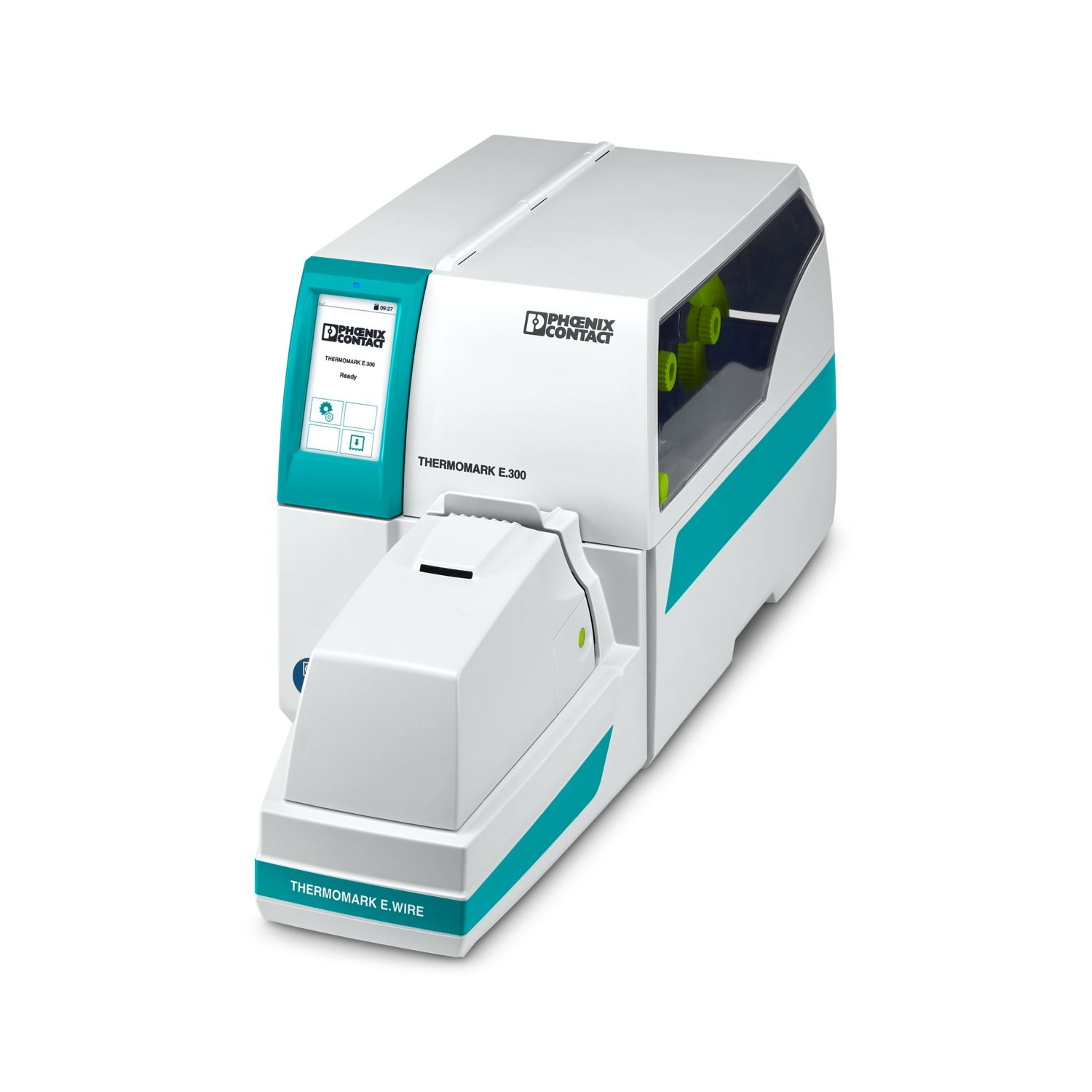

When it comes to wire and cable marking, the THERMOMARK E.WIRE set elevates productivity to the next level. The combination of the THERMOMARK E.300 roll printer and the THERMOMARK E.WIRE applicator offers maximum efficiency for wire and cable identification processes. This provides you with an automated printing and application system that enables you to achieve time savings of up to 70% compared to manual identification processes.

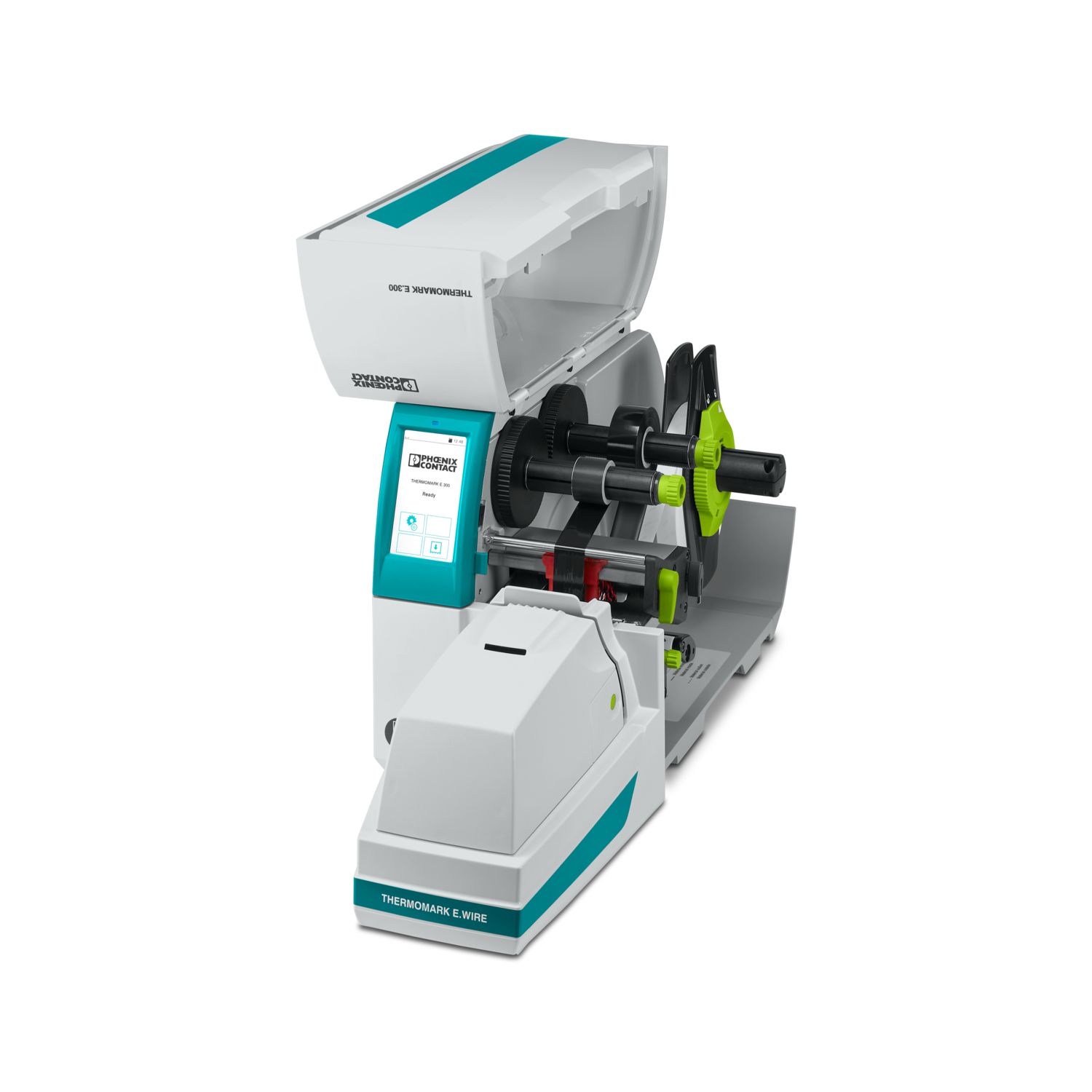

The movable markers are suitable for all types of cylindrical objects as well as twisted wires. Thanks to their triangular shape, they can be marked on all three sides. In this process, the THERMOMARK E.WIRE automatically measures the diameter of the cylindrical object, cuts the E-WM... marking foil in continuous format printed by the THERMOMARK E.300 BASIC to the appropriate length, places this around the cylindrical object, and then seals the marker shut with a heat-sealed joint. This results in a captive marker that is optimally tailored to the diameter and can also move radially and axially. Thanks to this unique system, all diameters between 1.8 mm/0.07" and 5.6 mm/0.22" can be marked efficiently using just one type of material.

Scope of supply:

THERMOMARK E.WIRE (1203216), TM E.WIRE/E.SLEEVE-PR pressure roller (1259203), THERMOMARK E.300 BASIC, power cable (pin connector pattern: type F), USB cable, and multilingual packing slip.

Note:

The THERMOMARK E.300 (D) BASIC printing system is equipped for immediate use in combination with the corresponding applicator. It differs from the THERMOMARK E.300 (D)/E.600 (D) standard printer in that it has a reduced scope of supply. The TM E.300/E.600-FRONT COVER front cover (1285305), TM E.300/E.600-TEAR OFF PLATE tear-off plate (1263118), TRM-PRESSURE ROLLER STANDARD standard pressure roller (0804655), EML (20X8)R/TL label roll (0802999), and THERMOMARK-RIBBON 110/50 ink ribbon (0800687) are not included.