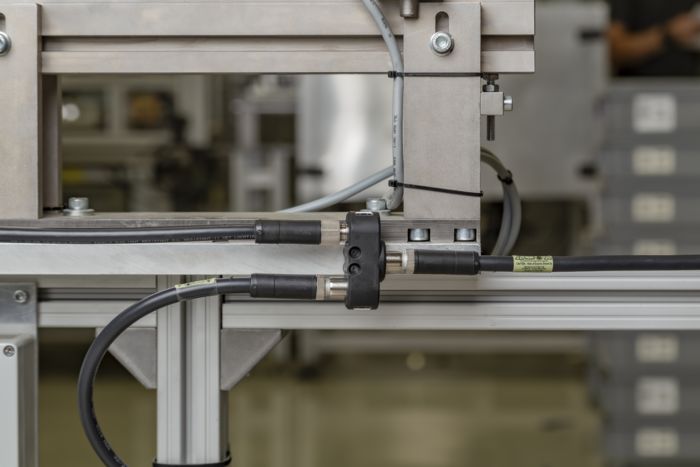

Connect a variety of power cables easily and flexibly with our wide range of power cordsets and connectors. Depending on the demands of your power distribution application, choose between simple, prefabricated cordsets, device connectors for wired or PCB connections, convenient field-wired connectors with a range of termination methods, and distribution blocks to connect trunk lines to taps to further distribute power among several devices.

Which system is right for you?

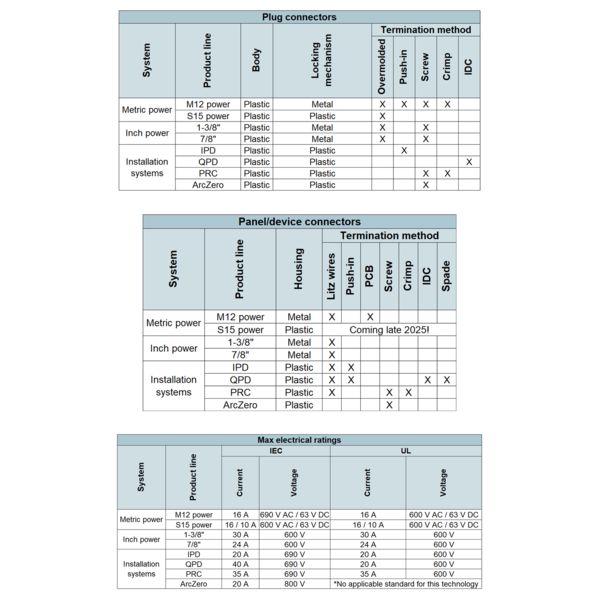

With so many different form factors to consider, a comparison of some of the most basic aspects of these power connectors can help narrow the options significantly. Here is a quick look at the applicable termination methods and basic electrical limits.

Metric power

Electronic device manufacturers, panel builders, and industrial equipment users require standardized options for power connectivity that save space, increase functionality, and enhance performance. Globally accepted metric standards for power connections have driven IEC standardization with significantly smaller form factors for distributing power to the places it is needed most!

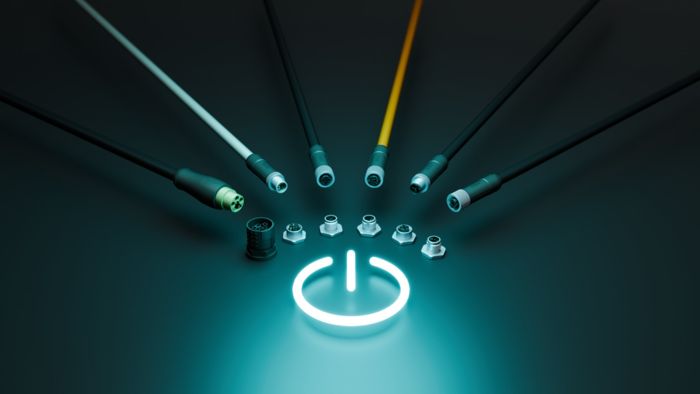

The traditional cables and connectors used to power devices are typically bulky with large circulars. Now, the compact M12 form factor is ready for power applications. Traditional M12 sensor connectors provided current with up to four amps max. With the newly designed M12 power current, up to 16 amps is now achievable. Also, by sizing up slightly to 15mm, the new S15 cordsets can provide the same high level of power with the possibility of combining signal requirements in the same connector.

M12 power

AC power - U.S. production, Speedy Transaction

DC power - Global production

S15 Hybrid Power

TC-ER-rated cordsets and the NEC Tap Rule

The utilization of TC-ER-rated cordsets in environments governed by NFPA 79 and the NEC Tap Rule offers a cost-effective, safe, and efficient way to design and deploy distributed power networks. TC-ER-rated cordsets reduce installation time, material costs, and complexity by eliminating the need to run cabling through raceways or conduit. This is especially true in systems where tap conductors are under 25 amps and the run distances for those tap lines are under 25 feet (7.5 meters), as is often seen in many intralogistics and intelligent assembly networks.

3-meter (10') rule

Feeder taps of up to 3 meters need to utilize conductors that are rated for no less than 1/10 of the trunk line. For example, a 40-amp trunk must have feeder taps that are rated for a minimum of 4 amps each.

7.5-meter (25') rule

Feeder taps of 3 to 7.5 meters need to utilize conductors that are rated for no less than 1/3 of the trunk line. For example, a 30-amp trunk must have feeder taps that are rated for a minimum of 10 amps each.

Inch power

While bulkier than their metric counterparts, inch-based connector systems have found their way into mainstream use throughout North America for a host of different power distribution networks. Given their widespread use despite more globally accepted metric standards, Phoenix Contact has created an offering of inch connectors to better integrate into legacy power distribution systems.

Installation power

Connect cables easily and flexibly with our installation systems. Choose between simple cable connections, convenient power distribution, or compact device connections. Robust housings and high degrees of protection facilitate reliable power transmission outdoors and in wet environments.