DFK-2,8 BU

-

Panel feed-through terminal block

0706029

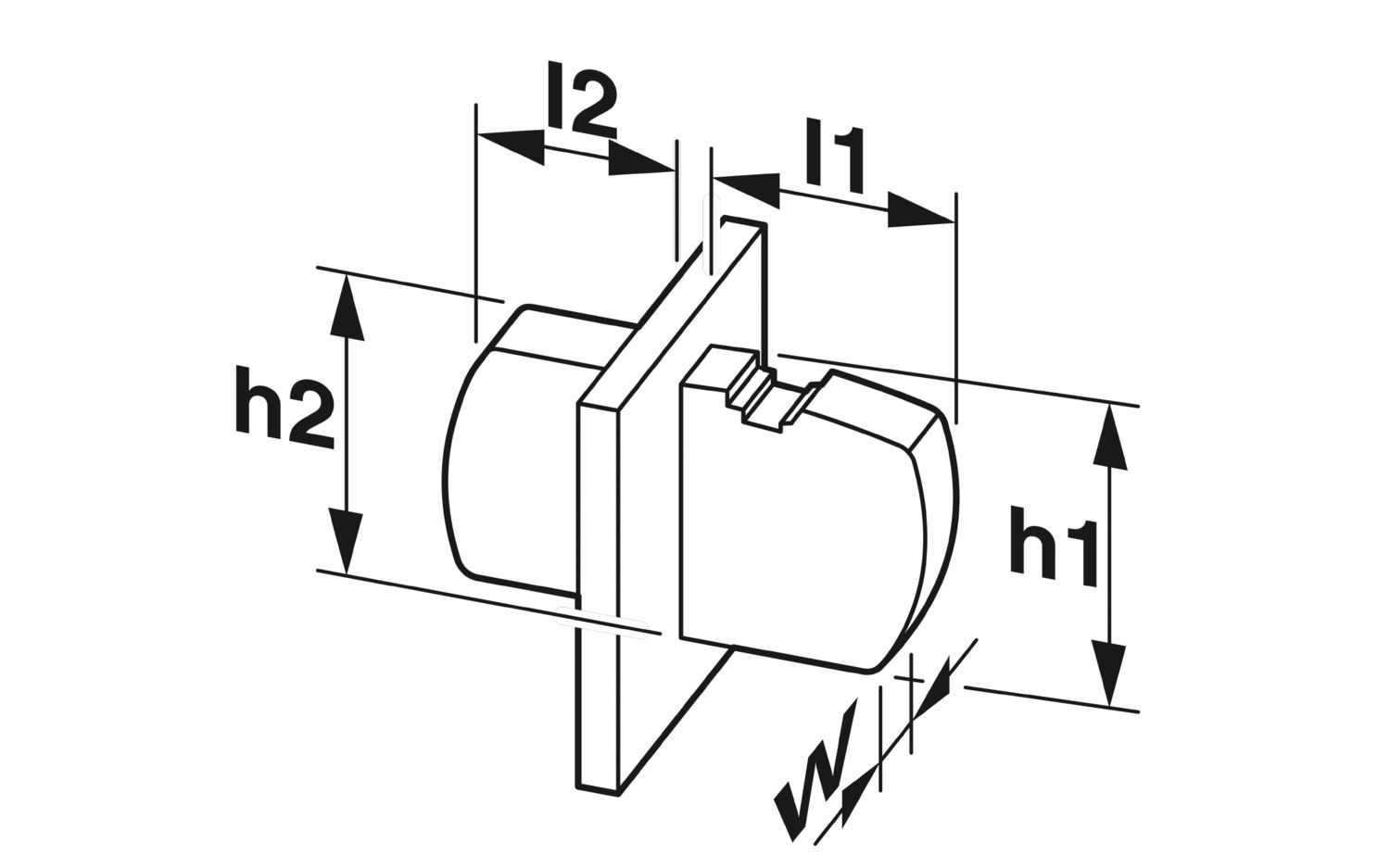

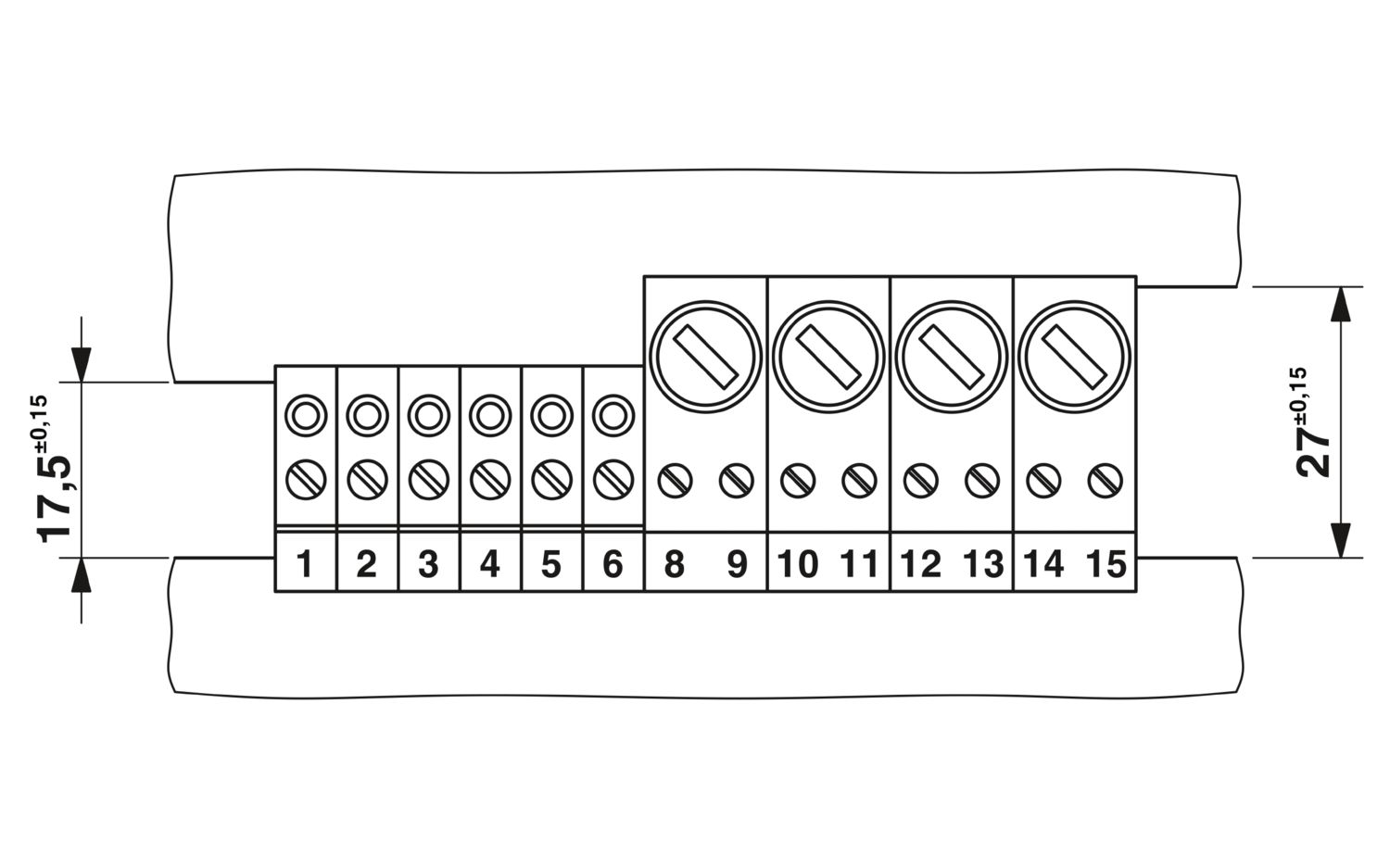

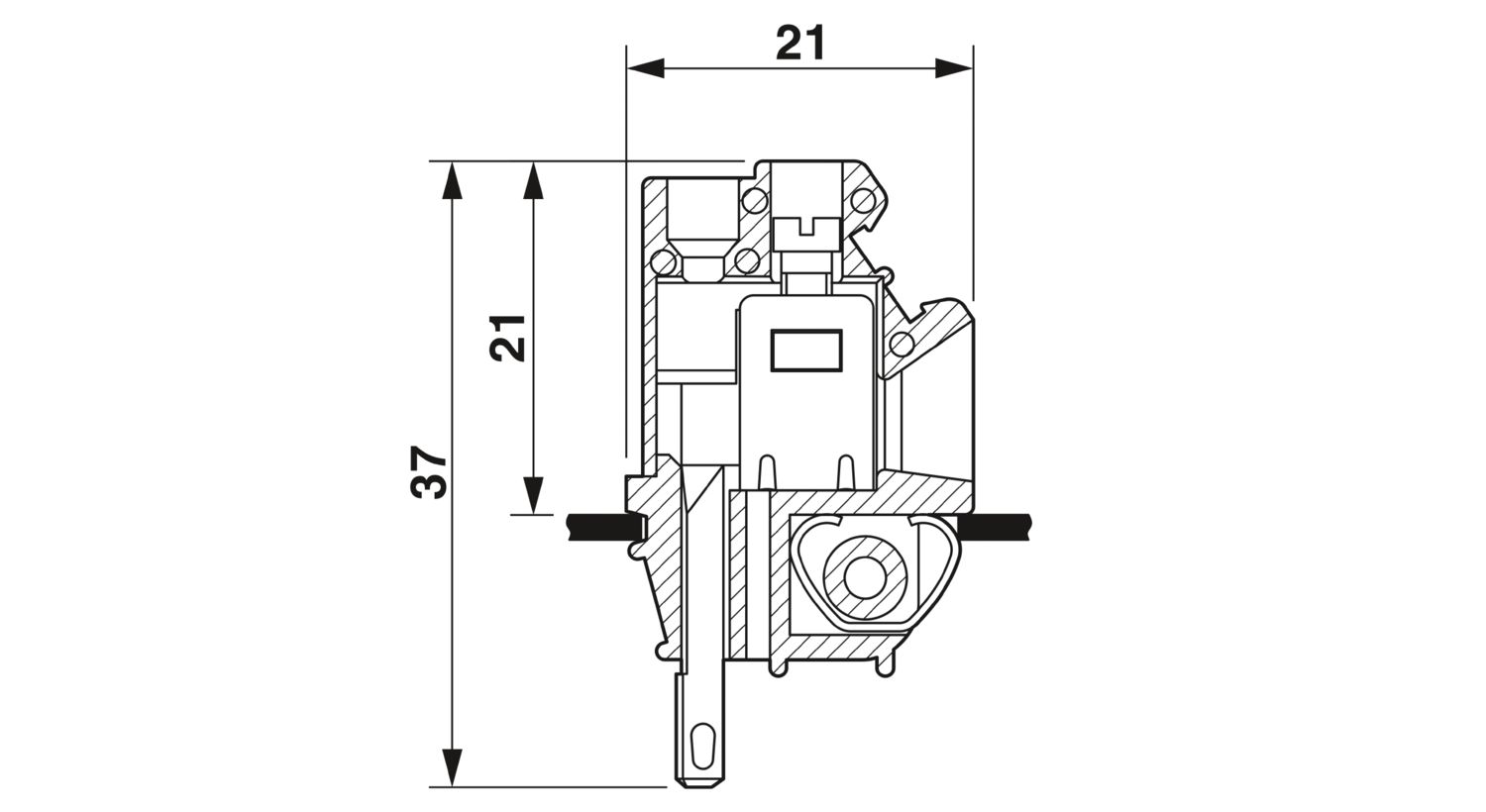

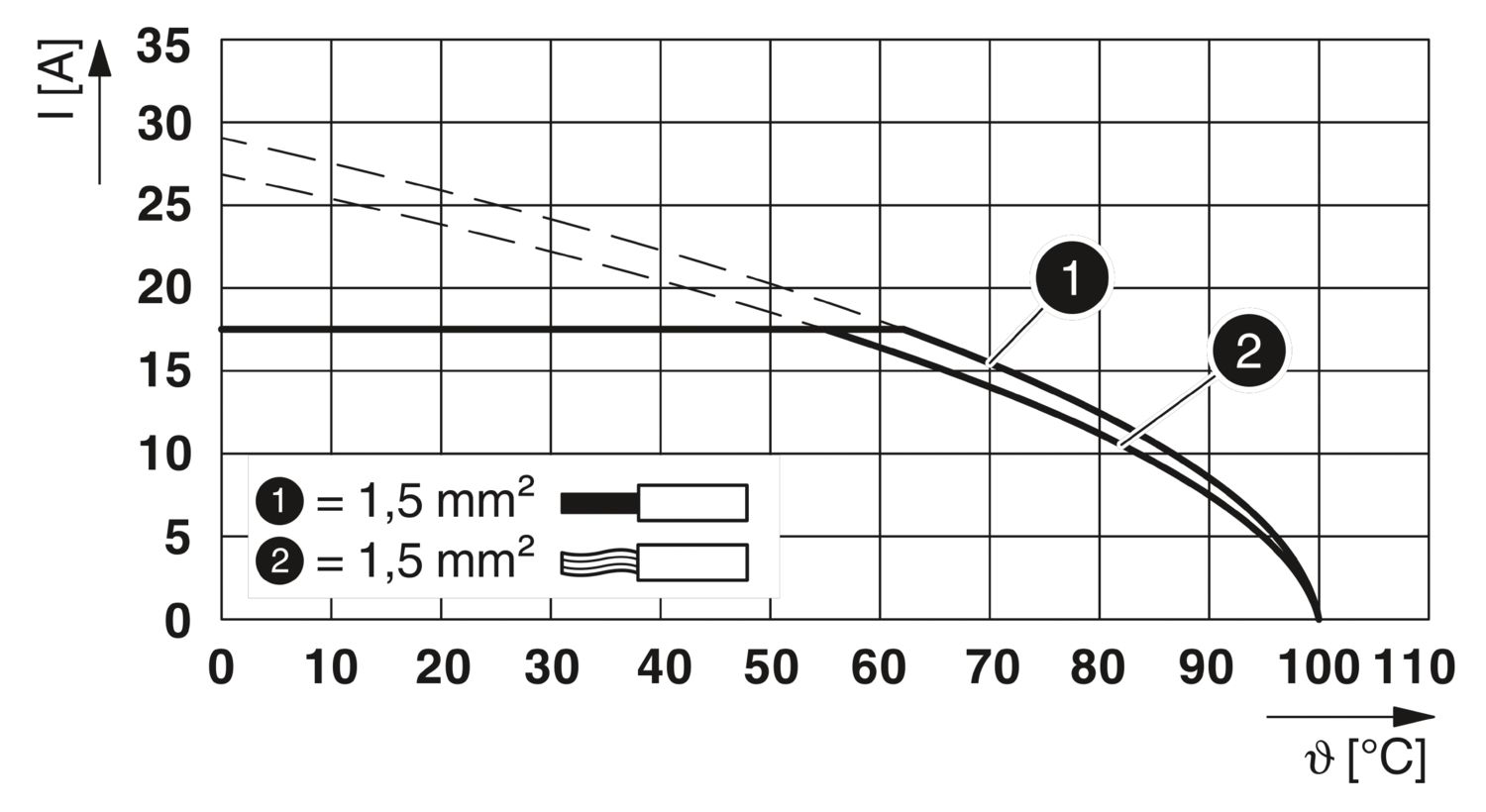

Panel feed-through terminal block, connection method: Screw connection with tension sleeve, Solder/Slip-on connection, number of positions: 1, load current: 18 A, cross section: 0.2 mm2 - 4 mm2, connection direction of the conductor to plug-in direction: 90 °, width: 6 mm, color: blue

Product details

Compatible products

Your advantages

Well-known connection principle allows worldwide use

Low temperature rise, thanks to maximum contact force

Allows connection of two conductors

Tool-free snap-in principle enables easy mounting on the device panel