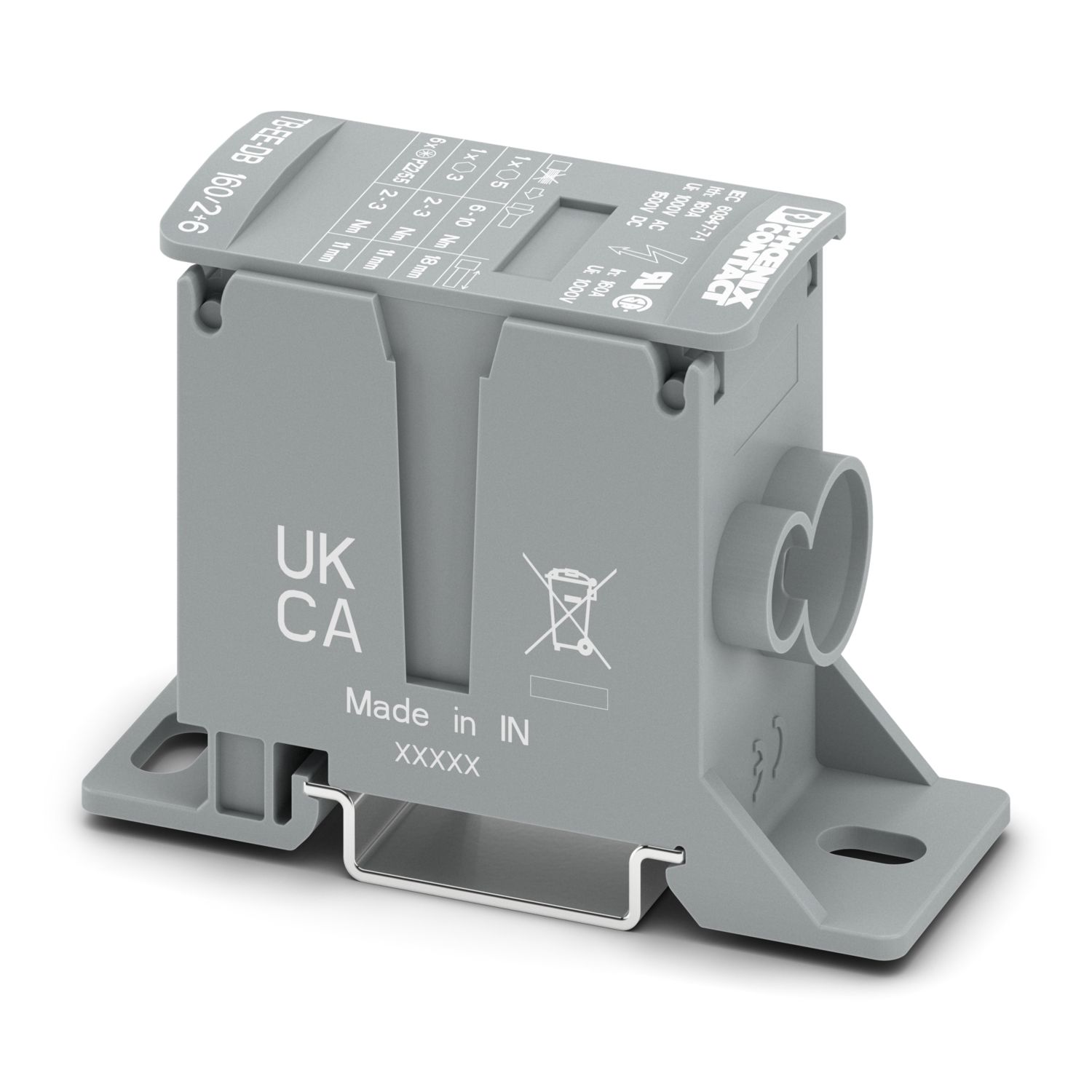

TB-EE-DB 160/2+6

-

Distribution block

1725166

Distribution block, nom. voltage: 1000 V, nominal current: 150 A, Thermal continuous current Ith: 160 A, number of connections: 8, number of positions: 1, connection method: Screw connection, Rated cross section: 50 mm2, Line contact, cross section: 16 mm2 - 70 mm2, Screw connection, Load contact, cross section: 2.5 mm2 - 16 mm2, mounting type: NS 35/7,5, NS 35/15, Direct mounting, color: dark gray

Product details

| General | |

| Note | The maximum load current of a single clamping unit must not be exceeded. |

| For power distribution applications, IEC 60364-4-43.2008; modified + corrigendum Okt. 2008 (DIN VDE 0100-430:2010-10) section 433.2 ff must be observed! | |

| Product family | TB |

| Area of application | Machine building |

| Number of positions | 1 |

| Number of connections | 8 |

| Number of rows | 1 |

| Insulation characteristics | |

| Degree of pollution | 3 |

| Rated surge voltage | 8 kV |

| Number of connections per level | 8 |

| Nominal cross section | 50 mm² |

| Rated cross section AWG | 2 |

| Line contact | |

| Connection method | Screw connection |

| Screw thread | M10 |

| Number of connections | 1 |

| Note | Ferrules are mandatory when using flexible conductors |

| Tightening torque | 6 ... 10 Nm |

| Stripping length | 18 mm |

| Connection in acc. with standard | IEC 60947-7-1 |

| Conductor cross-section rigid | 16 mm² ... 70 mm² |

| Cross section AWG | 4 ... 00 (converted acc. to IEC) |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 16 mm² ... 50 mm² |

| Nominal cross section | 50 mm² |

| Thermal continuous current Ith | 160 A |

| Nominal current | 150 A |

| Nominal voltage | 1000 V AC (suitable for 1500 V DC) |

| Load contact | |

| Connection method | Screw connection |

| Screw thread | M5 |

| Number of connections | 6 |

| Note | Ferrules are mandatory when using flexible conductors |

| Tightening torque | 2 ... 3 Nm |

| Stripping length | 11 mm |

| Connection in acc. with standard | IEC 60947-7-1 |

| Conductor cross-section rigid | 2.5 mm² ... 16 mm² |

| Cross section AWG | 12 ... 6 (converted acc. to IEC) |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 2.5 mm² ... 16 mm² |

| Load contact | |

| Connection method | Screw connection |

| Screw thread | M6 |

| Number of connections | 1 |

| Note | Ferrules are mandatory when using flexible conductors |

| Tightening torque | 2 ... 3 Nm |

| Stripping length | 11 mm |

| Connection in acc. with standard | IEC 60947-7-1 |

| Conductor cross-section rigid | 6 mm² ... 16 mm² |

| Cross section AWG | 8 ... 6 (converted acc. to IEC) |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 2.5 mm² ... 16 mm² |

| Width | 29.4 mm |

| Height | 75 mm |

| Depth | 50.8 mm |

| Depth on NS 35/7,5 | 52.3 mm |

| Depth on NS 35/15 | 59.8 mm |

| Color | basalt gray (RAL 7012) |

| Flammability rating according to UL 94 | V0 |

| Insulating material group | I |

| Relative insulation material temperature index (Elec., UL 746 B) | 125 °C |

| Surge voltage test | |

| Test voltage setpoint | 9.8 kV |

| Result | Test passed |

| Temperature-rise test | |

| Requirement temperature-rise test | Increase in temperature ≤45 K |

| Result | Test passed |

| Short-time withstand current 50 mm² | 6 kA |

| Result | Test passed |

| Power-frequency withstand voltage | |

| Test voltage setpoint | 3.82 kV |

| Result | Test passed |

| Mechanical data | |

| Open side panel | No |

| Mechanical strength | |

| Result | Test passed |

| Attachment on the carrier | |

| DIN rail/fixing support | NS 35 |

| Result | Test passed |

| Test for conductor damage and slackening | |

| Rotation speed | 9 rpm |

| Revolutions | 135 |

| Conductor cross-section/weight | 10 mm² / 2 kg |

| 16 mm² / 2.9 kg | |

| 70 mm²/10.4 kg | |

| Result | Test passed |

| Needle-flame test | |

| Time of exposure | 5 s |

| Result | Test passed |

| Ambient conditions | |

| Degree of protection | IP20 |

| Ambient temperature (operation) | -40 °C ... 110 °C (Operating temperature range incl. self-heating; for max. short-term operating temperature, see RTI Elec.) |

| Ambient temperature (storage/transport) | -25 °C ... 60 °C (for a short time, not exceeding 24 h, -60 °C to +70 °C) |

| Ambient temperature (assembly) | -5 °C ... 70 °C |

| Ambient temperature (actuation) | -5 °C ... 70 °C |

| Permissible humidity (operation) | 20 % ... 90 % |

| Permissible humidity (storage/transport) | 30 % ... 70 % |

| Connection in acc. with standard | IEC 60947-7-1 |

| IEC 60947-7-1 | |

| IEC 60947-7-1 |

| Mounting type | NS 35/7,5 |

| NS 35/15 | |

| Direct mounting |

| Item number | 1725166 |

| Packing unit | 1 pc |

| Minimum order quantity | 1 pc |

| Sales key | 31BBE |

| Product key | BEK823 |

| GTIN | 4067923281103 |

| Weight per piece (including packing) | 129,7 g |

| Weight per piece (excluding packing) | 129,7 g |

| Customs tariff number | 85369010 |

| Country of origin | IN |

ECLASS

| ECLASS-13.0 | 27250118 |

| ECLASS-15.0 | 27250118 |

ETIM

| ETIM 9.0 | EC000897 |

UNSPSC

| UNSPSC 21.0 | 39121400 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes |

| Exemption | 6(c) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-50

An article-related China RoHS declaration table can be found in the download area for the respective article under "Manufacturer declaration". For all articles with EFUP-E, no China RoHS declaration table issued and required.

|

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | Lead (CAS: 7439-92-1) |

Compatible products

-

UCT6M-TM 5 - Marker for terminal blocks 0830756

-

UCT6M-TM 5 CUS - Marker for terminal blocks from the SNK series from ABB 0830762

-

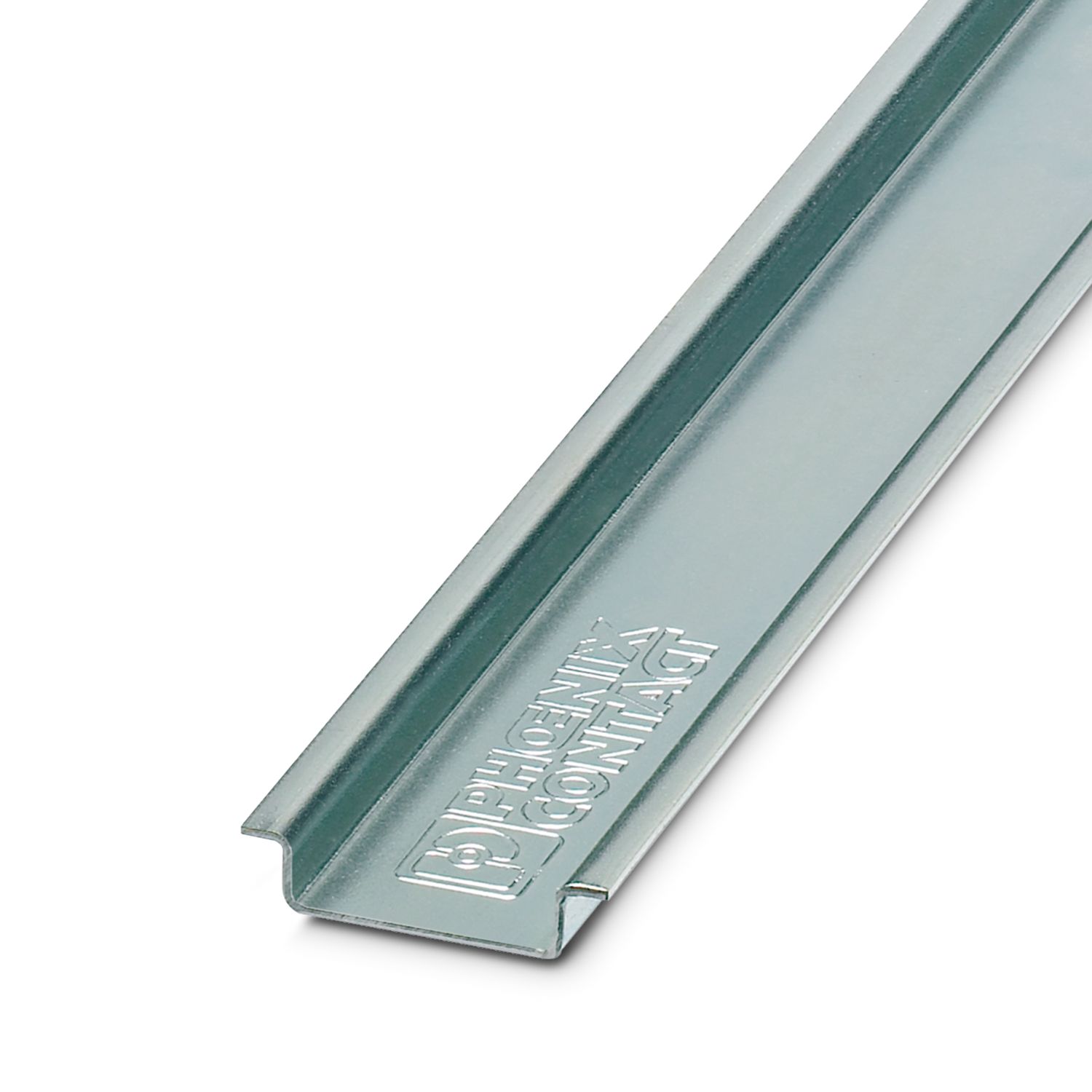

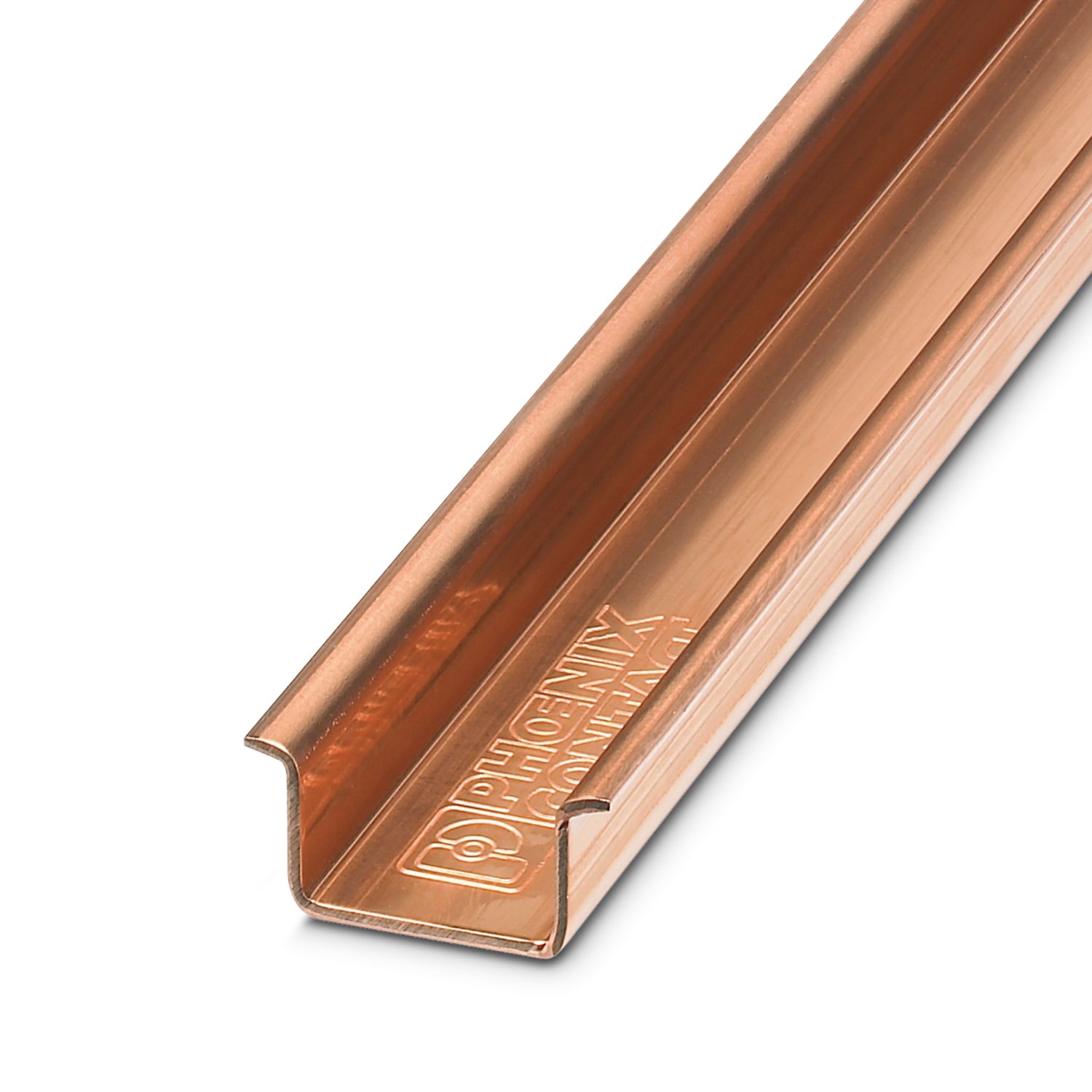

NS 35/ 7,5 PERF 2000MM - DIN rail perforated 0801733

-

NS 35/ 7,5 UNPERF 2000MM - DIN rail, unperforated 0801681

-

NS 35/ 7,5 WH PERF 2000MM - DIN rail perforated 1204119

-

NS 35/ 7,5 WH UNPERF 2000MM-VPE 10 - DIN rail, unperforated 1204122

-

NS 35/ 7,5 AL UNPERF 2000MM - DIN rail, unperforated 0801704

-

NS 35/ 7,5 ZN PERF 2000MM - DIN rail perforated 1206421

-

NS 35/ 7,5 ZN UNPERF 2000MM - DIN rail, unperforated 1206434

-

NS 35/ 7,5 CU UNPERF 2000MM-VPE 10 - DIN rail, unperforated 0801762

-

NS 35/ 7,5 CAP - End cap 1206560

-

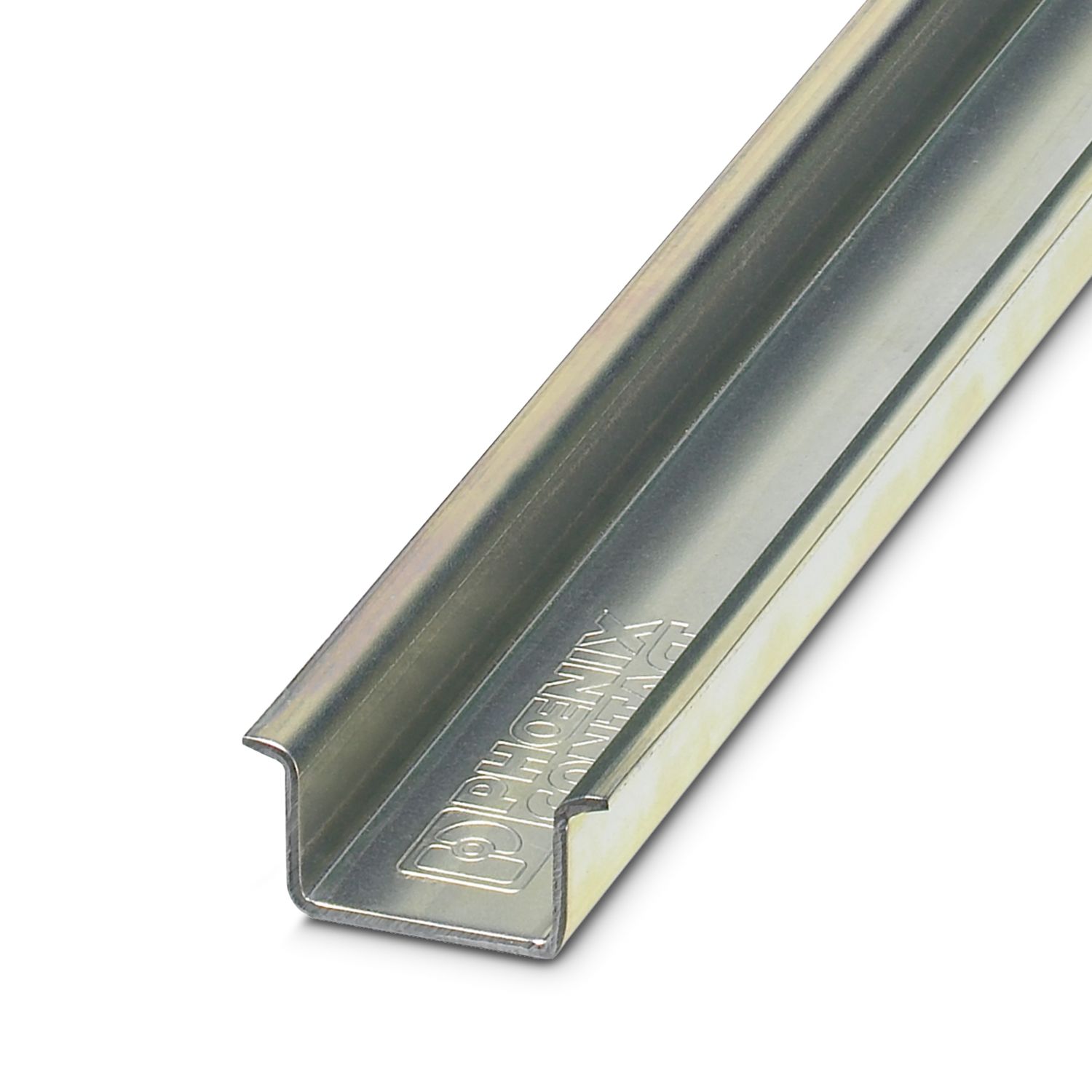

NS 35/15 PERF 2000MM - DIN rail perforated 1201730

-

NS 35/15 UNPERF 2000MM - DIN rail, unperforated 1201714

-

NS 35/15 WH PERF 2000MM - DIN rail perforated 0806602

-

NS 35/15 WH UNPERF 2000MM-VPE 10 - DIN rail, unperforated 1204135

-

NS 35/15 AL UNPERF 2000MM - DIN rail, unperforated 1201756

-

NS 35/15 ZN PERF 2000MM - DIN rail perforated 1206599

-

NS 35/15 ZN UNPERF 2000MM - DIN rail, unperforated 1206586

-

NS 35/15 CU UNPERF 2000MM-VPE 10 - DIN rail, unperforated 1201895

-

NS 35/15 CAP - End cap 1206573

Your advantages

Fast installation via ready-to-connect distributor and collection block

Blocks can be snapped to each other to form function groups

As well as saving space, the compact design enables user-friendly wiring in a small amount of space

Flexible use, thanks to DIN rail and direct mounting

Reversible cover for optimum readability of the technical data

PHOENIX CONTACT AS

Strømsveien 344; N-1081 Oslo