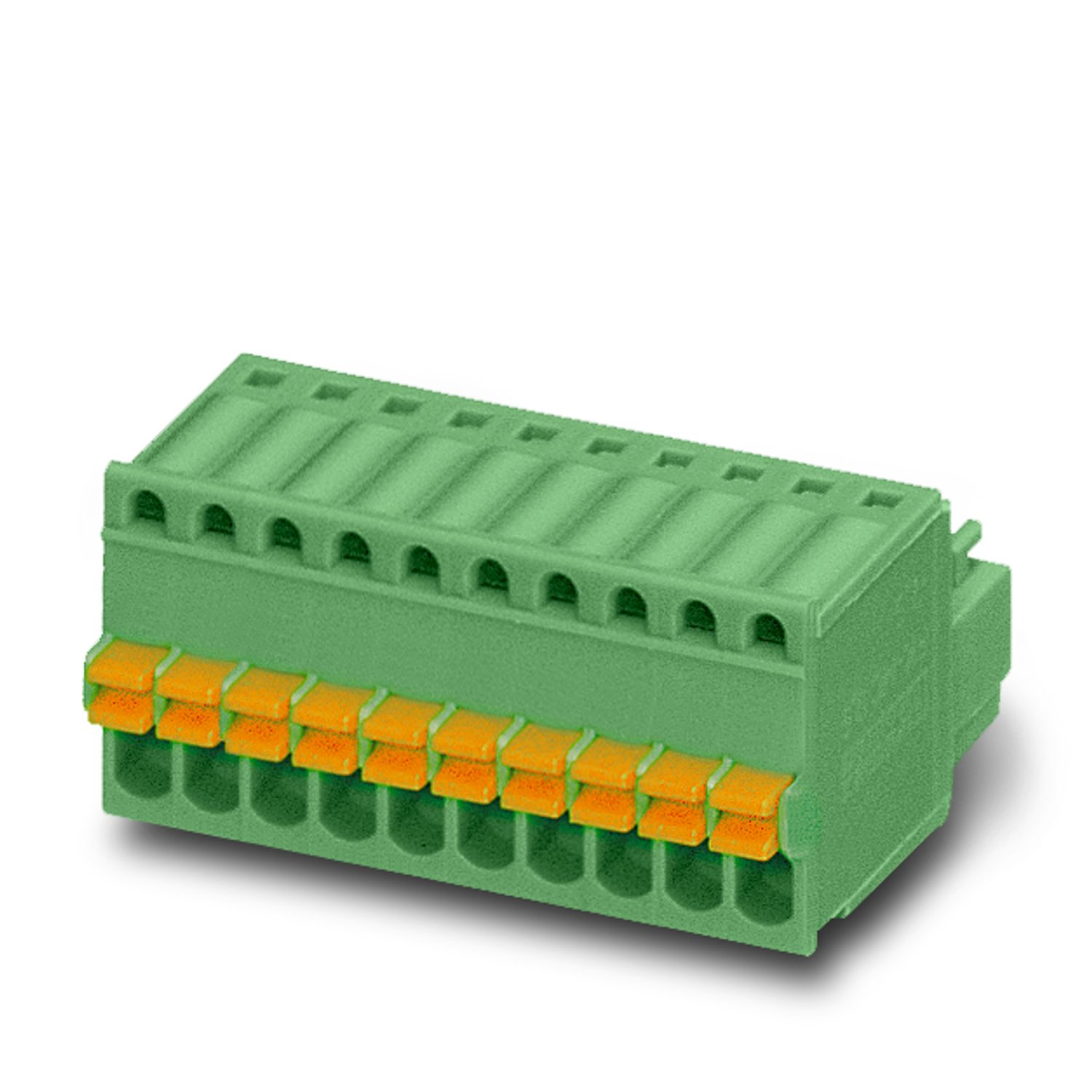

FK-MC 0,5/ 9-STZ2-2,5BKBDWH1-9

-

PCB connector

1702691

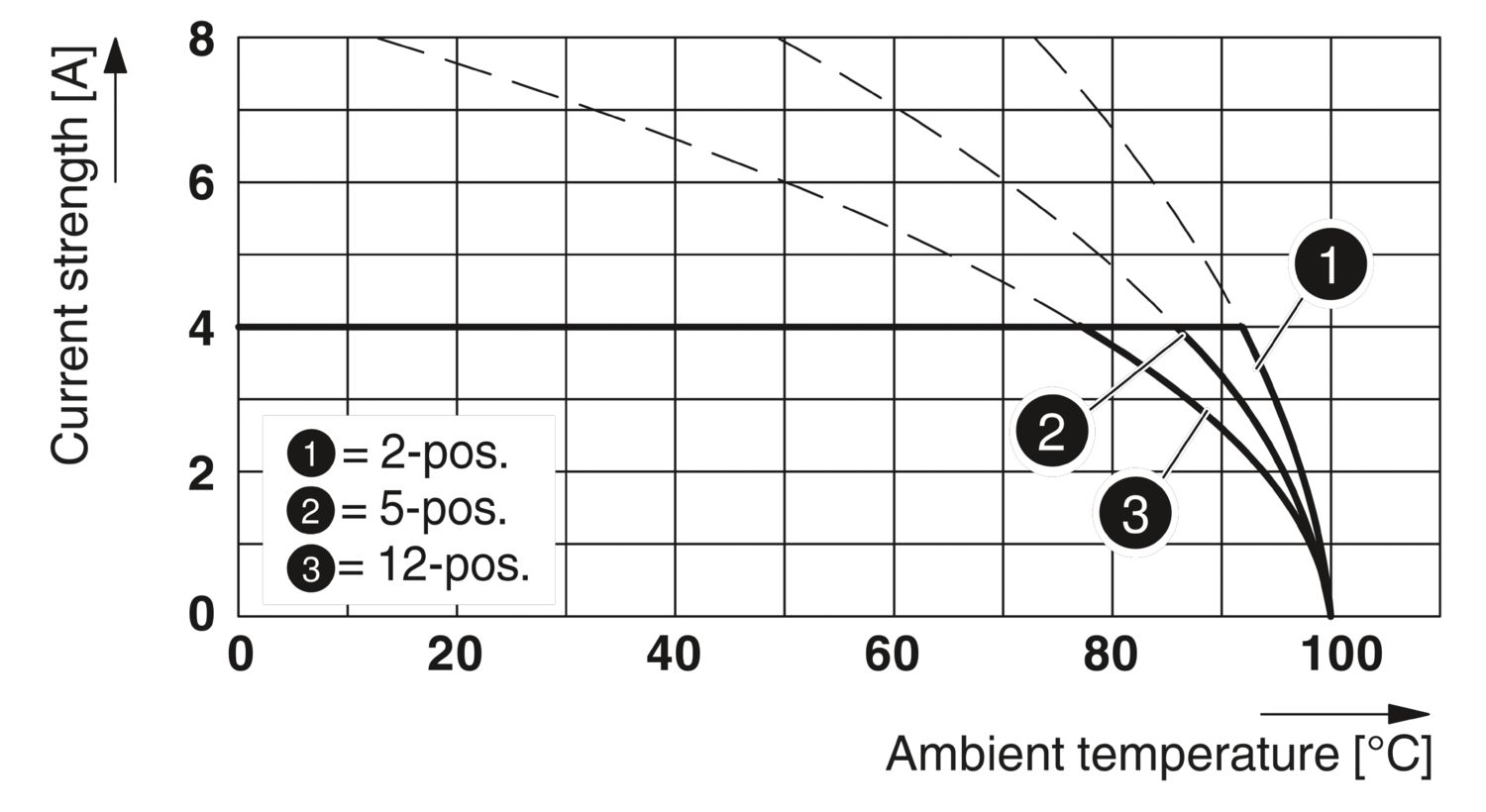

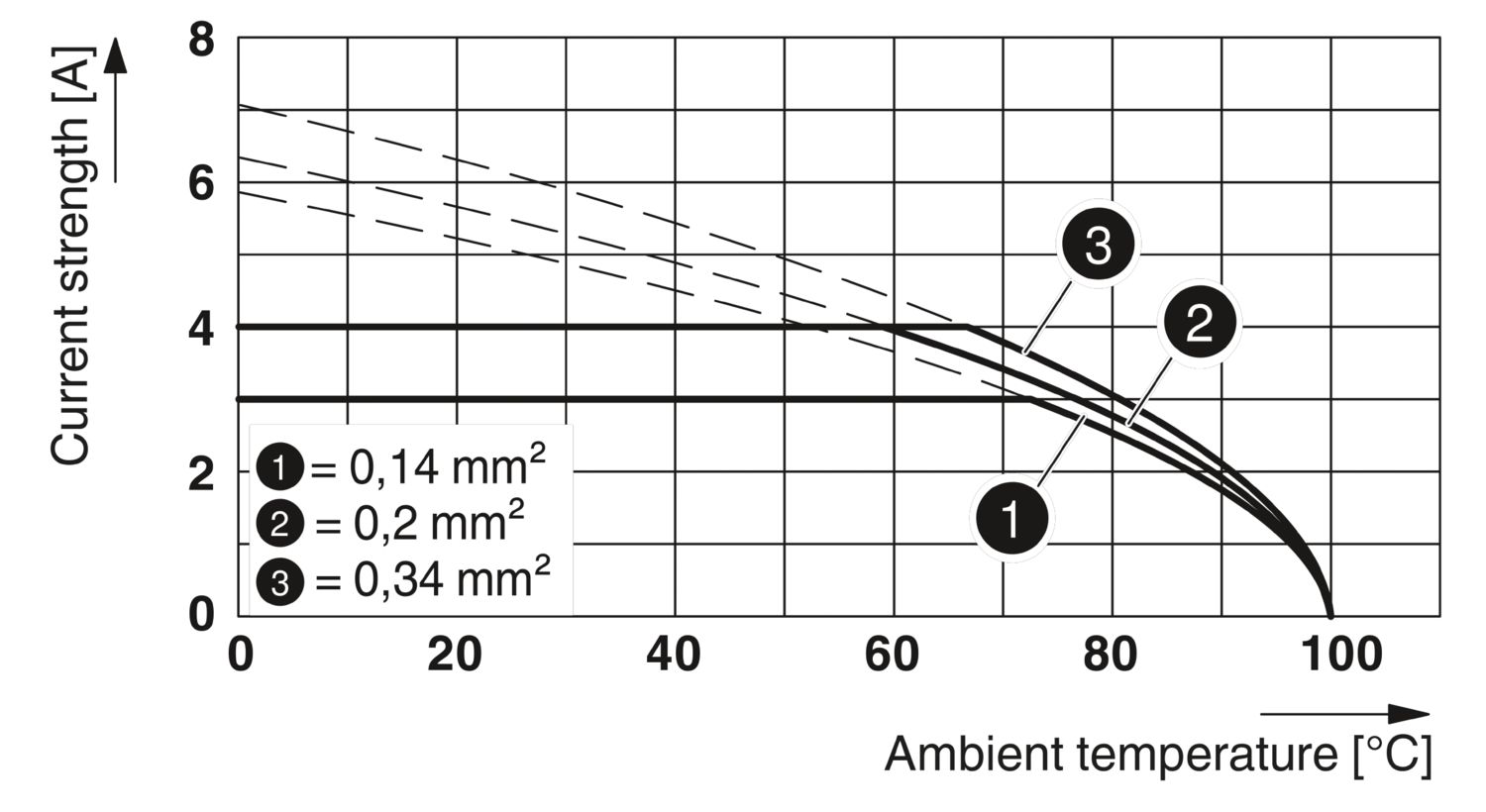

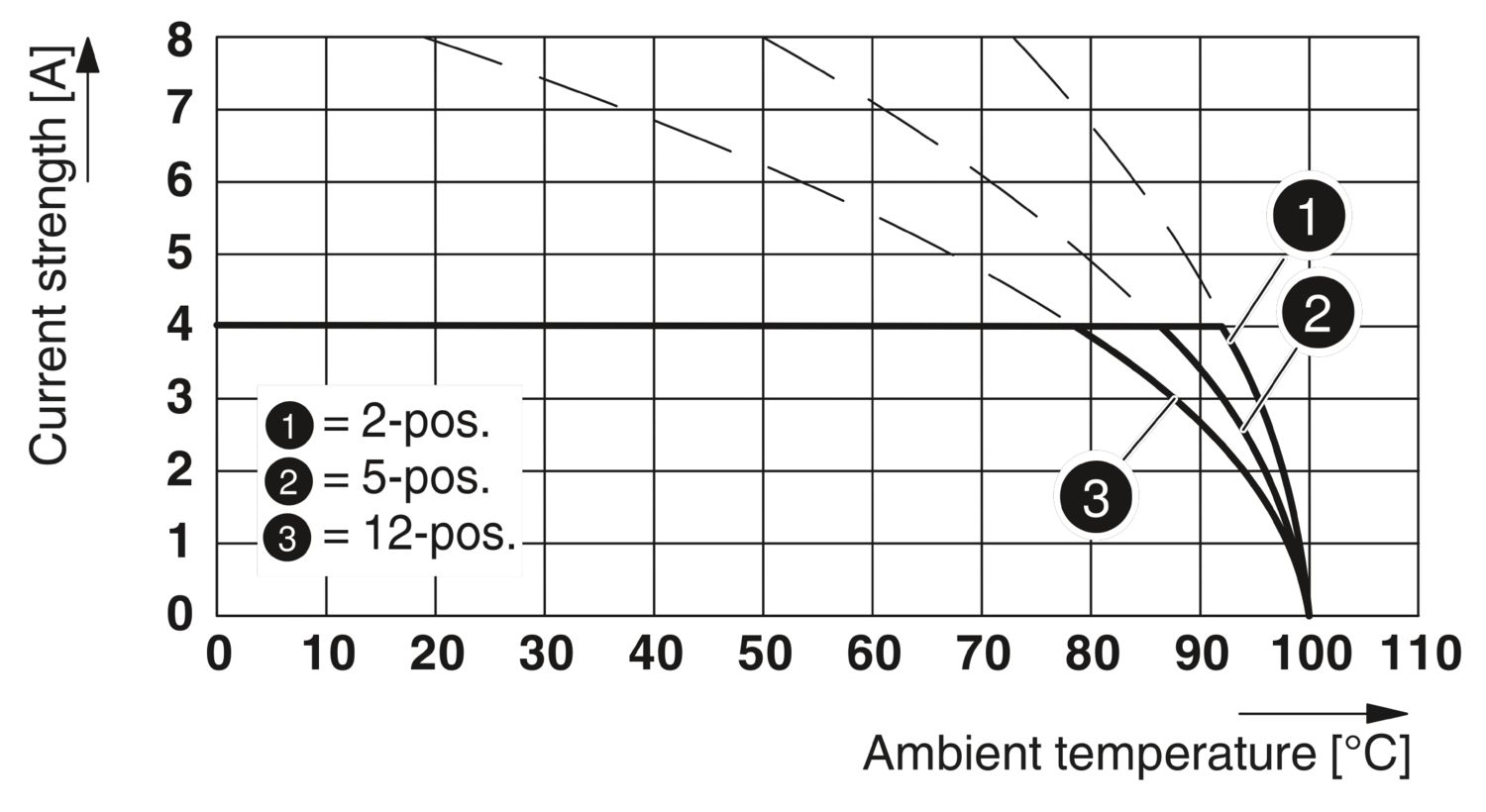

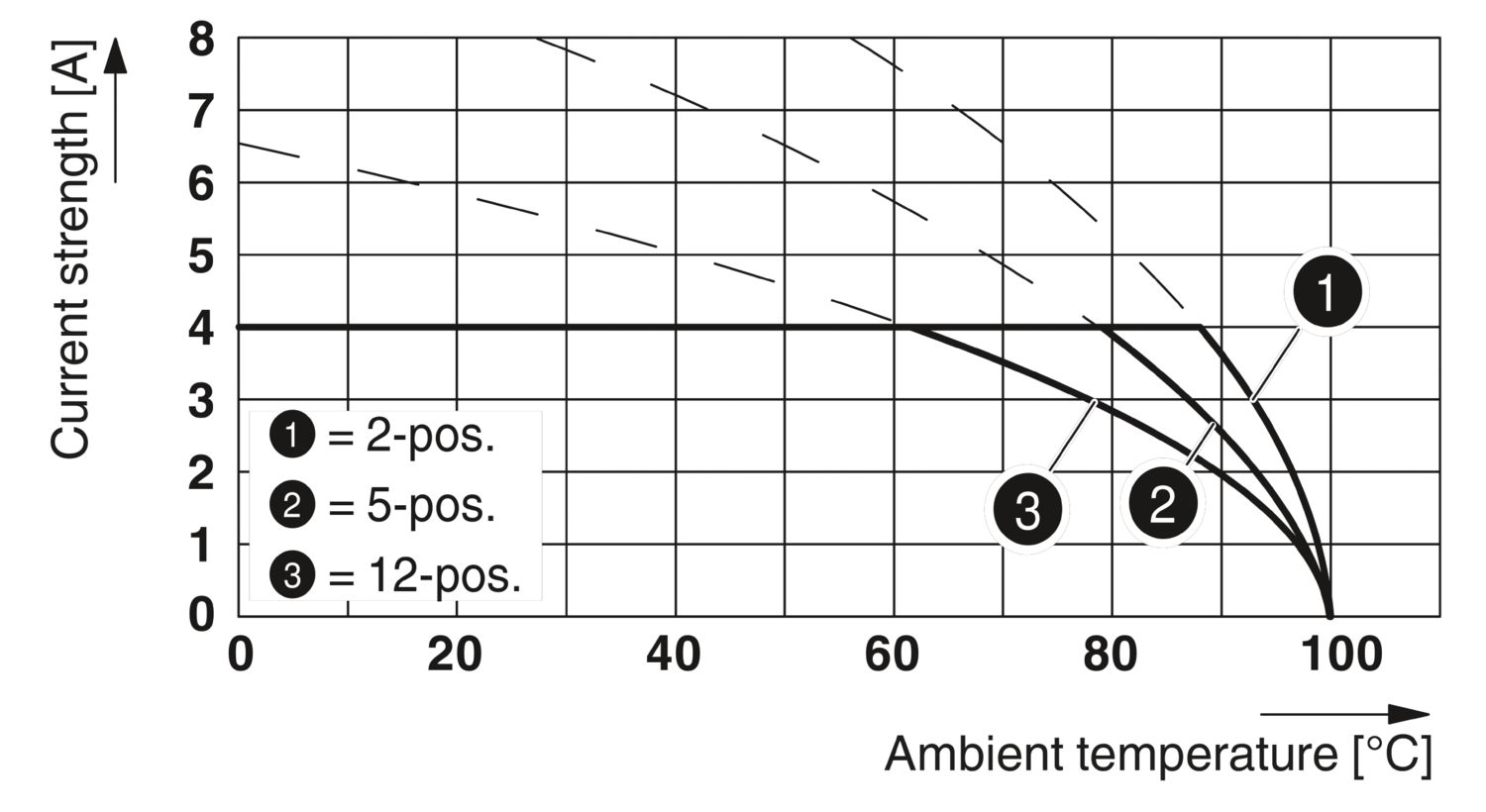

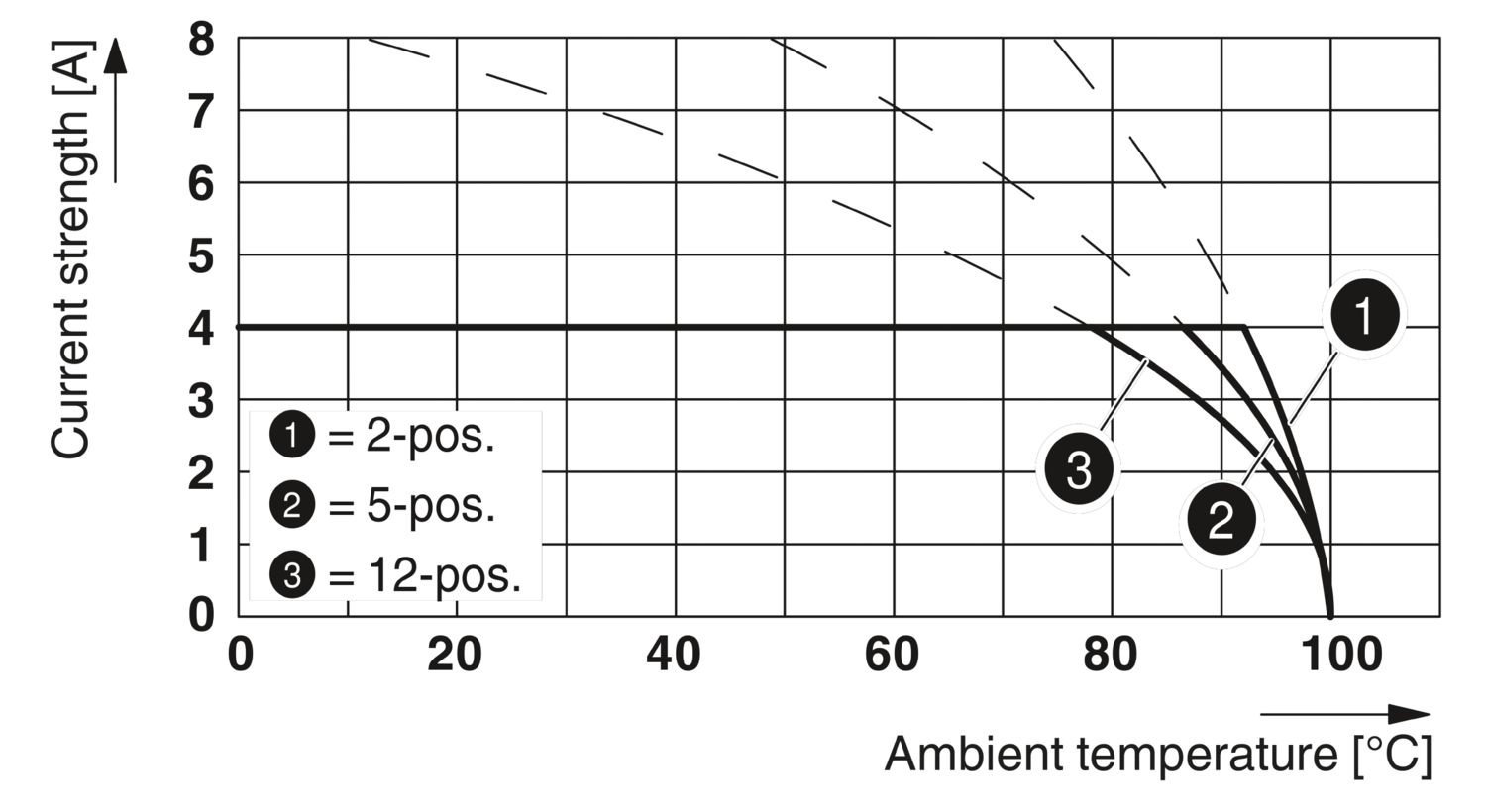

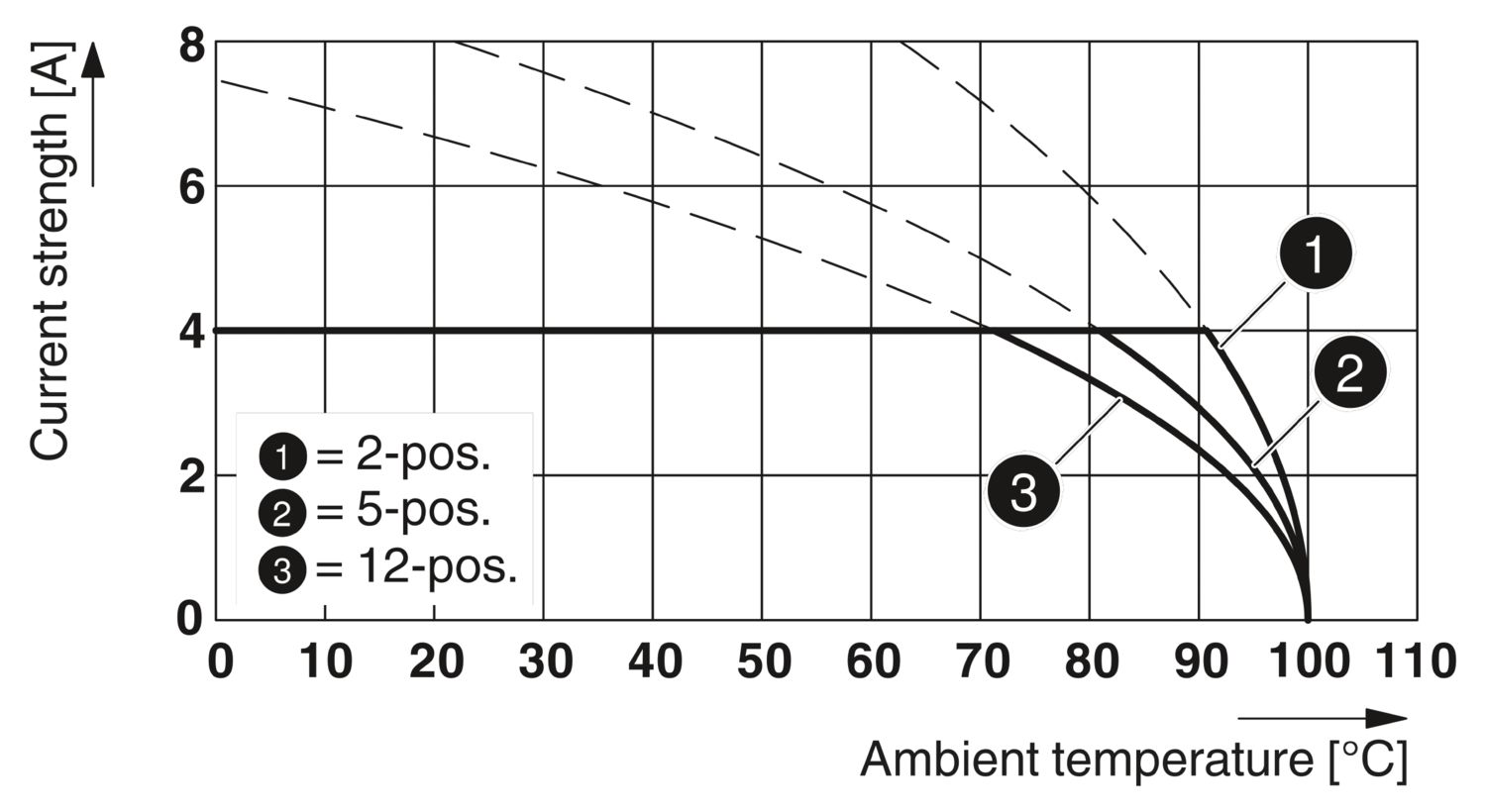

PCB connector, nominal cross section: 0.5 mm2, color: black, nominal current: 4 A, rated voltage (III/2): 160 V, contact surface: Sn, contact connection type: Socket, number of potentials: 9, number of rows: 1, number of positions: 9, number of connections: 9, product range: FK-MC 0,5/..-ST, pitch: 2.5 mm, connection method: Push-in spring connection, conductor/PCB connection direction: 0 °, plug-in system: COMBICON FK-MC 0,5, locking: without, mounting method: without, type of packaging: packed in cardboard, Pull-out aid (STZ2)

Product details

Compatible products

Your advantages

Time saving push-in connection, tools not required

Defined contact force ensures that contact remains stable over the long term

Intuitive operation due to color-coded actuating push button

Operation and conductor connection from one direction enable integration into front of device

Quick and convenient testing using integrated test option