Biological treatment in wastewater treatment With our monitoring and control solutions for biological wastewater treatment, you can realize a more energy-efficient and reliable plant operation.

The challenge

High energy requirements and fluctuating process variables

Biological wastewater treatment is both the core and also the largest energy consumer in the cleaning process of a wastewater treatment plant. Precise closed-loop control of process values, such as the oxygen content in the aeration tank, is an essential requirement when it comes to the optimum treatment process for wastewater.

Solution

Optimum wastewater cleaning process

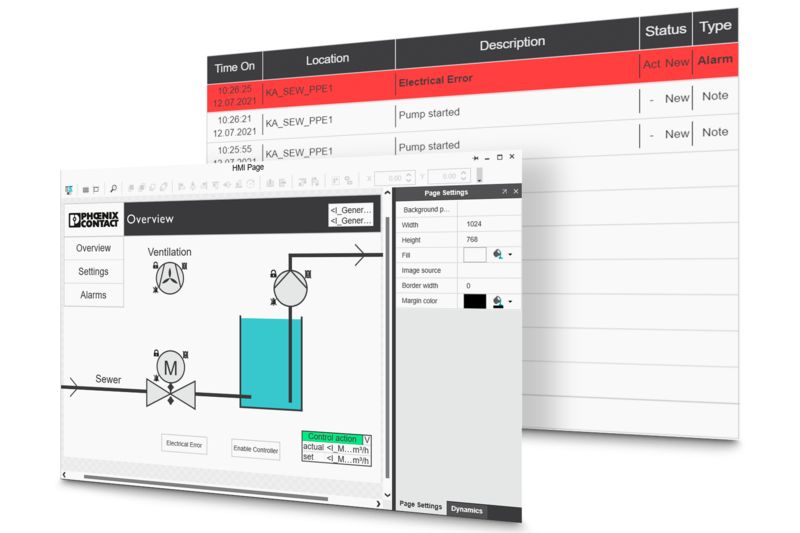

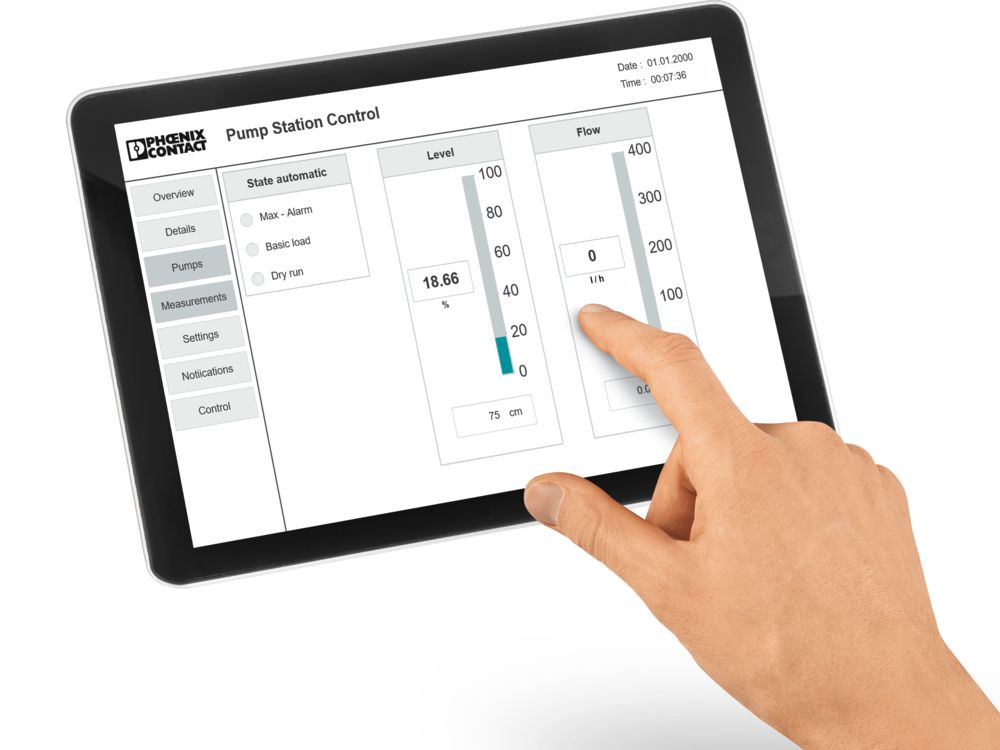

Utilize our software libraries for control and monitoring to realize energy-efficient and reliable plant operation. All plant parts can be easily integrated into the software, especially measurement and control technology.

You can implement a flexible connection of all system parts with the network components, and ensure secure remote access. You can then use the data, for example, for more precise control of the system or for predictive maintenance.

Easy integration of industry-typical equipment

Programmed function blocks from the Water Functions library simplify the manufacturer-independent connection of equipment such as measuring devices and frequency converters in pumps and blowers. All key process data such as speeds of rotation, power consumption, and fill levels are acquired reliably using a controller from the PLCnext Control family and transmitted to the control system. The modular design enables the plant to be enhanced at any time.

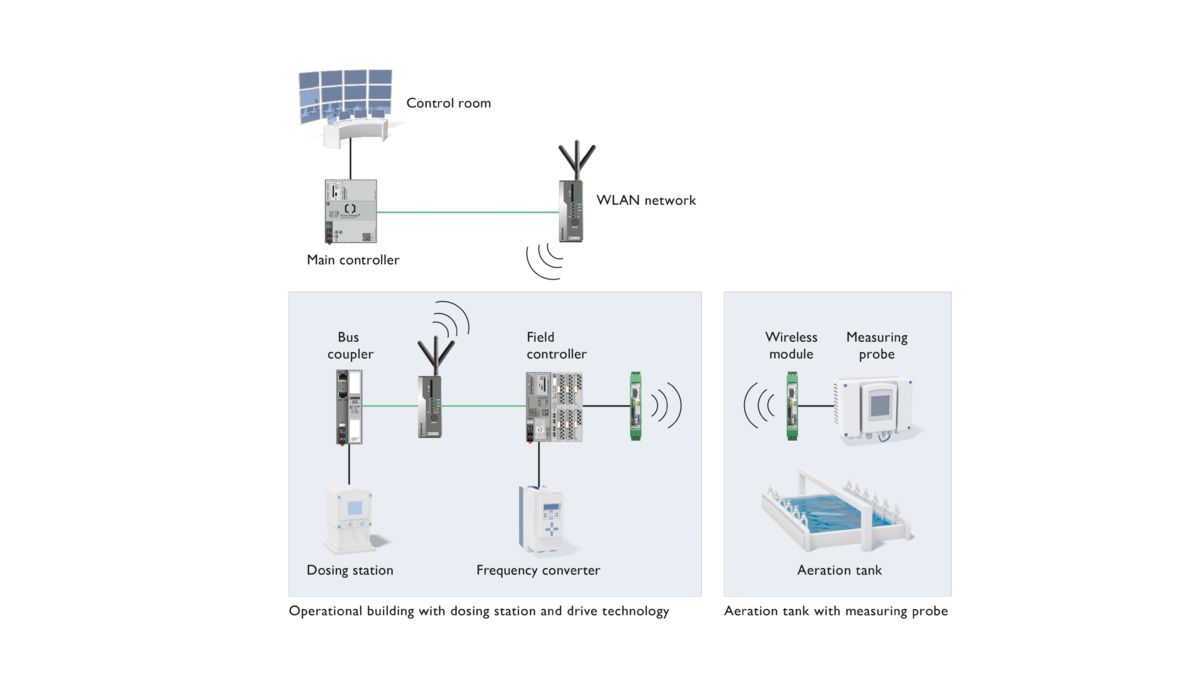

Wireless data transmission from the aeration tank to the control room

Connection to the control room and access to the different parts of the plant is realized in various ways with modern technology. However, the costs for retrofitting cables are often high, in particular in upgrade projects. Wireless transmission procedures are a flexible and cost-effective alternative for communicating process data from the field to the control room.

Modern wireless communication provides you with the required flexibility for every application. Process data is exchanged between individual areas, such as the dosing station and aeration tank, via PROFINET and WLAN. All relevant process values are safely transmitted to the control room.

Your advantages

- Reliable communication with communication technology from the measurement point all the way to the control room

- A high level of IT security with certificate-driven communication

- Flexible monitoring procedures for various fields of application: cable-bound solutions such as DSL, GPRS, UMTS, LTE, Bluetooth, and LoRaWAN

Contact

Products

Still haven’t found the right product?

Feel free to contact us. We will consult with you to find the ideal solution together.