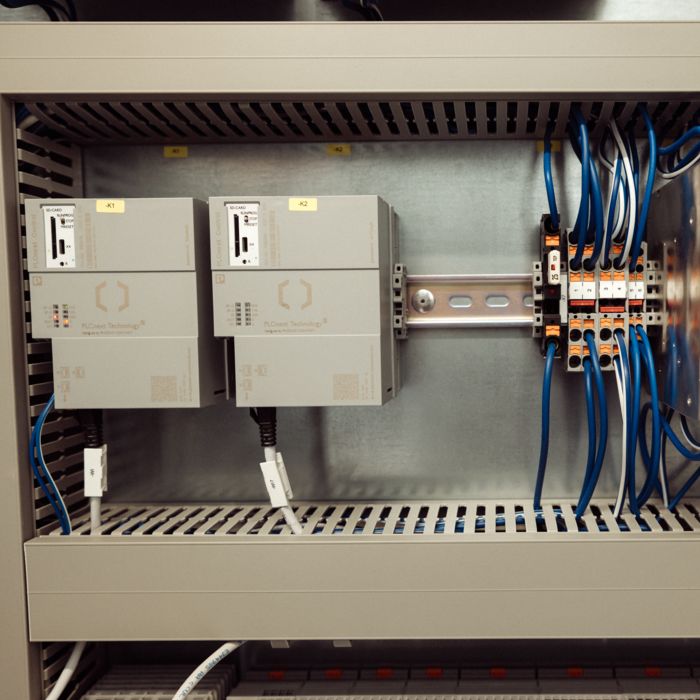

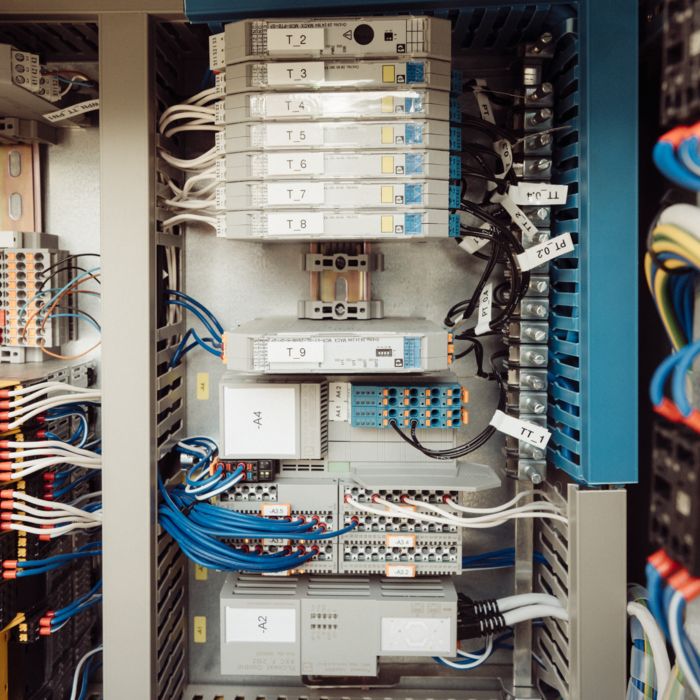

One functional modular system economically covers both Ex and non-Ex areas. In the control cabinet, only processes from the Axioline product family are equipped with Ex I/O modules in which Ex protection is actually required. For example, input cards are used in the HyRunner for the valves of the hydrogen lines. They can be used to wire the signals directly to the correspondingly certified I/O modules. Separate Ex barriers are therefore superfluous or are only used where separate I/O modules would not be economical due to very few signal types. This saves valuable space and reduces costs. Outside of the Ex zone, the standard I/O portfolio from the Axioline modular system is sufficient, without functional limitations for a consistent overall system.