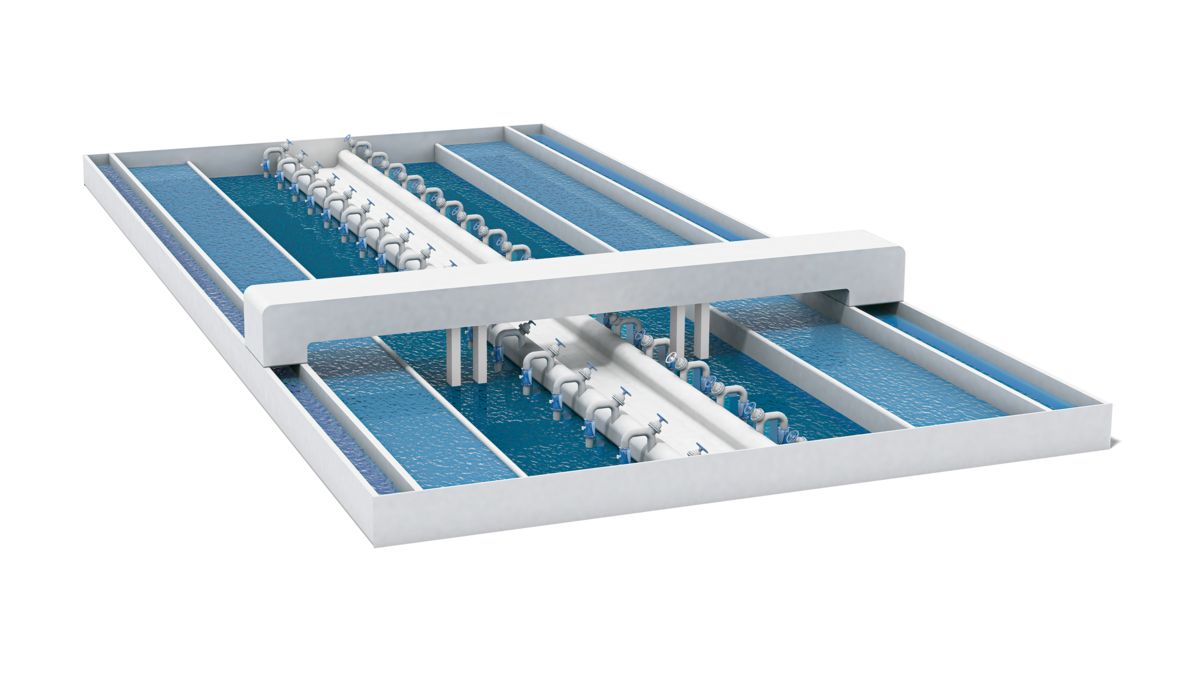

Ensuring an efficient initial treatment stage is a prerequisite for reliable operation of the entire wastewater treatment plant. Removing solid particles from raw wastewater and sludge protects downstream process stages from clogging and sedimentation. This requires reliable processes for the removal of impurities.

Solution

Low-wear and low-maintenance processes

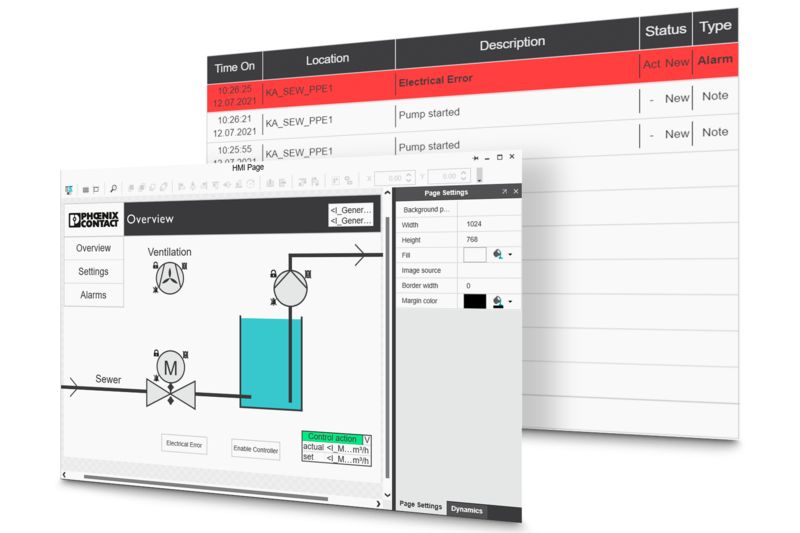

Our monitoring and control solutions meet the comprehensive requirements for trouble-free operation in mechanical precleaning. We offer particularly robust hardware adapted to the conditions as well as software solutions for the closed-loop control and actuation of field devices. For monitoring drives in potentially explosive areas, we provide you with tailored communication solutions as well.

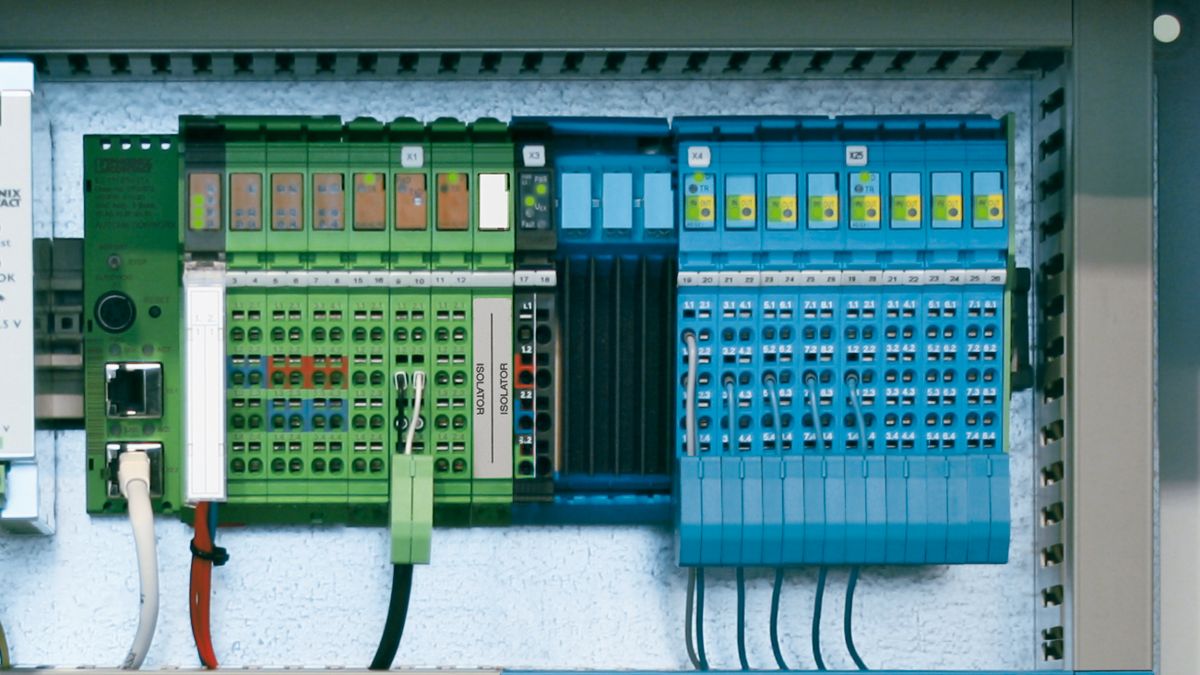

Protect against explosions

Due to unforeseeable events, such as unauthorized wastewater discharge, digestion processes or accidents, wastewater treatment plants always represent an explosion hazard. Coarse and fine screens are particularly explosive systems in wastewater technology plants. Intrinsically safe signal acquisition is ideal for protecting these areas.

Phoenix Contact provides a comprehensive product range for the potentially explosive area. You install your I/O station easily and safely in zone2. The sensors and actuators are separated from this and installed in zone0, 1, or 2 as required.

Consistent process automation

Thanks to the cooperation with manufacturers of industry-specific field devices such as frequency converters and various measuring devices, the Phoenix Contact Water Functions library ensures convenient integration into your infrastructure. The functional scope of the process library is continuously being expanded to keep pace with the current state of technology.

Benefit from versatile options to securely connect your distributed stations to the control room. Gain central access and perform continuous monitoring of your process data directly from the control room.

Your advantages

- Quick and easy: closed-loop control and actuation of field devices using pre-programmed software blocks

- Communication solutions for any infrastructure with technology for the Ex area

- State-of-the-art technology with continuous development of the Water Functions software library

Contact

Products

Still haven’t found the right product?

Feel free to contact us. We will consult with you to find the ideal solution together.