SAMPLE PTSM 0,5/1-2,5-H SMD WHL

-

PCB terminal block

1833453

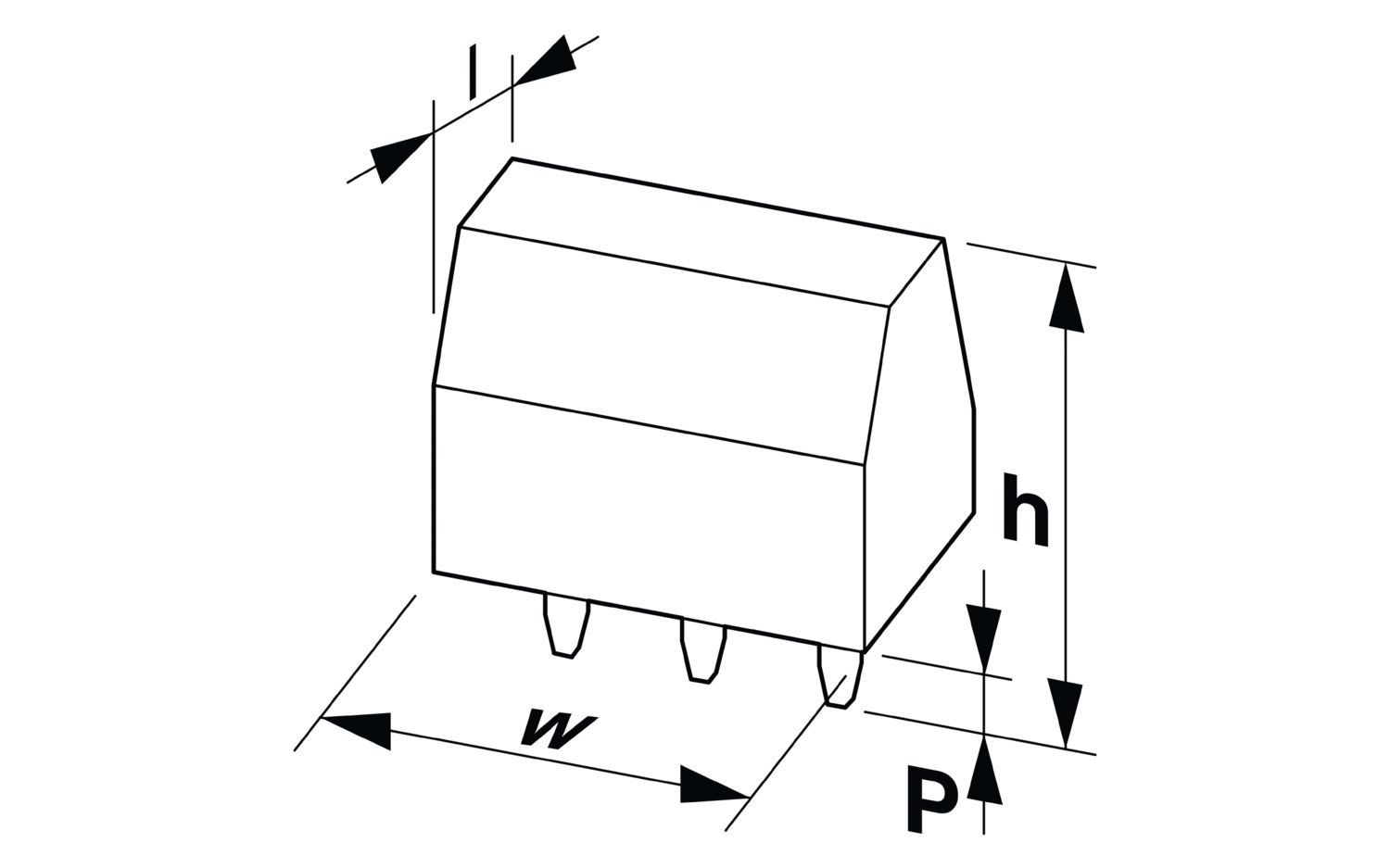

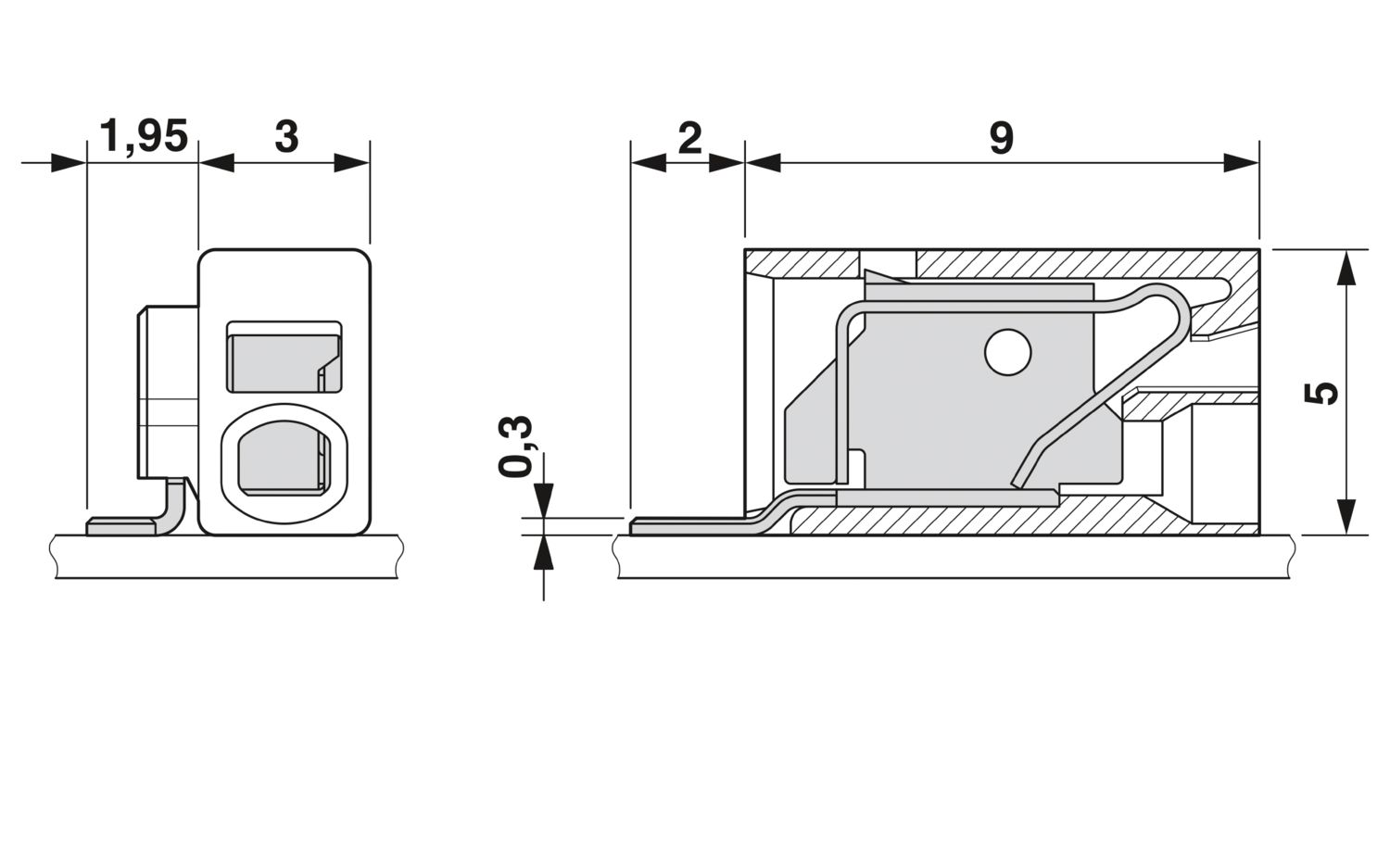

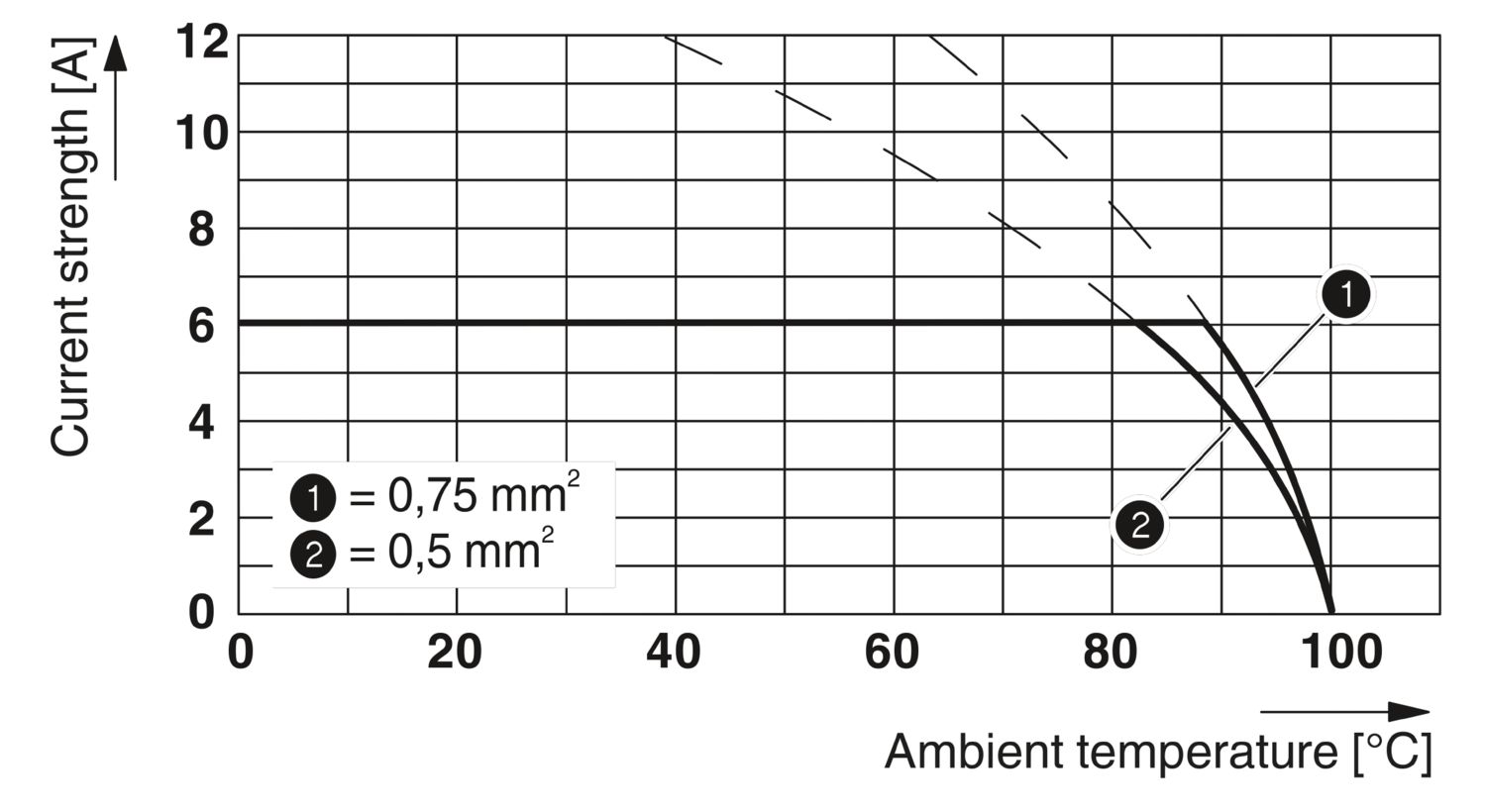

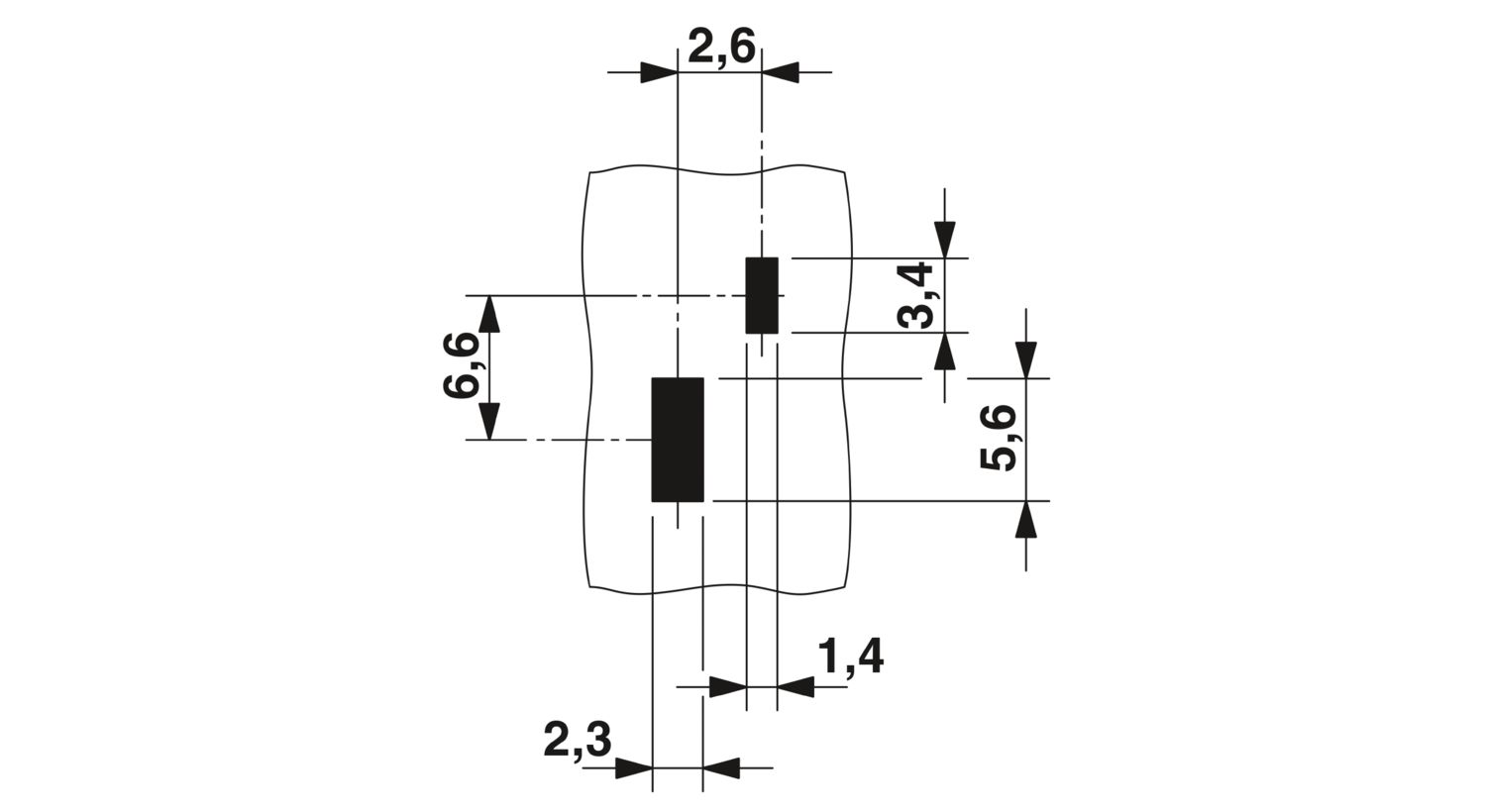

Printed circuit board terminal, nominal current: 6 A, rated voltage (III/2): 160 V, nominal cross section: 0.5 mm2, number of potentials: 1, number of rows: 1, number of positions per row: 1, product range: PTSM 0,5/..-H-SMD WH, pitch: 2.5 mm, connection method: Push-in spring connection, mounting: SMD soldering, conductor/PCB connection direction: 0 °, color: signal white, Pin layout: Linear pad geometry, number of solder pins per potential: 1, type of packaging: packed in cardboard. SAMPLE set with 5 items in belt section. When used as part of soldering process, please use items without SAMPLE marking

Product details

Compatible products

Your advantages

White design: Stable color when welding and during use

Time saving push-in connection, tools not required

Defined contact force ensures that contact remains stable over the long term

High current carrying capacity of 6 A in very compact dimensions

Designed for integration into the SMT soldering process

Additional solder anchors reduce the mechanical strain on the soldering spots