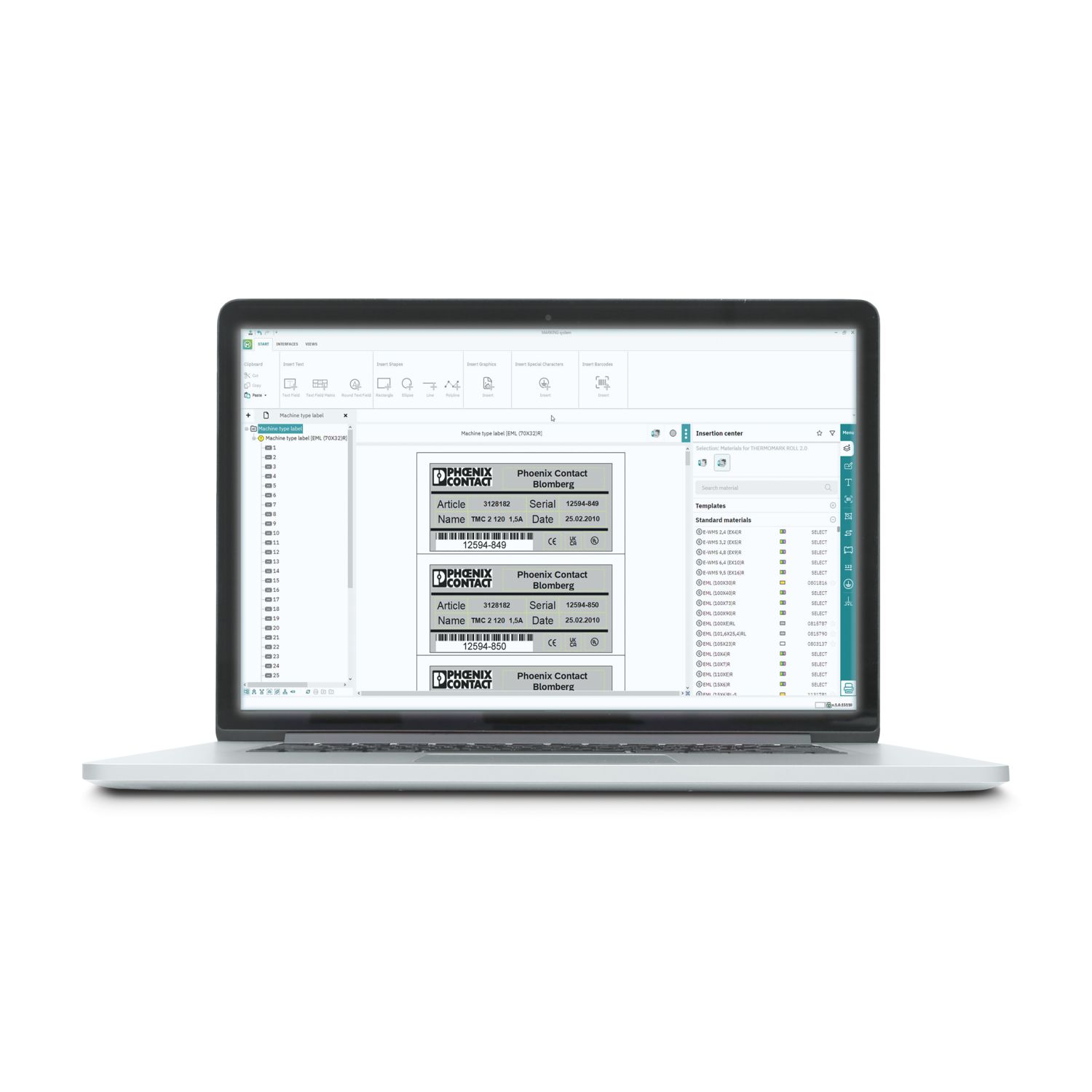

Create marking data easily:

The MARKING system software enables you to implement your custom-designed marking solutions easily and conveniently. All Phoenix Contact marking systems can be controlled and managed centrally from this software.

Comprehensive, application-specific functions and design options enable you to create customized marking solutions for terminal blocks, wires and cables, equipment, and plants.

In addition to many functions for the visual design of the marking materials, the user-friendly software ensures efficient marking processes with its powerful data import functions and interfaces to common ECAD programs and spreadsheet formats. The interface to clipx ENGINEER ensures seamless processes from planning through to production.

The Wire Marking Application Center even guides you through the entire printing and applying process all the way to the finished marked wire or cable.

MARKING SYSTEM SOFTWARE

-

Software

1669297

Create marking files easily and conveniently on your laptop or desktop PC. All Phoenix Contact marking systems as well as standard office printers can be controlled via the software. The software is available for download.

Product details

Compatible products

Your advantages

Everything from a single source: The MARKING system software supports all marking systems and marking materials from Phoenix Contact

End-to-end process support from product search and creation to ready-to-assemble marking material

Structuring using the project tree: Efficient creation of structured marking projects in accordance with IEC 81346 with a clear project tree, intuitive user interface, and extensive design options

Perfect ECAD integration: High-performance interfaces for the efficient import of data from ECAD systems and common data exchange formats

Intuitive operation via context-sensitive menu: Get automated design options tailored to the respective step

Decentralized marking processes on site: For efficient identification directly at the control cabinet, you can quickly and easily transfer marking projects to the printing and marking systems, thus displaying all information on the device display

Centralized marking processes: Manage and control all marking systems using the MARKING system software and assign your projects to the printing and marking systems

Reduction of downtimes due to monitoring the entire identification process: In addition to standard control via Ethernet, the THERMOMARK E SERIES offers another advantage: by using the bidirectional OPC UA communication interface, you are informed in real time about the project and operating status of the individual devices

Efficient and easy wire identification with MARKING system: The Wire Marking Application Center supports you throughout the entire wire preparation process by visualizing the wire and cable identifications

Template Designer: Design labels according to your own specifications and add graphics, barcode types, special characters, safety symbols, and geometric designs, for example