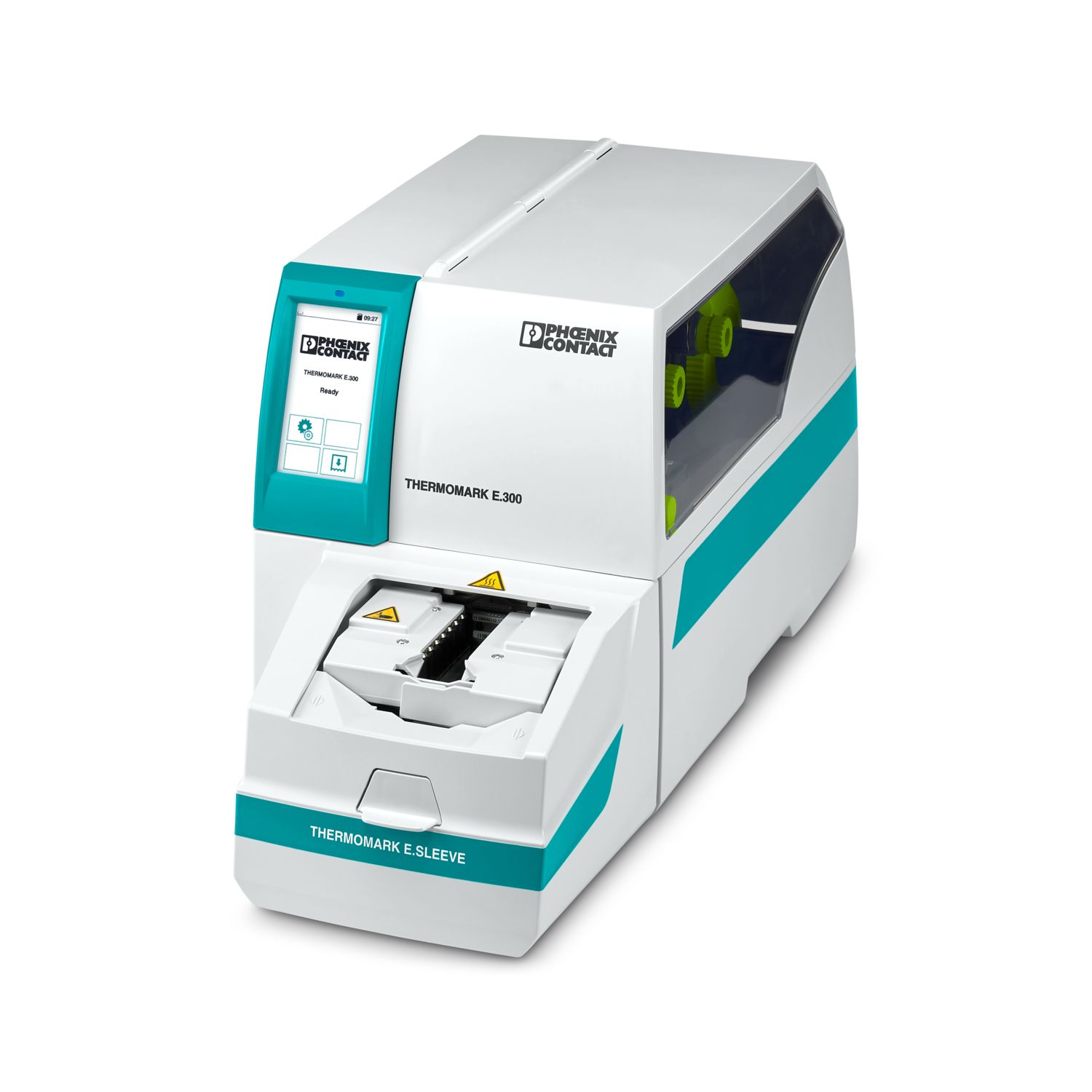

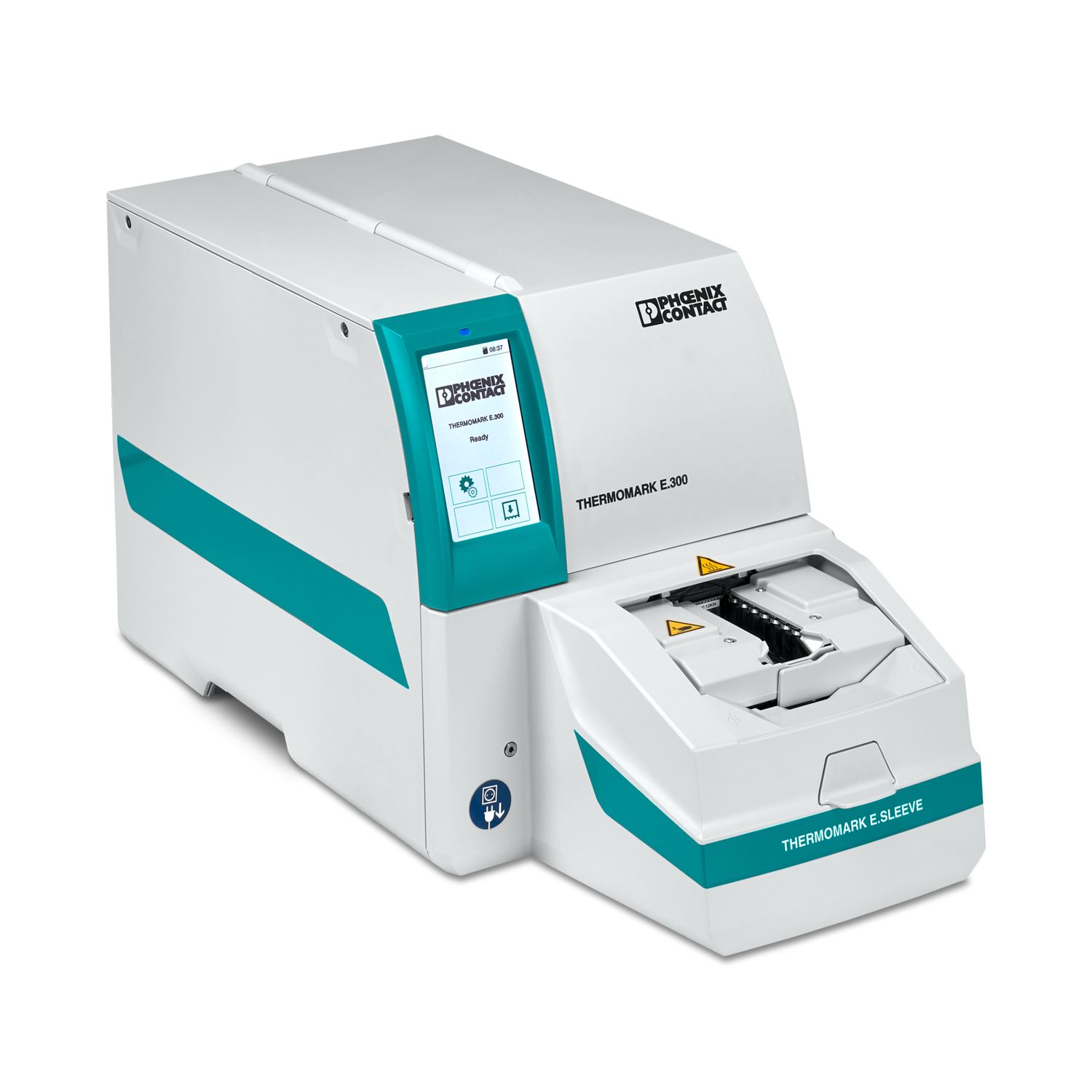

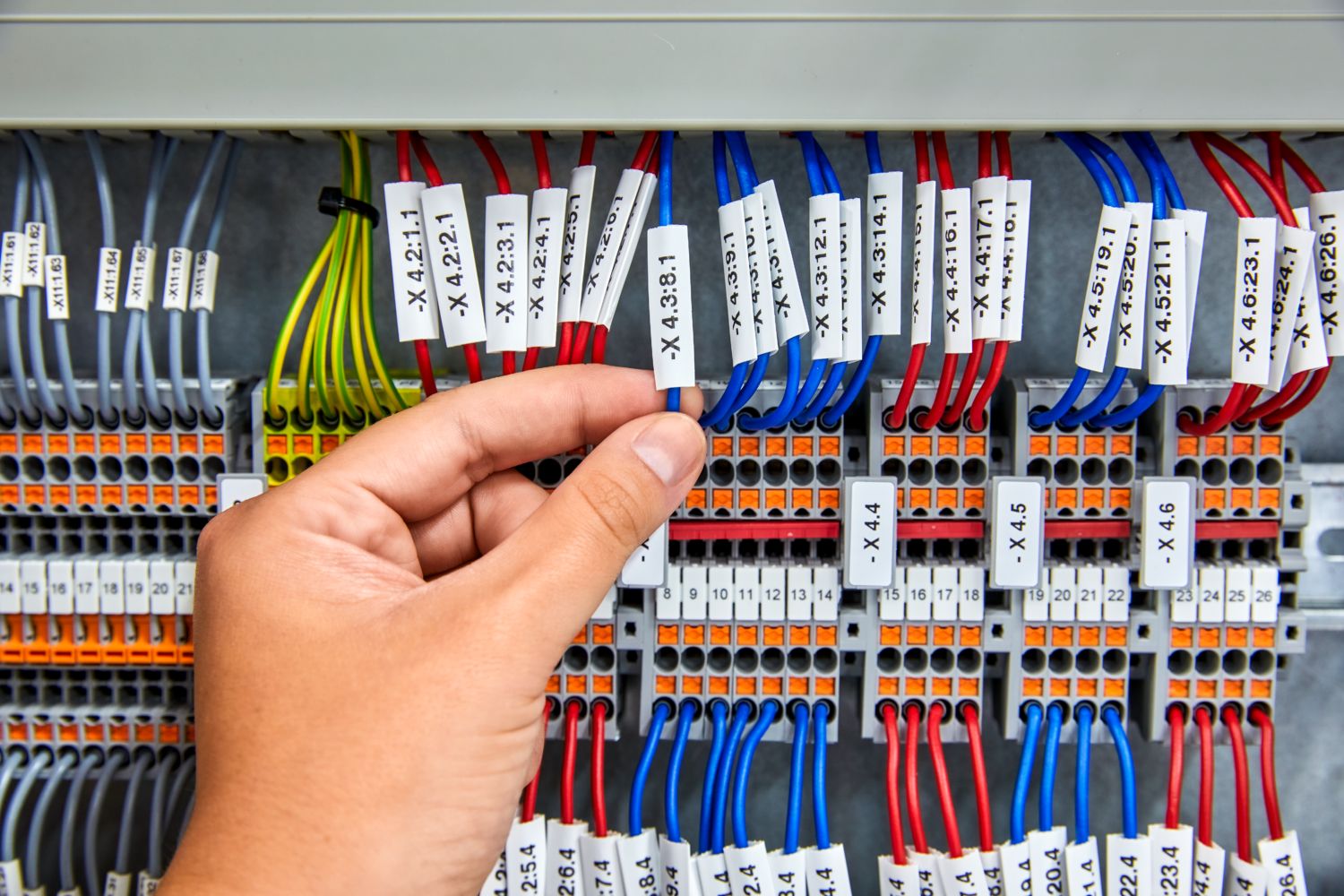

When it comes to wire and cable marking, the THERMOMARK E.SLEEVE set elevates productivity to the next level. When combined, the THERMOMARK E.300 BASIC roll printer and the THERMOMARK E.SLEEVE applicator provide maximum efficiency in wire and cable identification processes. This provides you with an automated printing and applying system that enables you to achieve time savings of up to 75% compared to manual identification processes.

The THERMOMARK E.SLEEVE cuts the ready-printed E-WMS... shrink sleeves and marking sleeves in continuous format to the appropriate length, opens the individual markers, and feeds them in as far as the removal position so that the user can apply the finished markers to the wire/cable very easily. This unique system enables the efficient and demand-oriented creation of custom marker lengths between 15 mm/0.59" and 51 mm/2.0". Automated identification of all types of cylindrical objects that have a diameter of between 0.8 mm/0.03" and 8.5 mm/0.33" is supported.

Scope of supply:

THERMOMARK E.SLEEVE (1192932), TM E.WIRE/E.SLEEVE-PR pressure roller (1259203), THERMOMARK E.300 BASIC, power cable (pin connector pattern: type F), USB cable, and multilingual packing slip.

Note:

The THERMOMARK E.300 (D) BASIC printing system is equipped for immediate use in combination with the respective applicator. It differs from the THERMOMARK E.300 (D)/E.600 (D) standard printer in that it has a reduced scope of supply. The TM E.300/E.600-FRONT COVER front cover (1285305), TM E.300/E.600-TEAR OFF PLATE tear-off plate (1263118), TRM-PRESSURE ROLLER STANDARD standard pressure roller (0804655), EML (20X8)R/TL label roll (0802999), and THERMOMARK-RIBBON 110/50 ink ribbon (0800687) are not included.