Pulse and high-current laboratory

Highest-performance laboratory for surge protective devices in the world

The new building houses high-voltage and high-current laboratories with offices for development, design, and marketing under one roof. The laboratory space, which covers around 1,300 m², is tailored specifically to the technological and safety requirements of testing technology and satisfies almost all internationally standardized requirements of established certification authorities.

Thanks to the testing facilities, the technology center in Blomberg may be regarded as the world’s best equipped laboratory for surge protective devices.

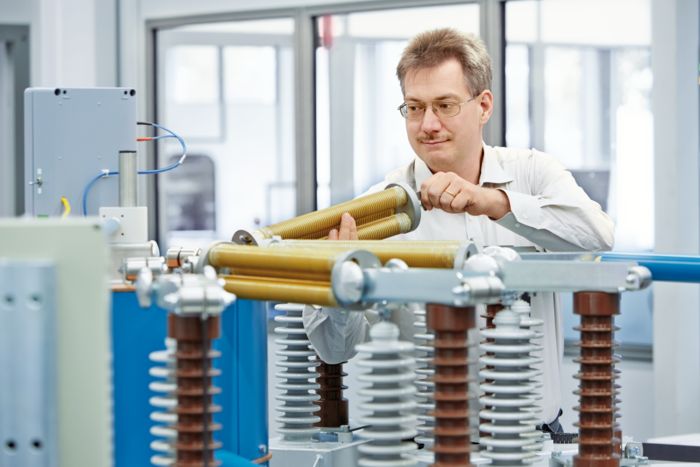

Surge current generators in the laboratory

The right equipment for powerful testing

The testing systems in the laboratory are able to generate surge currents and surge voltages with different pulse shapes. Even mains frequency short-circuit currents and DC currents can be generated, by means of the finely adjustable voltage.

One special feature of the laboratory is that the high-performance power supply system can be coupled with surge current generators. This enables a realistic environment to be created for testing surge protective devices.

High-current test laboratory

The high-current test laboratory

Tests with surge current pulses up to 100 kA (8/20) μs in combination with a powerful alternating current source on surge protective devices are possible here.

The test simulates the operating behavior of the protective devices and their interaction with the power supply system in the event of a overvoltage.

Alongside this special test for surge protective devices, the test laboratory can be used universally for single- to three-phase applications.

Test procedures

Surge current testing technology

The surge current testing system generates lightning currents with a waveform of (10/350) μs to 100 kA and surge currents with a waveform of (8/20) μs to 200 kA. This enables surge protective devices in the highest performance class to be tested in compliance with standards.

In order to generate the pulses, energy is provided at 141 kJ, which is taken from a capacitor bank with 44 μF and a maximum charging voltage of 80 kV. A modular measuring data acquisition system with a high sampling rate supplies extremely precise measuring data.

Direct current testing technology

The DC testing system functions autonomously and consists of a high-performance DC source as well as a special pulse current generator. This generator is set up to precisely meet the requirements in the field of direct current testing technology.

In order to qualify the surge protective devices for DC applications, the system offers the option of coupling power pulse currents (8/20) μs into the DC system. Among other tests, this system permits tests in accordance with EN 61643-31, “Requirements and test methods for SPDs for photovoltaic installations”. The DC source is also used for tests with short-circuit currents up to 7,000 A. The voltage can be adjusted in 1 V increments up to 1,800 V DC.

Automated testing

Automated testing is a key factor in the success of cost-effective testing operations. The focus here is on time-intensive testing processes. These processes are particularly relevant to IEC/EN 61643-21, “Surge protective devices connected to telecommunications and signaling networks”.

The testing systems developed in-house are equipped with the latest automation technology which controls and monitors the entire testing process. The testing system documents and analyzes the measured values and then creates a meaningful test report.

Our range of services

- Complete testing of lightning current arresters and surge protective devices in accordance with standards IEC/EN 61643-11, IEC/EN 61643-31, IEC/EN 61643-21, and UL 1449

- Lightning surge current testing with pulse shape (10/350) μs with an amplitude of up to 100 kA

- Surge current testing with pulse shape (8/20) μs up to an amplitude of 200 kA

- Verification of the effectiveness of surge protection concepts based on EN CLC/TS 61643-12

- Testing the dielectric strength with a power-frequency withstand voltage of up to 12 kV AC and 16 kV DC

- Single- and three-phase short-circuit current tests up to:

50 kA up to 500 V/50 Hz

25 kA up to 1000 V/50 Hz

DAkkS accreditation

Accredited in accordance with DIN EN ISO/IEC 17025

The test laboratory is accredited based on DIN EN ISO/IEC 17025. This standard describes the “General requirements for the competence of testing and calibration laboratories”. The German National Accreditation Body (DAkkS) has verified and confirmed that the requirements of ISO 17025 have been implemented and met.

The accreditation certifies:

- Specialist and technical competence

- Effective management system for quality assurance

- Independence and impartiality regarding third parties

Test reports from accredited test laboratories are widely accepted internationally.