IO-Link

What is IO-Link?

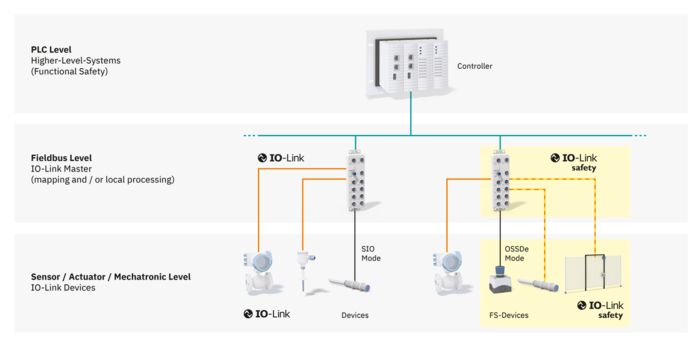

IO-Link is the first globally standardized I/O interface. The technology has established itself as the communication standard in machine building and systems manufacturing. The number of products with IO-Link interface used is growing rapidly. The communication standard offers you many advantages, creates new application opportunities, and constitutes an investment in important matters such as the Industrial Internet of Things (IIoT). By definition, IO-Link is an open, serial point-to-point communication protocol for connecting sensors and actuators to an automation system.

IO-Link Safety implements safe communication from start to finish. This means that users also benefit from typical IO-Link advantages in the field of functional safety, such as simple parameterization with IODD or fast device replacement.

Advantages of IO-Link

- Increased productivity

- Simplified installation, maintenance, and replacement processes

- Increased data availability and accuracy

- Troubleshooting via remote diagnostics

Productivity

IO-Link devices provide the controller with detailed condition data. This data aids maintenance planning because you can identify problems quickly. If you as a user receive a warning message from dirty sensors every six months, for example, you can plan cleaning them twice a year at convenient times. Furthermore, real-time fault detection of devices enables you to reduce operating costs by minimizing unplanned downtimes.

Simplicity

Everything in IO-Link is easy. Installation is easy because you can use standard cables and connectors. Maintenance is easy because you can monitor your systems and modify the settings. Using the error detection feature of IO-Link devices, you can determine the cause of a problem quickly and easily. The replacement process is also easy because the parameter data is stored in the controller. If an IO-Link device needs to be replaced, the stored parameters are automatically copied to the IO-Link device without using a programming device. As a result, your system is quickly ready to operate again.

Increased data availability and accuracy

Analog sensors without IO-Link often pass through multiple A/D conversions before data reaches the controller, which may result in errors. In IO-Link devices, there is only one A/D conversion. This increases measuring accuracy and thus the accuracy of the entire process.

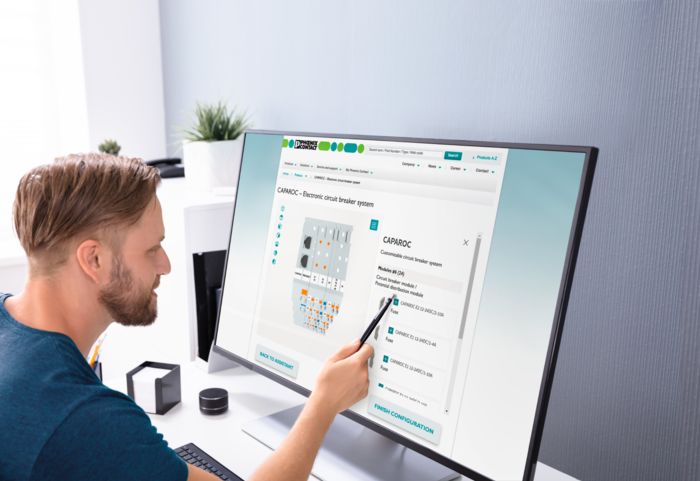

Remote configuration

You can modify the parameters of the IO-Link device from your desk by responding to status messages. You therefore no longer have to shut down the production line and physically access the devices in order to rectify faults.

Components of an IO-Link system

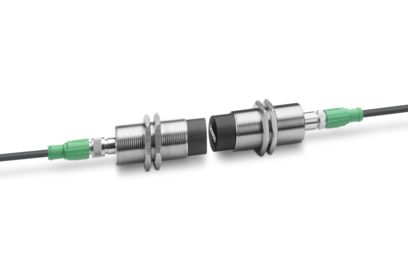

The architecture of an IO-Link system consists of a controller, an IO-Link master, and one or more IO-Link devices. They are connected by simple three-wire, unshielded cables, which makes installation easier and more cost-effective.

What can an IO-Link device do that a standard sensor cannot?

IO-Link devices supply three types of data:

-

Process data: Condition information that the IO-Link device reads and sends to the IO-Link master or information that the IO-Link master sends to the IO-Link device. Status information is also transmitted in this process. You can thus check whether the process data is valid. An example of process data is the distance measured by a distance sensor.

-

Service data: Information that can be written to the IO-Link device or read from the IO-Link device. Example: The model or manufacturer number of the sensor helps to identify a device or configure a new one.

-

Event data: Notifications such as error messages, which are sent from the IO-Link device to the IO-Link master as soon as an event e.g., overheating, occurs.

IO-Link products

Our product portfolio for communication from start to finish: