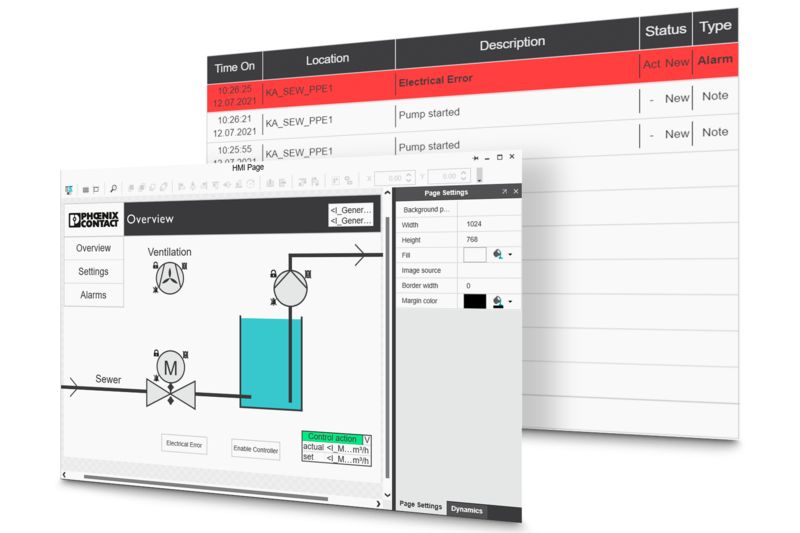

For the precise control of the treatment plant when chlorine dioxide is applied, the measured values for flow rate and residual chlorine are used. The combination of modular control technology with integrated eHMI and ready-programmed visualization blocks allows precise control with on-site operation using a web-based touch display.