SAC-4P-MS-FR-3L SCO/.../...

-

Sensor/actuator cable

1535707

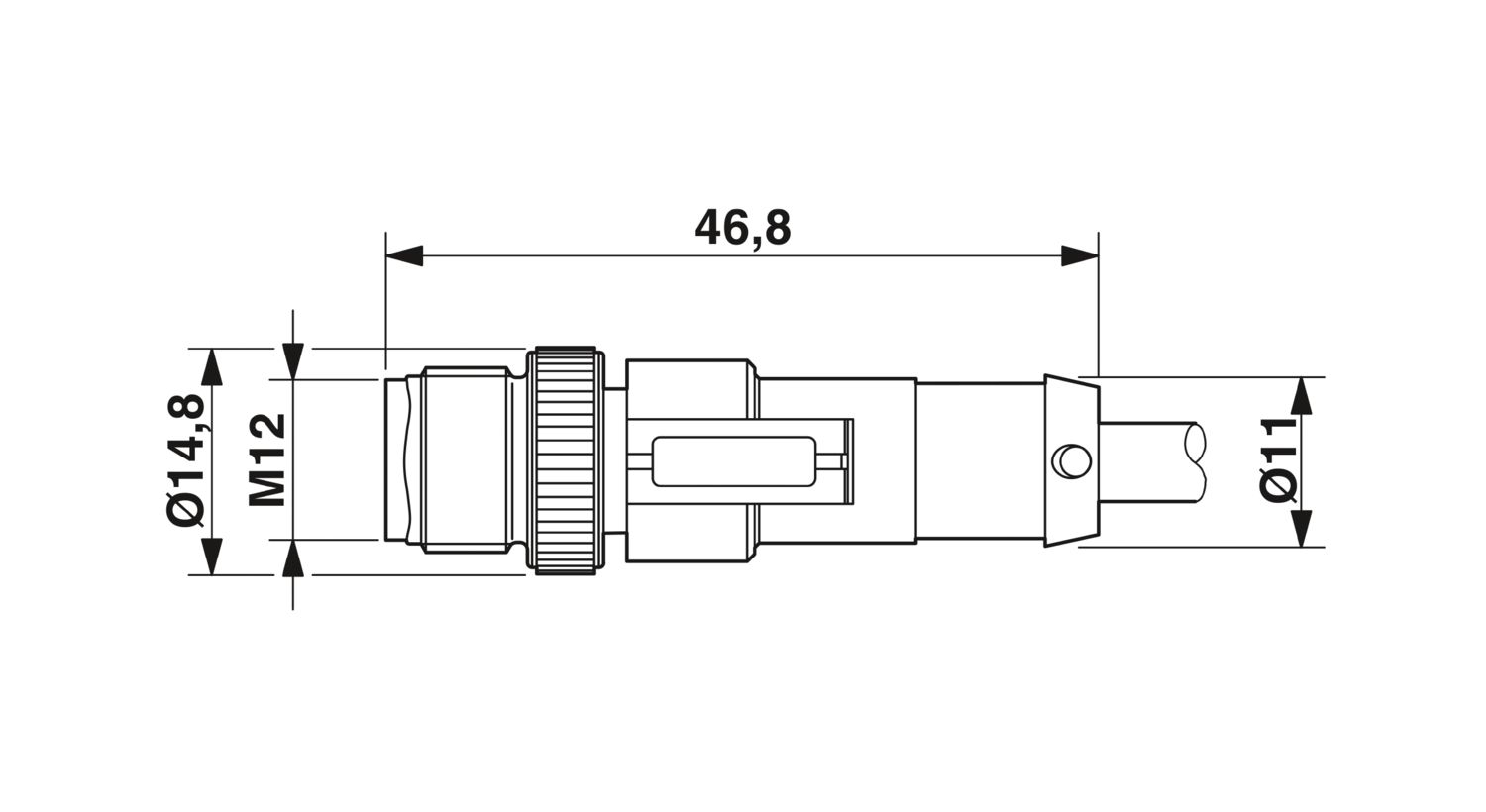

Sensor/actuator cable, 4-position, Plug straight M12 SPEEDCON, coding: A, with 3 LEDs, on Socket angled M12 SPEEDCON, coding: A, with 3 LEDs, cable length: Free input (0.2 ... 40.0 m)

Product details

| Application | Standard |

| Number of positions | 4 |

| No. of cable outlets | 1 |

| Shielded | no |

| Coding | A |

| Insulation characteristics | |

| Overvoltage category | II |

| Degree of pollution | 3 |

| Flammability rating according to UL 94 | HB |

| Seal material | NBR |

| Material of grip body | TPU, hardly inflammable, self-extinguishing |

| Contact material | CuSn |

| Contact surface material | Ni/Au |

| Contact carrier material | TPU GF |

| Material for screw connection | Zinc die-cast, nickel-plated |

| Insulation resistance | ≥ 100 MΩ |

| Nominal voltage UN | 24 V |

| Nominal current IN | 4 A |

| Mechanical data | |

| Insertion/withdrawal cycles | ≥ 100 |

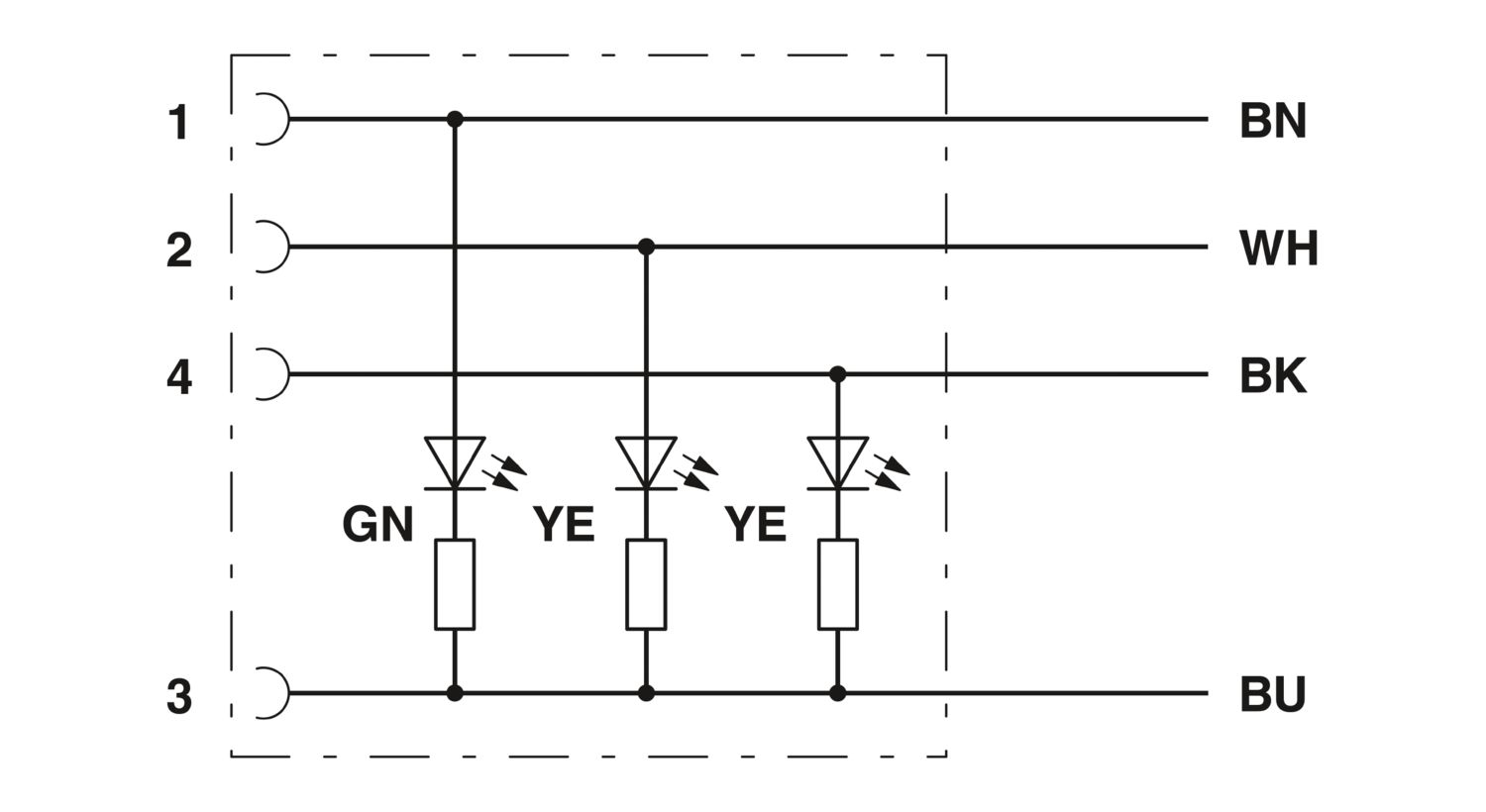

| Status display | 3 LEDs |

| Status display present | yes |

| Conductor connection | |

| Tightening torque | 0.4 Nm (M12 connector) |

| Connection 1 | |

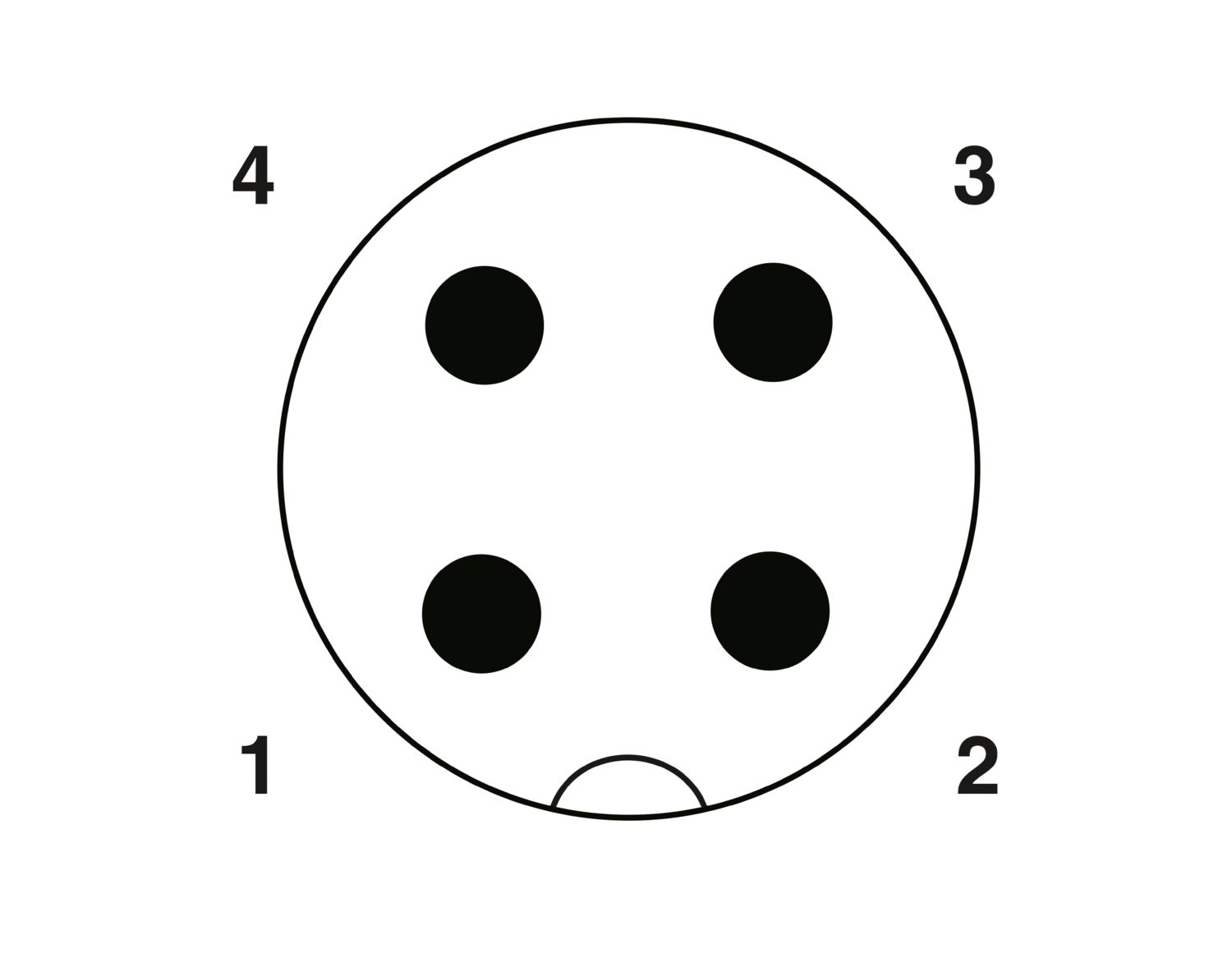

| Type | Plug straight M12 SPEEDCON |

| Number of positions | 4 |

| Locking type | SPEEDCON |

| Coding type | A |

| Connection 2 | |

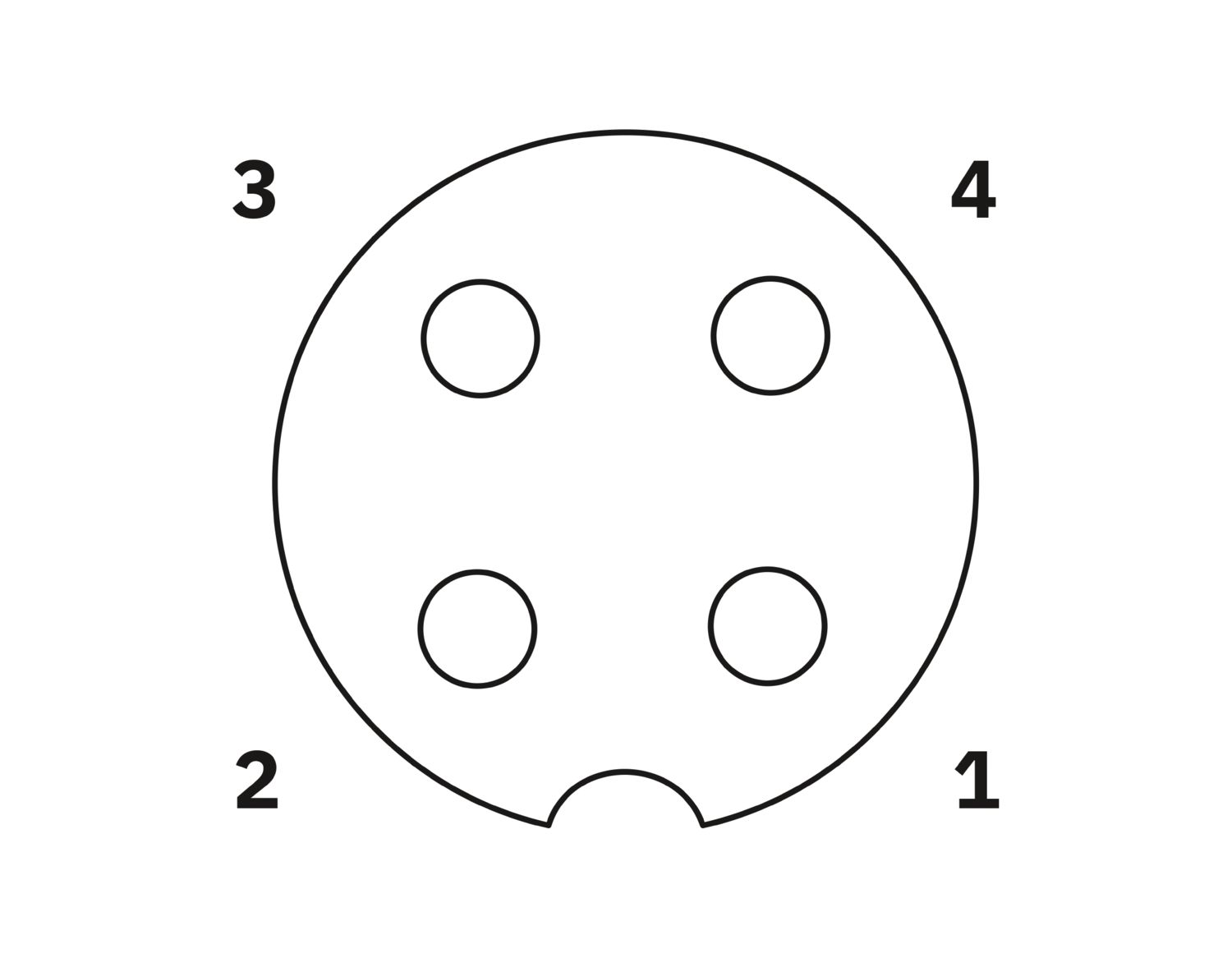

| Type | Socket angled M12 SPEEDCON |

| Number of positions | 4 |

| Locking type | SPEEDCON |

| Coding type | A |

| Cable length | Free input (0.2 ... 40.0 m) |

| PUR halogen-free black [PUR] | |

| Cable weight | 30 kg/km |

| UL AWM Style | 20549 / 10493 (80°C/300 V) |

| Number of positions | 4 |

| Shielded | no |

| Cable type | PUR halogen-free black [PUR] |

| PUR halogen-free black PUR | |

| Conductor structure signal line | 42x 0.10 mm |

| AWG signal line | 22 |

| Conductor cross section | 4x 0.34 mm² (Signal line) |

| Wire diameter incl. insulation | 1.27 mm ±0.02 mm |

| External cable diameter | 4.20 mm ±0.15 mm |

| Outer sheath, material | PUR |

| External sheath, color | black-gray RAL 7021 |

| Conductor material | Bare Cu litz wires |

| Material wire insulation | PP |

| Single wire, color | brown, white, blue, black |

| Thickness, insulation | ≥ 0.21 mm |

| Thickness, outer sheath | approx. 0.50 mm |

| Overall twist | 4 wires, twisted |

| Max. conductor resistance | ≤ 58 Ω/km |

| Insulation resistance | ≥ 1 GΩ*km |

| Nominal voltage, cable | ≤ 300 V |

| Test voltage | ≥ 3000 V |

| Minimum bending radius, fixed installation | 5 x D |

| Minimum bending radius, flexible installation | 10 x D |

| Smallest bending radius, fixed installation | 21 mm |

| Smallest bending radius, movable installation | 42 mm |

| Dynamic load capacity (bending) | Max. bending cycles: 10000000, Bending radius: 42 mm, Bending radius: 10 x D, Traversing path: 10 m, Traversing rate: 3 m/s, Acceleration: 10 m/s² |

| Dynamic load capacity (torsion) | Torsion: ±180 °/m, Torsion cycles: ≥2000000, Torsional frequency: 35 cycles/min. |

| Halogen-free | in accordance with DIN VDE 0472 part 815 |

| in accordance with DIN EN 50267-2-1 | |

| Flame resistance | in accordance with UL 758/1581 FT2 |

| DIN EN 60332-2-2 (20 s) | |

| Resistance to oil | in accordance with DIN EN 60811-2-1 |

| Other resistance | Highly resistant to acids, alkaline solutions and solvents |

| hydrolysis and microbe resistant | |

| partly UV-resistant (in accordance with DIN EN ISO 4892-2-A) | |

| Low adhesion | |

| abrasion-resistant | |

| Special properties | Flexible cable conduit capable |

| Silicone-free | |

| Free of substances which would hinder coating with paint or varnish | |

| flexible | |

| Ambient temperature (operation) | -40 °C ... 80 °C (cable, fixed installation) |

| -25 °C ... 80 °C (Cable, flexible installation) | |

| PUR/PVC yellow [140] | |

| Cable weight | 39 kg/km |

| UL AWM Style | 20549 |

| Number of positions | 4 |

| Shielded | no |

| Cable type | PUR/PVC yellow [140] |

| PUR/PVC yellow 140 | |

| Conductor structure signal line | 42x 0.10 mm |

| AWG signal line | 22 |

| Conductor cross section | 4x 0.34 mm² (Signal line) |

| Wire diameter incl. insulation | 1.5 mm ±0.05 mm |

| External cable diameter | 5.20 mm ±0.2 mm |

| Outer sheath, material | PUR |

| External sheath, color | yellow |

| Conductor material | Bare Cu litz wires |

| Material wire insulation | PVC |

| Single wire, color | brown, white, blue, black |

| Thickness, insulation | approx. 0.30 mm (Core insulation) |

| ≥ 0.38 mm (Outer cable sheath) | |

| approx. 0.35 mm (Inner sheath) | |

| Overall twist | 4 wires, twisted |

| Max. conductor resistance | max. 58 Ω/km (at 20 °C) |

| Insulation resistance | ≥ 1 GΩ*km (at 20 °C) |

| Nominal voltage, cable | ≤ 300 V |

| Test voltage | ≥ 3000 V |

| Smallest bending radius, fixed installation | 52 mm |

| Smallest bending radius, movable installation | 52 mm |

| Dynamic load capacity (bending) | Max. bending cycles: 2000000, Bending radius: 52 mm, Traversing path: 5 m, Traversing rate: 3 m/s |

| Flame resistance | in accordance with DIN UL-Style 20549 |

| Ambient temperature (operation) | -25 °C ... 80 °C (cable, fixed installation) |

| -5 °C ... 80 °C (Cable, flexible installation) | |

| PUR irradiated halogen-free orange [150] | |

| Number of positions | 4 |

| Shielded | no |

| Cable type | PUR irradiated halogen-free orange [150] |

| PUR irradiated halogen-free orange 150 | |

| Conductor structure signal line | 19x 0.15 mm |

| AWG signal line | 22 |

| Conductor cross section | 4x 0.34 mm² (Signal line) |

| Wire diameter incl. insulation | 1.05 mm ±0.05 mm (Signal line) |

| External cable diameter | 5.20 mm ±0.2 mm |

| Outer sheath, material | PUR |

| External sheath, color | orange RAL 2003 |

| Conductor material | Bare Cu litz wires |

| Material wire insulation | PE |

| Single wire, color | brown, white, blue, black |

| Overall twist | 4 wires, twisted |

| Length of twist, overall twist | 27 mm |

| Max. conductor resistance | max. 57 Ω/km |

| Nominal voltage, cable | 320 V (AC) |

| Test voltage | 2500 V (50 Hz, 5 minutes) |

| Smallest bending radius, fixed installation | min. 15 mm |

| Smallest bending radius, movable installation | min. 30 mm |

| Dynamic load capacity (bending) | Max. bending cycles: 5000000, Bending radius: 52 mm, Traversing path: 10 m, Traversing rate: 3 m/s |

| Dynamic load capacity (torsion) | Torsion: ±360 °/m |

| Halogen-free | The cable is halogen-free |

| Other resistance | hydrolysis and microbe resistant |

| Resistant to welding splashes | |

| Special properties | Silicone-free |

| Irradiated | |

| Ambient temperature (operation) | -50 °C ... 105 °C (cable, fixed installation) |

| -40 °C ... 105 °C (Cable, flexible installation) | |

| PUR irradiated halogen-free yellow [160] | |

| Number of positions | 4 |

| Shielded | no |

| Cable type | PUR irradiated halogen-free yellow [160] |

| PUR irradiated halogen-free yellow 160 | |

| Conductor structure signal line | 19x 0.15 mm |

| AWG signal line | 22 |

| Conductor cross section | 4x 0.34 mm² (Signal line) |

| Wire diameter incl. insulation | 1.05 mm ±0.05 mm (Signal line) |

| External cable diameter | 5.20 mm ±0.2 mm |

| Outer sheath, material | PUR |

| External sheath, color | yellow |

| Conductor material | Bare Cu litz wires |

| Material wire insulation | PE |

| Single wire, color | brown, white, blue, black |

| Overall twist | 4 wires, twisted |

| Length of twist, overall twist | 27 mm |

| Max. conductor resistance | ≤ 57 Ω/km |

| Nominal voltage, cable | 320 V AC |

| Test voltage | 2500 V AC (50 Hz, 5 minutes) |

| Smallest bending radius, fixed installation | min. 15 mm |

| Smallest bending radius, movable installation | min. 30 mm |

| Dynamic load capacity (bending) | Max. bending cycles: 5000000, Bending radius: 52 mm, Traversing path: 10 m, Traversing rate: 3 m/s |

| Dynamic load capacity (torsion) | Torsion: 360 °/m |

| Halogen-free | The cable is halogen-free |

| Flame resistance | DIN VDE 0472 part 804, test type B |

| Other resistance | hydrolysis and microbe resistant |

| Special properties | Silicone-free |

| Irradiated | |

| Ambient temperature (operation) | -50 °C ... 105 °C (cable, fixed installation) |

| -40 °C ... 105 °C (Cable, flexible installation) | |

| PUR halogen-free orange [180] | |

| Cable weight | 30 kg/km |

| UL AWM Style | 20549 |

| Number of positions | 4 |

| Shielded | no |

| Cable type | PUR halogen-free orange [180] |

| PUR halogen-free orange 180 | |

| Conductor structure signal line | 42x 0.10 mm |

| AWG signal line | 22 |

| Conductor cross section | 4x 0.34 mm² (Signal line) |

| Wire diameter incl. insulation | 1.27 mm ±0.02 mm (Signal line) |

| External cable diameter | 4.70 mm ±0.15 mm |

| Outer sheath, material | PUR |

| External sheath, color | orange RAL 2003 |

| Conductor material | Bare Cu litz wires |

| Material wire insulation | PP |

| Single wire, color | brown, white, blue, black |

| Thickness, insulation | ≥ 0.21 mm (Core insulation) |

| approx. 0.80 mm (Outer cable sheath) | |

| Overall twist | 4 wires, twisted |

| Max. conductor resistance | max. 58 Ω/km (at 20 °C) |

| Insulation resistance | ≥ 1 GΩ*km (at 20 °C) |

| Nominal voltage, cable | ≤ 300 V |

| Test voltage | ≥ 3000 V |

| Dynamic load capacity (bending) | Max. bending cycles: 4000000, Bending radius: 47 mm, Traversing path: 10 m, Traversing rate: 3 m/s, Acceleration: 10 m/s² |

| Halogen-free | in accordance with DIN VDE 0472 part 815 |

| in accordance with DIN EN 50267-2-1 | |

| Flame resistance | in accordance with UL 758/1581 FT2 |

| Resistance to oil | in accordance with DIN EN 60811-2-1 |

| Other resistance | Resistant to salt water |

| hydrolysis and microbe resistant | |

| Special properties | Free of substances which would hinder coating with paint or varnish |

| Ambient temperature (operation) | -40 °C ... 80 °C (cable, fixed installation) |

| -25 °C ... 80 °C (Cable, flexible installation) | |

| PUR halogen-free yellow [240] | |

| Cable weight | 30 kg/km |

| Number of positions | 4 |

| Shielded | no |

| Cable type | PUR halogen-free yellow [240] |

| PUR halogen-free yellow 240 | |

| Conductor structure signal line | 42x 0.10 mm |

| AWG signal line | 22 |

| Conductor cross section | 4x 0.34 mm² |

| Wire diameter incl. insulation | 1.27 mm ±0.02 mm |

| External cable diameter | 4.70 mm ±0.15 mm |

| Outer sheath, material | PUR |

| External sheath, color | yellow |

| Conductor material | Bare Cu litz wires |

| Material wire insulation | PP |

| Single wire, color | brown, white, blue, black |

| Thickness, insulation | ≥ 0.21 mm (Core insulation) |

| approx. 0.80 mm (Outer cable sheath) | |

| Overall twist | 4 wires, twisted |

| Length of twist, overall twist | 49.5 mm |

| Max. conductor resistance | max. 58 Ω/km (at 20 °C) |

| Insulation resistance | ≥ 1 GΩ*km (at 20 °C) |

| Nominal voltage, cable | ≤ 300 V |

| Test voltage | ≥ 3000 V |

| Smallest bending radius, fixed installation | 23.5 mm |

| Smallest bending radius, movable installation | 47 mm |

| Dynamic load capacity (bending) | Max. bending cycles: 4000000, Bending radius: 47 mm, Traversing path: 10 m, Traversing rate: 3 m/s, Acceleration: 10 m/s² |

| Halogen-free | in accordance with DIN VDE 0472 part 815 |

| in accordance with DIN EN 50267-2-1 | |

| Flame resistance | in accordance with DIN UL-Style 20549 |

| in accordance with FT1 as per UL 758 | |

| Resistance to oil | in accordance with DIN EN 60811-2-1 |

| Other resistance | Highly resistant to acids, alkaline solutions and solvents |

| hydrolysis and microbe resistant | |

| Special properties | Flexible cable conduit capable |

| Silicone-free | |

| Free of substances which would hinder coating with paint or varnish | |

| Ambient temperature (operation) | -40 °C ... 80 °C (cable, fixed installation) |

| -25 °C ... 80 °C (Cable, flexible installation) | |

| PUR halogen-free gray [280] | |

| Cable weight | 30 kg/km |

| UL AWM Style | 20549 / 10493 (80°C/300 V) |

| Number of positions | 4 |

| Shielded | no |

| Cable type | PUR halogen-free gray [280] |

| PUR halogen-free gray 280 | |

| Conductor structure signal line | 42x 0.10 mm |

| AWG signal line | 22 |

| Conductor cross section | 4x 0.34 mm² (Signal line) |

| Wire diameter incl. insulation | 1.27 mm ±0.02 mm |

| External cable diameter | 4.20 mm ±0.15 mm |

| Outer sheath, material | PUR |

| External sheath, color | gray RAL 7001 |

| Conductor material | Bare Cu litz wires |

| Material wire insulation | PP |

| Single wire, color | brown, white, blue, black |

| Thickness, insulation | ≥ 0.21 mm |

| Thickness, outer sheath | approx. 0.50 mm |

| Overall twist | 4 wires, twisted |

| Max. conductor resistance | ≤ 58 Ω/km |

| Insulation resistance | ≥ 1 GΩ*km |

| Nominal voltage, cable | ≤ 300 V |

| Test voltage | ≥ 3000 V |

| Minimum bending radius, fixed installation | 5 x D |

| Minimum bending radius, flexible installation | 10 x D |

| Smallest bending radius, fixed installation | 21 mm |

| Smallest bending radius, movable installation | 42 mm |

| Dynamic load capacity (bending) | Max. bending cycles: 10000000, Bending radius: 10 x D, Traversing path: 10 m, Traversing rate: 3 m/s, Acceleration: 10 m/s² |

| Halogen-free | in accordance with DIN VDE 0472 part 815 |

| in accordance with DIN EN 50267-2-1 | |

| Flame resistance | in accordance with UL 758/1581 FT2 |

| DIN EN 60332-2-2 (20 s) | |

| Resistance to oil | in accordance with DIN EN 60811-2-1 |

| Other resistance | Highly resistant to acids, alkaline solutions and solvents |

| hydrolysis and microbe resistant | |

| partly UV-resistant (in accordance with DIN EN ISO 4892-2-A) | |

| Low adhesion | |

| abrasion-resistant | |

| Special properties | Flexible cable conduit capable |

| Silicone-free | |

| Free of substances which would hinder coating with paint or varnish | |

| flexible | |

| Ambient temperature (operation) | -40 °C ... 80 °C (cable, fixed installation) |

| -25 °C ... 80 °C (Cable, flexible installation) | |

| PVC black [PVC] | |

| Cable weight | 40 kg/km |

| UL AWM Style | 2464 / 1729 (80°C/300 V) |

| Number of positions | 4 |

| Shielded | no |

| Cable type | PVC black [PVC] |

| PVC black PVC | |

| Conductor structure signal line | 19x 0.15 mm |

| AWG signal line | 22 |

| Conductor cross section | 4x 0.34 mm² (Signal line) |

| Wire diameter incl. insulation | 1.26 mm ±0.05 mm |

| External cable diameter | 4.70 mm ±0.15 mm |

| Outer sheath, material | PVC |

| External sheath, color | black RAL 9005 |

| Conductor material | Bare Cu litz wires |

| Material wire insulation | PVC |

| Single wire, color | brown, white, blue, black |

| Thickness, insulation | ≥ 0.23 mm (Core insulation) |

| Thickness, outer sheath | ≥ 0.76 mm |

| Overall twist | 4 wires, twisted |

| Max. conductor resistance | ≤ 57 Ω/km (at 20 °C) |

| Insulation resistance | ≥ 200 MΩ*km (at 20 °C) |

| Nominal voltage, cable | ≤ 300 V |

| Test voltage | ≥ 3000 V |

| Minimum bending radius, fixed installation | 5 x D |

| Minimum bending radius, flexible installation | 10 x D |

| Smallest bending radius, fixed installation | 24 mm |

| Smallest bending radius, movable installation | 47 mm |

| Flame resistance | As per UL-Style 2464 |

| Resistance to oil | according to DIN EN 60811-2-1, 168 h at 60 °C |

| Ambient temperature (operation) | -25 °C ... 80 °C (cable, fixed installation) |

| -10 °C ... 80 °C (Cable, flexible installation) | |

| PVC gray [500] | |

| Cable weight | 40 kg/km |

| UL AWM Style | 2464 / 1729 (80°C/300 V) |

| Number of positions | 4 |

| Shielded | no |

| Cable type | PVC gray [500] |

| PVC gray 500 | |

| Conductor structure signal line | 19x 0.15 mm |

| AWG signal line | 22 |

| Conductor cross section | 4x 0.34 mm² (Signal line) |

| Wire diameter incl. insulation | 1.26 mm ±0.05 mm |

| External cable diameter | 4.70 mm ±0.15 mm |

| Outer sheath, material | PVC |

| External sheath, color | gray RAL 7001 |

| Conductor material | Bare Cu litz wires |

| Material wire insulation | PVC |

| Single wire, color | brown, white, blue, black |

| Thickness, insulation | ≥ 0.23 mm (Core insulation) |

| Thickness, outer sheath | ≥ 0.76 mm |

| Overall twist | 4 wires, twisted |

| Max. conductor resistance | max. 57 Ω/km (at 20 °C) |

| Insulation resistance | ≥ 200 MΩ*km (at 20 °C) |

| Nominal voltage, cable | ≤ 300 V |

| Test voltage | ≥ 3000 V |

| Minimum bending radius, fixed installation | 5 x D |

| Minimum bending radius, flexible installation | 10 x D |

| Smallest bending radius, fixed installation | 24 mm |

| Smallest bending radius, movable installation | 47 mm |

| Ambient temperature (operation) | -40 °C ... 80 °C (cable, fixed installation) |

| -25 °C ... 80 °C (Cable, flexible installation) | |

| PVC yellow [540] | |

| Cable weight | 40 kg/km |

| Number of positions | 4 |

| Shielded | no |

| Cable type | PVC yellow [540] |

| PVC yellow 540 | |

| Conductor structure signal line | 42x 0.10 mm |

| AWG signal line | 22 |

| Conductor cross section | 0.34 mm² (Signal line) |

| Wire diameter incl. insulation | 1.45 mm ±0.05 mm |

| External cable diameter | 5.20 mm ±0.15 mm |

| Outer sheath, material | PVC |

| External sheath, color | yellow |

| Conductor material | Bare Cu litz wires |

| Material wire insulation | PVC |

| Single wire, color | brown, white, blue, black |

| Thickness, insulation | ≥ 0.23 mm (Core insulation) |

| ≥ 0.76 mm (Outer cable sheath) | |

| Overall twist | 4 wires, twisted |

| Max. conductor resistance | max. 58 Ω/km (at 20 °C) |

| Insulation resistance | ≥ 1 GΩ*km (at 20 °C) |

| Nominal voltage, cable | ≤ 300 V (AC) |

| Test voltage | ≥ 3000 V |

| Flame resistance | As per UL-Style 2464 |

| according to UL 758/1581 FT1 | |

| Resistance to oil | in accordance with DIN EN 60811-2-1 |

| Ambient temperature (operation) | -40 °C ... 80 °C (cable, fixed installation) |

| -25 °C ... 80 °C (Cable, flexible installation) | |

| PVC yellow 105 °C [542] | |

| Cable weight | 43 kg/km |

| Number of positions | 4 |

| Shielded | no |

| Cable type | PVC yellow 105 °C [542] |

| PVC yellow 105 °C 542 | |

| Conductor structure signal line | 42x 0.10 mm |

| AWG signal line | 22 |

| Conductor cross section | 0.34 mm² (Signal line) |

| Wire diameter incl. insulation | 1.55 mm ±0.05 mm |

| External cable diameter | 5.50 mm ±0.2 mm |

| Outer sheath, material | PVC |

| External sheath, color | yellow |

| Conductor material | Bare Cu litz wires |

| Material wire insulation | PVC |

| Single wire, color | brown, white, blue, black |

| Thickness, insulation | ≥ 0.38 mm (Core insulation) |

| ≥ 0.76 mm (Outer cable sheath) | |

| Overall twist | 4 wires, twisted |

| Max. conductor resistance | ≤ 58 Ω/km (at 20 °C) |

| Insulation resistance | ≥ 100 MΩ*km (at 20 °C) |

| Nominal voltage, cable | ≤ 300 V |

| Test voltage | ≥ 3000 V |

| Flame resistance | in accordance with UL-Style 2517 |

| in acc. to UL VW1 | |

| Ambient temperature (operation) | -25 °C ... 105 °C (cable, fixed installation) |

| Gray, highly flexible PUR [800] | |

| Note | Due to the extremely robust outer sheath, this cable should only be stripped in 5 cm increments. |

| Cable weight | 33.5 kg/km |

| UL AWM Style | 20549 |

| Number of positions | 4 |

| Shielded | no |

| Cable type | Gray, highly flexible PUR [800] |

| Gray, highly flexible PUR 800 | |

| Conductor structure signal line | 42x 0.10 mm |

| AWG signal line | 22 |

| Conductor cross section | 4x 0.34 mm² (Signal line) |

| Wire diameter incl. insulation | 1.3 mm ±0.05 mm (Signal line) |

| External cable diameter | 4.80 mm ±0.2 mm |

| Outer sheath, material | PUR |

| External sheath, color | gray RAL 7001 |

| Conductor material | Bare Cu litz wires |

| Material wire insulation | PP |

| Single wire, color | brown, white, blue, black |

| Overall twist | 4 wires, twisted |

| Max. conductor resistance | approx. 53 Ω/km |

| Insulation resistance | ≥ 20 MΩ*km |

| Nominal voltage, cable | 300 V |

| Test voltage | 2000 V |

| Minimum bending radius, fixed installation | 4 x D |

| Minimum bending radius, flexible installation | 7.5 x D |

| Smallest bending radius, fixed installation | 20 mm |

| Smallest bending radius, movable installation | 36 mm |

| Dynamic load capacity (bending) | Max. bending cycles: 10000000, Bending radius: 7,5 x D, Traversing path: 5 m, Traversing rate: 3.3 m/s, Acceleration: 5 m/s² |

| Max. bending cycles: 15000000, Bending radius: 50 mm, Traversing path: 0.9 m, Traversing rate: 5 m/s, Acceleration: 30 m/s² | |

| Dynamic load capacity (torsion) | Torsion: ±360 °/m, Torsion cycles: 1000000, Torsional frequency: 35 cycles/min. |

| Halogen-free | in accordance with DIN VDE 0472 part 815 |

| Flame resistance | in accordance with UL 758/1581 FT2 |

| Resistance to oil | in accordance with DIN EN 60811-2-1 |

| Other resistance | Highly resistant to acids, alkaline solutions and solvents |

| Silicone-free | |

| Special properties | Cable jacket is welding spark-resistant, recyclable, matt, low-adhesion, abrasion-resistant, flame-retardant, and self-extinguishing |

| Free from silicone and cadmium | |

| Free of substances which would hinder coating with paint or varnish | |

| Ambient temperature (operation) | -40 °C ... 80 °C (cable, fixed installation) |

| -25 °C ... 80 °C (Cable, flexible installation) | |

| Ambient conditions | |

| Degree of protection | IP65 |

| IP67 | |

| IP68 | |

| Ambient temperature (operation) (male connector/female connector) | -25 °C ... 90 °C (Plug / socket) |

| Standard designation | M12 connector |

| Standards/specifications | IEC 61076-2-101 |

| Item number | 1535707 |

| Packing unit | 1 pc |

| Minimum order quantity | 25 pc |

| Note | Made to order (non-returnable) |

| Sales key | ***** |

| Product key | BF1CCA |

| Customs tariff number | 85444290 |

| Country of origin | PL |

ECLASS

| ECLASS-13.0 | 27060311 |

| ECLASS-15.0 | 27060311 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes (No exemptions) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-50

An article-related China RoHS declaration table can be found in the download area for the respective article under "Manufacturer declaration". For all articles with EFUP-E, no China RoHS declaration table issued and required.

|

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | No substance above 0.1 wt% |

Compatible products

-

-

SAC-M12-EXCLIP-M - Locking clip 1558988

-

UCT-WMT (23X4) - Conductor marker 0801453

-

UC-WMT (23X4) - Conductor marker 0819411

-

US-WMT (23X4) - Cable marker 0828769

-

WMTW (23X4)R - Cable marker 0831004

-

PROT-M12 MS-PA-CHAIN - Screw plug 1430899

-

SAC-M12-EXCLIP-F - Locking clip 1558991

-

B-STIFT - Marker pen 1051993

-

TSD 04 SAC - Torque screwdriver 1208429

-

TSD-M 1,2NM - Torque screwdriver 1212224

-

TSD-M SAC-BIT ADAPTER - Adapter insert 1212600

-

SAC BIT M12-D15 - Tool 1208432

Your advantages

Easy and safe: 100 % electrically tested plug-in components

Save time, thanks to installation with SPEEDCON fast locking system

Flexible solutions - configurable materials with variable cable types and cable lengths

Convenient: increased machine availability thanks to quick and easy diagnostics

PHOENIX CONTACT (SEA) Pte Ltd

80 Bendemeer Road, #09-01A | #10-02 (Reception), Singapore 339949