What is a digital twin? Digital twins are virtual models that can be used to better understand, test, and optimize processes.

Brief summary

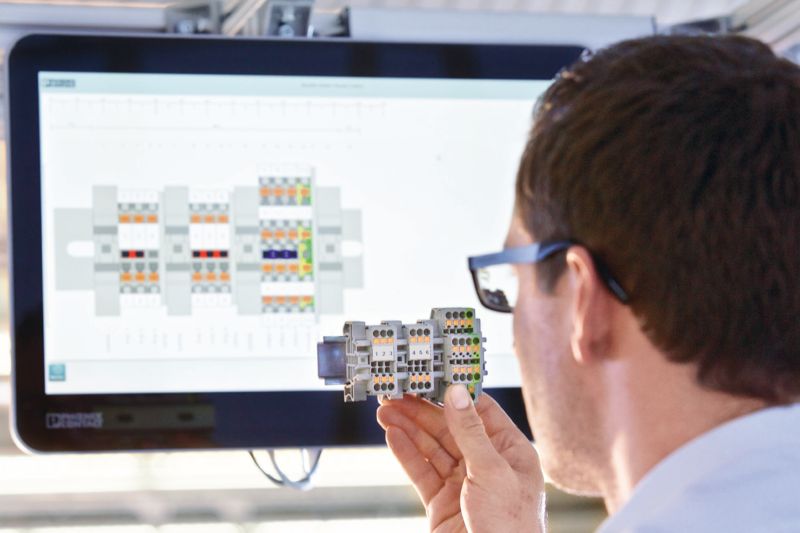

A digital twin is a virtual model of a physical object or system that represents its real counterpart in the digital world. Engineers and IT specialists can use their help to better understand, test, and optimize processes. Decisions can be made based on data analysis, which leads to an increase in efficiency and product quality.

In industry, digital twins help to avoid downtimes

Digital twins in industry

Digital twins are used in the manufacturing industry to monitor and optimize production processes. They help to avoid downtimes. By integrating real-time data, digital twins can detect anomalies at an early stage and provide proactive maintenance options. The simulation of complex scenarios is particularly important in areas such as construction and automotive production where safety and precision are essential. In the power industry, digital twins provide support for monitoring networks and systems, which also helps to reduce emissions. In logistics, they help by making supply chains more efficient.

What we call a digital twin for the process industry is a digital map of all sensors and actuators present in the field, including the stored maintenance cycles, their configuration, and the error status of the devices in the event of errors.

Advantages of digital twins

- Ability to optimize processes

- Increased efficiency, minimized potential risks, and minimized downtimes

- Cost reductions by avoiding unnecessary resource consumption

- High-level innovation potentials through virtual scenario and parameter testing

- Faster time-to-market with competitive advantages

- Improved quality assurance

- Promoting sustainability

Challenges for digital twins

- Integrating real-time data from different sources is a complicated task

- Implementation requires specialized knowledge

- Data protection breaches and cyberthreats

- Ongoing maintenance and updating must be continuous

The future of the digital twin

With the progress in artificial intelligence and the Internet of Things (IoT), digital twins are becoming more intelligent and better integrated. They enable automated decisions and real-time analysis, increase efficiency, and generate new business models. Companies must continuously develop their digital twins so that they can benefit from market changes and technological innovations. Using blockchain technology is a potential way of increasing the security of digital twins by ensuring data integrity. In addition, digital twins promote sustainable practices and help companies to reduce their ecological footprint.

Summary

Given the broad spectrum of applications and advantages of digital twins, it is becoming clear that they are not just a temporary technology trend, but also a decisive factor for future success in a wide range of industries. They provide a platform that enables companies to optimize their processes, resulting in significant increases in efficiency and cost savings. In particular in industries with complex, multi-stage production processes, digital twins can be useful tools for minimizing downtimes and improving product quality.

Connect with our experts

More posts

The All Electric Society – how sector coupling works

Flexibility with a battery storage system and energy management.

Coupling of factory and building

The Emalytics Automation building management system harmonizes data formats and intelligently networks sectors.

Sensors make sheet metal forming more reliable

In automotive engineering, surface quality is the crowning discipline – with its sensor technology and digitalization, the retrofit system achieves greater process transparency, even in older press lines.